NIST Next-Generation Nanometrology research.

Nanometrology is a subfield of metrology, concerned with the science of measurement at the nanoscale

level. Nanometrology has a crucial role in order to produce

nanomaterials and devices with a high degree of accuracy and reliability

in nanomanufacturing.

A challenge in this field is to develop or create new measurement

techniques and standards to meet the needs of next-generation advanced

manufacturing, which will rely on nanometer scale materials and

technologies. The needs for measurement and characterization of new

sample structures and characteristics far exceed the capabilities of

current measurement science. Anticipated advances in emerging U.S.

nanotechnology industries will require revolutionary metrology with

higher resolution and accuracy than has previously been envisioned.

Introduction

Control

of the critical dimensions are the most important factors in

nanotechnology. Nanometrology today, is to a large extent based on the

development in semiconductor technology. Nanometrology is the science of measurement

at the nanoscale level. Nanometer or nm is equivalent to 10^-9 m. In

Nanotechnology accurate control of dimensions of objects is important.

Typical dimensions of nanosystems vary from 10 nm to a few hundred nm

and while fabricating such systems measurement up to 0.1 nm is required.

At nanoscale due to the small dimensions various new physical

phenomena can be observed. For example, when the crystal size is smaller

than the electron mean free path the conductivity

of the crystal changes. Another example is the discretization of

stresses in the system. It becomes important to measure the physical

parameters so as to apply these phenomena into engineering of

nanosystems and manufacturing them. The measurement of length or size,

force, mass, electrical and other properties is included in

Nanometrology.

The problem is how to measure these with reliability and accuracy. The

measurement techniques used for macro systems cannot be directly used

for measurement of parameters in nanosystems. Various techniques based

on physical phenomena have been developed which can be used for measure

or determine the parameters for nanostructures and nanomaterials. Some

of the popular ones are X-Ray diffraction, transmission electron microscopy, High Resolution Transmission Electron Microscopy, atomic force microscopy, scanning electron microscopy, field emission scanning electron microscopy and Brunauer, Emmett, Teller method to determine specific surface.

Nanotechnology is an important field because of the large number

of applications it has and it has become necessary to develop more

precise techniques of measurement and globally accepted standards. Hence

progress is required in the field of Nanometrology.

Development needs

Nanotechnology can be divided into two branches. The first being molecular nanotechnology which involves bottom up manufacturing and the second is engineering nanotechnology

which involve the development and processing of materials and systems

at nanoscale. The measurement and manufacturing tools and techniques

required for the two branches are slightly different.

Furthermore, Nanometrology requirements are different for the

industry and research institutions. Nanometrology of research has

progressed faster than that for industry mainly because implementing

nanometrology for industry is difficult. In research oriented

nanometrology resolution is important whereas in industrial

nanometrology accuracy is given precedence over resolution.

Further due to economic reasons it is important to have low time costs

in industrial nanometrology it is not important for research

nanometrology. The various measurement techniques available today

require a controlled environment like in vacuum, vibration

and noise free environment. Also, in industrial nanometrology requires

that the measurements be more quantitative with minimum number of

parameters.

Standards

International standards

Metrology standards

are objects or ideas that are designated as being authoritative for

some accepted reason. Whatever value they possess is useful for

comparison to unknowns for the purpose of establishing or confirming an

assigned value based on the standard. The execution of measurement

comparisons for the purpose of establishing the relationship between a

standard and some other measuring device is calibration. The ideal

standard is independently reproducible without uncertainty. The

worldwide market for products with nanotechnology applications is

projected to be at least a couple of hundred billion dollars in the near

future.[citation needed] Until recently, there almost no established internationally accepted standards for nanotechnology related field. The International Organisation for Standardization TC-229 Technical Committee on Nanotechnology recently published few standards for terminology, characterization of nanomaterials and nanoparticles using measurement tools like AFM, SEM, Interferometers,

optoacoustic tools, gas adsorption methods etc. Certain standards for

standardization of measurements for electrical properties have been

published by the International Electrotechnical Commission.

Some important standards which are yet to be established are standards

for measuring thickness of thin films or layers, characterization of

surface features, standards for force measurement at nanoscale,

standards for characterization of critical dimensions of nanoparticles

and nanostructures and also Standards for measurement for physical

properties like conductivity, elasticity etc.

National standards

Because

of the importance of nanotechnology in the future, countries around the

world have programmes to establish national standards for nanometrology

and nanotechnology. These programmes are run by the national standard

agencies of the respective countries. In the United States, National Institute of Standards and Technology

has been working on developing new techniques for measurement at

nanoscale and has also established some national standards for

nanotechnology. These standards are for nanoparticle characterization, Roughness Characterization, magnification standard, calibration standards etc.

Calibration

It is difficult to provide samples using which precision instruments can be calibrated at nanoscale. Reference or calibration

standards are important for repeatability to be ensured. But there are

no international standards for calibration and the calibration artefacts

provided by the company along with their equipment is only good for

calibrating that particular equipment. Hence it is difficult to select a

universal calibration artefact using which we can achieve repeatability

at nanoscale. At nanoscale while calibrating care needs to be taken for

influence of external factors like vibration, noise, motions caused by thermal drift and creep and internal factors like the interaction between the artefact and the equipment which can cause significant deviations.

Measurement techniques

In

the last 70 years various techniques for measuring at nanoscale have

been developed. Most of them based on some physical phenomena observed

on particle interactions or forces at nanoscale. Some of the most

commonly used techniques are Atomic Force Microscopy, X-Ray Diffraction,

Scanning Electron Microscopy, Transmission Electron Microscopy, High

Resolution Transmission Electron Microscopy, and Field Emission Scanning

Electron Microscopy.

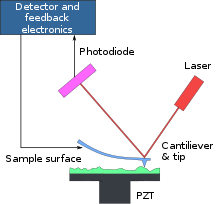

Block Diagram of atomic force microscope.

Atomic force microscopy

(AFM) is one of the most common measurement techniques. It can be used

to measure Topology, grain size, frictional characteristics and

different forces. It consists of a silicon cantilever with a sharp tip

with a radius of curvature of a few nanometers. The tip is used as a

probe on the specimen to be measured. The forces acting at the atomic

level between the tip and the surface of the specimen cause the tip to

deflect and this deflection is detected using a laser spot which is

reflected to an array of photodiodes.

Diagram of Scanning tunneling microscope.

Scanning tunneling microscopy (STM) is another instrument commonly

used. It is used to measure 3-D topology of the specimen. The STM is

based on the concept of quantum tunneling. When a conducting tip is

brought very near to the surface to be examined, a bias (voltage

difference) applied between the two can allow electrons to tunnel

through the vacuum between them. Measurements are made by monitoring the

current as the tip's position scans across the surface, which can then

be used to display an image.

Another commonly used instrument is the scanning electron

microscopy (SEM) which apart from measuring the shape and size of the

particles and topography of the surface can be used to determine the

composition of elements and compounds the sample is composed of. In SEM

the specimen surface is scanned with a high energy electron beam. The

electrons in the beam interact with atoms in the specimen and

interactions are detected using detectors. The interactions produced are

back scattering of electrons, transmission of electrons, secondary

electrons etc. To remove high angle electrons magnetics lenses are used.

The instruments mentioned above produce realistic pictures of the

surface are excellent measuring tools for research. Industrial

applications of nanotechnology require the measurements to be produced

need to be more quantitative. The requirement in industrial

nanometrology is for higher accuracy than resolution as compared to

research nanometrology.

Nano coordinate measuring machine

A coordinate measuring machine

(CMM) that works at the nanoscale would have a smaller frame than the

CMM used for macroscale objects. This is so because it may provide the

necessary stiffness and stability to achieve nanoscale uncertainties in

x,y and z directions. The probes for such a machine need to be small to

enable a 3-D measurement of nanometre features from the sides and from

inside like nanoholes. Also for accuracy laser interferometers need to

be used. NIST has developed a surface measuring instrument, called the

Molecular Measuring Machine. This instrument is basically an STM. The

x- and y-axes are read out by laser interferometers. The molecules on

the surface area can be identified individually and at the same time the

distance between any two molecules can be determined. For measuring

with molecular resolution, the measuring times become very large for

even a very small surface area. Ilmenau Machine is another nanomeasuring

machine developed by researchers at the Ilmenau University of

Technology.

Dimensional metrology using CMM.

The components of a nano CMM include nanoprobes, control hardware, 3D-nanopositioning platform, and instruments with high resolution and accuracy for linear and angular measurement.

List of some of the measurement techniques

Traceability

In

metrology at macro scale achieving traceability is quite easy and

artefacts like scales, laser interferometers, step gauges, and straight

edges are used. At nanoscale a crystalline highly oriented pyrolytic graphite (HOPG), mica or silicon

surface is considered suitable used as calibration artefact for

achieving traceability. But it is not always possible to ensure

traceability. Like what is a straight edge at nanoscale and even if take

the same standard as that for macroscale there is no way to calibrate

it accurately at nanoscale. This so because the requisite

internationally or nationally accepted reference standards are not

always there. Also the measurement equipment required to ensure

traceability has not been developed. The generally used for traceability

are miniaturisation of traditional metrology

standards hence there is a need for establishing nanoscale standards.

Also there is a need to establish some kind of uncertainty estimation

model. Traceability is one of the fundamental requirements for

manufacturing and assembly of products when multiple producers are

there.

Tolerance

Integrated circuit made using monolithic integration technique.

Tolerance

is the permissible limit or limits of variation in dimensions,

properties, or conditions without significantly affecting functioning of

equipment or a process. Tolerances are specified to allow reasonable

leeway for imperfections and inherent variability without compromising

performance. In nanotechnology the systems have dimensions in the range

of nanometers. Defining tolerances at nanoscale with suitable

calibration standards for traceability is difficult for different nanomanufacturing methods. There are various integration techniques developed in the semiconductor industry that are used in nanomanufacturing.

Integration techniques

- In hetero integration direct fabrication of nanosystems from compound substrates is done. Geometric tolerances are required to achieve the functionality of the assembly.

- In hybrid integration nanocomponents are placed or assembled on a substrate fabricating functioning nanosystems. In this technique, the most important control parameter is the positional accuracy of the components on the substrate.

- In monolithic integration all the fabrication process steps are integrated on a single substrate and hence no mating of components or assembly is required. The advantage of this technique is that the geometric measurements are no longer of primary importance for achieving functionality of nanosystem or control of the fabrication process.

Classification of nanostructures

There

are a variety of nanostructures like nanocomposites, nanowires,

nanopowders, nanotubes, fullerenes nanofibers, nanocages,

nanocrystallites, nanoneedles,

nanofoams, nanomeshes, nanoparticles, nanopillars, thin films,

nanorods, nanofabrics, quantumdots etc. The most common way to classify

nano structures is by their dimensions.

SEM of nanowire.

Dimensional classification

| Dimensions | Criteria | Examples |

|---|---|---|

| Zero-dimensional (0-D) | The nanostructure has all dimensions in the nanometer range. | Nanoparticles, quantum dots, nanodots |

| One-dimensional (1-D) | One dimension of the nanostructure is outside the nanometer range. | Nanowires, nanorods, nanotubes |

| Two-dimensional (2-D) | Two dimensions of the nanostructure are outside the nanometer range. | Coatings, thin-film-multilayers |

| Three-dimensional (3-D) | Three dimensions of the nanostructure are outside the nanometer range. | Bulk |

Classification of grain structure

Nanostructures

can be classified on the basis of the grain structure and size there

are made up of. This is applicable in the cas of 2-dimensional and

3-Dimensional Nanostructurs.

Surface area measurement

For nanopowder to determine the specific surface area the B.E.T. method is commonly used. The drop of pressure of nitrogen in a closed container due to adsorption of the nitrogen

molecules to the surface of the material inserted in the container is

measured. Also, the shape of the nanopowder particles is assumed to be

spherical.

- D = 6/(ρ*A)

Where "D" is the effective diameter, "ρ" is the density and "A" is the surface area found from the B.E.T. method.

.

.