From Wikipedia, the free encyclopedia

Silicon, 14Si

|

| General properties |

| Pronunciation |

(SIL-ik-ən) |

| Appearance |

crystalline, reflective with bluish-tinged faces |

| Standard atomic weight (Ar, standard) |

[28.084, 28.086] conventional: 28.085 |

| Silicon in the periodic table |

|

|

| Atomic number (Z) |

14 |

| Group |

group 14 (carbon group) |

| Period |

period 3 |

| Element category |

metalloid |

| Block |

p-block |

| Electron configuration |

[Ne] 3s2 3p2 |

Electrons per shell

|

2, 8, 4 |

| Physical properties |

| Phase at STP |

solid |

| Melting point |

1687 K (1414 °C, 2577 °F) |

| Boiling point |

3538 K (3265 °C, 5909 °F) |

| Density (near r.t.) |

2.3290 g/cm3 |

| when liquid (at m.p.) |

2.57 g/cm3 |

| Heat of fusion |

50.21 kJ/mol |

| Heat of vaporization |

383 kJ/mol |

| Molar heat capacity |

19.789 J/(mol·K) |

Vapor pressure

| P (Pa) |

1 |

10 |

100 |

1 k |

10 k |

100 k |

| at T (K) |

1908 |

2102 |

2339 |

2636 |

3021 |

3537 |

|

| Atomic properties |

| Oxidation states |

4, 3, 2, 1[1] −1, −2, −3, −4 (an amphoteric oxide) |

| Electronegativity |

Pauling scale: 1.90 |

| Ionization energies |

- 1st: 786.5 kJ/mol

- 2nd: 1577.1 kJ/mol

- 3rd: 3231.6 kJ/mol

- (more)

|

| Atomic radius |

empirical: 111 pm |

| Covalent radius |

111 pm |

| Van der Waals radius |

210 pm |

|

|

| Miscellanea |

| Crystal structure |

face-centered diamond-cubic

|

| Speed of sound thin rod |

8433 m/s (at 20 °C) |

| Thermal expansion |

2.6 µm/(m·K) (at 25 °C) |

| Thermal conductivity |

149 W/(m·K) |

| Electrical resistivity |

2.3×103 Ω·m (at 20 °C)[2] |

| Band gap |

1.12 eV (at 300 K) |

| Magnetic ordering |

diamagnetic[3] |

| Magnetic susceptibility |

−3.9·10−6 cm3/mol (298 K)[4] |

| Young's modulus |

130–188 GPa[5] |

| Shear modulus |

51–80 GPa[5] |

| Bulk modulus |

97.6 GPa[5] |

| Poisson ratio |

0.064–0.28[5] |

| Mohs hardness |

6.5 |

| CAS Number |

7440-21-3 |

| History |

| Naming |

after Latin 'silex' or 'silicis', meaning flint |

| Prediction |

Antoine Lavoisier (1787) |

| Discovery and first isolation |

Jöns Jacob Berzelius[6][7] (1823) |

| Named by |

Thomas Thomson (1817) |

| Main isotopes of silicon |

|

|

|

Silicon is a

chemical element with symbol

Si and

atomic number 14. A hard and brittle crystalline solid with a blue-grey metallic lustre, it is a

tetravalent metalloid and

semiconductor. It is a member of

group 14 in the periodic table, along with

carbon above it and

germanium,

tin, and

lead

below. It is rather unreactive, though less so than germanium, and has a

very large chemical affinity for oxygen; as such, it was first prepared

and characterized in pure form only in 1823 by

Jöns Jakob Berzelius.

Its melting and boiling points of 1414 °C and 3265 °C respectively are

the second-highest among all the metalloids and nonmetals, being only

surpassed by boron (carbon sublimes rather than melts at atmospheric

pressure, albeit at a higher temperature than boron).

Silicon is the eighth most

common element in the universe by mass, but very rarely occurs as the pure element in the Earth's crust. It is most widely distributed in

dusts,

sands,

planetoids, and

planets as various forms of

silicon dioxide (silica) or

silicates. Over 90% of the Earth's crust is composed of

silicate minerals, making silicon the

second most abundant element in the Earth's crust (about 28% by mass) after

oxygen.

Most silicon is used commercially without being separated, and often

with little processing of the natural minerals. Such use includes

industrial construction with

clays,

silica sand, and

stone. Silicates are used in

Portland cement for

mortar and

stucco, and mixed with silica sand and

gravel to make

concrete for walkways, foundations, and roads. They are also used in whiteware

ceramics such as

porcelain, and in traditional

quartz-based

soda-lime glass and many other specialty

glasses. Silicon compounds such as

silicon carbide

are used as abrasives and components of high-strength ceramics. Silicon

is the basis of the widely used synthetic polymers called

silicones.

Elemental silicon also has a large impact on the modern world economy. Most free silicon is used in the

steel refining,

aluminium-casting, and fine chemical industries (often to make

fumed silica).

Even more visibly, the relatively small portion of very highly purified

elemental silicon used in semiconductor electronics (< 10%) is

essential to

integrated circuits — most computers, cell phones, and modern technology depend on it.

Silicon is an essential element in biology, although only traces are required by animals. However, various

sea sponges and microorganisms, such as

diatoms and

radiolaria, secrete skeletal structures made of silica. Silica is deposited in many plant tissues, such as in the bark and wood of

Chrysobalanaceae and the silica cells and silicified trichomes of

Cannabis sativa,

horsetails and many

grasses.

[8]

History

In 1787

Antoine Lavoisier suspected that

silica might be an oxide of a fundamental

chemical element,

[9] but the

chemical affinity of silicon for oxygen is high enough that he had no means to reduce the oxide and isolate the element.

[10] After an attempt to isolate silicon in 1808,

Sir Humphry Davy proposed the name "silicium" for silicon, from the Latin

silex,

silicis for flint, and adding the "-ium" ending because he believed it to be a metal.

[11] Most other languages use transliterated forms of Davy's name, sometimes adapted to local phonology (e.g.

German Silizium,

Turkish silisyum). A few others use instead a

calque of the Latin root (e.g.

Russian кремний, from

кремень "flint";

Greek πυριτιο from

πυρ "fire";

Finnish pii from

piikivi "flint").

[12]

In 1811,

Gay-Lussac and

Thénard are thought to have prepared impure

amorphous silicon, through the heating of recently isolated

potassium metal with

silicon tetrafluoride, but they did not purify and characterize the product, nor identify it as a new element.

[13] Silicon was given its present name in 1817 by Scottish chemist

Thomas Thomson. He retained part of Davy's name but added "-on" because he believed that silicon was a

nonmetal similar to

boron and

carbon.

[14] In 1823,

Jöns Jacob Berzelius

prepared amorphous silicon using approximately the same method as

Gay-Lussac (reducing potassium fluorosilicate with molten potassium

metal), but purifying the product to a brown powder by repeatedly

washing it.

[15] As a result, he is usually given credit for the element's discovery.

[16][17] The same year, Berzelius became the first to prepare

silicon tetrachloride;

silicon tetrafluoride had already been prepared long before in 1771 by

Carl Wilhelm Scheele by dissolving silica in

hydrofluoric acid.

[10]

Silicon in its more common crystalline form was not prepared until 31 years later, by

Deville.

[18][19] By

electrolyzing a mixture of

sodium chloride and

aluminium chloride containing approximately 10% silicon, he was able to obtain a slightly impure

allotrope of silicon in 1854.

[20] Later, more cost-effective methods have been developed to isolate several allotrope forms, the most recent being

silicene in 2010.

[21][22] Meanwhile, research on the chemistry of silicon continued;

Friedrich Wöhler discovered the first volatile hydrides of silicon, synthesising

trichlorosilane in 1857 and

silane itself in 1858, but a detailed investigation of the

silanes was only carried out in the early 20th century by

Alfred Stock, despite early speculation on the matter dating as far back as the beginnings of synthetic organic chemistry in the 1830s.

[23] Similarly, the first

organosilicon compound,

tetraethylsilane, was synthesised by

Charles Friedel and

James Crafts in 1863, but detailed characterisation of organosilicon chemistry was only done in the early 20th century by

Frederick Kipping.

[10]

Starting in the 1920s, the work of

William Lawrence Bragg on

X-ray crystallography successfully elucidated the compositions of the silicates, which had previously been known from

analytical chemistry but had not yet been understood, together with

Linus Pauling's development of

crystal chemistry and

Victor Goldschmidt's development of

geochemistry. The middle of the 20th century saw the development of the chemistry and industrial use of

siloxanes and the growing use of

silicone polymers,

elastomers, and

resins. In the late 20th century, the complexity of the crystal chemistry of

silicides was mapped, along with the solid-state chemistry of

doped semiconductors.

[10]

Because silicon is an important element in high-technology

semiconductor devices, many places in the world bear its name. For

example,

Santa Clara Valley in

California acquired the nickname

Silicon Valley

since the element is the base material used in the semiconductor

industry located there. Since then, many other locations have been

nicknamed for similar reasons.

[24]

Characteristics

Physical and atomic

Silicon crystallizes in a diamond cubic crystal structure

A silicon atom has fourteen

electrons. In the ground state, they are arranged in the electron configuration [Ne]3s

23p

2. Of these, four are

valence electrons, occupying the 3s orbital and two of the 3p orbitals. Like the other members of its group, the lighter

carbon and the heavier

germanium,

tin, and

lead, it has the same number of valence electrons as valence orbitals: hence, it can complete its

octet and obtain the stable

noble gas configuration of

argon by forming

sp3 hybrid orbitals, forming tetrahedral SiX

4 derivatives where the central silicon atom shares an electron pair with each of the four atoms it is bonded to.

[25] The first four

ionisation energies

of silicon are 786.3, 1576.5, 3228.3, and 4354.4 kJ/mol respectively;

these figures are high enough to preclude the possibility of simple

cationic chemistry for the element. Following

periodic trends,

its single-bond covalent radius of 117.6 pm is intermediate between

those of carbon (77.2 pm) and germanium (122.3 pm). The hexacoordinate

ionic radius of silicon may be considered to be 40 pm, although this

must be taken as a purely notional figure given the lack of a simple Si

4+ cation in reality.

[26]

At standard temperature and pressure, silicon is a shiny

semiconductor

with a bluish-grey metallic lustre; as typical for semiconductors, its

resistivity drops as temperature rises. This arises because silicon has a

small energy gap between its highest occupied energy levels (the

valence band) and the lowest unoccupied ones (the conduction band). The

Fermi level

is about halfway between the valence and conduction bands and is the

energy at which a state is as likely to be occupied by an electron as

not. Hence pure silicon is an insulator at room temperature. However,

doping silicon with a

pnictogen such as

phosphorus,

arsenic, or

antimony

introduces one extra electron per dopant and these may then be excited

into the conduction band either thermally or photolytically, creating an

n-type semiconductor. Similarly, doping silicon with a

group 13 element such as

boron,

aluminium, and

gallium

results in the introduction of acceptor levels that trap electrons that

may be excited from the filled valence band, creating a

p-type semiconductor. Joining n-type silicon to p-type silicon creates a

p-n junction

with a common Fermi level; electrons flow from n to p, while holes flow

from p to n, creating a voltage drop. This p-n junction thus acts as a

diode that can rectify alternating current that allows current to pass more easily one way than the other. A

transistor

is an n-p-n junction, with a thin layer of weakly p-type silicon

between two n-type regions. Biasing the emitter through a small forward

voltage and the collector through a large reverse voltage allows the

transistor to act as a

triode amplifier.

[27]

Silicon crystallises in a giant covalent structure at standard conditions, specifically in a

diamond cubic

lattice. It thus has a high melting point of 1414 °C, as a lot of

energy is required to break the strong covalent bonds and melt the

solid. It is not known to have any allotropes at standard pressure, but

several other crystal structures are known at higher pressures. The

general trend is one of increasing

coordination number with pressure, culminating in a

hexagonal close-packed allotrope at about 40

gigapascals

known as Si–VII (the standard modification being Si–I). Silicon boils

at 3265 °C: this, while high, is still lower than the temperature at

which its lighter congener

carbon sublimes (3642 °C) and silicon similarly has a lower

heat of vaporisation than carbon, consistent with the fact that the Si–Si bond is weaker than the C–C bond.

[27]

Isotopes

Naturally occurring silicon is composed of three stable

isotopes,

28Si (92.23%),

29Si (4.67%), and

30Si (3.10%).

[28] Out of these, only

29Si is of use in

NMR and

EPR spectroscopy,

[29] as it is the only one with a nuclear spin (

I =

1/2).

[30] All three are produced in stars through the

oxygen-burning process, with

28Si being made as part of the

alpha process and hence the most abundant. The fusion of

28Si with alpha particles by

photodisintegration rearrangement in stars is known as the

silicon-burning process; it is the last stage of

stellar nucleosynthesis before the rapid collapse and violent explosion of the star in question in a

type II supernova.

[31]

Twenty

radioisotopes have been characterized, with the two stablest being

32Si with a

half-life of about 150 years, and

31Si with a half-life of 2.62 hours.

[28] All of the remaining

radioactive

isotopes have half-lives that are less than seven seconds, and the

majority of these have half-lives that are less than one tenth of a

second.

[28] Silicon does not have any known

nuclear isomers.

[28] 32Si undergoes low-energy

beta decay to

32P and then stable

32S.

31Si may be produced by the

neutron activation

of natural silicon and is thus useful for quantitative analysis; it can

be easily detected by its characteristic beta decay to stable

31P, in which the emitted electron carries up to 1.48

MeV of energy.

[30]

The known isotopes of silicon range in

mass number from 22 to 44.

[28] The most common

decay mode of the isotopes with mass numbers lower than the three stable isotopes is

inverse beta decay, primarily forming aluminium isotopes (13 protons) as

decay products.

[28]

The most common decay mode for the heavier unstable isotopes is beta

decay, primarily forming phosphorus isotopes (15 protons) as decay

products.

[28]

Chemistry and compounds

Crystalline bulk silicon is rather inert, but becomes more reactive

at high temperatures. Like its neighbour aluminium, silicon forms a

thin, continuous surface layer of

silicon dioxide (SiO

2)

that protects the metal from oxidation. Thus silicon does not

measurably react with the air below 900 °C, but formation of the

vitreous dioxide rapidly increases between 950 °C and 1160 °C and when 1400 °C is reached, atmospheric

nitrogen also reacts to give the nitrides SiN and Si

3N

4. Silicon reacts with gaseous

sulfur at 600 °C and gaseous

phosphorus at 1000 °C. This oxide layer nevertheless does not prevent reaction with the

halogens;

fluorine attacks silicon vigorously at room temperature,

chlorine does so at about 300 °C, and

bromine and

iodine at about 500 °C. Silicon does not react with most aqueous acids, but is oxidised and fluorinated by a mixture of concentrated

nitric acid and

hydrofluoric acid; it readily dissolves in hot aqueous alkali to form

silicates. At high temperatures, silicon also reacts with

alkyl halides; this reaction can be catalysed by

copper to directly synthesise

organosilicon chlorides as precursors to

silicone polymers. Upon melting, silicon becomes extremely reactive, alloying with most metals to form

silicides, and reducing most metal oxides because the

heat of formation of silicon dioxide is so large. As a result, containers for liquid silicon must be made of

refractory, unreactive materials such as

zirconium dioxide or group 4, 5, and 6 borides.

[27]

Tetrahedral coordination is a major structural motif in silicon

chemistry just as it is for carbon chemistry. However, the 3p subshell

is rather more diffuse than the 2p subshell and does not hybridise as

well with the 3s subshell. As a result, the chemistry of silicon and its

heavier congeners shows significant differences from that of carbon,

[32] and thus octahedral coordination is also significant.

[27] For example, the

electronegativity

of silicon (1.90) is much less than that of carbon (2.55), because the

valence electrons of silicon are further from the nucleus than those of

carbon and hence experience smaller electrostatic forces of attraction

from the nucleus. The poor overlap of 3p orbitals also results in a much

lower tendency towards

catenation

(formation of Si–Si bonds) for silicon than for carbon due to the

concomitant weakening of the Si–Si bond compared to the C–C bond:

[33] the average Si–Si bond energy is approximately 226 kJ/mol, compared to a value of 356 kJ/mol for the C–C bond.

[34]

This results in multiply bonded silicon compounds generally being much

less stable than their carbon counterparts, an example of the

double bond rule. On the other hand, the presence of 3d orbitals in the valence shell of silicon suggests the possibility of

hypervalence, as seen in five- and six-coordinate derivatives of silicon such as

SiX−

5 and

SiF2−

6.

[33] Lastly, because of the increasing energy gap between the valence s and p

orbitals as the group is descended, the divalent state grows in

importance from carbon to lead, so that a few unstable divalent

compounds are known for silicon; this lowering of the main oxidation

state, in tandem with increasing atomic radii, results in an increase of

metallic character down the group. Silicon already shows some incipient

metallic behaviour, particularly in the behaviour of its oxide

compounds and its reaction with acids as well as bases (though this

takes some effort), and is hence often referred to as a

metalloid rather than a nonmetal.

[33]

However, metallicity does not become clear in group 14 until germanium

and dominant until tin, with the growing importance of the lower +2

oxidation state.

[10]

Silicon shows clear differences with carbon. For example,

organic chemistry has very few analogies with silicon chemistry, while

silicate minerals have a structural complexity unseen in

oxocarbons.

[10] Silicon tends to resemble germanium far more than it does carbon, and this resemblance is enhanced by the

d-block contraction resulting in the size of the germanium atom being much closer to that of the silicon atom than periodic trends would predict.

[26]

Nevertheless, there are still some differences because of the growing

importance of the divalent state in germanium compared to silicon, that

result in germanium being significantly more metallic than silicon.

Additionally, the lower Ge–O bond strength compared to the Si–O bond

strength results in the absence of "germanone" polymers that would be

analogous to

silicone polymers.

[34]

Silicides

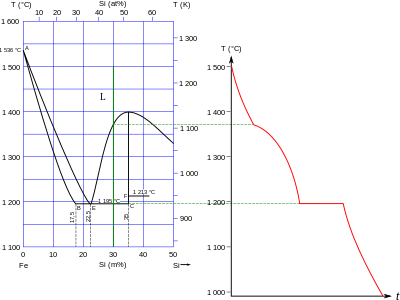

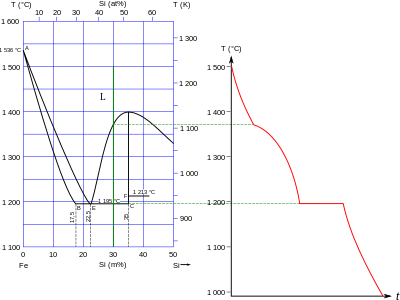

Phase diagram of the Fe–Si system

Many metal

silicides are known, most of which have formulae that cannot be explained through simple appeals to

valence: their bonding ranges from

metallic to

ionic and

covalent. Some known stoichiometries are M

6Si, M

5Si, M

4Si, M

15Si

4, M

3Si, M

5Si

2, M

2Si, M

5Si

3, M

3Si

2, MSi, M

2Si

3, MSi

2, MSi

3, and MSi

6. They are structurally more similar to the

borides than the

carbides, in keeping with the

diagonal relationship between

boron

and silicon, although the larger size of silicon than boron means that

exact structural analogies are few and far between. The heats of

formation of the silicides are usually similar to those of the borides

and carbides of the same elements, but they usually melt at lower

temperatures.

[35] Silicides are known for all stable elements in groups 1–10, with the exception of

beryllium: in particular,

uranium and the transition metals of groups 4–10 show the widest range of stoichiometries. Except for

copper, the metals in groups 11–15 do not form silicides. Most instead form

eutectic mixtures, although the heaviest

post-transition metals mercury,

thallium,

lead, and

bismuth are completely immiscible with liquid silicon.

[35]

Silicides are usually prepared by direct reaction of the elements. For example, the

alkali metals and

alkaline earth metals

react with silicon or silicon oxide to give silicides. Nevertheless,

even with these highly electropositive elements true silicon anions are

not obtainable, and most of these compounds are semiconductors. For

example, the alkali metal silicides

(M+)

4(E4−

4) contain pyramidal tricoordinate silicon in the

Si4−

4 anion, isoeelctronic with

white phosphorus, P

4.

[35][36] Metal-rich silicides tend to have isolated silicon atoms (e.g. Cu

5Si); with increasing silicon content, catenation increases, resulting in isolated clusters of two (e.g. U

3Si

2) or four silicon atoms (e.g. [K

+]

4[Si

4]

4−) at first, followed by chains (e.g. CaSi), layers (e.g. CaSi

2), or three-dimensional networks of silicon atoms spanning space (e.g. α-ThSi

2) as the silicon content rises even higher.

[35]

The silicides of the group 1 and 2 metals are usually more reactive

than the transition metal silicides. The latter usually do not react

with aqueous reagents, except for

hydrofluoric acid; however, they do react with much more aggressive reagents like liquid

potassium hydroxide, or gaseous fluorine or

chlorine

when red-hot. The pre-transition metal silicides instead readily react

with water and aqueous acids, usually producing hydrogen or silanes:

[35]

- Na2Si + 3 H2O → Na2SiO3 + 3 H2

- Mg2Si + 2 H2SO4 → 2 MgSO4 + SiH4

Products often vary with the stoichiometry of the silicide reactant. For example, Ca

2Si is polar and non-conducting and has the anti-PbCl

2 structure with single isolated silicon atoms, and reacts with water to produce

calcium hydroxide,

hydrated silicon dioxide, and hydrogen gas. CaSi with its zigzag chains

of silicon atoms instead reacts to give silanes and polymeric SiH

2, while CaSi

2

with its puckered layers of silicon atoms does not react with water,

but will react with dilute hydrochloric acid: the product is a yellow

polymeric solid with stoichiometry Si

2H

2O.

[35]

Silanes

Speculation on silicon hydride chemistry started from the 1830s, contemporary with the development of synthetic

organic chemistry.

Silane itself, as well as

trichlorosilane, were first synthesised by

Friedrich Wöhler and

Heinrich Buff in 1857 by reacting aluminium–silicon alloys with

hydrochloric acid, and characterised as SiH

4 and SiHCl

3 by

Charles Friedel and

Albert Ladenburg in 1867.

Disilane (Si

2H

6) followed in 1902, when it was first made by

Henri Moissan and

Samuel Smiles by the

protonolysis of

magnesium silicides.

Further investigation had to wait until 1916 because of the great

reactivity and thermal instability of the silanes; it was then that

Alfred Stock

began the study of silicon hydrides in earnest with new greaseless

vacuum techniques, as they were found as contaminants of his focus, the

boron hydrides. The names

silanes and

boranes are due to him, based on analogy with the

alkanes.

[23][37][38]

Moissan and Smiles' method of preparation of silanes and silane

derivatives via protonolysis of metal silicides is still used, although

the yield is lowered by the hydrolysis of the products that occurs

simultaneously, and thus the preferred route today is to treat

substituted silanes with hydride reducing agents such as

lithium aluminium hydride

in etheric solutions at low temperatures. Direct reaction of HX or RX

with silicon, possibly with a catalyst such as copper, is also a viable

method to produce substituted silanes.

[23]

The silanes comprise a

homologous series of silicon hydrides with the general formula Si

nH

2n + 2. They are all strong

reducing agents. Unbranched and branched trains are known up to

n = 8, and the cycles Si

5H

10 and Si

6H

12

are also known. The first two, silane and disilane, are colourless

gases; the heavier members of the series are volatile liquids. All

silanes are very reactive and catch fire or explode spontaneously in

air. They become less thermally stable with room temperature, so that

only silane is indefinitely stable at room temperature, although

disilane does not decompose very quickly (only 2.5% of a sample

decomposes after eight months have passed).

[23] They decompose to form polymeric

polysilicon hydride and hydrogen gas.

[39][40]

As expected from the difference in atomic weight, the silanes are less

volatile than the corresponding alkanes and boranes, but more volatile

than the corresponding germanes. They are much more reactive than the

corresponding alkanes, because the larger radius of silicon compared to

carbon facilitates

nucleophilic attack

at the silicon, the greater polarity of the Si–H bond compared to the

C–H bond, and the ability of silicon to expand its octet and hence form

adducts and lower the reaction's

activation energy.

[23]

Silane

pyrolysis

gives polymeric species and finally elemental silicon and hydrogen;

indeed ultrapure silicon is commercially produced by the pyrolysis of

silane. While the thermal decomposition of alkanes starts by the

breaking of a C–H or C–C bond and the formation of radical

intermediates, polysilanes decompose by eliminating

silenes :SiH

2

or :SiHR, as the activation energy of this process (~210 kJ/mol) is

much less than the Si–Si and Si–H bond energies. While pure silanes do

not react with pure water or dilute acids, traces of alkali catalyse

immediate hydrolysis to hydrated silicon dioxide. If the reaction is

carried out in

methanol, controlled solvolysis results in the products SiH

2(OMe)

2, SiH(OMe)

3, and Si(OMe)

4. The Si–H bond also adds to

alkenes,

a reaction which proceeds slowly and speeds up with increasing

substitution of the silane involved. At 450 °C, silane participates in

an

addition reaction with

acetone, as well as a

ring-opening reaction with

ethylene oxide.

Direct reaction of the silanes with chlorine or bromine results in

explosions at room temperature, but the reaction of silane with bromine

at −80 °C is controlled and yields bromosilane and dibromosilane. The

monohalosilanes may be formed by reacting silane with the appropriate

hydrogen halide with an Al

2X

6 catalyst, or by reacting silane with a solid

silver halide in a heated flow reactor:

[23]

- SiH4 + 2 AgCl 260 °C→ SiH3Cl + HCl + 2 Ag

Among the derivatives of silane,

iodosilane (SiH

3I) and

potassium silanide (KSiH

3)

are very useful synthetic intermediates in the production of more

complicated silicon-containing compounds: the latter is a colourless

crystalline ionic solid containing K

+ cations and

SiH−

3 anions in the

NaCl structure, and is made by the reduction of silane by

potassium metal.

[41] Additionally, the reactive hypervalent species

SiH−

5 is also known.

[23]

With suitable organic substituents it is possible to produce stable

polysilanes: they have surprisingly high electric conductivities,

arising from

sigma delocalisation of the electrons in the chain.

[42]

Halides

Silicon and

silicon carbide readily react with all four stable halogens, forming the colourless, reactive and volatile silicon tetrahalides.

[43] Silicon tetrafluoride may also be made by fluorinating the other silicon halides, and is produced by the attack of

hydrofluoric acid on glass.

[44]

Heating two different tetrahalides together also produce a random

mixture of mixed halides, which may also be produced by halogen exchange

reactions. The melting and boiling points of these species usually rise

with increasing atomic weight, though there are many exceptions: for

example, the melting and boiling points drop as one passes from SiFBr

3 through SiFClBr

2 to SiFCl

2Br.

The shift from the hypoelectronic elements in group 13 and earlier to

the group 14 elements is illustrated by the change from an infinite

ionic structure in

aluminium fluoride

to a lattice of simple covalent silicon tetrafluoride molecules, as

dictated by the lower electronegativity of aluminium than silicon, the

stoichiometry (the +4 oxidation state being too high for true ionicity),

and the smaller size of the silicon atom compared to the aluminium

atom.

[43] Silicon tetrachloride is manufactured on a huge scale as a precursor to the production of pure silicon, silicon dioxide, and some silicon

esters.

[43]

The silicon tetrahalides hydrolyse readily in water, unlike the carbon

tetrahalides, again because of the larger size of the silicon atom

rendering it more open to nucleophilic attack and the ability of the

silicon atom to expand its octet which carbon lacks.

[44] The reaction of silicon fluoride with excess

hydrofluoric acid produces the octahedral

hexafluorosilicate anion

SiF2−

6.

[44]

Analogous to the silanes, halopolysilanes Si

nX

2n + 2

are also known. While catenation in carbon compounds is maximised in

the hydrogen compounds rather than the halides, the opposite is true for

silicon, so that the halopolysilanes are known up to at least Si

14F

30, Si

6Cl

14, and Si

4Br

10.

A suggested explanation for this phenomenon is the compensation for the

electron loss of silicon to the more electronegative halogen atoms by

pi backbonding from the filled p

π orbitals on the halogen atoms to the empty d

π orbitals on silicon: this is similar to the situation of

carbon monoxide in

metal carbonyl complexes and explains their stability. These halopolysilanes may be produced by

comproportionation of silicon tetrahalides with elemental silicon, or by condensation of lighter halopolysilanes (

trimethylammonium being a useful catalyst for this reaction).

[43]

Silica

Silicon dioxide (SiO

2), also known as silica, is one of the most well-studied compounds, second only to

water. Twelve different crystal modifications of silica are known, the most common being α-

quartz, a major constituent of many rocks such as

granite and

sandstone. It is also known to occur pure as

rock crystal; impure forms are known as

rose quartz,

smoky quartz,

morion,

amethyst, and

citrine. Some poorly crystalline forms of quartz are also known, such as

chalcedony,

chrysoprase,

carnelian,

agate,

onyx,

jasper,

heliotrope, and

flint. Other modifications of silicon dioxide are known in some other minerals such as

tridymite and

cristobalite, as well as the much less common

coesite and

stishovite. Biologically generated forms are also known as

kieselguhr and

diatomaceous earth.

Vitreous silicon dioxide is known as

tektites, and

obsidian, and rarely as

lechatelierite. Some synthetic forms are known as

keatite and

W-silica.

Opals are composed of complicated crystalline aggregates of partially hydrated silicon dioxide.

[45]

Most crystalline forms of silica are made of infinite arrangements of {SiO

4}

tetrahedra (with Si at the centre) connected at their corners, with

each oxygen atom linked to two silicon atoms. In the thermodynamically

stable room-temperature form, α-quartz, these tetrahedra are linked in

intertwined helical chains with two different Si–O distances (159.7 and

161.7 pm) with a Si–O–Si angle of 144°. These helices can be either

left- or right-handed, so that individual α-quartz crystals are

optically active. At 537 °C, this transforms quickly and reversibly into

the similar β-quartz, with a change of the Si–O–Si angle to 155° but a

retention of handedness. Further heating to 867 °C results in another

reversible phase transition to β-tridymite, in which some Si–O bonds are

broken to allow for the arrangement of the {SiO

4} tetrahedra

into a more open and less dense hexagonal structure. This transition is

slow and hence tridymite occurs as a metastable mineral even below this

transition temperature; when cooled to about 120 °C it quickly and

reversibly transforms by slight displacements of individual silicon and

oxygen atoms to α-tridymite, similarly to the transition from α-quartz

to β-quartz. β-tridymite slowly transforms to cubic β-cristobalite at

about 1470 °C, which once again exists metastably below this transition

temperature and transforms at 200–280 °C to α-cristobalite via small

atomic displacements. β-cristobalite melts at 1713 °C; the freezing of

silica from the melt is quite slow and

vitrification, or the formation of a

glass, is likely to occur instead. In vitreous silica, the {SiO

4}

tetrahedra remain corner-connected, but the symmetry and periodicity of

the crystalline forms are lost. Because of the slow conversions between

these three forms, it is possible upon rapid heating to melt β-quartz

(1550 °C) or β-tridymite (1703 °C). Silica boils at approximately

2800 °C. Other high-pressure forms of silica are known, such as coesite

and stishovite: these are known in nature, formed under the shock

pressure of a meteorite impact and then rapidly quenched to preserve the

crystal structure. Similar melting and cooling of silica occurs

following

lightning strikes, forming glassy

lechatelierite. W-silica is an unstable low-density form involving {SiO

4} tetrahedra sharing opposite edges instead of corners, forming parallel chains similarly to

silicon disulfide (SiS

2) and

silicon diselenide (SiSe

2): it quickly returns to forming amorphous silica with heat or traces of water.

[45]

Condensed polysilicic acid

Silica is rather inert chemically. It is not attacked by any acids

other than hydrofluoric acid. However, it slowly dissolves in hot

concentrated alkalis, and does so rather quickly in fused metal

hydroxides or carbonates to give metal silicates. Among the elements, it

is attacked only by fluorine at room temperature to form silicon

tetrafluoride: hydrogen and carbon also react, but require temperatures

over 1000 °C to do so. Silica nevertheless reacts with many metal and

metalloid

oxides to form a wide variety of compounds important in the glass and

ceramic industries above all, but also have many other uses: for

example,

sodium silicate is often used in detergents due to its

buffering,

saponifying, and

emulsifying properties.

[45]

Silicic acids

Adding water to silica drops its melting point by around 800 °C due

to the breaking of the structure by replacing Si–O–Si linkages with

terminating Si–OH groups. Increasing water concentration results in the

formation of hydrated

silica gels and

colloidal silica dispersions. Many hydrates and

silicic acids

exist in the most dilute of aqueous solutions, but these are rather

insoluble and quickly precipitate and condense and cross-link to form

various polysilicic acids of variable combinations following the formula

[SiO

x(OH)

4−2x]

n, similar to the behaviour of

boron,

aluminium, and

iron, among other elements. Hence, although some simple silicic acids have been identified in dilute solutions, such as

orthosilicic acid Si(OH)

4 and

metasilicic acid SiO(OH)

2, none of these are likely to exist in the solid state.

[45]

Silicate minerals

About 95% of the Earth's

crustal rocks are made of silica or silicate and

aluminosilicate minerals, as reflected in oxygen, silicon, and aluminium being the three most common elements in the crust (in that order).

[46] Measured by mass, silicon makes up 27.7% of the

Earth's crust.

[47]

Pure silicon crystals are very rarely found in nature, but notable

exceptions are crystals as large as to 0.3 mm across found during

sampling gases from the

Kudriavy volcano on the island of

Iturup, one of the

Kuril Islands.

[48][49]

Silicate and aluminosilicate minerals have many different structures

and varying stoichiometry, but they may be classified following some

general principles. Tetrahedral {SiO

4} units are common to

almost all these compounds, either as discrete structures, or combined

into larger units by the sharing of corner oxygen atoms. These may be

divided into

neso-silicates (discrete {SiO

4} units) sharing no oxygen atoms,

soro-silicates (discrete {Si

2O

7} units) sharing one,

cyclo-silicates (closed ring structures) and

ino-silicates (continuous chain or ribbon structures) both sharing two,

phyllo-silicates (continuous sheets) sharing three, and

tecto-silicates

(continuous three-dimensional frameworks) sharing four. The lattice of

oxygen atoms that results is usually close-packed or close to it, with

the charge being balanced by other cations in various different

polyhedral sites according to size.

[46]

The

orthosilicates M

II

2SiO

4 (M = Be, Mg, Mn, Fe, Zn) and ZrSiO

4 are

neso-silicates. Be

2SiO

4 (

phenacite) is rather unusual as both Be

II and Si

IV

occupy tetrahedral four-coordinated sites; the other divalent cations

instead occupy six-coordinated octahedral sites and often isomorphously

replace each other as in

olivine, (Mg,Fe,Mn)

2SiO

4.

Zircon, ZrSiO

4, demands eight-coordination of the Zr

IV cations due to stoichiometry and because of their larger ionic radius (84 pm). Also significant are the

garnets, [M

II

3M

III

2(SiO

4)

3],

in which the divalent cations (e.g. Ca, Mg, Fe) are eight-coordinated

and the trivalent ones are six-coordinated (e.g. Al, Cr, Fe). Regular

coordination is not always present: for example, it is not found in Ca

2SiO

4, which mixes six- and eight-coordinate sites for Ca

II.

Soro-silicates, involving discrete double or triple tetrahedral units, are quite rare: metasilicates involving cyclic "[(SiO

3)

n]

2n−" units of corner-abutting tetrahedra forming a polygonal ring are also known.

[46]

Chain metasilicates, {SiO

2−

3}

∞, form by the corner-sharing of an indefinite chain of linked {SiO

4}

tetrahedra. Many differences arise due to the differing repeat

distances of conformation across the line of tetrahedra. A repeat

distance of two is most common, as in most

pyroxene

minerals, but repeat distances of one, three, four, five, six, seven,

nine, and twelve are also known. These chains can then link across each

other to form double chains and ribbons, as in the

asbestos minerals, involving repeated chains of cyclic tetrahedron rings.

[46]

A typical zeolite structure

Layer silicates, such as the clay minerals and the

micas,

are very common, and are often formed by horizontal cross-linking of

metasilicate chains or planar condensation of smaller units. An example

is

kaolinite [Al

2(OH)

4Si

2O

5]; in many of these minerals cation and anion replacement is common, so that for example tetrahedral Si

IV may be replaced by Al

III, octahedral Al

III by Mg

II, and OH

− by F

−. Three-dimensional framework aluminosilicates are structurally very complex; they may be conceived of as starting from the SiO

2 structure, but having replaced up to one-half of the Si

IV atoms with Al

III they require more cations to be included in the structure to balance charge. Examples include

feldspars (the most abundant minerals on the Earth),

zeolites, and

ultramarines. Many feldspars can be thought of as forming part of the ternary system NaAlSi

3O

8–KAlSi

3O

8–CaAl

2Si

2O

8. Their lattice is destroyed by high pressure prompting Al

III to undergo six-coordination rather than four-coordination, and this reaction destroying feldspars may be a reason for the

Mohorovičić discontinuity,

which would imply that the crust and mantle have the same chemical

composition but different lattices, although this is not a universally

held view. Zeolites have many polyhedral cavities in their frameworks (

truncated cuboctahedra

being most common, but other polyhedra are also known as zeolite

cavities), allowing them to include loosely bound molecules such as

water in their structure. Ultramarines alternate silicon and aluminium

atoms and include a variety of other anions such as Cl

−,

SO2−

4, and

S2−

2, but are otherwise similar to the feldspars.

[46]

Other inorganic compounds

Silicon disulfide (SiS

2)

is formed by burning silicon in gaseous sulfur at 100 °C; sublimation

of the resulting compound in nitrogen results in white, flexible long

fibres reminiscent of

asbestos

with a structure similar to W-silica. This melts at 1090 °C and

sublimes at 1250 °C; at high temperature and pressure this transforms to

a crystal structure analogous to cristobalite. However, SiS

2 lacks the variety of structures of SiO

2, and quickly hydrolyses to silica and

hydrogen sulfide. It is also ammonoloysed quickly and completely by liquid

ammonia as follows to form an

imide:

[50]

- SiS2 + 4 NH3 → Si(NH)2 + 2 NH4SH

It reacts with the sulfides of sodium, magnesium, aluminium, and iron to form metal

thiosilicates: reaction with

ethanol results in

ethylsilicate Si(OEt)

4

and hydrogen sulfide. Ethylsilicate is useful as its controlled

hydrolysis produces adhesive or film-like forms of silica. Reacting

hydrogen sulfide with silicon tetrahalides yields silicon thiohalides

such as S(SiCl)

3, cyclic Cl

2Si(μ-S)

2SiCl

2, and crystalline (SiSCl

2)

4. Despite the

double bond rule, stable organosilanethiones RR'Si=S have been made thanks to the stabilising mechanism of intermolecular coordination via an

amine group.

[50]

Silicon nitride, Si

3N

4,

can be formed by directly reacting silicon with nitrogen above 1300 °C,

but a more economical means of production is by heating silica and coke

in a stream of nitrogen and hydrogen gas at 1500 °C. It would make a

promising

ceramic

if not for the difficulty of working with and sintering it: it is

chemically near-totally inert, and even above 1000 °C it keeps its

strength, shape, and continues to be resistant to wear and corrosion. It

is very hard (9 on the

Mohs hardness scale), dissociates only at 1900 °C at 1 atm, and is quite dense (density 3.185 g/cm

3), because of its compact structure similar to that of phenacite (Be

2SiO

4). A similar refractory material is Si

2N

2O,

formed by heating silicon and silica at 1450 °C in an argon stream

containing 5% nitrogen gas, involving 4-coordinate silicon and

3-coordinate nitrogen alternating in puckered hexagonal tilings

interlinked by non-linear Si–O–Si linkages to each other.

[50]

Reacting silyl halides with ammonia or alkylammonia derivatives in

the gaseous phase or in ethanolic solution produces various volatile

silylamides, which are silicon analogues of the

amines:

[50]

- 3 SiH3Cl + 4 NH3 → N(SiH3)3 + 3 NH4Cl

- SiH3Br + 2 Me2NH → SiH3NMe2 + Me2NH2Br

- 4 SiH3I + 5 N2H4 → (SiH3)2NN(SiH3)2 + 4 N2H5I

Many such compounds have been prepared, the only known restriction

being that the nitrogen is always tertiary, and species containing the

SiH–NH group are unstable at room temperature. The stoichiometry around

the nitrogen atom in compounds such as N(SiH

3)

3is planar, which has been attributed to a p

π–d

π interaction between a lone pair on nitrogen and an empty d

π orbital on silicon. Similarly, trisilylamines are weaker as ligands than their carbon analogues, the tertiary

amines, although substitution of some SiH

3 groups by CH

3 groups mitigates this weakness. Thus, for example, N(SiH

3)

3 does not form an

adduct with

BH3 at all, while MeN(SiH

3)

2 and Me

2NSiH

3 form adducts at low temperatures that decompose upon warming. Some silicon analogues of

imines, with a Si=N double bond, are known: the first found was Bu

t2Si=N–SiBu

t3, which was discovered in 1986.

[50]

Silicon carbide (SiC) was first made by

Edward Goodrich Acheson in 1891, who named it carborundum to reference its intermediate hardness and abrasive power between

diamond (an allotrope of carbon) and

corundum (

aluminium oxide). He soon founded a company to manufacture it, and today about one million tonnes are produced each year.

[51] Silicon carbide exists in about 250 crystalline forms.

[52]

The polymorphism of SiC is characterized by a large family of similar

crystalline structures called polytypes. They are variations of the same

chemical compound that are identical in two dimensions and differ in

the third. Thus, they can be viewed as layers stacked in a certain

sequence.

[53] It is made industrially by reduction of quartz sand with excess coke or anthracite at 2000–2500 °C in an electric furnace:

[51]

- SiO2 + 2 C → Si + 2 CO

- Si + C → SiC

It is the most thermally stable binary silicon compound, only

decomposing through loss of silicon starting from around 2700 °C. It is

resistant to most aqueous acids,

phosphoric acid being an exception. It forms a protective layer of

silicon dioxide

on the surface and hence only oxidises appreciably in air above

1000 °C; removal of this layer by molten hydroxides or carbonates leads

to quick oxidation. Silicon carbide is rapidly attacked by chlorine gas,

which forms SiCl

4 and carbon at 100 °C and SiCl

4 and

CCl4

at 1000 °C. It is mostly used as an abrasive and a refractory materia,

as it is chemically stable and very strong, and it fractures to form a

very sharp cutting edge. It is also useful as an intrinsic

semiconductor, as well as an extrinsic semiconductor upon being doped.

[51] In its diamond-like behaviour it serves as an illustration of the chemical similarity between carbon and silicon.

[54]

Organosilicon compounds

A hydrosilylation reaction, in which Si–H is added to an unsaturated substrate

Because the Si–C bond is close in strength to the C–C bond,

organosilicon compounds tend to be markedly thermally and chemically

stable. For example,

tetraphenylsilane (SiPh

4) may be distilled in air even at its boiling point of 428 °C, and so can its substituted derivatives Ph

3SiCl and Ph

2SiCl

2,

which boil at 378 °C and 305 °C respectively. Furthermore, since carbon

and silicon are chemical congeners, organosilicon chemistry shows some

significant similarities with carbon chemistry, for example in the

propensity of such compounds for catenation and forming multiple bonds.

[54] However, significant differences also arise: since silicon is more

electropositive than carbon, bonds to more electronegative elements are

generally stronger with silicon than with carbon, and vice versa. Thus

the Si–F bond is significantly stronger than even the

C–F bond

and is one of the strongest single bonds, while the Si–H bond is much

weaker than the C–H bond and is readily broken. Furthermore, the ability

of silicon to expand its octet is not shared by carbon, and hence some

organosilicon reactions have no organic analogues. For example,

nucleophilic attack on silicon does not proceed by the

SN2 or

SN1

processes, but instead goes through a negatively charged true

pentacoordinate intermediate and appears like a substitution at a

hindered tertiary atom. This works for silicon, unlike for carbon,

because the long Si–C bonds reduce the steric hindrance and the

d-orbital of silicon is geometrically unconstrained for nucleophilic

attack, unlike for example a C–O σ* antibonding orbital. Nevertheless,

despite these differences, the mechanism is still often called "S

N2 at silicon" for simplicity.

[55]

One of the most useful silicon-containing groups is

trimethylsilyl, Me

3Si–.

The Si–C bond connecting it to the rest of the molecule is reasonably

strong, allowing it to remain while the rest of the molecule undergoes

reactions, but is not so strong that it cannot be removed specifically

when needed, for example by the

fluoride

ion, which is a very weak nucleophile for carbon compounds but a very

strong one for organosilicon compounds. It may be compared to acidic

protons;

while trisilylmethyl is removed by hard nucleophiles instead of bases,

both removals usually promote elimination. As a general rule, while

saturated carbon is best attacked by nucleophiles that are neutral

compounds, those based on nonmetals far down on the periodic table (e.g.

sulfur,

selenium, or

iodine),

or even both, silicon is best attacked by charged nucleophiles,

particularly those involving such highly electronegative nonmetals as

oxygen, fluorine, or chlorine. For example, enolates react at the carbon

in

haloalkanes, but at the oxygen in

silyl

chlorides; and when trimethylsilyl is removed from an organic molecule

using hydroxide as a nucleophile, the product of the reaction is not the

silanol as one would expect from using carbon chemistry as an analogy,

because the siloxide is strongly nucleophilic and attacks the original

molecule to yield the

silyl ether hexamethyldisiloxane, (Me

3Si)

2O. Conversely, while the S

N2 reaction is mostly unaffected by the presence of a partial positive charge (δ+) at the carbon, the analogous "S

N2" reaction at silicon is so affected. Thus, for example, the silyl

triflates are so electrophilic that they react 10

8 to 10

9 times faster than silyl chlorides with oxygen-containing nucleophiles.

Trimethylsilyl triflate is in particular a very good

Lewis acid and is used to convert

carbonyl compounds to

acetals and

silyl enol ethers, reacting them together analogously to the

aldol reaction.

[55]

Si–C bonds are commonly formed in three ways. In the laboratory,

preparation is often carried out in small quantities by reacting

tetrachlorosilane with

organolithium,

Grignard, or

organoaluminium

reagents, or by catalytic addition of Si–H across C=C double bonds. The

second route has the drawback of not being applicable to the most

important silanes, the methyl and phenyl silanes. Organosilanes are made

industrially by directly reacting alkyl or aryl halides with silicon

with 10% by weight metallic

copper

as a catalyst. Standard organic reactions suffice to produce many

derivatives; the resulting organosilanes are often significantly more

reactive than their carbon congeners, readily undergoing hydrolysis,

ammonolysis, alcoholysis, and condensation to form cyclic oligomers or

linear polymers.

[54]

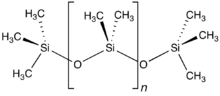

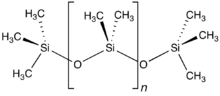

Silicone polymers

The word "silicone" was first used by

Frederick Kipping in 1901. He invented the word to illustrate the similarity of chemical formulae between Ph

2SiO and

benzophenone, Ph

2CO, although he also stressed the lack of chemical resemblance due to the polymeric structure of Ph

2SiO, which is not shared by Ph

2CO.

[54]

Silicones may be considered analogous to mineral silicates, in which the methyl groups of the silicones correspond to the

isoelectronic O

− of the silicates.

[54]

They are quite stable to extreme temperatures, oxidation, and water,

and have useful dielectric, antistick, and antifoam properties.

Furthermore, they are resistant over long periods of time to ultraviolet

radiation and weathering, and are inert physiologically. They are

fairly unreactive, but do react with concentrated solutions bearing the

hydroxide ion and fluorinating agents, and occasionally can be even used

as mild reagents for selective syntheses. For example, (Me

3Si)

2O is valuable for the preparation of derivatives of

molybdenum and

tungsten oxyhalides, converting a

tungsten hexachloride suspension in

dichloroethane solution quantitatively to WOCl

4 in under an hour at room temperature, and then to yellow WO

2Cl

2 at 100 °C in light petroleum at a yield of 95% overnight.

[54]

Occurrence

In the universe, silicon is the seventh most abundant element, coming after

hydrogen,

helium,

carbon,

nitrogen,

oxygen, and

neon.

These abundances are not replicated well on Earth due to substantial

separation of the elements taking place during the formation of the

Solar System.

Silicon makes up 27.2% of the Earth's crust by weight, second only to

oxygen at 45.5%, with which it is always associated in nature. Further

fractionation took place in the formation of the Earth by

planetary differentiation:

Earth's core, which makes up 31.5% of the mass of the Earth, has approximate composition Fe

25Ni

2Co

0.1S

3; the

mantle makes up 68.1% of the Earth's mass and is composed mostly of denser oxides and silicates, an example being

olivine, (Mg,Fe)

2SiO

4; while the lighter siliceous minerals such as

aluminosilicates rise to the surface and form the crust, making up 0.4% of the Earth's mass.

[56]

The crystallisation of

igneous rocks

from magma depends on a number of factors; among them are the chemical

composition of the magma, the cooling rate, and some properties of the

individual minerals to be formed, such as

lattice energy, melting point, and complexity of their crystal structure. As magma is cooled,

olivine appears first, followed by

pyroxene,

amphibole,

biotite mica,

orthoclase feldspar,

muscovite mica,

quartz,

zeolites,

and finally hydrothermal minerals. This sequence shows a trend towards

increasingly complex silicate units with cooling, and the introduction

of

hydroxide and

fluoride anions in addition to oxides. Many metals can substitute for silicon. After these igneous rocks undergo

weathering, transport, and deposition,

sedimentary rocks like clay, shale, and sandstone are formed.

Metamorphism also can occur at high temperatures and pressures, creating an even vaster variety of minerals.

[56]

Production

Silicon of 96–99% purity is made by reducing

quartzite or sand with highly pure

coke. The reduction is carried out in an

electric arc furnace, with an excess of SiO

2 used to stop

silicon carbide (SiC) from accumulating:

[30]

- SiO2 + 2 C → Si + 2 CO

- 2 SiC + SiO2 → 3 Si + 2 CO

This reaction, known as carbothermal reduction of silicon dioxide, is

usually conducted in the presence of scrap iron with low amounts of

phosphorus and

sulfur, produing

ferrosilicon.

[30] Ferrosilicon, an iron-silicon alloy that contains varying ratios of

elemental silicon and iron, accounts for about 80% of the world's

production of elemental silicon, with China, the leading supplier of

elemental silicon, providing 4.6 million

tonnes

(or 2/3 of the world output) of silicon, most of which is in the form

of ferrosilicon. It is followed by Russia (610,000 t), Norway (330,000

t), Brazil (240,000 t) and the United States (170,000 t).

[57]

Ferrosilicon is primarily used by the iron and steel industry (see

below) with primary use as alloying addition in iron or steel and for

de-oxidation of steel in integrated steel plants.

[30] Another sometimes used reaction is aluminothermal reduction of silicon dioxide, as follows:

[58]

- 3 SiO2 + 4 Al → 3 Si + 2 Al2O3

Leaching powdered 96–97% pure silicon with water results in ~98.5%

pure silicon, which is used in the chemical industry. However, even

greater purity is needed for semiconductor applications, and this is

produced from the reduction of tetrachlorosilane or trichlorosilane. The

former is made by chlorinating scrap silicon and the latter is a

byproduct of

silicone production. These compounds are volatile and hence can be purified by repeated

fractional distillation, followed by reduction to elemental silicon with very pure

zinc

metal as the reducing agent. The spongy pieces of silicon thus produced

are melted and then grown to form cylindrical single crystals, before

being purified by

zone refining. Other routes use the thermal decomposition of silane or tetraiodosilane. Another process used is the reduction of

sodium hexafluorosilicate, a common waste product of the phosphate fertiliser industry, by metallic

sodium:

this is highly exothermic and hence requires no outside fuel source.

Hyperfine silicon is made at a higher purity than almost every other

material:

transistor production requires impurity levels in silicon crystals less than 1 part per 10

10, and in special cases impurity levels below 1 part per 10

12 are needed and attained.

[30]

Applications

Compounds

Most silicon is used industrially without being purified, and indeed

often with comparatively little processing from its natural form. Over

90% of the Earth's crust is composed of

silicate minerals,

which are compounds of silicon and oxygen, often with metallic ions

when negatively charged silicate anions require cations to balance the

charge. Many of these have direct commercial uses, such as clays,

silica

sand and most kinds of building stone. Thus, the vast majority of uses

for silicon are as structural compounds, either as the silicate minerals

or silica (crude silicon dioxide). Silicates are used in making

Portland cement (made mostly of calcium silicates) which is used in

building mortar and modern

stucco, but more importantly, combined with silica sand, and gravel (usually containing silicate minerals like granite), to make the

concrete that is the basis of most of the very largest industrial building projects of the modern world.

[59]

Silica is used to make

fire brick, a type of ceramic. Silicate minerals are also in whiteware

ceramics, an important class of products usually containing various types of fired

clay minerals (natural aluminium phyllosilicates). An example is

porcelain which is based on the silicate mineral

kaolinite. Traditional

glass (silica-based

soda-lime glass) also functions in many of the same ways, and is also used for windows and containers. In addition, specialty silica based

glass fibers are used for

optical fiber, as well as to produce

fiberglass for structural support and

glass wool for thermal insulation.

Silicones are often used in

waterproofing treatments,

molding compounds, mold-

release agents, mechanical seals, high temperature

greases and waxes, and

caulking compounds. Silicone is also sometimes used in

breast implants, contact lenses,

explosives and

pyrotechnics.

[60] Silly Putty was originally made by adding

boric acid to

silicone oil.

[61] Other silicon compounds function as high-technology abrasives and new high-strength ceramics based upon

silicon carbide. Silicon is a component of some

superalloys.

Alloys

Elemental silicon is added to molten

cast iron as

ferrosilicon or silicocalcium alloys to improve performance in casting thin sections and to prevent the formation of

cementite

where exposed to outside air. The presence of elemental silicon in

molten iron acts as a sink for oxygen, so that the steel carbon content,

which must be kept within narrow limits for each type of steel, can be

more closely controlled. Ferrosilicon production and use is a monitor of

the steel industry, and although this form of elemental silicon is

grossly impure, it accounts for 80% of the world's use of free silicon.

Silicon is an important constituent of

electrical steel, modifying its

resistivity and

ferromagnetic properties.

The properties of silicon can be used to modify alloys with metals

other than iron. "Metallurgical grade" silicon is silicon of 95–99%

purity. About 55% of the world consumption of metallurgical purity

silicon goes for production of aluminium-silicon alloys (

silumin alloys) for aluminium part

casts, mainly for use in the

automotive industry. Silicon's importance in aluminium casting is that a significantly high amount (12%) of silicon in aluminium forms a

eutectic mixture

which solidifies with very little thermal contraction. This greatly

reduces tearing and cracks formed from stress as casting alloys cool to

solidity. Silicon also significantly improves the hardness and thus

wear-resistance of aluminium.

[62][63]

Electronics

Silicon wafer with mirror finish

Most elemental silicon produced remains as a ferrosilicon alloy, and

only about 20% is refined to metallurgical grade purity (a total of

1.3–1.5 million metric tons/year). An estimated 15% of the world

production of metallurgical grade silicon is further refined to

semiconductor purity.

[63] This typically is the "nine-9" or 99.9999999% purity

[64] nearly defect-free single

crystalline material.

[65]

Monocrystalline silicon of such purity is usually produced by the

Czochralski process, is used to produce

silicon wafers used in the

semiconductor industry, in electronics, and in some high-cost and high-efficiency

photovoltaic applications.

[66] Pure silicon is an

intrinsic semiconductor, which means that unlike metals, it conducts

electron holes and electrons released from atoms by heat; silicon's

electrical conductivity increases with higher temperatures. Pure silicon has too low a conductivity (i.e., too high a

resistivity) to be used as a circuit element in electronics. In practice, pure silicon is

doped

with small concentrations of certain other elements, which greatly

increase its conductivity and adjust its electrical response by

controlling the number and charge (

positive or

negative) of activated carriers. Such control is necessary for

transistors,

solar cells,

semiconductor detectors, and other

semiconductor devices used in the computer industry and other technical applications.

[67] In

silicon photonics, silicon can be used as a continuous wave

Raman laser medium to produce coherent light.

[68]

In common

integrated circuits,

a wafer of monocrystalline silicon serves as a mechanical support for

the circuits, which are created by doping and insulated from each other

by thin layers of

silicon oxide,

an insulator that is easily produced by exposing the element to oxygen

under the proper conditions. Silicon has become the most popular

material for both high power semiconductors and integrated circuits

because it can withstand the highest temperatures and greatest

electrical activity without suffering

avalanche breakdown (an

electron avalanche

is created when heat produces free electrons and holes, which in turn

pass more current, which produces more heat). In addition, the

insulating oxide of silicon is not soluble in water, which gives it an

advantage over

germanium (an element with similar properties which can also be used in semiconductor devices) in certain fabrication techniques.

[69]

Monocrystalline silicon is expensive to produce, and is usually

justified only in production of integrated circuits, where tiny crystal

imperfections can interfere with tiny circuit paths. For other uses,

other types of pure silicon may be employed. These include

hydrogenated amorphous silicon and upgraded metallurgical-grade silicon (UMG-Si) used in the production of low-cost,

large-area electronics in applications such as

liquid crystal displays and of large-area, low-cost, thin-film

solar cells.

Such semiconductor grades of silicon are either slightly less pure or

polycrystalline rather than monocrystalline, and are produced in

comparable quatities as the monocrystalline silicon: 75,000 to 150,000

metric tons per year. The market for the lesser grade is growing more

quickly than for monocrystalline silicon. By 2013, polycrystalline

silicon production, used mostly in solar cells, was projected to reach

200,000 metric tons per year, while monocrystalline semiconductor grade

silicon was expected to remain less than 50,000 tons/year.

[63]

Biological role

A diatom, enclosed in a silica cell wall

Although silicon is readily available in the form of

silicates, very few organisms use it directly.

Diatoms,

radiolaria and

siliceous sponges use

biogenic silica as a structural material for skeletons. In more advanced plants, the silica

phytoliths (opal phytoliths) are rigid microscopic bodies occurring in the cell; some plants, for example

rice, need silicon for their growth.

[70][71][72] There is some evidence that silicon is important to nail, hair, bone and skin health in humans,

[73] for example in studies that show that premenopausal women with higher dietary silicon intake have higher

bone density, and that silicon supplementation can increase bone volume and density in patients with

osteoporosis.

[74] Silicon is needed for synthesis of

elastin and

collagen, of which the

aorta contains the greatest quantity in the human body

[75] and has been considered an

essential element;

[76]

nevertheless, it is difficult to prove its essentiality, because

silicon is very common and hence deficiency symptoms are difficult to

reproduce.

[77]

Silicon is currently under consideration for elevation to the status

of a "plant beneficial substance by the Association of American Plant

Food Control Officials (AAPFCO)."

[78][79] Silicon has been shown to improve plant cell wall strength and structural integrity in some plants.

[80]

Safety

People can be exposed to elemental silicon in the workplace by

breathing it in, swallowing it, skin contact, and eye contact. In the

latter two cases, silicon poses a slight hazard as an irritant; it is

hazardous if inhaled.

[81] The

Occupational Safety and Health Administration (OSHA) has set the legal limit (

Permissible exposure limit) for silicon exposure in the workplace as 15 mg/m

3 total exposure and 5 mg/m

3 respiratory exposure over an 8-hour workday. The

National Institute for Occupational Safety and Health (NIOSH) has set a

Recommended exposure limit (REL) of 10 mg/m

3 total exposure and 5 mg/m

3 respiratory exposure over an 8-hour workday.

[82] Inhalation of

crystalline silica dust may lead to

silicosis, an

occupational lung disease marked by

inflammation and scarring in the form of

nodular lesions in the upper lobes of the

lungs.

[83]