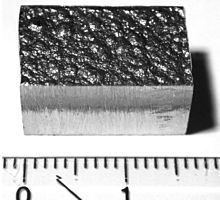

Four common conflict minerals, clockwise from top left: coltan, cassiterite, gold ore, and wolframite.

Conflict resources are natural resources extracted in a conflict zone and sold to perpetuate the fighting.

There is both statistical and anecdotal evidence that belligerent

accessibility to precious commodities can prolong conflicts (a "resource curse"). The most prominent contemporary example has been the eastern provinces of the Democratic Republic of the Congo

(DRC), where various armies, rebel groups, and outside actors have

profited from mining while contributing to violence and exploitation

during wars in the region.

The four most commonly mined conflict minerals (known as 3TGs, from their initials) are cassiterite (for tin), wolframite (for tungsten), coltan (for tantalum), and gold

ore, which are extracted from the eastern Congo, and passed through a

variety of intermediaries before being purchased. These minerals are

essential in the manufacture of a variety of devices, including consumer electronics such as mobile phones, laptops, and MP3 players.

The extraction and sale of blood diamonds, also known as "conflict diamonds", is a better-known phenomenon which occurs under virtually identical conditions. Even petroleum can be a conflict resource; ISIS used oil revenue to finance its military and terrorist activities.

There have been international efforts to reduce trade in conflict

resources, which try to reduce incentives to extract and fight over

them. For example, in the United States, the 2010 Dodd–Frank Wall Street Reform and Consumer Protection Act required manufacturers to audit their supply chains and report use of conflict minerals. In 2015 a US federal appeals court struck down some aspects of the reporting requirements as a violation of corporations’ freedom of speech, but left others in place.

History

The concept of 'conflict resource', or 'conflict commodity' emerged in the late 1990s, initially in relation to the 'conflict diamonds' that were financing rebellions in Angola and Sierra Leone. (The media often called these 'blood diamonds'.) Then 'conflict timber' financed hostilities in Cambodia and Liberia.

Conventions

The concept was first officially discussed by the UN General Assembly in the context of 'conflict diamonds': The UN Security Council has since referred to conflict resources in several resolutions.

Global Witness

has called for an international standardized definition to facilitate a

more systematic application of UN resolutions, the prevention of

complicity in abuses during hostilities by commercial entities

exploiting or trading in conflict resources, and the prosecution of war profiteers suspected of supporting or abetting war criminals."

...natural resources whose systematic exploitation and trade in a context of conflict contribute to, benefit from or result in the commission of serious violations of human rights, violations of international humanitarian law or violations amounting to crimes under international law.

— Global Witness, proposed Definition of conflict resources

Since 1996 the Bonn International Center for Conversion has tracked resource governance and conflict intensity by country. Aside from fossil fuels, metals, diamonds, and timber it tracks the governance of other primary goods that might fund conflicts, including: poppy seeds and talc (Afghanistan), rubber (Côte d'Ivoire), cotton (Zambia), and cocoa (Indonesia).

Conflict minerals

The four most prominent conflict minerals, for example codified in the U.S. Conflict Minerals Law, are:

- Columbite-tantalite (or coltan, the colloquial African term) is the metal ore from which the element tantalum is extracted. Tantalum is used primarily for the production of tantalum capacitors, particularly for applications requiring high performance, a small compact format and high reliability, from hearing aids and pacemakers, to airbags, GPS, ignition systems and anti-lock braking systems in automobiles, through to laptop computers, mobile phones, video game consoles, video cameras and digital cameras. In its carbide form, tantalum possesses significant hardness and wear resistance properties. As a result, it is used in jet engine/turbine blades, drill bits, end mills and other tools.

- Cassiterite is the chief ore needed to produce tin, essential for the production of tin cans and the solder on the circuit boards of electronic equipment. Tin is also commonly a component of biocides, fungicides and as tetrabutyl tin/tetraoctyl tin, an intermediate in polyvinyl chloride (PVC) and high performance paint manufacturing.

- Wolframite is an important source of the element tungsten. Tungsten is a very dense metal and is frequently used for this property, such as in fishing weights, dart tips and golf club heads. Like tantalum carbide, tungsten carbide possesses hardness and wear resistance properties and is frequently used in applications like metalworking tools, drill bits and milling. Smaller amounts are used to substitute lead in "green ammunition". Minimal amounts are used in electronic devices, including the vibration mechanism of cell phones.

- Gold is used in jewelry, investments, electronics, and dental products. It is also present in some chemical compounds used in certain semiconductor manufacturing processes.

These are sometimes referred to as "the 3T's and gold", 3TG, or even simply the "3T's". Under the US Conflict Minerals Law, additional minerals may be added to this list in the future.

Democratic Republic of the Congo

As of 2010, the conflict resource fueling the world's deadliest war is gold in the Congo. Gold bars are less traceable than diamonds, and gold is abundant in the Kivu conflict region. In any case, no jewellery

industry standard exists for verifying gold origination, as it does for

diamonds (though jeweler's total outlay on gold is five times that on

diamonds). Other conflict minerals being illicitly exported from the Congo include cobalt, tungsten, cassiterite, and coltan (which provides the tantalum for mobile phones, and is also said to be directly sustaining the conflict).

Armed conflict and mineral resource looting by the Congolese National Army and various armed rebel groups, including the Democratic Forces for the Liberation of Rwanda (FDLR) and the National Congress for the Defense of the People

(CNDP), a proxy Rwandan militia group, has occurred throughout the late

20th century and the early 21st century. Additionally, the looting of

the Congo's natural resources is not limited to domestic actors. During

the Congo Wars (First Congo War (1996–1997) and Second Congo War

(1998–2003)), Rwanda, Uganda and Burundi particularly profited from the

Congo's resources. These governments continued to smuggle resources out

of the Congo to this day.

The profits from the sale of these minerals have financed

fighting in the Second Congo War and ongoing follow-on conflicts.

Control of lucrative mines has also itself become a military objective.

Mines

Mines, in

eastern Congo, are often located far from populated areas in remote and

dangerous regions. A recent study by International Peace Information

Service (IPIS) indicates that armed groups are present at more than 50%

of mining sites. At many sites, armed groups illegally tax, extort, and

coerce civilians to work. Miners, including children, work up to

48-hour shifts amidst mudslides and tunnel collapses that kill many.

The groups are often affiliated with rebel groups, or with the

Congolese National Army, but both use rape and violence to control the

local population.

United States law

In April 2009, Senator Sam Brownback (R-KS) introduced the Congo Conflict Minerals Act of 2009 (S. 891)

to require electronics companies to verify and disclose their sources

of cassiterite, wolframite, and tantalum. This legislation died in

committee. However, Brownback added similar language as Section 1502 of

the Dodd–Frank Wall Street Reform and Consumer Protection Act, which passed Congress and was signed into law by President Barack Obama on July 21, 2010.

The U.S. Securities and Exchange Commission (SEC) draft regulations to implement the Conflict Mineral Law, published in the Federal Register of December 23, 2010.

would have required U.S. and certain foreign companies to report and

make public their use of so-called "conflict minerals" from the

Democratic Republic of the Congo or adjoining countries in their

products. Comments on this proposal were extended until March 2, 2011. The comments on the proposal were reviewable by the public.

One report on the proposal stated the following statistics for the submitted comments:

- Slightly more than 700 comment letters were submitted to SEC on the proposal;

- Approximately 65% of those were form letters or basic letters from the general public supporting the rule's intent;

- The remaining 35% (roughly 270) represent views of businesses, trade/industry associations, the investment/financial community, professional auditing firms, and other relevant governmental entities; and

- Of those 270 comments, an estimated 200 contained substantive and/or technical comments.

That report also contained what it calls a "preview of the final SEC

regulations" synthesized from their detailed research and analysis of a

large body of documents, reports and other information on the law,

proposed regulation and the current budget/political setting facing the

SEC in the current administration.

The final rule went into effect 13 November 2012.

The SEC rule did not go unnoticed by the international community,

including entities seeking to undermine traceability efforts. A report

published by a metals trading publication illustrated one DRC

ore/mineral flow method that has apparently been devised to thwart

detection.

On July 15, 2011, the US State Department issued a statement on the subject. Section 1502(c) of the Law mandates that the State Department work in conjunction with SEC on certain elements of conflict minerals policy development and support.

On October 23, 2012 U.S. State Dept Officials asserted that

ultimately, it falls on the U.S. State Dept. to determine when this rule

would no longer apply.

In April 2014, the United States Court of Appeals for the

District of Columbia Circuit struck down several parts of the SEC Rules

as unconstitutional.

Auditing and reporting requirements

US Conflict Minerals Law contains two requirements that are closely connected:

- independent third party supply chain traceability audits

- reporting of audit information to the public and SEC.

Even companies not directly regulated by the SEC will be impacted by

the audit requirements because they will be pushed down through entire

supply chains, including privately held and foreign-owned companies.

SEC estimated that 1,199 "issuers" (i.e., companies subject to

filing other SEC reports) will be required to submit full conflict

mineral reports. This estimate was developed by finding the amount of

tantalum produced by the DRC in comparison to global production (15% –

20%). The Commission selected the higher figure of 20% and multiplied

that by 6,000 (the total number of "issuers" SEC will be required to do

initial product/process evaluations).

This estimate does not account for the companies who supply materials

to the "issuers" (but are not themselves SEC-regulated) but who will

almost certainly be required to conduct conflict minerals audits to meet

the demands of those customers. Other estimates indicate that the

total number of US companies likely impacted may exceed 12,000.

A study of the potential impact of the regulation in early 2011 by the IPC – Association Connecting Electronic Industries trade association. was submitted with the association's comments to the SEC.

The study states that the IPC survey respondents had a median of 163

direct suppliers. Applying that number to the SEC's estimated number of

impacted issuers results in the possibility of over 195,000 businesses

that could be subject to some level of supply chain traceability effort.

Applicability in general

Under the law, companies have to submit an annual conflict minerals report to the SEC if:

- (a) they are required to file reports with the SEC under the Exchange Act of 1934

- (b) conflict minerals are necessary to the functionality or production of a product that they manufacture or contract to be manufactured. That statement contains two separate – but critical concepts: the purpose of the conflict mineral in the product/process, and the control that the company exerts over the manufacturing process/specifications.

A company would be deemed to contract an item to be manufactured if it:

- Exerts any influence over the manufacturing process; or,

- Offers a generic product under its own brand name or a separate brand name (regardless of whether the company has any influence over the manufacturing process) and the company contracted to have the product manufactured specifically for itself.

This language implied that some retailers who are not manufacturers might be subject to the audit and disclosure requirements.

"Contracting to manufacture" a product requires some actual

influence over the manufacturing of process that product, a

determination based on facts and circumstances. A company is not to be deemed to have influence over the manufacturing process if it merely:

- Affixes its brand, marks, logo, or label to a generic product manufactured by a third party.

- Services, maintains, or repairs a product manufactured by a third party.

- Specifies or negotiates contractual terms with a manufacturer that do not directly relate to the manufacturing of the product.

The proposed regulations attempted to clarify that tools used in assembly and manufacturing will not trigger the law.

The intent was to cover minerals/metals in the final product only.

Nothing specifically addresses intermediate chemical processes that use

chemicals that contain conflict minerals. Additionally, neither the law nor the proposed regulation established a de minimis quantity or other form of materiality threshold that would preclude the applicability of the auditing/reporting requirements.

Supply chain traceability auditing

The

law mandates the use of an "independent private sector auditor" to

conduct the audits. SEC has proposed two different standards for the

audits: the "reasonable inquiry" and the "due diligence". Should the final rule include this structure, the reasonable inquiry

would be the first step to determine if the company can on its own,

using reasonable efforts and trustworthy information, make a reliable

determination as to the source/origin of its tin, tantalum, tungsten

and/or gold. Where companies are unable to make such a determination

for any reason, they would then be required to take the next step of the

"due diligence", which is the independent private sector audit.

The statute specified that the audits be "conducted in accordance with standards established by the Comptroller General of the United States,

in accordance with rules promulgated by the Commission." This means

that the same auditing standards that apply to other SEC auditing

requirements will apply to conflict minerals audits

Because of this language, SEC will have little discretion to allow

companies to issue self-generated statements or certifications to

satisfy the law.

Third party audits for conflict minerals supply chain

traceability began in summer 2010 under the Electronic Industry

Citizenship Coalition (EICC), a US-based electronics manufacturing trade

association.

Under this program, EICC selected three audit firms to conduct the

actual audits, with two of the three participating in the pilot audits

in 2010. After concluding the pilot, one of the two firms involved in

2010 withdrew from the program specifically in response to the SEC's

proposal and to reduce potential legal risks to the audited entities.

Neither the law nor the proposed regulations provide guidance on

what will be considered an acceptable audit scope or process, preferring

to allow companies the flexibility meeting the requirement in a manner

that is responsive to their own individual business and supply chain.

At the same time, the law contains a provision that preserves the

government's rights to deem any report, audit or other due diligence

processes as being unreliable, and in such cases, the report shall not

satisfy the requirements of the regulations,

further emphasizing the need for such audits to conform to established

SEC auditing standards. Comments on the proposed regulation pointed out

that, should SEC not specify an applicable audit standard, it cannot

also be silent or ambiguous on the auditor standards as well, or the

Commission will violate the plain language of the Law mandating

"standards established by the Comptroller General of the United States".

It is generally expected that SEC will provide specificity on both the

audit standard and the auditor standard. SEC's proposal attempted to

clarify its position on auditor requirements.

The Organisation for Economic Co-operation and Development (OECD) published its Guidance on conflict minerals supply chain traceability.

This guidance is gaining much momentum as "the" standard within US

policy. However, a recent critical analysis of the standard in

comparison to existing US auditing standards under SEC highlighted a

number of significant inconsistencies and conflict with relevant US

standards.

Companies subject to the US law who implement the OECD Guidance

without regard for the SEC auditing standards may face legal compliance

risks.

Reporting and disclosure

Companies

subject to the SEC reporting requirement would be required to disclose

whether the minerals used in their products originated in the DRC or

adjoining countries (as defined above). The law mandates that this

reporting be submitted/made available annually. Many comments to the

proposed regulation asked SEC to clarify whether the report must be

"furnished"—meaning it is made available to SEC but not directly

incorporated within the company's formal financial report—or

"submitted"—meaning the report is directly incorporated into the

financial report.

At first glance, this may appear to be a minor point; however, this

difference is very important in determining the audit/auditor standards

and related liabilities.

If it is determined that none of the minerals originated in the

DRC or adjoining countries, the report must include a statement to that

effect and provide an explanation of the country of origin analysis that

was used to arrive at the ultimate conclusion. On the other hand, if

conflict minerals originating in the DRC or adjoining countries were

used (or if it is not possible to determine the country of origin of the

conflict minerals used), companies would be required to state as such

in the annual report. In either case, companies would also be required

to make this information public by posting their annual conflict

minerals report on their websites, and providing the SEC with the

internet addresses where the reports may be found. Further, the proposed

regulations would require companies to maintain records relating to the

country of origin of conflict minerals used in their products.

Media outlets have reported that many companies required to file Specialized Disclosure Reports to the U.S. Securities and Exchange Commission

(SEC) and any necessary conflict minerals reports for 2013 under the

SEC’s conflict minerals rule are struggling to meet the June 2, 2014

report filing deadline. Many impacted companies were hoping for clarification regarding filing requirements, from the United States Court of Appeals for the District of Columbia Circuit from a lawsuit filed by the National Association of Manufacturers.

The appellate court’s ruling left the necessary conflict minerals

reporting requirements largely intact and it has been suggested that

impacted companies should review the SEC’s Division of Corporation

Finance’s response to the court’s ruling which provides guidance regarding the effect of the appellate court’s ruling.

On August 18, 2015 the divided D.C. Circuit Court again held the SEC's conflict materials rule violates the First Amendment. Senior Circuit Judge A. Raymond Randolph, joined by Senior Circuit Judge David B. Sentelle, weighed if the required disclosures were effective and uncontroversial. Citing news reports and a Congressional hearing, the court decided the policy was ineffective.

The court next found the required label was controversial because it

"is a metaphor that conveys moral responsibility for the Congo war." As such, the court struck down the conflict materials rule’s disclosure requirements as a violation of corporations’ freedom of speech. Circuit Judge Sri Srinivasan dissented, writing that the required disclosures were not controversial because they were truthful.

Criticism of the law

The

law has been criticised for not addressing the root causes of the

conflict, leaving to the Congolese government the responsibility for

providing an environment in which companies can practice due diligence

and legitimately purchase the minerals they need, when the reality is

that mechanisms for transparency do not exist.

The effect has been to halt legitimate mining ventures that provided

livelihoods for people, reducing the Congo's legal exports of tantalum

by 90%.

An investigation by the U.S. Government Accountability Office (GAO) found that most companies were unable to determine the source of their conflict minerals.

Technology manufacturers criticized a law which required them to label a product as not "DRC Conflict Free" as compelled speech, and in violation of the First Amendment.

Proposed law in Europe

The

European Parliament passed legislation in 2015; negotiations are

currently underway among member states as to specific wording details.

On 16 June 2016 the European Parliament confirmed that "mandatory

due diligence" would be required for "all but the smallest EU firms

importing tin, tungsten, tantalum, gold and their ores".

On May 17, 2017 the EU passed Regulation (EU) 2017/821 of the

Parliament and of the Council on the supply chain due diligence

obligations for importers of tin, tantalum, tungsten, their ores, and

gold from conflict-affected and high risk areas. The regulation will

take effect in January 2021, and will directly apply to companies that

import 3TG metals into the EU, no matter where they originate.

On August 10, 2018 The European Commission published their

non-binding guidelines for the identification of conflict-affected and

high-risk areas and other supply chain risks under Regulation (EU)

2017/821 of the European Parliament and of the Council.

Conflict resources in supply chains

Increases

in business process outsourcing to globally dispersed production

facilities means that social problems and human rights violations are no

longer only an organization matter, but also often occur in companies’

supply chains, and challenge for supply chain managers.

Besides the harm conflict minerals do where they are produced, human

rights violations also raise an enormous risk to corporate reputations.

Consumers, mass media and employees expect companies to behave

responsibly and have become intolerant of those who don't.

Consequently, firms that are located downstream in the supply

chain and that are more visible to stakeholders are particularly

threatened by social supply chain problems. The recent debate concerning

conflict minerals illustrates the importance of social and human rights

issues in supply chain management practice as well as the emerging need

to react to social conflicts. Conflict minerals are processed in many

different components throughout various industries and hence have a high

overall impact on business.

Initiatives like the Dodd–Frank Wall Street Reform and Consumer Protection Act or the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas

demand that supply chain managers verify purchased goods as

‘‘conflict-free’’ or implement measures to better manage any inability

to do so.

Minerals mined in Eastern Congo pass through the hands of

numerous middlemen as they are shipped out of Congo, through neighboring

countries such as Rwanda or Burundi, to East Asian processing plants.

Because of this, the US Conflict Minerals Law applies to materials

originating (or claimed to originate) from the DRC as well as the nine

adjoining countries: Angola, Burundi, Central African Republic, Congo Republic, Rwanda, South Sudan, Zimbabwe, Uganda, and Zambia.

Firms have begun to apply governance mechanisms to avoid adverse

effects of conflict mineral sourcing. However, the mere transfer of

responsibilities upstream in the supply chain apparently will not stop

the trade with conflict minerals, notably due to two reasons:

- On the one hand, globalization has created governance gaps in a sense that companies are able to abuse human rights without being sanctioned by independent third parties. This gap results in a non-allocation of responsibility that makes the problem of human rights abuses and social conflicts within dispersed supply chains very likely to endure, particularly without collaborative approaches to remedy these deficiencies.

- On the other hand, conflict minerals usually originate from globally diverse deposits and are difficult to track within components and manufactured products. This is the case because they are mixed with minerals of different origin and added to metal alloys. Consequently, although the share of these minerals in single end products may be negligible, they are prevalent in numerous products and commodities. Together, these circumstances leave downstream firms nearly incapable of detecting risks associated with conflict minerals. Hence, the topic of conflict minerals becomes one of supply chain management rather than of individual companies’ legal or compliance divisions alone. What is needed is effective and supply-chain wide-mechanisms of traceability and due diligence that allow firms to take individual and collective responsibility as parts of supply chains.

In the context of mineral supply chains, due diligence represents a

holistic concept that aims at providing a chain of custody tracking from

mine to export at country level, regional tracking of mineral flows

through the creation of a database on their purchases, independent

audits on all actors in the supply chain, and a monitoring of the whole

mineral chain by a mineral chain auditor. In this sense, due diligence

transcends conventional risk management approaches that usually focus on

the prevention of direct impacts on the core business activities of

companies. Moreover, due diligence focuses on a maximum of transparency

as an end itself while risk management is always directed towards the

end of averting direct damages. However, besides the Dodd–Frank Wall Street Reform and Consumer Protection Act

and the OECD Guidance, there is still a gap in due diligence practices

as international norms are just emerging. Studies found that the

motivation for supply chain due diligence as well as expected outcomes

of these processes vary among firms.

Furthermore, different barriers, drivers, and implementation patterns

of supply chain due diligence have been identified in scholarly

research.

Organizations and activists involved

A number of organizations and celebrities working to find solutions and raise awareness of conflict minerals. These include:

- Save the Congo

- The Enough Project

- Partnership Africa Canada

- The Conflict Free Tin Initiative

- Solutions for Hope

- Raise Hope for Congo

- Stand Canada

- Conflictminerals.org

- Congo Siasa

- ReliefWeb

- Ashley Judd

- Ryan Gosling

- Southern Africa Resource Watch

Moreover, FairPhone

Foundation raises awareness of conflict minerals in the mobile industry

and is a company which tries to produce a smart phone with 'fair'

conditions along the supply chain. Various industry and trade

associations are also monitoring developments in conflict minerals laws

and traceability frameworks. Some of these represent electronics,

retailers, jewelry, mining, electronics components, and general

manufacturing sectors. One organization – ITRI (a UK-based

international non-profit organization representing the tin industry and

sponsored/supported by its members, principally miners and smelters.)

had spearheaded efforts for the development and implementation of a

"bag and tag" scheme at the mine as a key element of credible

traceability.

The program and related efforts were initially not likely to extend

beyond the pilot phase due to a variety of implementation and funding

problems that occurred. In the end however, the device did enter the market.

In late March 2011, the UK government launched an informational

section on its Foreign & Commonwealth Office website dedicated to

conflict minerals.

This information resource is intended to assist British companies in

understanding the issues and, specifically, the US requirements.

On Jan 6th 2014, the semiconductor giant Intel announced that it

would distance itself from conflict minerals. As a result, all Intel

microprocessors henceforth will be conflict-free.

Commercial reporting solutions

Manufacturers

and supply chain partners needing to comply with the ever-increasing

reporting regulations have a few commercial options available.

A major research report from November 2012 by the Southern Africa Resource Watch revealed that gold miners in the east of the Democratic Republic of Congo

were being exploited by corrupt government officials, bureaucrats and

security personnel, who all demand illegal tax, fees and levies from the

miners without delivering any services in return. Despite the alleged

gold rush in regions of the country, none of the population and

workforce is benefiting from this highly lucrative industry.