Colloidal

quantum dots irradiated with a UV light. Different sized quantum dots

emit different color light due to quantum confinement.

Quantum dots (QD) are very small semiconductor particles, only several nanometres

in size, so small that their optical and electronic properties differ

from those of larger LED particles. They are a central theme in

nanotechnology. Many types of quantum dot will emit light

of specific frequencies if electricity or light is applied to them, and

these frequencies can be precisely tuned by changing the dots' size, shape and material, giving rise to many applications.

In the language of materials science, nanoscale semiconductor materials tightly confine either electrons or electron holes. Quantum dots are also sometimes referred to as artificial atoms, a term that emphasizes that a quantum dot is a single object with bound, discrete electronic states, as is the case with naturally occurring atoms or molecules.

Quantum dots exhibit properties that are intermediate between

those of bulk semiconductors and those of discrete atoms or molecules.

Their optoelectronic properties change as a function of both size and

shape.

Larger QDs (diameter of 5–6 nm, for example) emit longer wavelengths

resulting in emission colors such as orange or red. Smaller QDs

(diameter of 2–3 nm, for example) emit shorter wavelengths resulting in

colors like blue and green, although the specific colors and sizes vary

depending on the exact composition of the QD.

Because of their highly tunable properties, QDs are of wide interest. Potential applications include transistors, solar cells, LEDs, diode lasers and second-harmonic generation, quantum computing, and medical imaging. Additionally, their small size allows for QDs to be suspended in solution which leads to possible uses in inkjet printing and spin-coating. They have also been used in Langmuir-Blodgett thin-films. These processing techniques result in less expensive and less time-consuming methods of semiconductor fabrication.

Production

Quantum Dots with gradually stepping emission from violet to deep red

There are several ways to prepare quantum dots, the principal ones involving colloids.

Colloidal synthesis

Colloidal semiconductor nanocrystals are synthesized from solutions, much like traditional chemical processes. The main difference is the product neither precipitates as a bulk solid nor remains dissolved. Heating the solution at high temperature, the precursors

decompose forming monomers which then nucleate and generate

nanocrystals. Temperature is a critical factor in determining optimal

conditions for the nanocrystal growth. It must be high enough to allow

for rearrangement and annealing of atoms during the synthesis process while being low enough to promote crystal growth. The concentration of monomers

is another critical factor that has to be stringently controlled during

nanocrystal growth. The growth process of nanocrystals can occur in two

different regimes, "focusing" and "defocusing". At high monomer

concentrations, the critical size (the size where nanocrystals neither

grow nor shrink) is relatively small, resulting in growth of nearly all

particles. In this regime, smaller particles grow faster than large ones

(since larger crystals need more atoms to grow than small crystals)

resulting in "focusing" of the size distribution to yield nearly

monodisperse particles. The size focusing is optimal when the monomer

concentration is kept such that the average nanocrystal size present is

always slightly larger than the critical size. Over time, the monomer

concentration diminishes, the critical size becomes larger than the

average size present, and the distribution "defocuses".

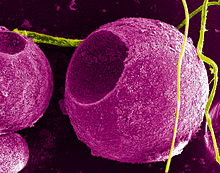

Cadmium sulfide quantum dots on cells

There are colloidal methods to produce many different semiconductors. Typical dots are made of binary compounds such as lead sulfide, lead selenide, cadmium selenide, cadmium sulfide, cadmium telluride, indium arsenide, and indium phosphide.

Dots may also be made from ternary compounds such as cadmium selenide

sulfide.

These quantum dots can contain as few as 100 to 100,000 atoms within the

quantum dot volume, with a diameter of ≈10 to 50 atoms. This

corresponds to about 2 to 10 nanometers,

and at 10 nm in diameter, nearly 3 million quantum dots could be lined

up end to end and fit within the width of a human thumb.

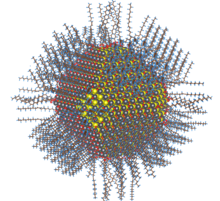

Ideallized

image of colloidal nanoparticle of lead sulfide (selenide) with

complete passivation by oleic acid, oleyl amine and hydroxyl ligands

(size ≈5nm)

Large batches of quantum dots may be synthesized via colloidal synthesis. Due to this scalability and the convenience of benchtop conditions, colloidal synthetic methods are promising for commercial applications. It is acknowledged[citation needed] to be the least toxic of all the different forms of synthesis.

Plasma synthesis

Plasma

synthesis has evolved to be one of the most popular gas-phase

approaches for the production of quantum dots, especially those with

covalent bonds.

For example, silicon (Si) and germanium (Ge) quantum dots have been

synthesized by using nonthermal plasma. The size, shape, surface and

composition of quantum dots can all be controlled in nonthermal plasma. Doping that seems quite challenging for quantum dots has also been realized in plasma synthesis.

Quantum dots synthesized by plasma are usually in the form of powder,

for which surface modification may be carried out. This can lead to

excellent dispersion of quantum dots in either organic solvents or water (i. e., colloidal quantum dots).

Fabrication

- Self-assembled quantum dots are typically between 5 and 50 nm in size. Quantum dots defined by lithographically patterned gate electrodes, or by etching on two-dimensional electron gasses in semiconductor heterostructures can have lateral dimensions between 20 and 100 nm.

- Some quantum dots are small regions of one material buried in another with a larger band gap. These can be so-called core–shell structures, e.g., with CdSe in the core and ZnS in the shell, or from special forms of silica called ormosil. Sub-monolayer shells can also be effective ways of passivating the quantum dots, such as PbS cores with sub-monolayer CdS shells.

- Quantum dots sometimes occur spontaneously in quantum well structures due to monolayer fluctuations in the well's thickness.

- Self-assembled quantum dots nucleate spontaneously under certain conditions during molecular beam epitaxy (MBE) and metallorganic vapor phase epitaxy (MOVPE), when a material is grown on a substrate to which it is not lattice matched. The resulting strain produces coherently strained islands on top of a two-dimensional wetting layer. This growth mode is known as Stranski–Krastanov growth. The islands can be subsequently buried to form the quantum dot. This fabrication method has potential for applications in quantum cryptography (i.e. single photon sources) and quantum computation. The main limitations of this method are the cost of fabrication and the lack of control over positioning of individual dots.

- Individual quantum dots can be created from two-dimensional electron or hole gases present in remotely doped quantum wells or semiconductor heterostructures called lateral quantum dots. The sample surface is coated with a thin layer of resist. A lateral pattern is then defined in the resist by electron beam lithography. This pattern can then be transferred to the electron or hole gas by etching, or by depositing metal electrodes (lift-off process) that allow the application of external voltages between the electron gas and the electrodes. Such quantum dots are mainly of interest for experiments and applications involving electron or hole transport, i.e., an electrical current.

- The energy spectrum of a quantum dot can be engineered by controlling the geometrical size, shape, and the strength of the confinement potential. Also, in contrast to atoms, it is relatively easy to connect quantum dots by tunnel barriers to conducting leads, which allows the application of the techniques of tunneling spectroscopy for their investigation.

The quantum dot absorption features correspond to transitions between discrete, three-dimensional particle in a box states of the electron and the hole, both confined to the same nanometer-size box.These discrete transitions are reminiscent of atomic spectra and have resulted in quantum dots also being called artificial atoms.

- Confinement in quantum dots can also arise from electrostatic potentials (generated by external electrodes, doping, strain, or impurities).

- Complementary metal-oxide-semiconductor (CMOS) technology can be employed to fabricate silicon quantum dots. Ultra small (L=20 nm, W=20 nm) CMOS transistors behave as single electron quantum dots when operated at cryogenic temperature over a range of −269 °C (4 K) to about −258 °C (15 K). The transistor displays Coulomb blockade due to progressive charging of electrons one by one. The number of electrons confined in the channel is driven by the gate voltage, starting from an occupation of zero electrons, and it can be set to 1 or many.

Viral assembly

Genetically engineered M13 bacteriophage viruses allow preparation of quantum dot biocomposite structures. It had previously been shown that genetically engineered viruses can recognize specific semiconductor surfaces through the method of selection by combinatorial phage display. Additionally, it is known that liquid crystalline structures of wild-type viruses (Fd, M13, and TMV) are adjustable by controlling the solution concentrations, solution ionic strength, and the external magnetic field applied to the solutions. Consequently, the specific recognition properties of the virus can be used to organize inorganic nanocrystals,

forming ordered arrays over the length scale defined by liquid crystal

formation. Using this information, Lee et al. (2000) were able to create

self-assembled, highly oriented, self-supporting films from a phage and

ZnS

precursor solution. This system allowed them to vary both the length of

bacteriophage and the type of inorganic material through genetic

modification and selection.

Electrochemical assembly

Highly ordered arrays of quantum dots may also be self-assembled by electrochemical

techniques. A template is created by causing an ionic reaction at an

electrolyte-metal interface which results in the spontaneous assembly of

nanostructures, including quantum dots, onto the metal which is then

used as a mask for mesa-etching these nanostructures on a chosen

substrate.

Bulk-manufacture

Quantum

dot manufacturing relies on a process called "high temperature dual

injection" which has been scaled by multiple companies for commercial

applications that require large quantities (hundreds of kilograms to

tonnes) of quantum dots. This reproducible production method can be

applied to a wide range of quantum dot sizes and compositions.

The bonding in certain cadmium-free quantum dots, such as

III-V-based quantum dots, is more covalent than that in II-VI materials,

therefore it is more difficult to separate nanoparticle nucleation and

growth via a high temperature dual injection synthesis. An alternative

method of quantum dot synthesis, the “molecular seeding” process,

provides a reproducible route to the production of high quality quantum

dots in large volumes. The process utilises identical molecules of a

molecular cluster compound as the nucleation sites for nanoparticle

growth, thus avoiding the need for a high temperature injection step.

Particle growth is maintained by the periodic addition of precursors at

moderate temperatures until the desired particle size is reached.

The molecular seeding process is not limited to the production of

cadmium-free quantum dots; for example, the process can be used to

synthesise kilogram batches of high quality II-VI quantum dots in just a

few hours.

Another approach for the mass production of colloidal quantum

dots can be seen in the transfer of the well-known hot-injection

methodology for the synthesis to a technical continuous flow system. The

batch-to-batch variations arising from the needs during the mentioned

methodology can be overcome by utilizing technical components for mixing

and growth as well as transport and temperature adjustments. For the

production of CdSe based semiconductor nanoparticles this method has

been investigated and tuned to production amounts of kg per month. Since

the use of technical components allows for easy interchange in regards

of maximum through-put and size, it can be further enhanced to tens or

even hundreds of kilograms.

In 2011 a consortium of U.S. and Dutch companies reported a

"milestone" in high volume quantum dot manufacturing by applying the

traditional high temperature dual injection method to a flow system.

On January 23, 2013 Dow entered into an exclusive licensing agreement with UK-based Nanoco

for the use of their low-temperature molecular seeding method for bulk

manufacture of cadmium-free quantum dots for electronic displays, and on

September 24, 2014 Dow commenced work on the production facility in

South Korea capable of producing sufficient quantum dots for "millions

of cadmium-free televisions and other devices, such as tablets". Mass

production is due to commence in mid-2015.

On 24 March 2015 Dow announced a partnership deal with LG Electronics

to develop the use of cadmium free quantum dots in displays.

Heavy-metal-free quantum dots

In many regions of the world there is now a restriction or ban on the use of heavy metals in many household goods, which means that most cadmium-based quantum dots are unusable for consumer-goods applications.

For commercial viability, a range of restricted, heavy-metal-free

quantum dots has been developed showing bright emissions in the visible

and near infra-red region of the spectrum and have similar optical

properties to those of CdSe quantum dots. Among these systems are

InP/ZnS and CuInS/ZnS, for example.

Peptides are being researched as potential quantum dot material.

Since peptides occur naturally in all organisms, such dots would likely be nontoxic and easily biodegraded.

Health and safety

Some quantum dots pose risks to human health and the environment under certain conditions. Notably, the studies on quantum dot toxicity are focused on cadmium containing particles and has yet to be demonstrated in animal models after physiologically relevant dosing. In vitro

studies, based on cell cultures, on quantum dots (QD) toxicity suggests

that their toxicity may derive from multiple factors including its physicochemical

characteristics (size, shape, composition, surface functional groups,

and surface charges) and environment. Assessing their potential toxicity

is complex as these factors include properties such as QD size, charge,

concentration, chemical composition, capping ligands, and also on their

oxidative, mechanical and photolytic stability.

Many studies have focused on the mechanism of QD cytotoxicity using model cell cultures. It has been demonstrated that after exposure to ultraviolet radiation or oxidation by air, CdSe QDs release free cadmium ions causing cell death. Group II-VI QDs also have been reported to induce the formation of reactive oxygen species after exposure to light, which in turn can damage cellular components such as proteins, lipids and DNA.

Some studies have also demonstrated that addition of a ZnS shell

inhibit the process of reactive oxygen species in CdSe QDs. Another

aspect of QD toxicity is the process of their size dependent

intracellular pathways that concentrate these particles in cellular

organelles that are inaccessible by metal ions, which may result in

unique patterns of cytotoxicity compared to their constituent metal

ions. The reports of QD localization in the cell nucleus

present additional modes of toxicity because they may induce DNA

mutation, which in turn will propagate through future generation of

cells causing diseases.

Although concentration of QDs in certain organelles have been reported in in vivo

studies using animal models, no alterations in animal behavior, weight,

hematological markers or organ damage has been found through either

histological or biochemical analysis.

These finding have led scientists to believe that intracellular dose is

the most important deterring factor for QD toxicity. Therefore, factors

determining the QD endocytosis that determine the effective

intracellular concentration, such as QD size, shape and surface

chemistry determine their toxicity. Excretion of QDs through urine in

animal models also have demonstrated via injecting radio-labeled ZnS

capped CdSe QDs where the ligand shell was labelled with 99mTc. Though multiple other studies have concluded retention of QDs in cellular levels, exocytosis of QDs is still poorly studied in the literature.

While significant research efforts have broadened the

understanding of toxicity of QDs, there are large discrepancies in the

literature and questions still remains to be answered. Diversity of this

class material as compared to normal chemical substances makes the

assessment of their toxicity very challenging. As their toxicity may

also be dynamic depending on the environmental factors such as pH level,

light exposure and cell type, traditional methods of assessing toxicity of chemicals such as LD50

are not applicable for QDs. Therefore, researchers are focusing on

introducing novel approaches and adapting existing methods to include

this unique class of materials.

Furthermore, novel strategies to engineer safer QDs are still under

exploration by the scientific community. A recent novelty in the field

is the discovery of carbon quantum dots,

a new generation of optically-active nanoparticles potentially capable

of replacing semiconductor QDs, but with the advantage of much lower

toxicity.

Optical properties

Fluorescence

spectra of CdTe quantum dots of various sizes. Different sized quantum

dots emit different color light due to quantum confinement.

In semiconductors, light absorption generally leads to an electron

being excited from the valence to the conduction band, leaving behind a hole.

The electron and the hole can bind to each other to form an exciton.

When this exciton recombines (i.e. the electron resumes its ground

state), the exciton's energy can be emitted as light. This is called fluorescence.

In a simplified model, the energy of the emitted photon can be

understood as the sum of the band gap energy between the highest

occupied level and the lowest unoccupied energy level, the confinement

energies of the hole and the excited electron, and the bound energy of

the exciton (the electron-hole pair):

As the confinement energy depends on the quantum dot's size, both absorption

onset and fluorescence emission can be tuned by changing the size of

the quantum dot during its synthesis. The larger the dot, the redder (lower energy) its absorption onset and fluorescence spectrum. Conversely, smaller dots absorb and emit bluer (higher energy) light. Recent articles in Nanotechnology

and in other journals have begun to suggest that the shape of the

quantum dot may be a factor in the coloration as well, but as yet not

enough information is available. Furthermore, it was shown that the lifetime of fluorescence is determined by the size of the

quantum dot. Larger dots have more closely spaced energy levels in which

the electron-hole pair can be trapped. Therefore, electron-hole pairs

in larger dots live longer causing larger dots to show a longer

lifetime.

To improve fluorescence quantum yield,

quantum dots can be made with "shells" of a larger bandgap

semiconductor material around them. The improvement is suggested to be

due to the reduced access of electron and hole to non-radiative surface

recombination pathways in some cases, but also due to reduced Auger recombination in others.

Potential applications

Quantum dots are particularly promising for optical applications due to their high extinction coefficient. They operate like a single electron transistor and show the Coulomb blockade effect. Quantum dots have also been suggested as implementations of qubits for quantum information processing.

Tuning the size of quantum dots is attractive for many potential

applications. For instance, larger quantum dots have a greater

spectrum-shift towards red compared to smaller dots, and exhibit less

pronounced quantum properties. Conversely, the smaller particles allow

one to take advantage of more subtle quantum effects.

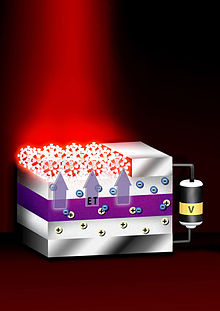

A device that produces visible light, through energy transfer from thin layers of quantum wells to crystals above the layers.

Being zero-dimensional, quantum dots have a sharper density of states

than higher-dimensional structures. As a result, they have superior

transport and optical properties. They have potential uses in diode lasers,

amplifiers, and biological sensors. Quantum dots may be excited within a

locally enhanced electromagnetic field produced by gold nanoparticles,

which can then be observed from the surface plasmon resonance

in the photoluminescent excitation spectrum of (CdSe)ZnS nanocrystals.

High-quality quantum dots are well suited for optical encoding and

multiplexing applications due to their broad excitation profiles and

narrow/symmetric emission spectra. The new generations of quantum dots

have far-reaching potential for the study of intracellular processes at

the single-molecule level, high-resolution cellular imaging, long-term

in vivo observation of cell trafficking, tumor targeting, and

diagnostics.

CdSe nanocrystals are efficient triplet photosensitizers.

Laser excitation of small CdSe nanoparticles enables the extraction of

the excited state energy from the Quantum Dots into bulk solution, thus

opening the door to a wide range of potential applications such as

photodynamic therapy, photovoltaic devices, molecular electronics, and

catalysis.

Biology

In modern biological analysis, various kinds of organic dyes are used. However, as technology advances, greater flexibility in these dyes is sought.

To this end, quantum dots have quickly filled in the role, being found

to be superior to traditional organic dyes on several counts, one of the

most immediately obvious being brightness (owing to the high extinction

coefficient combined with a comparable quantum yield to fluorescent

dyes) as well as their stability (allowing much less photobleaching). It has been estimated that quantum dots are 20 times brighter and 100 times more stable than traditional fluorescent reporters. For single-particle tracking, the irregular blinking of quantum dots

is a minor drawback. However, there have been groups which have

developed quantum dots which are essentially nonblinking and

demonstrated their utility in single molecule tracking experiments.

The use of quantum dots for highly sensitive cellular imaging has seen major advances.

The improved photostability of quantum dots, for example, allows the

acquisition of many consecutive focal-plane images that can be

reconstructed into a high-resolution three-dimensional image.

Another application that takes advantage of the extraordinary

photostability of quantum dot probes is the real-time tracking of

molecules and cells over extended periods of time. Antibodies, streptavidin, peptides, DNA, nucleic acid aptamers, or small-molecule ligands

can be used to target quantum dots to specific proteins on cells.

Researchers were able to observe quantum dots in lymph nodes of mice for

more than 4 months.

Quantum dots can have antibacterial properties similar to nanoparticles and can kill bacteria in a dose-dependent manner.

One mechanism by which quantum dots can kill bacteria is through

impairing the functions of antioxidative system in the cells and down

regulating the antioxidative genes. In addition, quantum dots can

directly damage the cell wall. Quantum dots have been shown to be

effective against both gram- positive and gram-negative bacteria.

Semiconductor quantum dots have also been employed for in vitro

imaging of pre-labeled cells. The ability to image single-cell

migration in real time is expected to be important to several research

areas such as embryogenesis, cancer metastasis, stem cell therapeutics, and lymphocyte immunology.

One application of quantum dots in biology is as donor fluorophores in Förster resonance energy transfer, where the large extinction coefficient and spectral purity of these fluorophores make them superior to molecular fluorophores

It is also worth noting that the broad absorbance of QDs allows

selective excitation of the QD donor and a minimum excitation of a dye

acceptor in FRET-based studies.

The applicability of the FRET model, which assumes that the Quantum Dot

can be approximated as a point dipole, has recently been demonstrated.

The use of quantum dots for tumor targeting under in vivo

conditions employ two targeting schemes: active targeting and passive

targeting. In the case of active targeting, quantum dots are

functionalized with tumor-specific binding sites to selectively bind to

tumor cells. Passive targeting uses the enhanced permeation and

retention of tumor cells for the delivery of quantum dot probes.

Fast-growing tumor cells typically have more permeable membranes than

healthy cells, allowing the leakage of small nanoparticles into the cell

body. Moreover, tumor cells lack an effective lymphatic drainage

system, which leads to subsequent nanoparticle-accumulation.

Quantum dot probes exhibit in vivo toxicity. For example, CdSe

nanocrystals are highly toxic to cultured cells under UV illumination,

because the particles dissolve, in a process known as photolysis,

to release toxic cadmium ions into the culture medium. In the absence

of UV irradiation, however, quantum dots with a stable polymer coating

have been found to be essentially nontoxic. Hydrogel encapsulation of quantum dots

allows for quantum dots to be introduced into a stable aqueous

solution, reducing the possibility of cadmium leakage.Then again, only

little is known about the excretion process of quantum dots from living

organisms.

In another potential application, quantum dots are being investigated as the inorganic fluorophore for intra-operative detection of tumors using fluorescence spectroscopy.

Delivery of undamaged quantum dots to the cell cytoplasm has been

a challenge with existing techniques. Vector-based methods have

resulted in aggregation and endosomal sequestration of quantum dots

while electroporation can damage the semi-conducting particles and

aggregate delivered dots in the cytosol. Via cell squeezing,

quantum dots can be efficiently delivered without inducing aggregation,

trapping material in endosomes, or significant loss of cell viability.

Moreover, it has shown that individual quantum dots delivered by this

approach are detectable in the cell cytosol, thus illustrating the

potential of this technique for single molecule tracking studies.

Photovoltaic devices

The tunable absorption spectrum and high extinction coefficients of

quantum dots make them attractive for light harvesting technologies such

as photovoltaics. Quantum dots may be able to increase the efficiency

and reduce the cost of today's typical silicon photovoltaic cells. According to an experimental proof from 2004, quantum dots of lead selenide can produce more than one exciton from one high energy photon via the process of carrier multiplication or multiple exciton generation

(MEG). This compares favorably to today's photovoltaic cells which can

only manage one exciton per high-energy photon, with high kinetic energy

carriers losing their energy as heat. Quantum dot photovoltaics would

theoretically be cheaper to manufacture, as they can be made "using

simple chemical reactions."

Quantum dot only solar cells

Aromatic self-assembled monolayers

(SAMs) (e.g. 4-nitrobenzoic acid) can be used to improve the band

alignment at electrodes for better efficiencies. This technique has

provided a record power conversion efficiency (PCE) of 10.7%.

The SAM is positioned between ZnO-PbS colloidal quantum dot (CQD) film

junction to modify band alignment via the dipole moment of the

constituent SAM molecule, and the band tuning may be modified via the

density, dipole and the orientation of the SAM molecule.

Quantum dot in hybrid solar cells

Colloidal quantum dots are also used in inorganic/organic hybrid solar cells. These solar cells are attractive because of the potential for low-cost fabrication and relatively high efficiency.

Incorporation of metal oxides, such as ZnO, TiO2, and Nb2O5

nanomaterials into organic photovoltaics have been commercialized using

full roll-to-roll processing. A 13.2% power conversion efficiency is claimed in Si nanowire/PEDOT:PSS hybrid solar cells.

Quantum dot with nanowire in solar cells

Another

potential use involves capped single-crystal ZnO nanowires with CdSe

quantum dots, immersed in mercaptopropionic acid as hole transport

medium in order to obtain a QD-sensitized solar cell. The morphology of

the nanowires allowed the electrons to have a direct pathway to the photoanode. This form of solar cell exhibits 50–60% internal quantum efficiencies.

Nanowires with quantum dot coatings on silicon nanowires (SiNW)

and carbon quantum dots. The use of SiNWs instead of planar silicon

enhances the antiflection properties of Si.

The SiNW exhibits a light-trapping effect due to light trapping in the

SiNW. This use of SiNWs in conjunction with carbon quantum dots resulted

in a solar cell that reached 9.10% PCE.

Graphene

quantum dots have also been blended with organic electronic materials

to improve efficiency and lower cost in photovoltaic devices and organic

light emitting diodes (OLEDs)

in compared to graphene sheets. These graphene quantum dots were

functionalized with organic ligands that experience photoluminescence

from UV-Vis absorption.

Light emitting diodes

Several methods are proposed for using quantum dots to improve existing light-emitting diode

(LED) design, including "Quantum Dot Light Emitting Diode" (QD-LED or

QLED) displays and "Quantum Dot White Light Emitting Diode" (QD-WLED)

displays. Because Quantum dots naturally produce monochromatic

light, they can be more efficient than light sources which must be

color filtered. QD-LEDs can be fabricated on a silicon substrate, which

allows them to be integrated onto standard silicon-based integrated circuits or microelectromechanical systems.

Quantum dot displays

Quantum dots are valued for displays because they emit light in very specific gaussian distributions. This can result in a display with visibly more accurate colors.

A conventional color liquid crystal display (LCD) is usually backlit by fluorescent lamps (CCFLs) or conventional white LEDs

that are color filtered to produce red, green, and blue pixels. Quantum

dot displays use blue-emitting LEDs rather than white LEDs as the light

sources. The converting part of the emitted light is converted into

pure green and red light by the corresponding color quantum dots placed

in front of the blue LED or using a quantum dot infused diffuser sheet

in the backlight optical stack. Blank pixels are also used to allow the

blue LED light to still generate blue hues. This type of white light as

the backlight of an LCD panel allows for the best color gamut at lower

cost than an RGB LED combination using three LEDs.

Another method by which quantum dot displays can be achieved is

the electroluminescent (EL) or electro-emissive method. This involves

embedding quantum dots in each individual pixel. These are then

activated and controlled via an electric current application. Since this is often light emitting itself, the achievable colors may be limited in this method. Electro-emissive QD-LED TVs exist in laboratories only.

The ability of QDs to precisely convert and tune a spectrum makes them attractive for LCD

displays. Previous LCD displays can waste energy converting red-green

poor, blue-yellow rich white light into a more balanced lighting. By

using QDs, only the necessary colors for ideal images are contained in

the screen. The result is a screen that is brighter, clearer, and more

energy-efficient. The first commercial application of quantum dots was

the Sony XBR X900A series of flat panel televisions released in 2013.

In June 2006, QD Vision announced technical success in making a proof-of-concept quantum dot display

and show a bright emission in the visible and near infra-red region of

the spectrum. A QD-LED integrated at a scanning microscopy tip was used

to demonstrate fluorescence near-field scanning optical microscopy (NSOM) imaging.

Photodetector devices

Quantum dot photodetectors (QDPs) can be fabricated either via solution-processing, or from conventional single-crystalline semiconductors.

Conventional single-crystalline semiconductor QDPs are precluded from

integration with flexible organic electronics due to the incompatibility

of their growth conditions with the process windows required by organic

semiconductors. On the other hand, solution-processed QDPs can be

readily integrated with an almost infinite variety of substrates, and

also postprocessed atop other integrated circuits. Such colloidal QDPs have potential applications in surveillance, machine vision, industrial inspection, spectroscopy, and fluorescent biomedical imaging.

Photocatalysts

Quantum dots also function as photocatalysts for the light driven chemical conversion of water into hydrogen as a pathway to solar fuel. In photocatalysis, electron hole pairs formed in the dot under band gap excitation drive redox reactions

in the surrounding liquid. Generally, the photocatalytic activity of

the dots is related to the particle size and its degree of quantum confinement. This is because the band gap determines the chemical energy that is stored in the dot in the excited state. An obstacle for the use of quantum dots in photocatalysis is the presence of surfactants on the surface of the dots. These surfactants (or ligands) interfere with the chemical reactivity of the dots by slowing down mass transfer and electron transfer processes. Also, quantum dots made of metal chalcogenides are chemically unstable under oxidizing conditions and undergo photo corrosion reactions.

Theory

Quantum

dots are theoretically described as a point like, or a zero dimensional

(0D) entity. Most of their properties depend on the dimensions, shape

and materials of which QDs are made. Generally QDs present different thermodynamic properties from the bulk materials of which they are made. One of these effects is the Melting-point depression. Optical properties of spherical metallic QDs are well described by the Mie scattering theory.

Quantum confinement in semiconductors

3D

confined electron wave functions in a quantum dot. Here, rectangular

and triangular-shaped quantum dots are shown. Energy states in

rectangular dots are more s-type and p-type. However, in a triangular dot the wave functions are mixed due to confinement symmetry. (Click for animation)

In a semiconductor crystallite whose size is smaller than twice the size of its exciton Bohr radius, the excitons are squeezed, leading to quantum confinement. The energy levels can then be predicted using the particle in a box

model in which the energies of states depend on the length of the box.

Comparing the quantum dots size to the Bohr radius of the electron and

hole wave functions, 3 regimes can be defined. A 'strong confinement

regime' is defined as the quantum dots radius being smaller than both

electron and hole Bohr radius, 'weak confinement' is given when the

quantum dot is larger than both. For semiconductors in which electron

and hole radii are markedly different, an 'intermediate confinement

regime' exists, where the quantum dot's radius is larger than the Bohr

radius of one charge carrier (typically the hole), but not the other

charge carrier.

Splitting

of energy levels for small quantum dots due to the quantum confinement

effect. The horizontal axis is the radius, or the size, of the quantum

dots and ab* is the Exciton Bohr radius.

- Band gap energy

- The band gap can become smaller in the strong confinement regime as

the energy levels split up. The Exciton Bohr radius can be expressed as:

- where ab is the Bohr radius=0.053 nm, m is the mass, μ is the reduced mass, and εr is the size-dependent dielectric constant (Relative permittivity). This results in the increase in the total emission energy (the sum of the energy levels in the smaller band gaps in the strong confinement regime is larger than the energy levels in the band gaps of the original levels in the weak confinement regime) and the emission at various wavelengths. If the size distribution of QDs is not enough peaked, the convolution of multiple emission wavelengths is observed as a continuous spectra.

- Confinement energy

- The exciton entity can be modeled using the particle in the box. The electron and the hole can be seen as hydrogen in the Bohr model with the hydrogen nucleus replaced by the hole of positive charge and negative electron mass. Then the energy levels of the exciton can be represented as the solution to the particle in a box at the ground level (n = 1) with the mass replaced by the reduced mass. Thus by varying the size of the quantum dot, the confinement energy of the exciton can be controlled.

- Bound exciton energy

- There is Coulomb attraction between the negatively charged electron and the positively charged hole. The negative energy involved in the attraction is proportional to Rydberg's energy and inversely proportional to square of the size-dependent dielectric constant of the semiconductor. When the size of the semiconductor crystal is smaller than the Exciton Bohr radius, the Coulomb interaction must be modified to fit the situation.

Therefore, the sum of these energies can be represented as:

where μ is the reduced mass, a is the radius of the quantum dot, me is the free electron mass, mh is the hole mass, and εr is the size-dependent dielectric constant.

Although the above equations were derived using simplifying

assumptions, they imply that the electronic transitions of the quantum

dots will depend on their size. These quantum confinement effects are

apparent only below the critical size. Larger particles do not exhibit

this effect. This effect of quantum confinement on the quantum dots has

been repeatedly verified experimentally and is a key feature of many emerging electronic structures.

The Coulomb

interaction between confined carriers can also be studied by numerical

means when results unconstrained by asymptotic approximations are

pursued.

Besides confinement in all three dimensions (i.e., a quantum dot), other quantum confined semiconductors include:

- Quantum wires, which confine electrons or holes in two spatial dimensions and allow free propagation in the third.

- Quantum wells, which confine electrons or holes in one dimension and allow free propagation in two dimensions.

Models

A variety

of theoretical frameworks exist to model optical, electronic, and

structural properties of quantum dots. These may be broadly divided into

quantum mechanical, semiclassical, and classical.

Quantum mechanics

Quantum mechanical models and simulations of quantum dots often involve the interaction of electrons with a pseudopotential or random matrix.

Semiclassical

Semiclassical models of quantum dots frequently incorporate a chemical potential. For example, the thermodynamic chemical potential of an N-particle system is given by

whose energy terms may be obtained as solutions of the Schrödinger equation. The definition of capacitance,

- ,

with the potential difference

may be applied to a quantum dot with the addition or removal of individual electrons,

- and .

Then

is the "quantum capacitance" of a quantum dot, where we denoted by I(N) the ionization potential and by A(N) the electron affinity of the N-particle system.

Classical mechanics

Classical models of electrostatic properties of electrons in quantum dots are similar in nature to the Thomson problem of optimally distributing electrons on a unit sphere.

The classical electrostatic treatment of electrons confined to

spherical quantum dots is similar to their treatment in the Thomson, or plum pudding model, of the atom.

The classical treatment of both two-dimensional and three-dimensional quantum dots exhibit electron shell-filling behavior. A "periodic table of classical artificial atoms" has been described for two-dimensional quantum dots.

As well, several connections have been reported between the

three-dimensional Thomson problem and electron shell-filling patterns

found in naturally-occurring atoms found throughout the periodic table.

This latter work originated in classical electrostatic modeling of

electrons in a spherical quantum dot represented by an ideal dielectric

sphere.

History

The term “quantum dot” was coined in 1986. They were first discovered in a glass matrix and in colloidal solutions by Alexey Ekimov and Louis Brus.