From Wikipedia, the free encyclopedia

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| General properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name, symbol | arsenic, As | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pronunciation | /ˈɑrsɨnɪk/, also /ɑrˈsɛnɪk/ when attributive AR-sə-nik, ar-SEN-ik |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Appearance | metallic grey | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Arsenic in the periodic table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic number | 33 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight | 74.921595(6) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element category | metalloid | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Group, block | group 15 (pnictogens), p-block | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Period | period 4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electron configuration | [Ar] 3d10 4s2 4p3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| per shell | 2, 8, 18, 5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Physical properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Phase | solid | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sublimation point | 887 K (615 °C, 1137 °F) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Density near r.t. | 5.727 g·cm−3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| liquid, at m.p. | 5.22 g·cm−3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Triple point | 1090 K, 3628 kPa[1] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Critical point | 1673 K, ? MPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of fusion | (grey) 24.44 kJ·mol−1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of vaporization | ? 34.76 kJ·mol−1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Molar heat capacity | 24.64 J·mol−1·K−1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

vapor pressure

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Oxidation states | 5, 3, 2, 1,[2] −3 (a mildly acidic oxide) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electronegativity | Pauling scale: 2.18 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ionization energies | 1st: 947.0 kJ·mol−1 2nd: 1798 kJ·mol−1 3rd: 2735 kJ·mol−1 (more) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic radius | empirical: 119 pm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Covalent radius | 119±4 pm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Van der Waals radius | 185 pm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Miscellanea | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Crystal structure | trigonal[3]

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal conductivity | 50.2 W·m−1·K−1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electrical resistivity | 333 nΩ·m (at 20 °C) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Magnetic ordering | diamagnetic[4] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Young's modulus | 8 GPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bulk modulus | 22 GPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mohs hardness | 3.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brinell hardness | 1440 MPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CAS Registry Number | 7440-38-2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Discovery | Early Bronze Age (2500 BC) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| First isolation | Albertus Magnus (1250) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Most stable isotopes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Arsenic is a chemical element with symbol As and atomic number 33. Arsenic occurs in many minerals, usually in conjunction with sulfur and metals, and also as a pure elemental crystal. Arsenic is a metalloid. It can exist in various allotropes, although only the gray form has important use in industry.

The main use of metallic arsenic is for strengthening alloys of copper and especially lead (for example, in car batteries). Arsenic is a common n-type dopant in semiconductor electronic devices, and the optoelectronic compound gallium arsenide is the most common semiconductor in use after doped silicon. Arsenic and its compounds, especially the trioxide, are used in the production of pesticides, treated wood products, herbicides, and insecticides. These applications are declining, however.[5]

A few species of bacteria are able to use arsenic compounds as respiratory metabolites. Experimentally, tiny quantities of arsenic are an essential dietary element in the rat, hamster, goat, chicken, and presumably many other species, including humans. However, the element often causes toxicity to multicellular life due to its presence in quantities far larger than needed. Arsenic contamination of groundwater is a problem that affects millions of people across the world.

Characteristics

Physical characteristics

The three most common arsenic allotropes are metallic gray, yellow, and black arsenic, with gray being the most common.[6] Gray arsenic (α-As, space group R3m No. 166) adopts a double-layered structure consisting of many interlocked, ruffled, six-membered rings. Because of weak bonding between the layers, gray arsenic is brittle and has a relatively low Mohs hardness of 3.5. Nearest and next-nearest neighbors form a distorted octahedral complex, with the three atoms in the same double-layer being slightly closer than the three atoms in the next.[7] This relatively close packing leads to a high density of 5.73 g/cm3.[8] Gray arsenic is a semimetal, but becomes a semiconductor with a bandgap of 1.2–1.4 eV if amorphized.[9] Gray arsenic is also the most stable form. Yellow arsenic is soft and waxy, and somewhat similar to tetraphosphorus (P

4). Both have four atoms arranged in a tetrahedral structure in which each atom is bound to each of the other three atoms by a single bond. This unstable allotrope, being molecular, is the most volatile, least dense, and most toxic. Solid yellow arsenic is produced by rapid cooling of arsenic vapor, As

4. It is rapidly transformed into the gray arsenic by light. The yellow form has a density of 1.97 g/cm3.[8] Black arsenic is similar in structure to red phosphorus.[8] Black arsenic can also be formed by cooling vapor at around 100–220 °C. It is glassy and brittle. It is also a poor electrical conductor.[10]

Isotopes

Naturally occurring arsenic is composed of one stable isotope, 75As.[11] This makes it a monoisotopic element. As of 2003, at least 33 radioisotopes have also been synthesized, ranging in atomic mass from 60 to 92. The most stable of these is 73As with a half-life of 80.30 days. All other isotopes have half-lives of under one day, with the exception of 71As (t1/2=65.30 hours), 72As (t1/2=26.0 hours), 74As (t1/2=17.77 days), 76As (t1/2=1.0942 days), and 77As (t1/2=38.83 hours). Isotopes that are lighter than the stable 75As tend to decay by β+ decay, and those that are heavier tend to decay by β− decay, with some exceptions.At least 10 nuclear isomers have been described, ranging in atomic mass from 66 to 84. The most stable of arsenic's isomers is 68mAs with a half-life of 111 seconds.[11]

Chemistry

When heated in air, arsenic oxidizes to arsenic trioxide; the fumes from this reaction have an odor resembling garlic. This odor can be detected on striking arsenide minerals such as arsenopyrite with a hammer. Arsenic (and some arsenic compounds) sublimes upon heating at atmospheric pressure, converting directly to a gaseous form without an intervening liquid state at 887 K (614 °C).[1] The triple point is 3.63 MPa and 1,090 K (820 °C).[8][1] Arsenic makes arsenic acid with concentrated nitric acid, arsenious acid with dilute nitric acid, and arsenic trioxide with concentrated sulfuric acid.[12]Compounds

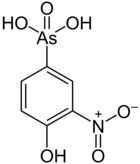

Arsenic compounds resemble in some respects those of phosphorus which occupies the same group (column) of the periodic table. Arsenic is less commonly observed in the pentavalent state, however. The most common oxidation states for arsenic are: −3 in the arsenides, such as alloy-like intermetallic compounds; and +3 in the arsenites, arsenates(III), and most organoarsenic compounds.

Arsenic also bonds readily to itself as seen in the square As3−

4 ions in the mineral skutterudite.[13] In the +3 oxidation state, arsenic is typically pyramidal owing to the influence of the lone pair of electrons.[6]

The protonation steps between the arsenate and arsenic acid are similar to those between phosphate and phosphoric acid. Unlike phosphorous acid, arsenous acid is genuinely tribasic, with the formula As(OH)3.

A broad variety of sulfur compounds of arsenic are known. Orpiment (As2S3) and realgar (As4S4) are somewhat abundant and were formerly used as painting pigments. In As4S10, arsenic has a formal oxidation state of +2 in As4S4 which features As-As bonds so that the total covalency of As is still 3.[14]

All trihalides of arsenic(III) are well known except the astatide which is unknown. Arsenic pentafluoride (AsF5) is the only important pentahalide, reflecting the lower stability of the 5+ oxidation state. (pentachloride is stable only below −50 °C.[8])

A large variety of organoarsenic compounds are known. Several were developed as chemical warfare agents during World War I, including vesicants such as lewisite and vomiting agents such as adamsite.[18][19][20] Cacodylic acid, which is of historic and practical interest, arises from the methylation of arsenic trioxide, a reaction that has no analogy in phosphorus chemistry.

Arsenic makes up about 1.5 ppm (0.00015%) of the Earth's crust, making it the 53rd most abundant element. Soil contains 1–10 ppm of arsenic. Seawater has only 1.6 ppb arsenic.[21]

Minerals with the formula MAsS and MAs2 (M = Fe, Ni, Co) are the dominant commercial sources of arsenic, together with realgar (an arsenic sulfide mineral) and native arsenic. An illustrative mineral is arsenopyrite (FeAsS), which is structurally related to iron pyrite. Many minor As-containing minerals are known. Arsenic also occurs in various organic forms in the environment.[22]

In 2005, China was the top producer of white arsenic with almost 50% world share, followed by Chile, Peru, and Morocco, according to the British Geological Survey and the United States Geological Survey.[23] Most operations in the US and Europe have closed for environmental reasons. The arsenic is recovered mainly as a side product from the purification of copper. Arsenic is part of the smelter dust from copper, gold, and lead smelters.[24]

On roasting in air of arsenopyrite, arsenic sublimes as arsenic(III) oxide leaving iron oxides,[22] while roasting without air results in the production of metallic arsenic. Further purification from sulfur and other chalcogens is achieved by sublimation in vacuum or in a hydrogen atmosphere or by distillation from molten lead-arsenic mixture.[25]

The word arsenic has its origin in the Syriac word ܠܐ ܙܐܦܢܝܐ (al) zarniqa,[27] from the Persian word زرنيخ zarnikh, meaning "yellow" (literally "gold-colored") and hence "(yellow) orpiment". It was adopted into Greek as arsenikon (ἀρσενικόν), a form that is folk etymology, being the neuter form of the Greek word arsenikos (ἀρσενικός), meaning "male", "virile". The Greek word was adopted in Latin as arsenicum, which in French became arsenic, from which the English word arsenic is taken.[27] Arsenic sulfides (orpiment, realgar) and oxides have been known and used since ancient times.[28] Zosimos (circa 300 AD) describes roasting sandarach (realgar) to obtain cloud of arsenic (arsenious oxide), which he then reduces to metallic arsenic.[29] As the symptoms of arsenic poisoning were somewhat ill-defined, it was frequently used for murder until the advent of the Marsh test, a sensitive chemical test for its presence. (Another less sensitive but more general test is the Reinsch test.) Owing to its use by the ruling class to murder one another and its potency and discreetness, arsenic has been called the "poison of kings" and the "king of poisons".[30]

During the Bronze Age, arsenic was often included in bronze, which made the alloy harder (so-called "arsenical bronze").[31][32] Albertus Magnus (Albert the Great, 1193–1280) is believed to have been the first to isolate the element from a compound in 1250, by heating soap together with arsenic trisulfide.[33] In 1649, Johann Schröder published two ways of preparing arsenic.[34] Crystals of elemental (native) arsenic are found in nature, although rare.

Cadet's fuming liquid (impure cacodyl), often claimed as the first synthetic organometallic compound, was synthesized in 1760 by Louis Claude Cadet de Gassicourt by the reaction of potassium acetate with arsenic trioxide.[35]

In the Victorian era, "arsenic" ("white arsenic" or arsenic trioxide) was mixed with vinegar and chalk and eaten by women to improve the complexion of their faces, making their skin paler to show they did not work in the fields. Arsenic was also rubbed into the faces and arms of women to "improve their complexion". The accidental use of arsenic in the adulteration of foodstuffs led to the Bradford sweet poisoning in 1858, which resulted in around 20 deaths.[36]

Two pigments based on arsenic have been widely used since their discovery – Paris Green and Scheele's Green. After arsenic's toxicity became widely known, they were less often used as pigments, so these compounds were more often used as insecticides. In the 1860s, an arsenic byproduct of dye production, London Purple – a solid consisting of a mixture of arsenic trioxide, aniline, lime, and ferrous oxide, which is insoluble in water and very toxic by inhalation and ingestion[37] – was widely used, but Paris Green, another arsenic-based dye, was later substituted for it.[38] With better understanding of the toxicology mechanism, two other compounds were used starting in the 1890s.[39] Arsenite of lime and arsenate of lead were used widely as insecticides until the discovery of DDT in 1942.[40][41][42]

The toxicity of arsenic to insects, bacteria, and fungi led to its use as a wood preservative.[43] In the 1950s, a process of treating wood with chromated copper arsenate (also known as CCA or Tanalith) was invented, and for decades, this treatment was the most extensive industrial use of arsenic. An increased appreciation of the toxicity of arsenic resulted in a ban for the use of CCA in consumer products; the European Union and United States initiated this process in 2004.[44][45] CCA remains in heavy use in other countries, however, e.g. Malaysian rubber plantations.[5]

Arsenic was also used in various agricultural insecticides and poisons. For example, lead hydrogen arsenate was a common insecticide on fruit trees,[46] but contact with the compound sometimes resulted in brain damage among those working the sprayers. In the second half of the 20th century, monosodium methyl arsenate (MSMA) and disodium methyl arsenate (DSMA) – less- toxic organic forms of arsenic – have replaced lead arsenate in agriculture. With the exception of cotton farming, the use of the organic arsenicals was phased out until 2013.[47]

Arsenic is used as a feed additive in poultry and swine production, in particular in the U.S. to increase weight gain, improve feed efficiency, and to prevent disease.[48][49] An example is roxarsone, which had been used as a broiler starter by about 70% of U.S. broiler growers.[50] The Poison-Free Poultry Act of 2009 proposed to ban the use of roxarsone in industrial swine and poultry production.[51] Alpharma, a subsidiary of Pfizer Inc., which produces roxarsone, voluntarily suspended sales of the drug in response to studies showing elevated levels of inorganic arsenic, a carcinogen, in treated chickens.[52] A successor to Alpharma, Zoetis, continues to sell nitarsone, primarily for use in turkeys.[52]

Arsphenamine, as well as neosalvarsan, was indicated for syphilis and trypanosomiasis, but has been superseded by modern antibiotics.

Arsenic trioxide has been used in a variety of ways over the past 500 years, most commonly in the treatment of cancer, but in medications as diverse as Fowler's solution in psoriasis.[54] The US Food and Drug Administration in the year 2000 approved this compound for the treatment of patients with acute promyelocytic leukemia that is resistant to all-trans retinoic acid.[55]

Recently, new research has been done in locating tumors using arsenic-74 (a positron emitter). The advantages of using this isotope instead of the previously used iodine-124 is that the signal in the PET scan is clearer as the body tends to transport iodine to the thyroid gland producing signal noise.[56]

In subtoxic doses, soluble arsenic compounds act as stimulants, and were once popular in small doses as medicine by people in the mid-18th to 19th centuries.[8]

Some species of bacteria obtain their energy by oxidizing various fuels while reducing arsenate to arsenite. Under oxidative environmental conditions some bacteria use arsenite, which is oxidized to arsenate as fuel for their metabolism.[68] The enzymes involved are known as arsenate reductases (Arr).[69]

In 2008, bacteria were discovered that employ a version of photosynthesis in the absence of oxygen with arsenites as electron donors, producing arsenates (just as ordinary photosynthesis uses water as electron donor, producing molecular oxygen). Researchers conjecture that, over the course of history, these photosynthesizing organisms produced the arsenates that allowed the arsenate-reducing bacteria to thrive. One strain PHS-1 has been isolated and is related to the gammaproteobacterium Ectothiorhodospira shaposhnikovii. The mechanism is unknown, but an encoded Arr enzyme may function in reverse to its known homologues.[70]

Although the arsenate and phosphate anions are similar structurally, no evidence exists for the replacement of phosphate in ATP or nucleic acids by arsenic.[71][72]

The Chinese brake fern (Pteris vittata) hyperaccumulates arsenic present in the soil into its leaves and has a proposed use in phytoremediation.[76]

In the United States, arsenic is most commonly found in the ground waters of the southwest.[88] Parts of New England, Michigan, Wisconsin, Minnesota and the Dakotas are also known to have significant concentrations of arsenic in ground water.[89] Increased levels of skin cancer have been associated with arsenic exposure in Wisconsin, even at levels below the 10 part per billion drinking water standard.[90] According to a recent film funded by the US Superfund, millions of private wells have unknown arsenic levels, and in some areas of the US, over 20% of wells may contain levels that exceed established limits.[91]

Low-level exposure to arsenic at concentrations of 100 parts per billion (i.e., above the 10 parts per billion drinking water standard) compromises the initial immune response to H1N1 or swine flu infection according to NIEHS-supported scientists. The study, conducted in laboratory mice, suggests that people exposed to arsenic in their drinking water may be at increased risk for more serious illness or death in response to infection from the virus.[92]

Some Canadians are drinking water that contains inorganic arsenic. Private dug well waters are most at risk for containing inorganic arsenic. Preliminary well water analyses typically does not test for arsenic. Researchers at the Geological Survey of Canada have modelled relative variation in natural arsenic hazard potential for the province of New Brunswick. This study has important implications for potable water and health concerns relating to inorganic arsenic.[93]

Epidemiological evidence from Chile shows a dose-dependent connection between chronic arsenic exposure and various forms of cancer, in particular when other risk factors, such as cigarette smoking, are present. These effects have been demonstrated to persist below 50 ppb.[94]

Analyzing multiple epidemiological studies on inorganic arsenic exposure suggests a small but measurable risk increase for bladder cancer at 10 ppb.[95] According to Peter Ravenscroft of the Department of Geography at the University of Cambridge,[96] roughly 80 million people worldwide consume between 10 and 50 ppb arsenic in their drinking water. If they all consumed exactly 10 ppb arsenic in their drinking water, the previously cited multiple epidemiological study analysis would predict an additional 2,000 cases of bladder cancer alone. This represents a clear underestimate of the overall impact, since it does not include lung or skin cancer, and explicitly underestimates the exposure. Those exposed to levels of arsenic above the current WHO standard should weigh the costs and benefits of arsenic remediation.

Early (1973) evaluations of the removal of dissolved arsenic by drinking water treatment processes demonstrated that arsenic is very effectively removed by co-precipitation with either iron or aluminum oxides. The use of iron as a coagulant, in particular, was found to remove arsenic with efficiencies exceeding 90%.[97][98] Several adsorptive media systems have been approved for point-of-service use in a study funded by the United States Environmental Protection Agency (US EPA) and the National Science Foundation (NSF). A team of European and Indian scientists and engineers have set up six arsenic treatment plants in West Bengal based on in-situ remediation method (SAR Technology). This technology does not use any chemicals and arsenic is left as an insoluble form (+5 state) in the subterranean zone by recharging aerated water into the aquifer and thus developing an oxidation zone to support arsenic oxidizing micro-organisms. This process does not produce any waste stream or sludge and is relatively cheap.[99]

Another effective and inexpensive method to remove arsenic from contaminated well water is to sink wells 500 feet or deeper to reach purer waters. A recent 2011 study funded by the US National Institute of Environmental Health Sciences' Superfund Research Program shows that deep sediments can remove arsenic and take it out of circulation. Through this process called adsorption in which arsenic sticks to the surfaces of deep sediment particles, arsenic can be naturally removed from well water.[100]

Magnetic separations of arsenic at very low magnetic field gradients have been demonstrated in point-of-use water purification with high-surface-area and monodisperse magnetite (Fe3O4) nanocrystals. Using the high specific surface area of Fe3O4 nanocrystals the mass of waste associated with arsenic removal from water has been dramatically reduced.[101]

Epidemiological studies have suggested a correlation between chronic consumption of drinking water contaminated with arsenic and the incidence of all leading causes of mortality.[102] The literature provides reason to believe arsenic exposure is causative in the pathogenesis of diabetes.[103]

Hungarian engineer László Schremmer has recently discovered that by the use of chaff-based filters it is possible to reduce the arsenic content of water to 3 µg/L. This is especially important in areas where the potable water is provided by filtering the water extracted from the underground aquifer.[104]

Arsenic may be solubilized by various processes. When pH is high, arsenic may be released from surface binding sites that lose their positive charge. When water levels drops and sulfide minerals are exposed to air, arsenic trapped in sulfide minerals can be released into water. When organic carbon is present in water, bacteria are fed by directly reducing As(V) to As(III) or by reducing the element at the binding site attached there and releases arsenic.[109]

The aquatic transformations of As are affected by pH, reduction-oxidation potential, organic matter concentration and the concentrations and forms of other elements especially iron and manganese. The main factors are pH and the redox potential. Generally, the main forms of As under oxic conditions are H3AsO4, H2AsO4−, HAsO42−, and AsO43− at pH 2, 2-7, 7-11 and 11, respectively. Under reducing conditions, H3AsO4 is predominant at pH 2-9.[110]

The oxidation and reduction of arsenic affect its ability to migrate in subsurface environments. Arsenite is the most stable soluble form of arsenic in reducing environments and arsenate, which is less mobile than arsenite, is dominant in oxidizing environments at neutral pH. Therefore, arsenic may be more mobile under reducing conditions. The reducing environment is also rich in organic matter which may enhance the solubility of arsenic compounds. As a result, the adsorption of arsenic is reduced and dissolved arsenic accumulates in groundwater. That is why the arsenic content is higher in reducing environments than in oxidizing environments.[111]

The presence of sulfur is another factor that affects the transformation of arsenic in natural water. Arsenic can precipitate when metal sulfides form. In this way, arsenic is removed from the water and its mobility decreases. When oxygenis present, bacteria oxidize reduced sulfur to generate energy potentially releasing bound arsenic.

Redox reactions involving Fe also appear to be essential factors in the fate of arsenic in aquatic systems. The reduction of iron oxyhydroxides plays a key role in the release of As to water. So As can be enriched in water with elevated Fe concentrations.[112] Under oxidizing conditions, arsenic can be mobilized from pyrite or iron oxides especially at elevated pH. Under reducing conditions, arsenic can be mobilized by reductive desorption or dissolution when associated with iron oxides. The reductive desorption occurs under two circumstances. One is when arsenate is reduced to arsenite which adsorbs to iron oxides less strongly. The other results from a change in the charge on the mineral surface which leads to the desorption of bound arsenic.[113]

Some species of bacteria catalyze redox transformations of arsenic. Dissimilatory arsenate-respiring prokaryotes (DARP) speed up the reduction of As(V) to As(III). DARP use As(V) as the electron acceptor of anaerobic respiration and obtain energy to survive. Other organic and inorganic substances can be oxidized in this process. Chemoautotrophic arsenite oxidizers (CAO) and heterotrophic arsenite oxidizers (HAO) convert As(III) into As(V). CAO combine the oxidation of As(III) with the reduction of oxygen or nitrate. They use obtained energy to fix produce organic carbon from CO2. HAO cannot obtain energy from As(III) oxidation. This process may be an arsenic detoxification mechanism for the bacteria.[114]

Equilibrium thermodynamic calculations predict that As(V) concentrations should be greater than As(III) concentrations in all but strongly reducing conditions, i.e. where SO42− reduction is occurring. However, abiotic redox reactions of arsenic are slow. Oxidation of As(III) by dissolved O2 is a particularly slow reaction. For example, Johnson and Pilson (1975) gave half-lives for the oxygenation of As(III) in seawater ranging from several months to a year.[115] In other studies, As(V)/As(III) ratios were stable over periods of days or weeks during water sampling when no particular care was taken to prevent oxidation, again suggesting relatively slow oxidation rates. Cherry found from experimental studies that the As(V)/As(III) ratios were stable in anoxic solutions for up to 3 weeks but that gradual changes occurred over longer timescales.[116] Sterile water samples have been observed to be less susceptible to speciation changes than non-sterile samples.[117] Oremland found that the reduction of As(V) to As(III) in Mono Lake was rapidly catalyzed by bacteria with rate constants ranging from 0.02 to 0.3 day−1.[118]

Although discontinued, this application is also one of the most concern to the general public. The vast majority of older pressure-treated wood was treated with CCA. CCA lumber is still in widespread use in many countries, and was heavily used during the latter half of the 20th century as a structural and outdoor building material. Although the use of CCA lumber was banned in many areas after studies showed that arsenic could leach out of the wood into the surrounding soil (from playground equipment, for instance), a risk is also presented by the burning of older CCA timber. The direct or indirect ingestion of wood ash from burnt CCA lumber has caused fatalities in animals and serious poisonings in humans; the lethal human dose is approximately 20 grams of ash.[citation needed] Scrap CCA lumber from construction and demolition sites may be inadvertently used in commercial and domestic fires. Protocols for safe disposal of CCA lumber do not exist evenly throughout the world; there is also concern in some quarters about the widespread landfill disposal of such timber.

Arsenic is known to cause arsenicosis owing to its manifestation in drinking water, "the most common species being arsenate [HAsO2−

4; As(V)] and arsenite [H3AsO3; As(III)]".

In 2008, based on its ongoing testing of a wide variety of American foods for toxic chemicals,[130] the U.S. Food and Drug Administration set 23 ppb as the "level of concern" for inorganic arsenic apple and pear juices based on non-carcinogenic effects, and began refusing imports and demanding recalls for domestic products exceeding this level.[127] In 2011, the national Dr. Oz television show broadcast a program highlighting tests performed by an independent lab hired by the producers. Though the methodology was disputed (it did not distinguish between organic and inorganic arsenic) the tests showed levels of arsenic up to 36 ppb.[131] In response, FDA testing of the worst brand from the Oz show showed much lower levels, and its ongoing testing found 95% of apple juice samples were below the level of concern. Later testing by Consumer Reports showed inorganic arsenic at levels slightly above 10 ppb, with the organization urging parents to reduce consumption.[132] In July 2013, after taking into account consumption by children, chronic exposure, and carcinogenic effect, the FDA established an "action level" of 10 ppb for apple juice, the same as the drinking water standard.[127]

Concern about arsenic in rice in Bangladesh was raised in 2002, but at the time only Australia had a legal limit for the level found in food (one milligram per kilogram).[133][134] The People's Republic of China has a food standard of 150 ppb for arsenic, as of 2011.[135] Further concern was raised about people who were eating U.S. rice exceeding WHO standards for personal arsenic intake in 2005.[136]

In the United States in 2012, testing by separate groups of researchers at the Children's Environmental Health and Disease Prevention Research Center at Dartmouth College (early in the year, focusing on urinary levels in children)[137] and Consumer Reports (in November)[138][139] found levels of arsenic in rice which resulted in calls for the FDA to set limits.[128] The FDA released some testing results in September 2012,[140][141] and as of July 2013 is still collecting data in support of a new potential regulation. It has not recommended any changes in consumer behavior.[142] Consumer Reports recommended that the EPA and FDA eliminate arsenic-containing fertilizer, drugs, and pesticides in food production; that the FDA establish a legal limit for food; that industry change production practices to lower arsenic levels, especially in food for children; and that consumers test home water supplies, eat a varied diet, and cook rice with excess water which is drained off (reducing inorganic arsenic by about one third along with a slight reduction in vitamin content).[139] Evidence-based public health advocates also recommend that, given the lack of regulation or labeling for arsenic in the U.S., children should eat no more than 1 to 1.5 servings per week of rice and should not drink rice milk as part of their daily diet before age 5.[143] They also offer recommendations for adults and infants on how to limit arsenic exposure from rice, drinking water, and fruit juice.[143]

A 2014 World Health Organization advisory conference will consider limits of 200–300 ppb for rice.[139]

Arsenic disrupts ATP production through several mechanisms. At the level of the citric acid cycle, arsenic inhibits lipoic acid, which is a cofactor for pyruvate dehydrogenase. In addition, by competing with phosphate, arsenate uncouples oxidative phosphorylation, thus inhibiting energy-linked reduction of NAD+, mitochondrial respiration and ATP synthesis. Hydrogen peroxide production is also increased, which, it is speculated, has potential to form reactive oxygen species and oxidative stress. These metabolic interferences lead to death from multi-system organ failure. The organ failure is presumed to be from necrotic cell death, not apoptosis, since energy reserves have been too depleted for apoptosis to occur.[144]

Although arsenic causes toxicity, it can also play a protective role.[145]

The ability of arsenic to undergo redox conversion between As(III) and As(V) makes its availability in the environment more abundant. According to Croal, Gralnick, Malasarn and Newman, "[the] understanding [of] what stimulates As(III) oxidation and/or limits As(V) reduction is relevant for bioremediation of contaminated sites (Croal). The study of chemolithoautotrophic As(III) oxidizers and the heterotrophic As(V) reducers can help the understanding of the oxidation and/or reduction of arsenic.[147] It has been proposed that As (III) which is more toxic than Arsenic (V) can be removed from the ground water using baker's yeast Saccharomyces cerevisiae.[148]

4 ions in the mineral skutterudite.[13] In the +3 oxidation state, arsenic is typically pyramidal owing to the influence of the lone pair of electrons.[6]

Inorganic compounds

Arsenic forms colorless, odorless, crystalline oxides As2O3 ("white arsenic") and As2O5 which are hygroscopic and readily soluble in water to form acidic solutions. Arsenic(V) acid is a weak acid. Its salts are called arsenates which are the basis of arsenic contamination of groundwater, a problem that affects many people. Synthetic arsenates include Paris Green (copper(II) acetoarsenite), calcium arsenate, and lead hydrogen arsenate. These three have been used as agricultural insecticides and poisons.The protonation steps between the arsenate and arsenic acid are similar to those between phosphate and phosphoric acid. Unlike phosphorous acid, arsenous acid is genuinely tribasic, with the formula As(OH)3.

A broad variety of sulfur compounds of arsenic are known. Orpiment (As2S3) and realgar (As4S4) are somewhat abundant and were formerly used as painting pigments. In As4S10, arsenic has a formal oxidation state of +2 in As4S4 which features As-As bonds so that the total covalency of As is still 3.[14]

All trihalides of arsenic(III) are well known except the astatide which is unknown. Arsenic pentafluoride (AsF5) is the only important pentahalide, reflecting the lower stability of the 5+ oxidation state. (pentachloride is stable only below −50 °C.[8])

Alloys

Arsenic is used as the group 5 element in the III-V semiconductors gallium arsenide, indium arsenide, and aluminium arsenide.[15] The valence electron count of GaAs is the same as a pair of Si atoms, but the band structure is completely different which results distinct bulk properties.[16] Other arsenic alloys include the II-V semiconductor cadmium arsenide.[17]Organoarsenic compounds

A large variety of organoarsenic compounds are known. Several were developed as chemical warfare agents during World War I, including vesicants such as lewisite and vomiting agents such as adamsite.[18][19][20] Cacodylic acid, which is of historic and practical interest, arises from the methylation of arsenic trioxide, a reaction that has no analogy in phosphorus chemistry.

Occurrence and production

Arsenic makes up about 1.5 ppm (0.00015%) of the Earth's crust, making it the 53rd most abundant element. Soil contains 1–10 ppm of arsenic. Seawater has only 1.6 ppb arsenic.[21]

Minerals with the formula MAsS and MAs2 (M = Fe, Ni, Co) are the dominant commercial sources of arsenic, together with realgar (an arsenic sulfide mineral) and native arsenic. An illustrative mineral is arsenopyrite (FeAsS), which is structurally related to iron pyrite. Many minor As-containing minerals are known. Arsenic also occurs in various organic forms in the environment.[22]

In 2005, China was the top producer of white arsenic with almost 50% world share, followed by Chile, Peru, and Morocco, according to the British Geological Survey and the United States Geological Survey.[23] Most operations in the US and Europe have closed for environmental reasons. The arsenic is recovered mainly as a side product from the purification of copper. Arsenic is part of the smelter dust from copper, gold, and lead smelters.[24]

On roasting in air of arsenopyrite, arsenic sublimes as arsenic(III) oxide leaving iron oxides,[22] while roasting without air results in the production of metallic arsenic. Further purification from sulfur and other chalcogens is achieved by sublimation in vacuum or in a hydrogen atmosphere or by distillation from molten lead-arsenic mixture.[25]

| Country | 2012 AsO3 Production[26] |

|---|---|

| Belgium | 1,000 T |

| Chile | 10,000 T |

| China | 25,000 T |

| Morocco | 6,000 T |

| Russia | 1,500 T |

| Other Countries | 300 T |

| World Total | 44,000 T |

History

The word arsenic has its origin in the Syriac word ܠܐ ܙܐܦܢܝܐ (al) zarniqa,[27] from the Persian word زرنيخ zarnikh, meaning "yellow" (literally "gold-colored") and hence "(yellow) orpiment". It was adopted into Greek as arsenikon (ἀρσενικόν), a form that is folk etymology, being the neuter form of the Greek word arsenikos (ἀρσενικός), meaning "male", "virile". The Greek word was adopted in Latin as arsenicum, which in French became arsenic, from which the English word arsenic is taken.[27] Arsenic sulfides (orpiment, realgar) and oxides have been known and used since ancient times.[28] Zosimos (circa 300 AD) describes roasting sandarach (realgar) to obtain cloud of arsenic (arsenious oxide), which he then reduces to metallic arsenic.[29] As the symptoms of arsenic poisoning were somewhat ill-defined, it was frequently used for murder until the advent of the Marsh test, a sensitive chemical test for its presence. (Another less sensitive but more general test is the Reinsch test.) Owing to its use by the ruling class to murder one another and its potency and discreetness, arsenic has been called the "poison of kings" and the "king of poisons".[30]

During the Bronze Age, arsenic was often included in bronze, which made the alloy harder (so-called "arsenical bronze").[31][32] Albertus Magnus (Albert the Great, 1193–1280) is believed to have been the first to isolate the element from a compound in 1250, by heating soap together with arsenic trisulfide.[33] In 1649, Johann Schröder published two ways of preparing arsenic.[34] Crystals of elemental (native) arsenic are found in nature, although rare.

Cadet's fuming liquid (impure cacodyl), often claimed as the first synthetic organometallic compound, was synthesized in 1760 by Louis Claude Cadet de Gassicourt by the reaction of potassium acetate with arsenic trioxide.[35]

In the Victorian era, "arsenic" ("white arsenic" or arsenic trioxide) was mixed with vinegar and chalk and eaten by women to improve the complexion of their faces, making their skin paler to show they did not work in the fields. Arsenic was also rubbed into the faces and arms of women to "improve their complexion". The accidental use of arsenic in the adulteration of foodstuffs led to the Bradford sweet poisoning in 1858, which resulted in around 20 deaths.[36]

Two pigments based on arsenic have been widely used since their discovery – Paris Green and Scheele's Green. After arsenic's toxicity became widely known, they were less often used as pigments, so these compounds were more often used as insecticides. In the 1860s, an arsenic byproduct of dye production, London Purple – a solid consisting of a mixture of arsenic trioxide, aniline, lime, and ferrous oxide, which is insoluble in water and very toxic by inhalation and ingestion[37] – was widely used, but Paris Green, another arsenic-based dye, was later substituted for it.[38] With better understanding of the toxicology mechanism, two other compounds were used starting in the 1890s.[39] Arsenite of lime and arsenate of lead were used widely as insecticides until the discovery of DDT in 1942.[40][41][42]

Applications

Agricultural

The toxicity of arsenic to insects, bacteria, and fungi led to its use as a wood preservative.[43] In the 1950s, a process of treating wood with chromated copper arsenate (also known as CCA or Tanalith) was invented, and for decades, this treatment was the most extensive industrial use of arsenic. An increased appreciation of the toxicity of arsenic resulted in a ban for the use of CCA in consumer products; the European Union and United States initiated this process in 2004.[44][45] CCA remains in heavy use in other countries, however, e.g. Malaysian rubber plantations.[5]

Arsenic was also used in various agricultural insecticides and poisons. For example, lead hydrogen arsenate was a common insecticide on fruit trees,[46] but contact with the compound sometimes resulted in brain damage among those working the sprayers. In the second half of the 20th century, monosodium methyl arsenate (MSMA) and disodium methyl arsenate (DSMA) – less- toxic organic forms of arsenic – have replaced lead arsenate in agriculture. With the exception of cotton farming, the use of the organic arsenicals was phased out until 2013.[47]

Arsenic is used as a feed additive in poultry and swine production, in particular in the U.S. to increase weight gain, improve feed efficiency, and to prevent disease.[48][49] An example is roxarsone, which had been used as a broiler starter by about 70% of U.S. broiler growers.[50] The Poison-Free Poultry Act of 2009 proposed to ban the use of roxarsone in industrial swine and poultry production.[51] Alpharma, a subsidiary of Pfizer Inc., which produces roxarsone, voluntarily suspended sales of the drug in response to studies showing elevated levels of inorganic arsenic, a carcinogen, in treated chickens.[52] A successor to Alpharma, Zoetis, continues to sell nitarsone, primarily for use in turkeys.[52]

Medical use

During the 18th, 19th, and 20th centuries, a number of arsenic compounds were used as medicines, including arsphenamine (by Paul Ehrlich) and arsenic trioxide (by Thomas Fowler).[53]Arsphenamine, as well as neosalvarsan, was indicated for syphilis and trypanosomiasis, but has been superseded by modern antibiotics.

Arsenic trioxide has been used in a variety of ways over the past 500 years, most commonly in the treatment of cancer, but in medications as diverse as Fowler's solution in psoriasis.[54] The US Food and Drug Administration in the year 2000 approved this compound for the treatment of patients with acute promyelocytic leukemia that is resistant to all-trans retinoic acid.[55]

Recently, new research has been done in locating tumors using arsenic-74 (a positron emitter). The advantages of using this isotope instead of the previously used iodine-124 is that the signal in the PET scan is clearer as the body tends to transport iodine to the thyroid gland producing signal noise.[56]

In subtoxic doses, soluble arsenic compounds act as stimulants, and were once popular in small doses as medicine by people in the mid-18th to 19th centuries.[8]

Alloys

The main use of metallic arsenic is in alloying with lead. Lead components in car batteries are strengthened by the presence of a very small percentage of arsenic.[5][57] Dezincification can be strongly reduced by adding arsenic to brass, a copper-zinc alloy.[58] "Phosphorus Deoxidized Arsenical Copper" with an arsenic content of 0.3% has an increased corrosion stability in certain environments.[59] Gallium arsenide is an important semiconductor material, used in integrated circuits. Circuits made from GaAs are much faster (but also much more expensive) than those made in silicon. Unlike silicon, it has a direct bandgap, so can be used in laser diodes and LEDs to directly convert electricity into light.[5]Military

After World War I, the United States built up a stockpile of 20,000 tonnes of lewisite (ClCH=CHAsCl2), a chemical weapon that is a vesicant (blister agent) and lung irritant. The stockpile was neutralized with bleach and dumped into the Gulf of Mexico after the 1950s.[60] During the Vietnam War, the United States used Agent Blue, a mixture of sodium cacodylate and its acid form, as one of the rainbow herbicides to deprive invading North Vietnamese soldiers of foliage cover and rice.[61][62]Other uses

- Copper acetoarsenite was used as a green pigment known under many names, including Paris Green and Emerald Green. It caused numerous arsenic poisonings. Scheele's Green, a copper arsenate, was used in the 19th century as a coloring agent in sweets.[63]

- In bronzing[64] and pyrotechnics

- Up to 2% of arsenic is used in lead alloys for lead shot and bullets.[65]

- Arsenic is added in small quantities to alpha-brass to make it dezincification-resistant. This grade of brass is used to make plumbing fittings or other items that are in constant contact with water.[66]

- Arsenic is also used for taxonomic sample preservation.

- Until recently, arsenic was used in optical glass. Modern glass manufacturers, under pressure from environmentalists, have removed it, along with lead.[67]

Biological role

Bacteria

Some species of bacteria obtain their energy by oxidizing various fuels while reducing arsenate to arsenite. Under oxidative environmental conditions some bacteria use arsenite, which is oxidized to arsenate as fuel for their metabolism.[68] The enzymes involved are known as arsenate reductases (Arr).[69]

In 2008, bacteria were discovered that employ a version of photosynthesis in the absence of oxygen with arsenites as electron donors, producing arsenates (just as ordinary photosynthesis uses water as electron donor, producing molecular oxygen). Researchers conjecture that, over the course of history, these photosynthesizing organisms produced the arsenates that allowed the arsenate-reducing bacteria to thrive. One strain PHS-1 has been isolated and is related to the gammaproteobacterium Ectothiorhodospira shaposhnikovii. The mechanism is unknown, but an encoded Arr enzyme may function in reverse to its known homologues.[70]

Although the arsenate and phosphate anions are similar structurally, no evidence exists for the replacement of phosphate in ATP or nucleic acids by arsenic.[71][72]

Essential trace element in higher animals

There is evidence for the essentiality of arsenic as a trace mineral in birds (chickens), and in mammals (rats, hamsters, and goats). However, the biological mechanism for its essential function is not known.[73]Heredity

Arsenic has been linked to epigenetic changes, heritable changes in gene expression that occur without changes in DNA sequence. These include DNA methylation, histone modification, and RNA interference. Toxic levels of arsenic cause significant DNA hypermethylation of tumor suppressor genes p16 and p53, thus increasing risk of carcinogenesis. These epigenetic events have been studied in vitro using human kidney cells and in vivo using rat liver cells and peripheral blood leukocytes in humans.[74] Inductively coupled plasma mass spectrometry (ICP-MS) is used to detect precise levels of intracellular arsenic and its other bases involved in epigenetic modification of DNA.[75] Studies investigating arsenic as an epigenetic factor will help in developing precise biomarkers of exposure and susceptibility.The Chinese brake fern (Pteris vittata) hyperaccumulates arsenic present in the soil into its leaves and has a proposed use in phytoremediation.[76]

Biomethylation

Inorganic arsenic and its compounds, upon entering the food chain, are progressively metabolized through a process of methylation.[77][78] For example, the mold Scopulariopsis brevicaulis produces significant amounts of trimethylarsine if inorganic arsenic is present.[79] The organic compound arsenobetaine is found in some marine foods such as fish and algae, and also in mushrooms in larger concentrations. The average person's intake is about 10–50 µg/day. Values about 1000 µg are not unusual following consumption of fish or mushrooms, but there is little danger in eating fish because this arsenic compound is nearly non-toxic.[80]Environmental issues

Exposure

Other naturally occurring pathways of exposure include volcanic ash, weathering of arsenic-containing minerals and ores, and dissolved in groundwater. It is also found in food, water, soil, and air.[81] Arsenic is absorbed by all plants, but is more concentrated in leafy vegetables, rice, apple and grape juice, and seafood.[82] An additional route of exposure is through inhalation.[83]Occurrence in drinking water

Widespread arsenic contamination of groundwater has led to a massive epidemic of arsenic poisoning in Bangladesh[84] and neighboring countries. It is estimated that approximately 57 million people in the Bengal basin are drinking groundwater with arsenic concentrations elevated above the World Health Organization's standard of 10 parts per billion (ppb).[85] However, a study of cancer rates in Taiwan[86] suggested that significant increases in cancer mortality appear only at levels above 150 ppb. The arsenic in the groundwater is of natural origin, and is released from the sediment into the groundwater, owing to the anoxic conditions of the subsurface. This groundwater began to be used after local and western NGOs and the Bangladeshi government undertook a massive shallow tube well drinking-water program in the late twentieth century. This program was designed to prevent drinking of bacteria-contaminated surface waters, but failed to test for arsenic in the groundwater. Many other countries and districts in Southeast Asia, such as Vietnam and Cambodia have geological environments conducive to generation of high-arsenic groundwaters. Arsenicosis was reported in Nakhon Si Thammarat, Thailand in 1987, and the Chao Phraya River is suspected of containing high levels of naturally occurring dissolved arsenic, but has not been a public health problem owing to the use of bottled water.[87]In the United States, arsenic is most commonly found in the ground waters of the southwest.[88] Parts of New England, Michigan, Wisconsin, Minnesota and the Dakotas are also known to have significant concentrations of arsenic in ground water.[89] Increased levels of skin cancer have been associated with arsenic exposure in Wisconsin, even at levels below the 10 part per billion drinking water standard.[90] According to a recent film funded by the US Superfund, millions of private wells have unknown arsenic levels, and in some areas of the US, over 20% of wells may contain levels that exceed established limits.[91]

Low-level exposure to arsenic at concentrations of 100 parts per billion (i.e., above the 10 parts per billion drinking water standard) compromises the initial immune response to H1N1 or swine flu infection according to NIEHS-supported scientists. The study, conducted in laboratory mice, suggests that people exposed to arsenic in their drinking water may be at increased risk for more serious illness or death in response to infection from the virus.[92]

Some Canadians are drinking water that contains inorganic arsenic. Private dug well waters are most at risk for containing inorganic arsenic. Preliminary well water analyses typically does not test for arsenic. Researchers at the Geological Survey of Canada have modelled relative variation in natural arsenic hazard potential for the province of New Brunswick. This study has important implications for potable water and health concerns relating to inorganic arsenic.[93]

Epidemiological evidence from Chile shows a dose-dependent connection between chronic arsenic exposure and various forms of cancer, in particular when other risk factors, such as cigarette smoking, are present. These effects have been demonstrated to persist below 50 ppb.[94]

Analyzing multiple epidemiological studies on inorganic arsenic exposure suggests a small but measurable risk increase for bladder cancer at 10 ppb.[95] According to Peter Ravenscroft of the Department of Geography at the University of Cambridge,[96] roughly 80 million people worldwide consume between 10 and 50 ppb arsenic in their drinking water. If they all consumed exactly 10 ppb arsenic in their drinking water, the previously cited multiple epidemiological study analysis would predict an additional 2,000 cases of bladder cancer alone. This represents a clear underestimate of the overall impact, since it does not include lung or skin cancer, and explicitly underestimates the exposure. Those exposed to levels of arsenic above the current WHO standard should weigh the costs and benefits of arsenic remediation.

Early (1973) evaluations of the removal of dissolved arsenic by drinking water treatment processes demonstrated that arsenic is very effectively removed by co-precipitation with either iron or aluminum oxides. The use of iron as a coagulant, in particular, was found to remove arsenic with efficiencies exceeding 90%.[97][98] Several adsorptive media systems have been approved for point-of-service use in a study funded by the United States Environmental Protection Agency (US EPA) and the National Science Foundation (NSF). A team of European and Indian scientists and engineers have set up six arsenic treatment plants in West Bengal based on in-situ remediation method (SAR Technology). This technology does not use any chemicals and arsenic is left as an insoluble form (+5 state) in the subterranean zone by recharging aerated water into the aquifer and thus developing an oxidation zone to support arsenic oxidizing micro-organisms. This process does not produce any waste stream or sludge and is relatively cheap.[99]

Another effective and inexpensive method to remove arsenic from contaminated well water is to sink wells 500 feet or deeper to reach purer waters. A recent 2011 study funded by the US National Institute of Environmental Health Sciences' Superfund Research Program shows that deep sediments can remove arsenic and take it out of circulation. Through this process called adsorption in which arsenic sticks to the surfaces of deep sediment particles, arsenic can be naturally removed from well water.[100]

Magnetic separations of arsenic at very low magnetic field gradients have been demonstrated in point-of-use water purification with high-surface-area and monodisperse magnetite (Fe3O4) nanocrystals. Using the high specific surface area of Fe3O4 nanocrystals the mass of waste associated with arsenic removal from water has been dramatically reduced.[101]

Epidemiological studies have suggested a correlation between chronic consumption of drinking water contaminated with arsenic and the incidence of all leading causes of mortality.[102] The literature provides reason to believe arsenic exposure is causative in the pathogenesis of diabetes.[103]

Hungarian engineer László Schremmer has recently discovered that by the use of chaff-based filters it is possible to reduce the arsenic content of water to 3 µg/L. This is especially important in areas where the potable water is provided by filtering the water extracted from the underground aquifer.[104]

San Pedro de Atacama

For several centuries, the people of San Pedro de Atacama in Chile have been drinking water that is contaminated with arsenic, and it is believed that they may have developed some immunity to the ill effects of consuming it.[105][106][107]Redox transformation of arsenic in natural waters

Arsenic is unique among the trace metalloids and oxyanion-forming trace metals (e.g. As, Se, Sb, Mo, V, Cr, U, Re). It is sensitive to mobilization at pH values typical of natural waters (pH 6.5–8.5) under both oxidizing and reducing conditions. Arsenic can occur in the environment in several oxidation states (-3, 0, +3 and +5), but in natural waters it is mostly found in inorganic forms as oxyanions of trivalent arsenite [As(III)] or pentavalent arsenate [As(V)]. Organic forms of As are produced by biological activity, mostly in surface waters, but are rarely quantitatively important. Organic As compounds may, however, occur where waters are significantly impacted by industrial pollution.[108]Arsenic may be solubilized by various processes. When pH is high, arsenic may be released from surface binding sites that lose their positive charge. When water levels drops and sulfide minerals are exposed to air, arsenic trapped in sulfide minerals can be released into water. When organic carbon is present in water, bacteria are fed by directly reducing As(V) to As(III) or by reducing the element at the binding site attached there and releases arsenic.[109]

The aquatic transformations of As are affected by pH, reduction-oxidation potential, organic matter concentration and the concentrations and forms of other elements especially iron and manganese. The main factors are pH and the redox potential. Generally, the main forms of As under oxic conditions are H3AsO4, H2AsO4−, HAsO42−, and AsO43− at pH 2, 2-7, 7-11 and 11, respectively. Under reducing conditions, H3AsO4 is predominant at pH 2-9.[110]

The oxidation and reduction of arsenic affect its ability to migrate in subsurface environments. Arsenite is the most stable soluble form of arsenic in reducing environments and arsenate, which is less mobile than arsenite, is dominant in oxidizing environments at neutral pH. Therefore, arsenic may be more mobile under reducing conditions. The reducing environment is also rich in organic matter which may enhance the solubility of arsenic compounds. As a result, the adsorption of arsenic is reduced and dissolved arsenic accumulates in groundwater. That is why the arsenic content is higher in reducing environments than in oxidizing environments.[111]

The presence of sulfur is another factor that affects the transformation of arsenic in natural water. Arsenic can precipitate when metal sulfides form. In this way, arsenic is removed from the water and its mobility decreases. When oxygenis present, bacteria oxidize reduced sulfur to generate energy potentially releasing bound arsenic.

Redox reactions involving Fe also appear to be essential factors in the fate of arsenic in aquatic systems. The reduction of iron oxyhydroxides plays a key role in the release of As to water. So As can be enriched in water with elevated Fe concentrations.[112] Under oxidizing conditions, arsenic can be mobilized from pyrite or iron oxides especially at elevated pH. Under reducing conditions, arsenic can be mobilized by reductive desorption or dissolution when associated with iron oxides. The reductive desorption occurs under two circumstances. One is when arsenate is reduced to arsenite which adsorbs to iron oxides less strongly. The other results from a change in the charge on the mineral surface which leads to the desorption of bound arsenic.[113]

Some species of bacteria catalyze redox transformations of arsenic. Dissimilatory arsenate-respiring prokaryotes (DARP) speed up the reduction of As(V) to As(III). DARP use As(V) as the electron acceptor of anaerobic respiration and obtain energy to survive. Other organic and inorganic substances can be oxidized in this process. Chemoautotrophic arsenite oxidizers (CAO) and heterotrophic arsenite oxidizers (HAO) convert As(III) into As(V). CAO combine the oxidation of As(III) with the reduction of oxygen or nitrate. They use obtained energy to fix produce organic carbon from CO2. HAO cannot obtain energy from As(III) oxidation. This process may be an arsenic detoxification mechanism for the bacteria.[114]

Equilibrium thermodynamic calculations predict that As(V) concentrations should be greater than As(III) concentrations in all but strongly reducing conditions, i.e. where SO42− reduction is occurring. However, abiotic redox reactions of arsenic are slow. Oxidation of As(III) by dissolved O2 is a particularly slow reaction. For example, Johnson and Pilson (1975) gave half-lives for the oxygenation of As(III) in seawater ranging from several months to a year.[115] In other studies, As(V)/As(III) ratios were stable over periods of days or weeks during water sampling when no particular care was taken to prevent oxidation, again suggesting relatively slow oxidation rates. Cherry found from experimental studies that the As(V)/As(III) ratios were stable in anoxic solutions for up to 3 weeks but that gradual changes occurred over longer timescales.[116] Sterile water samples have been observed to be less susceptible to speciation changes than non-sterile samples.[117] Oremland found that the reduction of As(V) to As(III) in Mono Lake was rapidly catalyzed by bacteria with rate constants ranging from 0.02 to 0.3 day−1.[118]

Wood preservation in the US

As of 2002, US-based industries consumed 19,600 metric tons of arsenic. Ninety percent of this was used for treatment of wood with chromated copper arsenate (CCA). In 2007, 50% of the 5,280 metric tons of consumption was still used for this purpose.[24][119] In the United States, the voluntary phasing-out of arsenic in production of consumer products and residential and general consumer construction products began on 31 December 2003, and alternative chemicals are now used, such as Alkaline Copper Quaternary, borates, copper azole, cyproconazole, and propiconazole.[120]Although discontinued, this application is also one of the most concern to the general public. The vast majority of older pressure-treated wood was treated with CCA. CCA lumber is still in widespread use in many countries, and was heavily used during the latter half of the 20th century as a structural and outdoor building material. Although the use of CCA lumber was banned in many areas after studies showed that arsenic could leach out of the wood into the surrounding soil (from playground equipment, for instance), a risk is also presented by the burning of older CCA timber. The direct or indirect ingestion of wood ash from burnt CCA lumber has caused fatalities in animals and serious poisonings in humans; the lethal human dose is approximately 20 grams of ash.[citation needed] Scrap CCA lumber from construction and demolition sites may be inadvertently used in commercial and domestic fires. Protocols for safe disposal of CCA lumber do not exist evenly throughout the world; there is also concern in some quarters about the widespread landfill disposal of such timber.

Mapping of industrial releases in the US

One tool that maps releases of arsenic to particular locations in the United States[121] and also provides additional information about such releases is TOXMAP. TOXMAP is a Geographic Information System (GIS) from the Division of Specialized Information Services of the United States National Library of Medicine (NLM) that uses maps of the United States to help users visually explore data from the United States Environmental Protection Agency's (EPA) Toxics Release Inventory and Superfund Basic Research Programs. TOXMAP is a resource funded by the US Federal Government. TOXMAP's chemical and environmental health information is taken from NLM's Toxicology Data Network (TOXNET)[122] and PubMed, and from other authoritative sources.Bioremediation

Physical, chemical, and biological methods have been used to decrease the concentration of arsenic in contaminated water.[123] Among these methods, bioremediation has been suggested to be cost effective and environmentally friendly[124] Bioremediation of ground water contaminated with arsenic aims to convert arsenite, the toxic form of arsenic to humans, to arsenate. Arsenate (+5 oxidation state) is the dominant form of arsenic in surface water, while arsenite (+3 oxidation state) is the dominant form in hypoxic to anoxic environments. Arsenite is more soluble and mobile than arsenate. Many species of bacteria can transform arsenite to arsenate in anoxic conditions by using arsenite as an electron donor.[125] This is a useful method in ground water remediation. Another bioremediation strategy is to use plants that accumulate arsenic in their tissues via phytoremediation but the disposal of contaminated plant material needs to be considered. In order to choose a suitable bioremediation approach for a site, its environmental conditions needs to be evaluated. Some sites may require the addition of an electron acceptor while others require added microbes (bioaugmentation). Regardless of the method used, constant monitoring is required to prevent future contamination.Toxicity and precautions

Arsenic and many of its compounds are especially potent poisons.Classification

Elemental arsenic and arsenic compounds are classified as "toxic" and "dangerous for the environment" in the European Union under directive 67/548/EEC. The International Agency for Research on Cancer (IARC) recognizes arsenic and arsenic compounds as group 1 carcinogens, and the EU lists arsenic trioxide, arsenic pentoxide and arsenate salts as category 1 carcinogens.Arsenic is known to cause arsenicosis owing to its manifestation in drinking water, "the most common species being arsenate [HAsO2−

4; As(V)] and arsenite [H3AsO3; As(III)]".

Legal limits, food, and drink

In the United States, since 2006, the maximum concentration in drinking water allowed by the Environmental Protection Agency (EPA) is 10 ppb[126] and the FDA set the same standard in 2005 for bottled water.[127][128][unreliable source?] The Department of Environmental Protection for New Jersey set a drinking water limit of 5 ppb in 2006.[129]In 2008, based on its ongoing testing of a wide variety of American foods for toxic chemicals,[130] the U.S. Food and Drug Administration set 23 ppb as the "level of concern" for inorganic arsenic apple and pear juices based on non-carcinogenic effects, and began refusing imports and demanding recalls for domestic products exceeding this level.[127] In 2011, the national Dr. Oz television show broadcast a program highlighting tests performed by an independent lab hired by the producers. Though the methodology was disputed (it did not distinguish between organic and inorganic arsenic) the tests showed levels of arsenic up to 36 ppb.[131] In response, FDA testing of the worst brand from the Oz show showed much lower levels, and its ongoing testing found 95% of apple juice samples were below the level of concern. Later testing by Consumer Reports showed inorganic arsenic at levels slightly above 10 ppb, with the organization urging parents to reduce consumption.[132] In July 2013, after taking into account consumption by children, chronic exposure, and carcinogenic effect, the FDA established an "action level" of 10 ppb for apple juice, the same as the drinking water standard.[127]

Concern about arsenic in rice in Bangladesh was raised in 2002, but at the time only Australia had a legal limit for the level found in food (one milligram per kilogram).[133][134] The People's Republic of China has a food standard of 150 ppb for arsenic, as of 2011.[135] Further concern was raised about people who were eating U.S. rice exceeding WHO standards for personal arsenic intake in 2005.[136]