In chemistry, a colloid is a mixture in which one substance of microscopically dispersed insoluble or soluble particles is suspended throughout another substance. Sometimes the dispersed substance alone is called the colloid; the term colloidal suspension refers unambiguously to the overall mixture (although a narrower sense of the word suspension is distinguished from colloids by larger particle size). Unlike a solution, whose solute and solvent constitute only one phase, a colloid has a dispersed phase (the suspended particles) and a continuous phase (the medium of suspension) that arise by phase separation. To qualify as a colloid, the mixture must be one that does not settle or would take a very long time to settle appreciably.

The dispersed-phase particles have a diameter between approximately 1 and 1000 nanometers. Such particles are normally easily visible in an optical microscope, although at the smaller size range (r < 250 nm), an ultramicroscope or an electron microscope may be required. Homogeneous mixtures with a dispersed phase in this size range may be called colloidal aerosols, colloidal emulsions, colloidal foams, colloidal dispersions, or hydrosols. The dispersed-phase particles or droplets are affected largely by the surface chemistry present in the colloid.

Some colloids are translucent because of the Tyndall effect, which is the scattering of light by particles in the colloid. Other colloids may be opaque or have a slight color. The cytoplasm of living cells is an example of a colloid, containing many types of biomolecular condensate.

Colloidal suspensions are the subject of interface and colloid science. This field of study was introduced in 1845 by Italian chemist Francesco Selmi and further investigated since 1861 by Scottish scientist Thomas Graham.

IUPAC definitionColloid: Short synonym for colloidal system. Colloidal: State of subdivision such that the molecules or polymolecular particles dispersed in a medium have at least one dimension between approximately 1 nm and 1 μm, or that in a system discontinuities are found at distances of that order.

Classification

Because the size of the dispersed phase may be difficult to measure, and because colloids have the appearance of solutions,

colloids are sometimes identified and characterized by their

physico-chemical and transport properties. For example, if a colloid

consists of a solid phase dispersed in a liquid, the solid particles

will not diffuse

through a membrane, whereas with a true solution the dissolved ions or

molecules will diffuse through a membrane. Because of the size

exclusion, the colloidal particles are unable to pass through the pores

of an ultrafiltration membrane with a size smaller than their own

dimension. The smaller the size of the pore of the ultrafiltration

membrane, the lower the concentration of the dispersed colloidal

particles remaining in the ultrafiltered liquid. The measured value of

the concentration of a truly dissolved species will thus depend on the

experimental conditions applied to separate it from the colloidal

particles also dispersed in the liquid. This is particularly important

for solubility studies of readily hydrolyzed species such as Al, Eu, Am, Cm, or organic matter complexing these species.

Colloids can be classified as follows:

| Medium/phase | Dispersed phase | |||

|---|---|---|---|---|

| Gas | Liquid | Solid | ||

| Dispersion medium |

Gas | No such colloids are known. Helium and xenon are known to be immiscible under certain conditions. |

Liquid aerosol Examples: fog, clouds, condensation, mist, hair sprays |

Solid aerosol Examples: smoke, ice cloud, atmospheric particulate matter |

| Liquid | Foam Example: whipped cream, shaving cream |

Emulsion Examples: milk (fat fraction), mayonnaise, hand cream; latex |

Sol Examples: milk (protein fraction), pigmented ink, blood | |

| Solid | Solid foam Examples: aerogel, styrofoam, pumice |

Gel Examples: agar, gelatin, jelly |

Solid sol Example: cranberry glass | |

Based on the nature of interaction between the dispersed phase and the dispersion medium, colloids can be classified as: Hydrophilic colloids: The colloid particles are attracted toward water. They are also called reversible sols. Hydrophobic colloids:

These are opposite in nature to hydrophilic colloids. The colloid

particles are repelled by water. They are also called irreversible sols.

In some cases, a colloid suspension can be considered a

homogeneous mixture. This is because the distinction between "dissolved"

and "particulate" matter can be sometimes a matter of approach, which

affects whether or not it is homogeneous or heterogeneous.

Interaction between particles

The following forces play an important role in the interaction of colloid particles:

- Excluded volume repulsion: This refers to the impossibility of any overlap between hard particles.

- Electrostatic interaction: Colloidal particles often carry an electrical charge and therefore attract or repel each other. The charge of both the continuous and the dispersed phase, as well as the mobility of the phases are factors affecting this interaction.

- van der Waals forces: This is due to interaction between two dipoles that are either permanent or induced. Even if the particles do not have a permanent dipole, fluctuations of the electron density gives rise to a temporary dipole in a particle. This temporary dipole induces a dipole in particles nearby. The temporary dipole and the induced dipoles are then attracted to each other. This is known as van der Waals force, and is always present (unless the refractive indexes of the dispersed and continuous phases are matched), is short-range, and is attractive.

- Entropic forces: According to the second law of thermodynamics, a system progresses to a state in which entropy is maximized. This can result in effective forces even between hard spheres.

- Steric forces between polymer-covered surfaces or in solutions containing non-adsorbing polymer can modulate interparticle forces, producing an additional steric repulsive force (which is predominantly entropic in origin) or an attractive depletion force between them. Such an effect is specifically searched for with tailor-made superplasticizers developed to increase the workability of concrete and to reduce its water content.

Preparation

There are two principal ways to prepare colloids:

- Dispersion of large particles or droplets to the colloidal dimensions by milling, spraying, or application of shear (e.g., shaking, mixing, or high shear mixing).

- Condensation of small dissolved molecules into larger colloidal particles by precipitation, condensation, or redox reactions. Such processes are used in the preparation of colloidal silica or gold.

Stabilization (peptization)

The stability of a colloidal system is defined by particles remaining suspended in solution at equilibrium.

Stability is hindered by aggregation and sedimentation phenomena,

which are driven by the colloid's tendency to reduce surface energy.

Reducing the interfacial tension will stabilize the colloidal system by

reducing this driving force.

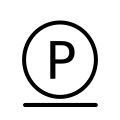

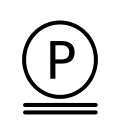

Examples of a stable and of an unstable colloidal dispersion.

Aggregation is due to the sum of the interaction forces between particles.

If attractive forces (such as van der Waals forces) prevail over the

repulsive ones (such as the electrostatic ones) particles aggregate in

clusters.

Electrostatic stabilization and steric stabilization are the two main mechanisms for stabilization against aggregation.

- Electrostatic stabilization is based on the mutual repulsion of like electrical charges. In general, different phases have different charge affinities, so that an electrical double layer forms at any interface. Small particle sizes lead to enormous surface areas, and this effect is greatly amplified in colloids. In a stable colloid, mass of a dispersed phase is so low that its buoyancy or kinetic energy is too weak to overcome the electrostatic repulsion between charged layers of the dispersing phase. The electrostatic repulsion between suspended colloidal particles is most readily quantified in terms of the zeta potential, a measurable quantity describing electrical potential at the slipping plane in an electrical double layer.

- Steric stabilization consists in covering the particles in polymers which prevents the particle to get close in the range of attractive forces.

A combination of the two mechanisms is also possible (electrosteric

stabilization). All the above-mentioned mechanisms for minimizing particle aggregation rely on the enhancement of the repulsive interaction forces.

Electrostatic and steric stabilization do not directly address the sedimentation/floating problem.

Particle sedimentation (and also floating, although this

phenomenon is less common) arises from a difference in the density of

the dispersed and of the continuous phase. The higher the difference in

densities, the faster the particle settling.

- The gel network stabilization represents the principal way to produce colloids stable to both aggregation and sedimentation.

The method consists in adding to the colloidal suspension a polymer

able to form a gel network and characterized by shear thinning

properties. Examples of such substances are xanthan and guar gum.

Steric and gel network stabilization.

Particle settling is hindered by the stiffness of the polymeric matrix where particles are trapped. In addition, the long polymeric chains can provide a steric or electrosteric stabilization to dispersed particles.

The rheological shear thinning properties find beneficial in the

preparation of the suspensions and in their use, as the reduced

viscosity at high shear rates facilitates deagglomeration, mixing and in

general the flow of the suspensions.

Destabilisation

Unstable colloidal dispersions can form either flocs or aggregates as the particles assemble due to interparticle attractions. Flocs

are loose and flexible conglomerates of the particles, whereas

aggregates are compact and rigid entities. There are methods that

distinguish between flocculation and aggregation, such as acoustic spectroscopy. Destabilization can be accomplished by different methods:

- Removal of the electrostatic barrier that prevents aggregation of the particles. This can be accomplished by the addition of salt to a suspension or changing the pH of a suspension to effectively neutralise or "screen" the surface charge of the particles in suspension. This removes the repulsive forces that keep colloidal particles separate and allows for coagulation due to van der Waals forces. Minor changes in pH can manifest in significant alteration to the zeta potential. When the magnitude of the zeta potential lies below a certain threshold, typically around ± 5mV, rapid coagulation or aggregation tends to occur.

- Addition of a charged polymer flocculant. Polymer flocculants can bridge individual colloidal particles by attractive electrostatic interactions. For example, negatively charged colloidal silica or clay particles can be flocculated by the addition of a positively charged polymer.

- Addition of non-adsorbed polymers called depletants that cause aggregation due to entropic effects.

- Physical deformation of the particle (e.g., stretching) may increase the van der Waals forces more than stabilisation forces (such as electrostatic), resulting coagulation of colloids at certain orientations.

Unstable colloidal suspensions of low-volume fraction form clustered

liquid suspensions, wherein individual clusters of particles fall to the

bottom of the suspension (or float to the top if the particles are less

dense than the suspending medium) once the clusters are of sufficient

size for the Brownian forces

that work to keep the particles in suspension to be overcome by

gravitational forces. However, colloidal suspensions of higher-volume

fraction form colloidal gels with viscoelastic properties. Viscoelastic

colloidal gels, such as bentonite and toothpaste,

flow like liquids under shear, but maintain their shape when shear is

removed. It is for this reason that toothpaste can be squeezed from a

toothpaste tube, but stays on the toothbrush after it is applied.

Monitoring stability

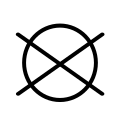

Measurement principle of multiple light scattering coupled with vertical scanning

Multiple light scattering coupled with vertical scanning is the most

widely used technique to monitor the dispersion state of a product,

hence identifying and quantifying destabilisation phenomena.

It works on concentrated dispersions without dilution. When light is

sent through the sample, it is backscattered by the particles /

droplets. The backscattering intensity is directly proportional to the

size and volume fraction of the dispersed phase. Therefore, local

changes in concentration (e.g.Creaming and Sedimentation) and global changes in size (e.g. flocculation, coalescence) are detected and monitored.

Accelerating methods for shelf life prediction

The

kinetic process of destabilisation can be rather long (up to several

months or even years for some products) and it is often required for the

formulator to use further accelerating methods in order to reach

reasonable development time for new product design. Thermal methods are

the most commonly used and consists in increasing temperature to

accelerate destabilisation (below critical temperatures of phase

inversion or chemical degradation). Temperature affects not only the

viscosity, but also interfacial tension in the case of non-ionic

surfactants or more generally interactions forces inside the system.

Storing a dispersion at high temperatures enables to simulate real life

conditions for a product (e.g. tube of sunscreen cream in a car in the

summer), but also to accelerate destabilisation processes up to 200

times.

Mechanical acceleration including vibration, centrifugation

and agitation are sometimes used. They subject the product to different

forces that pushes the particles / droplets against one another, hence

helping in the film drainage. However, some emulsions would never

coalesce in normal gravity, while they do under artificial gravity. Moreover, segregation of different populations of particles have been highlighted when using centrifugation and vibration.

As a model system for atoms

In physics, colloids are an interesting model system for atoms. Micrometre-scale colloidal particles are large enough to be observed by optical techniques such as confocal microscopy.

Many of the forces that govern the structure and behavior of matter,

such as excluded volume interactions or electrostatic forces, govern the

structure and behavior of colloidal suspensions. For example, the same

techniques used to model ideal gases can be applied to model

the behavior of a hard sphere colloidal suspension. In addition, phase

transitions in colloidal suspensions can be studied in real time using

optical techniques,

and are analogous to phase transitions in liquids. In many interesting

cases optical fluidity is used to control colloid suspensions.

Crystals

A colloidal crystal is a highly ordered

array of particles that can be formed over a very long range (typically

on the order of a few millimeters to one centimeter) and that appear analogous to their atomic or molecular counterparts. One of the finest natural examples of this ordering phenomenon can be found in precious opal, in which brilliant regions of pure spectral color result from close-packed domains of amorphous colloidal spheres of silicon dioxide (or silica, SiO2). These spherical particles precipitate in highly siliceous pools in Australia and elsewhere, and form these highly ordered arrays after years of sedimentation and compression under hydrostatic and gravitational forces. The periodic arrays of submicrometre spherical particles provide similar arrays of interstitial voids, which act as a natural diffraction grating for visible light waves, particularly when the interstitial spacing is of the same order of magnitude as the incident lightwave.

Thus, it has been known for many years that, due to repulsive Coulombic interactions, electrically charged macromolecules in an aqueous environment can exhibit long-range crystal-like

correlations with interparticle separation distances, often being

considerably greater than the individual particle diameter. In all of

these cases in nature, the same brilliant iridescence (or play of colors) can be attributed to the diffraction and constructive interference of visible lightwaves that satisfy Bragg’s law, in a matter analogous to the scattering of X-rays in crystalline solids.

The large number of experiments exploring the physics and chemistry

of these so-called "colloidal crystals" has emerged as a result of the

relatively simple methods that have evolved in the last 20 years for

preparing synthetic monodisperse colloids (both polymer and mineral)

and, through various mechanisms, implementing and preserving their

long-range order formation.

In biology

Colloidal

phase separation is an important organising principle for

compartmentalisation of both the cytoplasm and nucleus of cells, similar

in importance to compartmentalisation via lipid bilayer membranes. The

term biomolecular condensate has been used to refer to clusters of macromolecules that arise via liquid-liquid, liquid-gel, or liquid-solid phase separation within the cytosol. Macromolecular crowding strongly enhances colloidal phase separation and formation of biomolecular condensates.

In the environment

Colloidal particles can also serve as transport vector

of diverse contaminants in the surface water (sea water, lakes, rivers,

fresh water bodies) and in underground water circulating in fissured

rocks

(e.g. limestone, sandstone, granite). Radionuclides and heavy metals easily sorb onto colloids suspended in water. Various types of colloids are recognised: inorganic colloids (e.g. clay particles, silicates, iron oxy-hydroxides), organic colloids (humic and fulvic substances). When heavy metals or radionuclides form their own pure colloids, the term "eigencolloid" is used to designate pure phases, i.e., pure Tc(OH)4, U(OH)4, or Am(OH)3. Colloids have been suspected for the long-range transport of plutonium on the Nevada Nuclear Test Site.

They have been the subject of detailed studies for many years. However,

the mobility of inorganic colloids is very low in compacted bentonites and in deep clay formations

because of the process of ultrafiltration occurring in dense clay membrane.

The question is less clear for small organic colloids often mixed in porewater with truly dissolved organic molecules.

In soil science, the colloidal fraction in soils consists of tiny clay and humus particles that are less than 1ɥm in diameter and carry either positive and/or negative electrostatic charges that vary depending on the chemical conditions of the soil sample, i.e. soil pH.

Intravenous therapy

Colloid solutions used in intravenous therapy belong to a major group of volume expanders, and can be used for intravenous fluid replacement. Colloids preserve a high colloid osmotic pressure in the blood, and therefore, they should theoretically preferentially increase the intravascular volume, whereas other types of volume expanders called crystalloids also increase the interstitial volume and intracellular volume. However, there is still controversy to the actual difference in efficacy by this difference, and much of the research related to this use of colloids is based on fraudulent research by Joachim Boldt. Another difference is that crystalloids generally are much cheaper than colloids.