The New York City Subway is the world's largest single operator rapid transit system by number of stations served, utilizing hundreds of miles of electrified track.

The Shanghai Metro is the world's largest single operator rapid transit system by length, possessing hundreds of kilometers of electrified lines.

Transition zone of third-rail to overhead-wire supply on Chicago's Yellow Line (the "Skokie Swift")

A railway electrification system supplies electric power to railway trains and trams without an on-board prime mover or local fuel supply.

Electric railways use either electric locomotives (hauling passengers or freight in separate cars) or electric multiple units (passenger cars with their own motors).

Electricity is typically generated in large and relatively efficient generating stations,

transmitted to the railway network and distributed to the trains. Some

electric railways have their own dedicated generating stations and transmission lines, but most purchase power from an electric utility. The railway usually provides its own distribution lines, switches, and transformers.

Power is supplied to moving trains with a (nearly) continuous conductor running along the track that usually takes one of two forms: an overhead line, suspended from poles or towers along the track or from structure or tunnel ceilings, or a third rail mounted at track level and contacted by a sliding "pickup shoe".

Both overhead wire and third-rail systems usually use the running rails

as the return conductor, but some systems use a separate fourth rail

for this purpose.

In comparison to the principal alternative, the diesel engine, electric railways offer substantially better energy efficiency, lower emissions, and lower operating costs.

Electric locomotives are also usually quieter, more powerful, and more responsive and reliable than diesels.

They have no local emissions, an important advantage in tunnels and urban areas.

Some electric traction systems provide regenerative braking that turns the train's kinetic energy back into electricity and returns it to the supply system to be used by other trains or the general utility grid.

While diesel locomotives burn petroleum, electricity can be generated from diverse sources, including renewable energy.

Disadvantages of electric traction include: high capital costs

that may be uneconomic on lightly trafficked routes, a relative lack of

flexibility (since electric trains need third rails or overhead wires),

and a vulnerability to power interruptions. Electro-diesel locomotives and Electro-diesel multiple units mitigate these problems somewhat as they are capable of running on diesel power during an outage or on non-electrified routes.

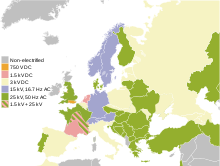

Different regions may use different supply voltages and

frequencies, complicating through service and requiring greater

complexity of locomotive power.

The limited clearances available under overhead lines may preclude

efficient double-stack container service.

Railway electrification has constantly increased in the past

decades, and as of 2012, electrified tracks account for nearly one third

of total tracks globally.

Classification

Electrification systems are classified by three main parameters:

- Voltage

- Current

- Direct current (DC)

- Alternating current (AC)

- Contact system

- Third rail

- Fourth rail

- Overhead lines (catenary)

- Overhead lines plus linear motor

Selection of an electrification system is based on economics of

energy supply, maintenance, and capital cost compared to the revenue

obtained for freight and passenger traffic. Different systems are used

for urban and intercity areas; some electric locomotives can switch to different supply voltages to allow flexibility in operation.

Standardised voltages

Six

of the most commonly used voltages have been selected for European and

international standardisation. Some of these are independent of the

contact system used, so that, for example, 750 V DC may be used with

either third rail or overhead lines.

There are many other voltage systems used for railway electrification systems around the world, and the list of railway electrification systems covers both standard voltage and non-standard voltage systems.

The permissible range of voltages allowed for the standardised voltages is as stated in standards BS EN 50163 and IEC 60850. These take into account the number of trains drawing current and their distance from the substation.

| Electrification system | Voltage | ||||

|---|---|---|---|---|---|

| Min. non-permanent | Min. permanent | Nominal | Max. permanent | Max. non-permanent | |

| 600 V DC | 400 V | 400 V | 600 V | 720 V | 800 V |

| 750 V DC | 500 V | 500 V | 750 V | 900 V | 1,000 V |

| 1,500 V DC | 1,000 V | 1,000 V | 1,500 V | 1,800 V | 1,950 V |

| 3 kV DC | 2 kV | 2 kV | 3 kV | 3.6 kV | 3.9 kV |

| 15 kV AC, 16.7 Hz | 11 kV | 12 kV | 15 kV | 17.25 kV | 18 kV |

| 25 kV AC, 50 Hz (EN 50163) and 60 Hz (IEC 60850) |

17.5 kV | 19 kV | 25 kV | 27.5 kV | 29 kV |

Direct current

Railroad rotary converter at Illinois Railway Museum

Increasing availability of high-voltage semiconductors may allow the

use of higher and more efficient DC voltages that heretofore have only

been practical with AC.

Overhead systems

Electric locomotives under an overhead line in Sweden

Nottingham Express Transit in the United Kingdom uses a 750 V DC overhead, in common with most modern tram systems.

1,500 V DC is used in Japan, Indonesia, Hong Kong (parts), Republic of Ireland, Australia (parts), France (also using 25 kV 50 Hz AC), New Zealand (Wellington), Singapore (on the North East MRT Line), the United States (Chicago area on the Metra Electric district and the South Shore Line interurban line and in Seattle, Washington – Sound Transit light-rail lines). In Slovakia, there are two narrow-gauge lines in the High Tatras (one a cog railway). In the Netherlands it is used on the main system, alongside 25 kV on the HSL-Zuid and Betuwelijn, and 3000 V south of Maastricht. In Portugal, it is used in the Cascais Line and in Denmark on the suburban S-train system (1650 V DC).

In the United Kingdom, 1,500 V DC was used in 1954 for the Woodhead trans-Pennine route (now closed); the system used regenerative braking,

allowing for transfer of energy between climbing and descending trains

on the steep approaches to the tunnel. The system was also used for

suburban electrification in East London and Manchester, now converted to 25 kV AC. It is now only used for the Tyne and Wear Metro.

In India, 1,500 V DC was the first electrification system launched in

1925 in Mumbai area. Between 2012-2016, the electrification was

converted to 25 kV 50 Hz AC which is the countrywide system.

3 kV DC is used in Belgium, Italy, Spain, Poland, Slovakia, Slovenia, South Africa, Chile, the northern portion of the Czech Republic, the former republics of the Soviet Union, and the Netherlands. It was formerly used by the Milwaukee Road

from Harlowton, Montana, to Seattle-Tacoma, across the Continental

Divide and including extensive branch and loop lines in Montana, and by

the Delaware, Lackawanna & Western Railroad (now New Jersey Transit, converted to 25 kV AC) in the United States, and the Kolkata suburban railway (Bardhaman Main Line) in India, before it was converted to 25 kV 50 Hz AC.

DC voltages between 600 V and 800 V are used by most tramways (streetcars), trolleybus networks and underground (subway) systems.

Overhead systems with linear motor

Third rail

A bottom-contact third rail on the Amsterdam Metro, Netherlands

Arcs like this are normal and occur when the collection shoes of a train drawing power reach the end of a section of power rail.

Most electrification systems use overhead wires, but third rail is an option up to 1,500 V, as is the case with Shenzhen Metro Line 3.

Third rail systems exclusively use DC distribution. The use of AC is

not feasible because the dimensions of a third rail are physically very

large compared with the skin depth

that the alternating current penetrates to 0.3 millimetres or 0.012

inches in a steel rail. This effect makes the resistance per unit length

unacceptably high compared with the use of DC.

Third rail is more compact than overhead wires and can be used in

smaller-diameter tunnels, an important factor for subway systems.

Fourth rail

London Underground track at Ealing Common on the District line, showing the third and fourth rails beside and between the running rails

A train on Milan Metro's Line 1 showing the fourth-rail contact shoe.

The London Underground

in England is one of the few networks that uses a four-rail system. The

additional rail carries the electrical return that, on third rail and

overhead networks, is provided by the running rails. On the London

Underground, a top-contact third rail is beside the track, energized at +420 V DC, and a top-contact fourth rail is located centrally between the running rails at −210 V DC, which combine to provide a traction voltage of 630 V DC. The same system was used for Milan's earliest underground line, Milan Metro's line 1, whose more recent lines use an overhead catenary or a third rail.

The key advantage of the four-rail system is that neither running

rail carries any current. This scheme was introduced because of the

problems of return currents, intended to be carried by the earthed (grounded)

running rail, flowing through the iron tunnel linings instead. This can

cause electrolytic damage and even arcing if the tunnel segments are

not electrically bonded

together. The problem was exacerbated because the return current also

had a tendency to flow through nearby iron pipes forming the water and

gas mains. Some of these, particularly Victorian mains that predated

London's underground railways, were not constructed to carry currents

and had no adequate electrical bonding between pipe segments. The

four-rail system solves the problem. Although the supply has an

artificially created earth point, this connection is derived by using

resistors which ensures that stray earth currents are kept to manageable

levels. Power-only rails can be mounted on strongly insulating ceramic

chairs to minimise current leak, but this is not possible for running

rails which have to be seated on stronger metal chairs to carry the

weight of trains. However, elastomeric rubber pads placed between the

rails and chairs can now solve part of the problem by insulating the

running rails from the current return should there be a leakage through

the running rails.

Linear motor

An S-series northbound train at Lawrence East station. Note the slab between the running rails.

Bombardier Innovia Metro systems run on conventional metal rails and pull power from a third rail, but are powered by a linear induction motor that provides traction by pulling on a "fourth rail" placed between the running rails.

The Vancouver SkyTrain is the largest such system in operation with just under 50 km (30 mi) of track along the Expo and Millennium lines.

In the case of Scarborough Line 3, the third and fourth rails are outside the track and the fifth rail is an aluminum slab between the running rails.

Rubber-tyred systems

The bogie of an MP 05, showing the flanged steel wheel inside the rubber-tyred one, as well as the vertical contact shoe on top of the steel rail

Bogie from an MP 89 Paris Métro vehicle. The lateral contact shoe is located between the rubber tyres

A few lines of the Paris Métro in France operate on a four-rail power system. The trains move on rubber tyres which roll on a pair of narrow roll ways made of steel and, in some places, of concrete. Since the tyres do not conduct the return current, the two guide bars provided outside the running 'roll ways' become, in a sense, a third and fourth rail which each provide 750 V DC, so at least electrically it is a four-rail system. Each wheel set of a powered bogie carries one traction motor. A side sliding (side running) contact shoe picks up the current from the vertical face of each guide bar. The return of each traction motor, as well as each wagon, is effected by one contact shoe each that slide on top of each one of the running rails. This and all other rubber-tyred metros that have a 1,435 mm (4 ft 8 1⁄2 in) standard gauge track between the roll ways operate in the same manner.

Alternating current

Image of a sign for high voltage above a railway electrification system

Railways and electrical utilities use AC for the same reason: to use transformers,

which require AC, to produce higher voltages.

The higher the voltage, the lower the current for the same power, which

reduces line loss, thus allowing higher power to be delivered.

Because alternating current is used with high voltages, this method of electrification is only used on overhead lines,

never on third rails. Inside the locomotive, a transformer steps the

voltage down for use by the traction motors and auxiliary loads.

An early advantage of AC is that the power-wasting resistors used in DC locomotives for speed control were not needed in an AC locomotive: multiple taps on the transformer

can supply a range of voltages.

Separate low-voltage transformer windings supply lighting and the motors

driving auxiliary machinery.

More recently, the development of very high power semiconductors has

caused the classic DC motor to be largely replaced with the three-phase induction motor fed by a variable frequency drive, a special inverter

that varies both frequency and voltage to control motor speed.

These drives can run equally well on DC or AC of any frequency, and many

modern electric locomotives are designed to handle different supply

voltages and frequencies to simplify cross-border operation.

Low-frequency alternating current

15 kV 16.7 Hz AC system used in Switzerland

Five European countries, Germany, Austria, Switzerland, Norway and Sweden, have standardized on 15 kV 16 2⁄3 Hz

(the 50 Hz mains frequency divided by three) single-phase AC. On

16 October 1995, Germany, Austria and Switzerland changed from 16 2⁄3 Hz

to 16.7 Hz which is no longer exactly one-third of the grid frequency.

This solved overheating problems with the rotary converters used to

generate some of this power from the grid supply.

In the UK, the London, Brighton and South Coast Railway pioneered overhead electrification of its suburban lines in London, London Bridge to Victoria being opened to traffic on 1 December 1909. Victoria to Crystal Palace via Balham and West Norwood opened in May 1911. Peckham Rye to West Norwood opened in June 1912. Further extensions were not made owing to the First World War. Two lines opened in 1925 under the Southern Railway serving Coulsdon North and Sutton railway station.

The lines were electrified at 6.7 kV 25 Hz. It was announced in 1926

that all lines were to be converted to DC third rail and the last

overhead electric service ran in September 1929.

Non-contact systems

It is possible to supply power to an electric train by inductive coupling. This allows the use of a high-voltage, insulated, conductor rail. Such a system was patented in 1894 by Nikola Tesla, U.S. Patent 514,972. It requires the use of high-frequency alternating current. Tesla did not specify a frequency but George Trinkaus suggests that around 1,000 Hz would be likely.

Inductive coupling is widely used in low-power applications, such as re-chargeable electric toothbrushes and more recently, mobile telephones and wearable computing devices (inductive charging).

Energy efficiency

Electric versus diesel

An early rail electrification substation at Dartford

Electric trains need not carry the weight of prime movers, transmission and fuel. This is partly offset by the weight of electrical equipment.

Regenerative braking

returns power to the electrification system so that it may be used

elsewhere, by other trains on the same system or returned to the general

power grid. This is especially useful in mountainous areas where

heavily loaded trains must descend long grades.

Central station electricity can often be generated with higher

efficiency than a mobile engine/generator. While the efficiency of power

plant generation and diesel locomotive generation are roughly the same

in the nominal regime, diesel motors decrease in efficiency in non-nominal regimes at low power

while if an electric power plant needs to generate less power it will

shut down its least efficient generators, thereby increasing efficiency.

The electric train can save energy (as compared to diesel) by regenerative braking

and by not needing to consume energy by idling as diesel locomotives do

when stopped or coasting. However, electric rolling stock may run

cooling blowers when stopped or coasting, thus consuming energy.

Large fossil fuel power stations operate at high efficiency, and can be used for district heating or to produce district cooling, leading to a higher total efficiency.

AC versus DC for mainlines

The

majority of modern electrification systems take AC energy from a power

grid that is delivered to a locomotive, and within the locomotive, transformed and rectified

to a lower DC voltage in preparation for use by traction motors. These

motors may either be DC motors which directly use the DC or they may be

3-phase AC motors which require further conversion of the DC to 3-phase

AC (using power electronics). Thus both systems are faced with the same

task: converting and transporting high-voltage AC from the power grid to

low-voltage DC in the locomotive. The difference between AC and DC

electrification systems lies in where the AC is converted to DC: at the

substation or on the train. Energy efficiency and infrastructure costs

determine which of these is used on a network, although this is often

fixed due to pre-existing electrification systems.

Both the transmission and conversion of electric energy involve

losses: ohmic losses in wires and power electronics, magnetic field

losses in transformers and smoothing reactors (inductors).

Power conversion for a DC system takes place mainly in a railway

substation where large, heavy, and more efficient hardware can be used

as compared to an AC system where conversion takes place aboard the

locomotive where space is limited and losses are significantly higher.

However, the higher voltages used in many AC electrification systems

reduces transmission losses over longer distances, allowing for fewer

substations or more powerful locomotives to be used. Also, the energy

used to blow air to cool transformers, power electronics (including

rectifiers), and other conversion hardware must be accounted for.

Comparison with diesel traction

Lots Road Power Station in a poster from 1910. This private power station, used by London Underground, gave London trains and trams a power supply independent from the main power network.

Electric locomotives may easily be constructed with greater power

output than most diesel locomotives. For passenger operation it is

possible to provide enough power with diesel engines but, at higher speeds, this proves costly and impractical. Therefore, almost all high speed trains

are electric. The high power of electric locomotives also gives them

the ability to pull freight at higher speed over gradients; in mixed

traffic conditions this increases capacity when the time between trains

can be decreased. The higher power of electric locomotives and an

electrification can also be a cheaper alternative to a new and less

steep railway if trains weights are to be increased on a system.

On the other hand, electrification may not be suitable for lines

with low frequency of traffic, because lower running cost of trains may

be outweighed by the high cost of the electrification infrastructure.

Therefore, most long-distance lines in developing or sparsely populated

countries are not electrified due to relatively low frequency of trains.

Maintenance costs of the lines may be increased by

electrification, but many systems claim lower costs due to reduced

wear-and-tear from lighter rolling stock.

There are some additional maintenance costs associated with the

electrical equipment around the track, such as power sub-stations and

the catenary wire itself, but, if there is sufficient traffic, the

reduced track and especially the lower engine maintenance and running

costs exceed the costs of this maintenance significantly.

Network effects are a large factor with electrification.

When converting lines to electric, the connections with other lines

must be considered. Some electrifications have subsequently been removed

because of the through traffic to non-electrified lines. If through traffic is to have any benefit, time consuming engine switches must occur to make such connections or expensive dual mode engines

must be used. This is mostly an issue for long distance trips, but many

lines come to be dominated by through traffic from long-haul freight

trains (usually running coal, ore, or containers to or from ports). In

theory, these trains could enjoy dramatic savings through

electrification, but it can be too costly to extend electrification to

isolated areas, and unless an entire network is electrified, companies

often find that they need to continue use of diesel trains even if

sections are electrified. The increasing demand for container traffic

which is more efficient when utilizing the double-stack car

also has network effect issues with existing electrifications due to

insufficient clearance of overhead electrical lines for these trains,

but electrification can be built or modified to have sufficient

clearance, at additional cost.

A problem specifically related to electrified lines are gaps in

the electrification. Electric vehicles, especially locomotives, lose

power when traversing gaps in the supply, such as phase change gaps in

overhead systems, and gaps over points in third rail systems. These

become a nuisance, if the locomotive stops with its collector on a dead

gap, in which case there is no power to restart. Power gaps can be

overcome by on-board batteries or motor-flywheel-generator systems.[citation needed]

In 2014, progress is being made in the use of large capacitors to power electric vehicles between stations, and so avoid the need for overhead wires between those stations.

Advantages

- No exposure to passengers to exhaust from the locomotive

- Lower cost of building, running and maintaining locomotives and multiple units

- Higher power-to-weight ratio (no onboard fuel tanks), resulting in

- Fewer locomotives

- Faster acceleration

- Higher practical limit of power

- Higher limit of speed

- Less noise pollution (quieter operation)

- Faster acceleration clears lines more quickly to run more trains on the track in urban rail uses

- Reduced power loss at higher altitudes (for power loss see Diesel engine)

- Independence of running costs from fluctuating fuel prices

- Service to underground stations where diesel trains cannot operate for safety reasons

- Reduced environmental pollution, especially in highly populated urban areas, even if electricity is produced by fossil fuels

- Easily accommodates kinetic energy brake reclaim using supercapacitors

- More comfortable ride on multiple units as trains have no underfloor diesel engines

- Somewhat higher energy efficiency in part due to regenerative braking and less power lost when "idling"

- More flexible primary energy source: can use coal, nuclear, hydro or wind as the primary energy source instead of oil

Disadvantages

The Royal Border Bridge in England, a protected monument. Adding electric catenary to older structures may be an expensive cost of electrification projects

Most overhead electrifications do not allow sufficient clearance for a double-stack car. Each container may be 9 ft 6 in (2.90 m) tall and the bottom of the well is 1 ft 2 in (0.36 m) above rail, making the overall height 20 ft 2 in (6.15 m) including the well car.

- Electrification cost: electrification requires an entire new infrastructure to be built around the existing tracks at a significant cost. Costs are especially high when tunnels, bridges and other obstructions have to be altered for clearance. Another aspect that can raise the cost of electrification are the alterations or upgrades to railway signalling needed for new traffic characteristics, and to protect signalling circuitry and track circuits from interference by traction current. Electrification may require line closures while the new equipment is being installed.

- Appearance: the overhead line structures and cabling can have a significant landscape impact compared with a non-electrified or third rail electrified line that has only occasional signalling equipment above ground level.

- Fragility and vulnerability: overhead electrification systems can suffer severe disruption due to minor mechanical faults or the effects of high winds causing the pantograph of a moving train to become entangled with the catenary, ripping the wires from their supports. The damage is often not limited to the supply to one track, but extends to those for adjacent tracks as well, causing the entire route to be blocked for a considerable time. Third-rail systems can suffer disruption in cold weather due to ice forming on the conductor rail.

- Theft: the high scrap value of copper and the unguarded, remote installations make overhead cables an attractive target for scrap metal thieves. Attempts at theft of live 25 kV cables may end in the thief's death from electrocution. In the UK, cable theft is claimed to be one of the biggest sources of delay and disruption to train services — though this normally relates to signalling cable, which is equally problematic for diesel lines.

- Birds may perch on parts with different charges, and animals may also touch the electrification system. Dead animals attract foxes or other predators, bringing risk of collision with trains.

- In most of the world's railway networks, the height clearance of overhead electrical lines is not sufficient for a double-stack container car or other unusually tall loads. It is extremely costly to upgrade electrified lines to the correct clearances (21 ft 8 in or 6.60 m) to take double-stacked container trains.