| |||

Thin-film solar cells, a second generation of photovoltaic (PV) solar cells:

|

Film thickness varies from a few nanometers (nm) to tens of micrometers (µm), much thinner than thin-film's rival technology, the conventional, first-generation crystalline silicon solar cell (c-Si), that uses wafers of up to 200 µm thick. This allows thin film cells to be flexible, and lower in weight. It is used in building integrated photovoltaics and as semi-transparent, photovoltaic glazing material that can be laminated onto windows. Other commercial applications use rigid thin film solar panels (sandwiched between two panes of glass) in some of the world's largest photovoltaic power stations.

Thin-film technology has always been cheaper but less efficient than conventional c-Si technology. However, it has significantly improved over the years. The lab cell efficiency for CdTe and CIGS is now beyond 21 percent, outperforming multicrystalline silicon, the dominant material currently used in most solar PV systems. Accelerated life testing of thin film modules under laboratory conditions measured a somewhat faster degradation compared to conventional PV, while a lifetime of 20 years or more is generally expected. Despite these enhancements, market-share of thin-film never reached more than 20 percent in the last two decades and has been declining in recent years to about 9 percent of worldwide photovoltaic installations in 2013.

Other thin-film technologies that are still in an early stage of ongoing research or with limited commercial availability are often classified as emerging or third generation photovoltaic cells and include organic, and dye-sensitized, as well as quantum dot, copper zinc tin sulfide, nanocrystal, micromorph, and perovskite solar cells.

History

Market-share of thin-film technologies in terms of annual production since 1990

Thin film cells are well-known since the late 1970s, when solar calculators powered by a small strip of amorphous silicon appeared on the market.

It is now available in very large modules used in sophisticated building-integrated installations and vehicle charging systems.

Although thin-film technology was expected to make significant

advances in the market and to surpass the dominating conventional crystalline silicon (c-Si) technology in the long-term,

market-share has been declining for several years now. While in 2010,

when there was a shortage of conventional PV modules, thin-film

accounted for 15 percent of the overall market, it declined to 8 percent

in 2014, and is expected to stabilize at 7 percent from 2015 onward,

with amorphous silicon expected to lose half of its market-share by the

end of the decade.

Materials

Cross-section of a TF cell

Thin-film technologies reduce the amount of active material in a

cell. Most sandwich active material between two panes of glass. Since

silicon solar panels only use one pane of glass, thin film panels are

approximately twice as heavy as crystalline silicon panels, although

they have a smaller ecological impact (determined from life cycle analysis). The majority of film panels have 2-3 percentage points lower conversion efficiencies than crystalline silicon. Cadmium telluride (CdTe), copper indium gallium selenide (CIGS) and amorphous silicon (a-Si) are three thin-film technologies often used for outdoor applications.

Cadmium telluride

Cadmium telluride

(CdTe) is the predominant thin film technology. With about 5 percent of

worldwide PV production, it accounts for more than half of the thin

film market. The cell's lab efficiency has also increased significantly

in recent years and is on a par with CIGS thin film and close to the

efficiency of multi-crystalline silicon as of 2013. Also, CdTe has the lowest Energy payback time of all mass-produced PV technologies, and can be as short as eight months in favorable locations. A prominent manufacturer is the US-company First Solar based in Tempe, Arizona, that produces CdTe-panels with an efficiency of about 14 percent at a reported cost of $0.59 per watt.

Although the toxicity of cadmium

may not be that much of an issue and environmental concerns completely

resolved with the recycling of CdTe modules at the end of their life

time, there are still uncertainties and the public opinion is skeptical towards this technology.

The usage of rare materials may also become a limiting factor to the

industrial scalability of CdTe thin film technology. The rarity of tellurium—of which telluride is the anionic form—is comparable to that of platinum in the earth's crust and contributes significantly to the module's cost.

Copper indium gallium selenide

A copper indium gallium selenide solar cell or CIGS cell uses an absorber made of copper, indium, gallium, selenide

(CIGS), while gallium-free variants of the semiconductor material are

abbreviated CIS. It is one of three mainstream thin-film technologies,

the other two being cadmium telluride and amorphous silicon, with a lab-efficiency above 20 percent and a share of 2 percent in the overall PV market in 2013. A prominent manufacturer of cylindrical CIGS-panels was the now-bankrupt company Solyndra

in Fremont, California. Traditional methods of fabrication involve

vacuum processes including co-evaporation and sputtering. In 2008, IBM

and Tokyo Ohka Kogyo Co., Ltd. (TOK) announced they had developed a

new, non-vacuum, solution-based manufacturing process for CIGS cells and

are aiming for efficiencies of 15% and beyond.

Hyperspectral imaging

has been used to characterize these cells. Researchers from IRDEP

(Institute of Research and Development in Photovoltaic Energy) in

collaboration with Photon etc.¸ were able to determine the splitting of the quasi-Fermi level with photoluminescence mapping while the electroluminescence data were used to derive the external quantum efficiency (EQE).

Also, through a light beam induced current (LBIC) cartography

experiment, the EQE of a microcrystalline CIGS solar cell could be

determined at any point in the field of view.

As of September 2014, current conversion efficiency record for a laboratory CIGS cell stands at 21.7%.

Silicon

Three major silicon-based module designs dominate:

- amorphous silicon cells

- amorphous / microcrystalline tandem cells (micromorph)

- thin-film polycrystalline silicon on glass.

Amorphous silicon

Amorphous silicon

(a-Si) is a non-crystalline, allotropic form of silicon and the most

well-developed thin film technology to-date. Thin-film silicon is an

alternative to conventional wafer (or bulk) crystalline silicon. While chalcogenide-based

CdTe and CIS thin films cells have been developed in the lab with great

success, there is still industry interest in silicon-based thin film

cells. Silicon-based devices exhibit fewer problems than their CdTe and

CIS counterparts such as toxicity and humidity issues with CdTe cells

and low manufacturing yields of CIS due to material complexity.

Additionally, due to political resistance to the use non-"green"

materials in solar energy production, there is no stigma in the use of

standard silicon.

This type of thin-film cell is mostly fabricated by a technique called plasma-enhanced chemical vapor deposition. It uses a gaseous mixture of silane (SiH4)

and hydrogen to deposit a very thin layer of only 1 micrometer (µm) of

silicon on a substrate, such as glass, plastic or metal, that has

already been coated with a layer of transparent conducting oxide. Other methods used to deposit amorphous silicon on a substrate include sputtering and hot wire chemical vapor deposition techniques.

a-Si is attractive as a solar cell material because it's an

abundant, non-toxic material. It requires a low processing temperature

and enables a scalable production upon a flexible, low-cost substrate

with little silicon material required. Due to its band gap of 1.7 eV,

amorphous silicon also absorbs a very broad range of the light spectrum, that includes infrared and even some ultraviolet

and performs very well at weak light. This allows the cell to generate

power in the early morning, or late afternoon and on cloudy and rainy

days, contrary to crystalline silicon cells, that are significantly less efficient when exposed at diffuse and indirect daylight.

However, the efficiency of an a-Si cell suffers a significant

drop of about 10 to 30 percent during the first six months of operation.

This is called the Staebler-Wronski effect

(SWE) – a typical loss in electrical output due to changes in

photoconductivity and dark conductivity caused by prolonged exposure to

sunlight. Although this degradation is perfectly reversible upon annealing at or above 150 °C, conventional c-Si solar cells do not exhibit this effect in the first place.

Its basic electronic structure is the p-i-n

junction. The amorphous structure of a-Si implies high inherent

disorder and dangling bonds, making it a bad conductor for charge

carriers. These dangling bonds act as recombination centers that

severely reduce carrier lifetime. A p-i-n structure is usually used, as

opposed to an n-i-p structure. This is because the mobility of electrons

in a-Si:H is roughly 1 or 2 orders of magnitude larger than that of

holes, and thus the collection rate of electrons moving from the n- to

p-type contact is better than holes moving from p- to n-type contact.

Therefore, the p-type layer should be placed at the top where the light

intensity is stronger, so that the majority of the charge carriers

crossing the junction are electrons.

Tandem-cell using a-Si/μc-Si

A layer of amorphous silicon can be combined with layers of other allotropic forms of silicon to produce a multi-junction solar cell. When only two layers (two p-n junctions) are combined, it is called a tandem-cell.

By stacking these layers on top of one other, a broader range of the

light spectra is absorbed, improving the cell's overall efficiency.

In micromorphous silicon, a layer of microcrystalline silicon

(μc-Si) is combined with amorphous silicon, creating a tandem cell. The

top a-Si layer absorbs the visible light, leaving the infrared part to

the bottom μc-Si layer. The micromorph stacked-cell concept was

pioneered and patented at the Institute of Microtechnology (IMT) of the

Neuchâtel University in Switzerland, and was licensed to TEL Solar. A new world record PV module based on the micromorph concept with 12.24% module efficiency was independently certified in July 2014.

Because all layers are made of silicon, they can be manufactured using PECVD. The band gap

of a-Si is 1.7 eV and that of c-Si is 1.1 eV. The c-Si layer can absorb

red and infrared light. The best efficiency can be achieved at

transition between a-Si and c-Si. As nanocrystalline silicon (nc-Si) has

about the same bandgap as c-Si, nc-Si can replace c-Si.

Tandem-cell using a-Si/pc-Si

Amorphous silicon can also be combined with protocrystalline

silicon (pc-Si) into a tandem-cell. Protocrystalline silicon with a low

volume fraction of nanocrystalline silicon is optimal for high open-circuit voltage.

These types of silicon present dangling and twisted bonds, which

results in deep defects (energy levels in the band gap) as well as

deformation of the valence and conduction bands (band tails).

Polycrystalline silicon on glass

A

new attempt to fuse the advantages of bulk silicon with those of

thin-film devices is thin film polycrystalline silicon on glass. These

modules are produced by depositing an anti-reflection coating and doped

silicon onto textured glass substrates using plasma-enhanced chemical

vapor deposition (PECVD). The texture in the glass enhances the

efficiency of the cell by approximately 3% by reducing the amount of

incident light reflecting from the solar cell and trapping light inside

the solar cell. The silicon film is crystallized by an annealing step,

temperatures of 400–600 Celsius, resulting in polycrystalline silicon.

These new devices show energy conversion efficiencies of 8% and

high manufacturing yields of greater than 90%. Crystalline silicon on glass

(CSG), where the polycrystalline silicon is 1–2 micrometers, is noted

for its stability and durability; the use of thin film techniques also

contributes to a cost savings over bulk photovoltaics. These modules do

not require the presence of a transparent conducting oxide layer. This

simplifies the production process twofold; not only can this step be

skipped, but the absence of this layer makes the process of constructing

a contact scheme much simpler. Both of these simplifications further

reduce the cost of production. Despite the numerous advantages over

alternative design, production cost estimations on a per unit area basis

show that these devices are comparable in cost to single-junction

amorphous thin film cells.

Gallium arsenide

The semiconductor material gallium arsenide

(GaAs) is also used for single-crystalline thin film solar cells.

Although GaAs cells are very expensive, they hold the world record for

the highest-efficiency, single-junction solar cell at 28.8%. GaAs is more commonly used in multi-junction solar cells for solar panels on spacecrafts, as the industry favors efficiency over cost for space-based solar power (InGaP/(In)GaAs/Ge cells). They are also used in concentrator photovoltaics,

an emerging technology best suited for locations that receive much

sunlight, using lenses to focus sunlight on a much smaller, thus less

expensive GaAs concentrator solar cell.

Emerging photovoltaics

An experimental silicon based solar cell developed at the Sandia National Laboratories

The National Renewable Energy Laboratory

(NREL) classifies a number of thin-film technologies as emerging

photovoltaics—most of them have not yet been commercially applied and

are still in the research or development phase. Many use organic

materials, often organometallic

compounds as well as inorganic substances. Despite the fact that their

efficiencies had been low and the stability of the absorber material was

often too short for commercial applications, there is a lot of research

invested into these technologies as they promise to achieve the goal of

producing low-cost, high-efficient solar cells.

Emerging photovoltaics, often called third generation photovoltaic cells, include:

- Copper zinc tin sulfide solar cell (CZTS), and derivates CZTSe and CZTSSe

- Dye-sensitized solar cell, also known as "Grätzel cell"

- Organic solar cell

- Perovskite solar cell

- Quantum dot solar cell

Especially the achievements in the research of perovskite cells have

received tremendous attention in the public, as their research

efficiencies recently soared above 20 percent. They also offer a wide

spectrum of low-cost applications. In addition, another emerging technology, concentrator photovoltaics (CPV), uses high-efficient, multi-junction solar cells in combination with optical lenses and a tracking system.

Efficiencies

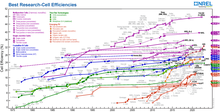

Solar cell efficiencies of various cell technologies as tracked by NREL

Incremental improvements in efficiency began with the invention of

the first modern silicon solar cell in 1954. By 2010 these steady

improvements had resulted in modules capable of converting 12 to 18

percent of solar radiation into electricity. The improvements to efficiency have continued to accelerate in the years since 2010, as shown in the accompanying chart.

Cells made from newer materials tend to be less efficient than bulk silicon, but are less expensive to produce. Their quantum efficiency is also lower due to reduced number of collected charge carriers per incident photon.

The performance and potential of thin-film materials are high, reaching cell efficiencies of 12–20%; prototype module efficiencies of 7–13%; and production modules in the range of 9%.

The thin film cell prototype with the best efficiency yields 20.4%

(First Solar), comparable to the best conventional solar cell prototype

efficiency of 25.6% from Panasonic.

NREL once predicted that costs would drop below $100/m2 in volume production, and could later fall below $50/m2.

A new record for thin film solar cell efficiency of 22.3% has been achieved by solar frontier the world's largest cis solar energy provider. In joint research with the New Energy and Industrial Technology Development Organization (NEDO) of Japan, Solar Frontier achieved 22.3% conversion efficiency on a 0.5 cm2

cell using its CIS technology. This is an increase of 0.6 percentage

points over the industry's previous thin-film record of 21.7%.

Absorption

Multiple

techniques have been employed to increase the amount of light that

enters the cell and reduce the amount that escapes without absorption.

The most obvious technique is to minimizing the top contact coverage of

the cell surface, reducing the area that blocks light from reaching the

cell.

The weakly absorbed long wavelength light can be obliquely

coupled into silicon and traverses the film several times to enhance

absorption.

Multiple methods have been developed to increase absorption by

reducing the number of incident photons being reflected away from the

cell surface. An additional anti-reflective coating can cause

destructive interference within the cell by modulating the refractive index of the surface coating. Destructive interference eliminates the reflective wave, causing all incident light to enter the cell.

Surface texturing is another option for increasing absorption,

but increases costs. By applying a texture to the active material's

surface, the reflected light can be refracted into striking the surface

again, thus reducing reflectance.For example, black silicon texturing by

reactive ion etching(RIE) is an effective and economic approach to

increase the absorption of thin-film silicon solar cells. A textured backreflector can prevent light from escaping through the rear of the cell.

In addition to surface texturing, the plasmonic light-trapping

scheme attracted a lot of attention to aid photocurrent enhancement in

thin film solar cells.

This method makes use of collective oscillation of excited free

electrons in noble metal nanoparticles, which are influenced by particle

shape, size and dielectric properties of the surrounding medium.

In addition to minimizing reflective loss, the solar cell

material itself can be optimized to have higher chance of absorbing a

photon that reaches it. Thermal processing techniques can significantly

enhance the crystal quality of silicon cells and thereby increase

efficiency. Layering thin-film cells to create a multi-junction solar cell

can also be done. Each layer's band gap can be designed to best absorb a

different range of wavelengths, such that together they can absorb a

greater spectrum of light.

Further advancement into geometric considerations can exploit

nanomaterial dimensionality. Large, parallel nanowire arrays enable long

absorption lengths along the length of the wire while maintaining short

minority carrier diffusion lengths along the radial direction.

Adding nanoparticles between the nanowires allows conduction. The

natural geometry of these arrays forms a textured surface that traps

more light.

Production, cost and market

With the advances in conventional crystalline silicon (c-Si) technology in recent years, and the falling cost of the polysilicon

feedstock, that followed after a period of severe global shortage,

pressure increased on manufacturers of commercial thin-film

technologies, including amorphous thin-film silicon (a-Si), cadmium

telluride (CdTe), and copper indium gallium diselenide (CIGS), leading

to the bankruptcy of several companies.

As of 2013, thin-film manufacturers continue to face price competition

from Chinese refiners of silicon and manufacturers of conventional c-Si

solar panels. Some companies together with their patents were sold to

Chinese firms below cost.

In

2013 thin-film technologies accounted for about 9 percent of worldwide

deployment, while 91 percent was held by crystalline silicon (mono-Si and multi-Si).

With 5 percent of the overall market, CdTe holds more than half of the

thin-film market, leaving 2 percent to each CIGS and amorphous silicon.

CIGS technology

- Several prominent manufacturers couldn't stand the pressure caused by advances in conventional c-Si technology of recent years. The company Solyndra ceased all business activity and filed for Chapter 11 bankruptcy in 2011, and Nanosolar, also a CIGS manufacturer, closed its doors in 2013. Although both companies produced CIGS solar cells, it has been pointed out, that the failure was not due to the technology but rather because of the companies themselves, using a flawed architecture, such as, for example, Solyndra's cylindrical substrates. In 2014, Korean LG Electronics terminated research on CIGS restructuring its solar business, and Samsung SDI decided to cease CIGS-production, while Chinese PV manufacturer Hanergy is expected to ramp up production capacity of their 15.5% efficient, 650 mm×1650 mm CIGS-modules. One of the largest producers of CI(G)S photovoltaics is the Japanese company Solar Frontier with a manufacturing capacity in the gigawatt-scale. (Also see List of CIGS companies).

CdTe technology

- The company First Solar, a leading manufacturer of CdTe, has been building several of the world's largest solar power stations, such as the Desert Sunlight Solar Farm and Topaz Solar Farm, both in the Californian desert with a 550 MW capacity each, as well as the 102-megawatt Nyngan Solar Plant in Australia, the largest PV power station in the Southern Hemisphere, commissioned in 2015.

- In 2011, GE announced plans to spend $600 million on a new CdTe solar cell plant and enter this market, and in 2013, First Solar bought GE's CdTe thin-film intellectual property portfolio and formed a business partnership. In 2012 Abound Solar, a manufacturer of cadmium telluride modules, went bankrupt.

a-Si technology

- In 2012, ECD solar, once one of the world's leading manufacturer of amorphous silicon (a-Si) technology, filed for bankruptcy in Michigan, United States. Swiss OC Oerlikon divested its solar division that produced a-Si/μc-Si tandem cells to Tokyo Electron Limited. In 2014, the Japanese electronics and semiconductor company announced the closure of its micromorph technology development program. "Micromorph" was the commercial name for a solar tandem cell using a microcrystalline silicon layer above the amorphous layer (a-Si/µ-Si).

- Other companies that left the amorphous silicon thin-film market include DuPont, BP, Flexcell, Inventux, Pramac, Schuco, Sencera, EPV Solar, NovaSolar (formerly OptiSolar) and Suntech Power that stopped manufacturing a-Si modules in 2010 to focus on conventional silicon solar panels. In 2013, Suntech filed for bankruptcy in China. In August 2013, the spot market price of thin-film a-Si and a-Si/µ-Si dropped to €0.36 and €0.46, respectively (about $0.50 and $0.60) per watt.

Awards

Thin-film photovoltaic cells were included in Time Magazine's Best Inventions of 2008.