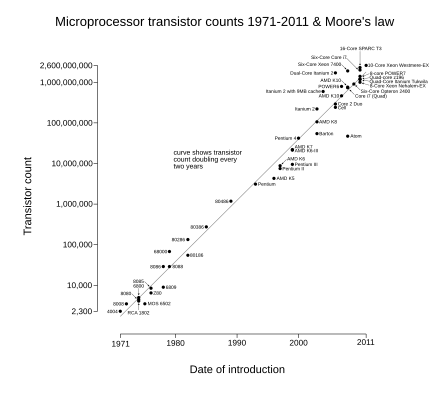

Plot of MOS transistor counts for microprocessors against dates of introduction. The curve shows counts doubling every two years, per Moore's law.

The transistor count is the number of transistors on an integrated circuit (IC). It typically refers to the number of MOSFETs

(metal-oxide-semiconductor field-effect transistors, or MOS

transistors) on an IC chip, as all modern ICs use MOSFETs. It is the

most common measure of IC complexity (although the majority of

transistors in modern microprocessors are contained in the cache memories, which consist mostly of the same memory cell circuits replicated many times). The rate at which MOS transistor counts have increased generally follows Moore's law, which observed that the transistor count doubles approximately every two years.

As of 2019, the largest transistor count in a commercially available microprocessor is 39.54 billion MOSFETs, in AMD's Zen 2 based Epyc Rome, which is a 3D integrated circuit (with eight dies in a single package) fabricated using TSMC's 7 nm FinFET semiconductor manufacturing process. As of 2018, the highest transistor count in a graphics processing unit (GPU) is Nvidia's GV100 Volta with 21.1 billion MOSFETs, manufactured using TSMC's 12 nm FinFET process. As of 2019, the highest transistor count in any IC chip is Samsung's 1 TB eUFS (3D-stacked) V-NAND flash memory chip, with 2 trillion floating-gate MOSFETs (4 bits per transistor). As of 2019, the highest transistor count in a non-memory chip is a deep learning

engine called the Wafer Scale Engine by Cerebras, using a special

design to route around any non-functional core on the device; it has 1.2 trillion MOSFETs, manufactured using TSMC's 16 nm FinFET process.

In terms of computer systems that consist of numerous integrated circuits, the supercomputer with the highest transistor count as of 2016 is the Chinese-designed Sunway TaihuLight, which has for all CPUs/nodes (1012 for the 10 million cores and for RAM 1015 for the 1.3 million GB) combined "about 400 trillion transistors in the processing part of the hardware" and "the DRAM includes about 12 quadrillion transistors, and that’s about 97 percent of all the transistors." To compare, the smallest computer, as of 2018

dwarfed by a grain of sand, has on the order of 100,000 transistors,

and the one, fully programmable, with the fewest transistors ever has

130 transistors or fewer.

In terms of the total number of transistors in existence, it has been estimated that a total of 13 sextillion (1.3 × 1022)

MOSFETs have been manufactured worldwide between 1960 and 2018,

accounting for at least 99.9% of all transistors. This makes the MOSFET

the most widely manufactured device in history.

Transistor count

Part of an IBM 7070 card cage populated with Standard Modular System cards

Among the earliest products to use transistors were portable transistor radios, introduced in 1954, which typically used 4 to 8 transistors, often advertising the number on the radio's case. However, early junction transistors were relatively bulky devices that were difficult to manufacture on a mass-production basis, limiting the transistor counts and restricting their usage to a number of specialised applications.

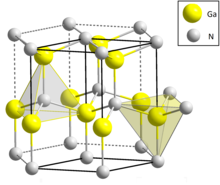

The MOSFET (MOS transistor), invented by Mohamed Atalla and Dawon Kahng at Bell Labs in 1959, was the first truly compact transistor that could be miniaturised and mass-produced for a wide range of uses. The MOSFET made it possible to build high-density integrated circuits (ICs), enabling Moore's law and very large-scale integration. Atalla first proposed the concept of the MOS integrated circuit (MOS IC) chip in 1960, followed by Kahng in 1961, both noting that the MOSFET's ease of fabrication made it useful for integrated circuits. The earliest experimental MOS IC to be demonstrated was a 16-transistor chip built by Fred Heiman and Steven Hofstein at RCA Laboratories in 1962. Further large-scale integration was made possible with an improvement in MOSFET semiconductor device fabrication, the CMOS process, developed by Chih-Tang Sah and Frank Wanlass at Fairchild Semiconductor in 1963.

Microprocessors

A microprocessor incorporates the functions of a computer's central processing unit on a single integrated circuit.

It is a multi-purpose, programmable device that accepts digital data as

input, processes it according to instructions stored in its memory, and

provides results as output.

The development of MOS integrated circuit technology in the 1960s led to the development of the first microprocessors. The 20-bit MP944, developed by Garrett AiResearch for the U.S. Navy's F-14 Tomcat fighter in 1970, is considered by its designer Ray Holt to be the first microprocessor. It was a multi-chip microprocessor, fabricated on six MOS chips. However, it was classified by the Navy until 1998. The 4-bit Intel 4004, released in 1971, was the first single-chip microprocessor. It was made possible with an improvement in MOSFET design, MOS silicon-gate technology (SGT), developed in 1968 at Fairchild Semiconductor by Federico Faggin, who went on to use MOS SGT technology to develop the 4004 with Marcian Hoff, Stanley Mazor and Masatoshi Shima at Intel.

All chips over e.g. a million transistors have lots of memory,

usually cache memories in level 1 and 2 or more levels, accounting for

most transistors on microprocessors in modern times, where large caches

have become the norm. The level 1 caches of the Pentium Pro

die accounted for over 14% of its transistors, while the much larger L2

cache was on a separate die, but on-package, so it's not included in

the transistor count. Later chips included more levels, L2 or even L3

on-chip. The last DEC Alpha chip made has 90% of it for cache.

While Intel's i960CA

small cache of 1 KB, at about 50,000 transistors, isn't a big part of

the chip, it alone would have been very large in early microprocessors.

In the ARM 3 chip, with 4 KB, the cache was over 63% of the chip, and in the Intel 80486 its larger cache is only over a third of it because the rest of the

chip is more complex. So cache memories are the largest factor, except

for in early chips with smaller caches or even earlier chips with no

cache at all. Then the inherent complexity, e.g. number of instructions,

is the dominant factor, more than e.g. the memory the registers of the

chip represent.

GPUs

A graphics processing unit

(GPU) is a specialized electronic circuit designed to rapidly

manipulate and alter memory to accelerate the building of images in a

frame buffer intended for output to a display.

The designer refers to the technology company that designs the logic of the integrated circuit chip (such as Nvidia and AMD). The manufacturer refers to the semiconductor company that fabricates the chip using its semiconductor manufacturing process at a foundry (such as TSMC and Samsung Semiconductor). The transistor count in a chip is dependent on a manufacturer's fabrication process, with smaller semiconductor nodes typically enabling higher transistor density and thus higher transistor counts.

The random-access memory (RAM) that comes with GPUs (such as VRAM, SGRAM or HBM) greatly increase the total transistor count, with the memory typically accounting for the majority of transistors in a graphics card. For example, Nvidia's Tesla P100 has 15 billion FinFETs (16 nm) in the GPU in addition to 16 GB of HBM2 memory, totaling about 150 billion MOSFETs on the graphics card.

Memory

Semiconductor memory is an electronic data storage device, often used as computer memory, implemented on integrated circuits. Nearly all semiconductor memory since the 1970s have used MOSFETs (MOS transistors), replacing earlier bipolar junction transistors. There are two major types of semiconductor memory, random-access memory (RAM) and non-volatile memory (NVM). In turn, there are two major RAM types, dynamic random-access memory (DRAM) and static random-access memory (SRAM), as well as two major NVM types, flash memory and read-only memory (ROM).

Typical CMOS

SRAM consists of six transistors per cell. For DRAM, 1T1C, which means

one transistor and one capacitor structure, is common. Capacitor charged

or not is used to store 1 or 0. For flash memory, the data is stored in

floating gate, and the resistance of the transistor is sensed to

interpret the data stored. Depending on how fine scale the resistance

could be separated, one transistor could store up to 3-bits,

meaning eight distinctive level of resistance possible per transistor.

However, the fine the scale comes with cost of repeatability therefore

reliability. Typically, low grade 2-bits MLC flash is used for flash drives, so a 16 GB flash drive contains roughly 64 billion transistors.

For SRAM chips, six-transistor cells (six transistors per bit) was the standard.

DRAM chips during the early 1970s had three-transistor cells (three

transistors per bit), before single-transistor cells (one transistor per

bit) became standard since the era of 4 Kb DRAM in the mid-1970s. In single-level flash memory, each cell contains one floating-gate MOSFET (one transistor per bit), whereas multi-level flash contains 2, 3 or 4 bits per transistor.

Flash memory chips are commonly stacked up in layers, up to 128-layer in production, and 136-layer managed, and available in end-user devices up to 69-layer from manufacturers.

Transistor computers

Before transistors were invented, relays were used in early computers. The world's first working programmable, fully automatic digital computer, the 1941 Z3 22-bit word length computer, had 2,600 relays, and operated at a clock frequency of about 4–5 Hz. The 1940 Complex Number Computer had fewer than 500 relays, but it was not fully programmable.

The second generation of computers were transistor computers that featured boards filled with discrete transistors and magnetic memory cores. The experimental 1953 48-bit Transistor Computer, developed at the University of Manchester,

is widely believed to be the first transistor computer to come into

operation anywhere in the world (the prototype had 92 point-contact

transistors and 550 diodes).

A later version the 1955 machine had a total of 250 junction

transistors and 1300 point diodes. The Computer also used a small number

of tubes in its clock generator, so it was not the first fully transistorized. The ETL Mark III, developed at the Electrotechnical Laboratory in 1956, may have been the first transistor-based electronic computer using the stored program

method. It had about "130 point-contact transistors and about 1,800

germanium diodes were used for logic elements, and these were housed on

300 plug-in packages which could be slipped in and out. The 1958 decimal architecture IBM 7070

was the first transistor computer to be fully programmable. It had

about 30,000 alloy-junction germanium transistors and 22,000 germanium

diodes, on approximately 14,000 Standard Modular System (SMS) cards. The 1959 MOBIDIC, short for "MOBIle DIgital Computer", at 12,000 pounds (6.0 short tons) mounted in the trailer of a semi-trailer truck, was a transistorized computer for battlefield data.

The third generation of computers used integrated circuits (ICs).[245] The 1962 15-bit Apollo Guidance Computer used "about 4,000 "Type-G" (3-input NOR gate) circuits" for about 12,000 transistors plus 32,000 resistors.

The first commercial IC-based computer was the IBM System/360 in 1964. The 1965 12-bit PDP-8

CPU had 1409 transistors and over 10,000 diodes. It was not a

microprocessor, as it used discrete transistors on many cards; but later

microprocessors, such as the Intersil 6100 reimplemented it.

The next generation of computers were the microcomputers, also known as home computers or personal computers (PC), which used MOS microprocessors,

in the 1970s. This list includes early transistorized computers (second

generation) and IC-based computers (third generation) from the 1950s

and 1960s.

Parallel systems

Historically, each processing element in earlier parallel systems—like all CPUs of that time—was a serial computer

built out of multiple chips. As transistor counts per chip increases,

each processing element could be built out of fewer chips, and then

later each multi-core processor chip could contain more processing elements.

Goodyear MPP: (1983?) 8 pixel processors per chip, 3,000 to 8,000 transistors per chip.

Brunel University Scape (single-chip array-processing element):

(1983) 256 pixel processors per chip, 120,000 to 140,000 transistors per

chip.

Cell Broadband Engine: (2006) with 9 cores per chip, had 234 million transistors per chip.

Transistor density

The transistor density is the number of transistors that are fabricated per unit area, typically measured in terms of the number of transistors per square millimeter (mm²). The transistor density usually correlates with the gate length of a semiconductor node (also known as a semiconductor manufacturing process), typically measured in nanometers (nm). As of 2019, the semiconductor node with the highest transistor density is TSMC's 5 nanometer node, with 171.3 million transistors per square millimeter.