Cradle-to-cradle design (also referred to as Cradle to Cradle, C2C, cradle 2 cradle, or regenerative design) is a biomimetic

approach to the design of products and systems that models human

industry on nature's processes viewing materials as nutrients

circulating in healthy, safe metabolisms.

The term itself is a play on the popular corporate phrase "Cradle to

Grave," implying that the C2C model is sustainable and considerate of

life and future generations (i.e. from the birth, or "cradle," of one

generation to the next versus from birth to death, or "grave," within

the same generation.)

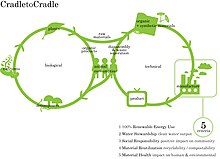

C2C suggests that industry must protect and enrich ecosystems and nature's biological metabolism while also maintaining a safe, productive technical metabolism for the high-quality use and circulation of organic and technical nutrients. It is a holistic, economic, industrial and social framework that seeks to create systems that are not only efficient but also essentially waste free. The model in its broadest sense is not limited to industrial design and manufacturing; it can be applied to many aspects of human civilization such as urban environments, buildings, economics and social systems.

The term Cradle to Cradle is a registered trademark of McDonough Braungart Design Chemistry (MBDC) consultants. Cradle to Cradle product certification began as a proprietary system; however, in 2012 MBDC turned the certification over to an independent non-profit called the Cradle to Cradle Products Innovation Institute. Independence, openness, and transparency are the Institute's first objectives for the certification protocols. The phrase "cradle to cradle" itself was coined by Walter R. Stahel in the 1970s. The current model is based on a system of "lifecycle development" initiated by Michael Braungart and colleagues at the Environmental Protection Encouragement Agency (EPEA) in the 1990s and explored through the publication A Technical Framework for Life-Cycle Assessment.

In 2002, Braungart and William McDonough published a book called Cradle to Cradle: Remaking the Way We Make Things, a manifesto for cradle to cradle design that gives specific details of how to achieve the model. The model has been implemented by a number of companies, organizations and governments around the world, predominantly in the European Union, China and the United States. Cradle to cradle has also been the subject of many documentary films, including the critically acclaimed Waste=Food.

C2C suggests that industry must protect and enrich ecosystems and nature's biological metabolism while also maintaining a safe, productive technical metabolism for the high-quality use and circulation of organic and technical nutrients. It is a holistic, economic, industrial and social framework that seeks to create systems that are not only efficient but also essentially waste free. The model in its broadest sense is not limited to industrial design and manufacturing; it can be applied to many aspects of human civilization such as urban environments, buildings, economics and social systems.

The term Cradle to Cradle is a registered trademark of McDonough Braungart Design Chemistry (MBDC) consultants. Cradle to Cradle product certification began as a proprietary system; however, in 2012 MBDC turned the certification over to an independent non-profit called the Cradle to Cradle Products Innovation Institute. Independence, openness, and transparency are the Institute's first objectives for the certification protocols. The phrase "cradle to cradle" itself was coined by Walter R. Stahel in the 1970s. The current model is based on a system of "lifecycle development" initiated by Michael Braungart and colleagues at the Environmental Protection Encouragement Agency (EPEA) in the 1990s and explored through the publication A Technical Framework for Life-Cycle Assessment.

In 2002, Braungart and William McDonough published a book called Cradle to Cradle: Remaking the Way We Make Things, a manifesto for cradle to cradle design that gives specific details of how to achieve the model. The model has been implemented by a number of companies, organizations and governments around the world, predominantly in the European Union, China and the United States. Cradle to cradle has also been the subject of many documentary films, including the critically acclaimed Waste=Food.

The current economic system, the current solution (the 3Rs), and the C2C framework as an alternative solution

Introduction

In the cradle to cradle model, all materials used in industrial or commercial processes—such as metals, fibers, dyes—fall into one of two categories: "technical" or "biological" nutrients. Technical nutrients

are strictly limited to non-toxic, non-harmful synthetic materials that

have no negative effects on the natural environment; they can be used

in continuous cycles as the same product without losing their integrity

or quality. In this manner these materials can be used over and over

again instead of being "downcycled" into lesser products, ultimately becoming waste.

Biological Nutrients are organic materials

that, once used, can be disposed of in any natural environment and

decompose into the soil, providing food for small life forms without

affecting the natural environment. This is dependent on the ecology of

the region; for example, organic material from one country or landmass

may be harmful to the ecology of another country or landmass.

Biological and Technical Cycles

Biological and technical cycle

The two types of materials each follow their own cycle in the regenerative economy envisioned by Keunen and Huizing.

Structure

Initially

defined by McDonough and Braungart, the Cradle to Cradle Products

Innovation Institute's five certification criteria are:

- Material health, which involves identifying the chemical composition of the materials that make up the product. Particularly hazardous materials (e.g. heavy metals, pigments, halogen compounds etc.) have to be reported whatever the concentration, and other materials reported where they exceed 100 ppm. For wood, the forest source is required. The risk for each material is assessed against criteria and eventually ranked on a scale with green being materials of low risk, yellow being those with moderate risk but are acceptable to continue to use, red for materials that have high risk and need to be phased out, and grey for materials with incomplete data. The method uses the term 'risk' in the sense of hazard (as opposed to consequence and likelihood).

- Material reutilization, which is about recovery and recycling at the end of product life.

- Assessment of energy required for production, which for the highest level of certification needs to be based on at least 50% renewable energy for all parts and subassemblies.

- Water, particularly usage and discharge quality.

- Social responsibility, which assesses fair labor practices.

The certification is available at several levels: basic, silver,

gold, platinum, with more stringent requirements at each. Prior to 2012,

MBDC controlled the certification protocol.

Health

Currently,

many human beings come into contact or consume, directly or indirectly,

many harmful materials and chemicals daily. In addition, countless

other forms of plant and animal life are also exposed. C2C seeks to

remove dangerous technical nutrients (synthetic materials such as mutagenic materials, heavy metals

and other dangerous chemicals) from current life cycles. If the

materials we come into contact with and are exposed to on a daily basis

are not toxic and do not have long term health effects, then the health

of the overall system can be better maintained. For example, a fabric

factory can eliminate all harmful technical nutrients by

carefully reconsidering what chemicals they use in their dyes to achieve

the colours they need and attempt to do so with fewer base chemicals.

Economics

The use of a C2C model often lowers the financial cost of systems. For example, in the redesign of the Ford River Rouge Complex,

the planting of Sedum (stonecrop) vegetation on assembly plant roofs

retains and cleanses rain water. It also moderates the internal

temperature of the building in order to save energy. The roof is part of

an $18 million rainwater treatment system designed to clean 20 billion

US gallons (76,000,000 m3) of rainwater annually. This saved Ford $50 million that would otherwise have been spent on mechanical treatment facilities.

If products are designed according to C2C design principles, they can

be manufactured and sold for less than alternative designs. They

eliminate the need for waste disposal such as landfills.

Definitions

- Cradle to Cradle a play on the phrase "Cradle to Grave", implying that the C2C model is sustainable and considerate of life and future generations.

- Technical nutrients are basically inorganic or synthetic materials manufactured by humans—such as plastics and metals—that can be used many times over without any loss in quality, staying in a continuous cycle.

- Biological nutrients and materials are organic materials that can decompose into the natural environment, soil, water, etc. without affecting it in a negative way, providing food for bacteria and microbiological life.

- Materials are usually referred to as the building blocks of other materials, such as the dyes used in colouring fibers or rubbers used in the sole of a shoe.

- Downcycling is the reuse of materials into lesser products. For example, a plastic computer case could be downcycled into a plastic cup, which then becomes a park bench, etc.; this may eventually lead to waste. In conventional understanding, this is no different from recycling that produces a supply of the same product or material.

- Waste = Food is a basic concept of organic waste materials becoming food for bugs, insects and other small forms of life who can feed on it, decompose it and return it to the natural environment which we then indirectly use for food ourselves.

Existing synthetic materials

The question of how to deal with the countless existing technical nutrients

(synthetic materials) that cannot be recycled or reintroduced to the

natural environment is dealt with in C2C design. The materials that can

be reused and retain their quality can be used within the technical

nutrient cycles while other materials are far more difficult to deal

with, such as plastics in the Pacific Ocean.

Hypothetical examples

One

effective example is a shoe that is designed and mass-produced using

the C2C model. The sole might be made of "biological nutrients" while

the upper parts might be made of "technical nutrients". The shoe is

mass-produced at a manufacturing plant that utilizes its waste material

by putting it back into the cycle; an example of this is using off-cuts

from the rubber soles to make more soles instead of merely disposing of

them (this is dependent on the technical materials not losing their

quality as they are reused). Once the shoes have been manufactured, they

are distributed to retail outlets where the customer buys the shoe at a

fraction of the price they would normally pay for a shoe of comparable

aspects; the customer is only paying for the use of the materials in the

shoe for the period of time that they will be using the shoe. When they

outgrow the shoe or it is damaged, they return it to the manufacturer.

When the manufacturer separates the sole from the upper parts

(separating the technical and biological nutrients), the biological

nutrients are returned to the natural environment while the technical

nutrients are used to create the sole of another shoe.

Another example of C2C design is a disposable cup, bottle, or

wrapper made entirely out of biological materials. When the user is

finished with the item, it can be disposed of and returned to the

natural environment; the cost of disposal of waste such as landfill and

recycling is eliminated. The user could also potentially return the item

for a refund so it can be used again.

Ford Model U is a design concept of a car, made completely from cradle-to-cradle materials. It also uses hydrogen propulsion.

Finished products

- Cradle-to-cradle shoes have been made through the Nike Considered project.

- The Edag light car

- Rohner Textile AG Climatex-textile

- Biofoam; a cradle-to-cradle alternative to expanded polystyrene

- Sewage sludge processing plants are facilities that create fertiliser from sewage sludge. This approach is green retrofit for the current (inefficient) system of organic waste disposal; as composting toilets are a better approach in the long run.

- Aquion Energy large scale batteries

- Ecovative Design packaging and insulation made from waste by binding it together with Mycelium

Implementation

The C2C model can be applied to almost any system in modern society: urban environments, buildings, manufacturing, social systems. 5 steps are outlined in Cradle to Cradle – Remaking the way we make things:

- Get "free of" known culprits

- Follow informed personal preferences

- Create "passive positive" lists – lists of materials used categorised according to their safety level:

- The X List – substances that must be phased out, such as teratogenic, mutagenic, carcinogenic.

- The Gray List – problematic substances that are not so urgently in need of phasing out

The P List – the "positive" list, substances actively defined as safe for use.

- Activate the positive list

- Reinvent – the redesign of the former system

Products that adhere to all steps can generally be granted a

certification. Two certifications used for cradle-to-cradle products

include Leadership in Energy and Environmental Design (LEED) and BRE Environmental Assessment Method (BREEAM).

C2C principles were first applied to systems in the early 1990s by Braungart's Hamburger Umweltinstitut (HUI) and The Environmental Institute in Brazil for biomass nutrient recycling of effluent to produce agricultural products and clean water as a byproduct.

In 2005, William McDonough helped found the Center for

Eco-Intelligent Management at Instituto de Empresa Business School. The

center's research produced the Biosphere Rules,

a set of five implementation principles that facilitate the adoption of

closed loop production approaches with a minimum of disruption for

established companies.

In 2007, MBDC and the EPEA formed a strategic partnership with global materials consultancy Material ConneXion

to help promote and disseminate C2C design principles by providing

greater global access to C2C material information, certification and

product development.

As of January 2008, Material ConneXion's Materials Libraries in New York, Milan, Cologne, Bangkok and Daegu, Korea

started to feature C2C assessed and certified materials and, in

collaboration with MBDC and EPEA, the company now offers C2C

Certification, and C2C product development.

While the C2C model has influenced the construction or

redevelopment of many smaller buildings, several large companies,

organisations and governments have also implemented the C2C model and

its ideas and concepts:

Major implementations

- The Lyle Center for Regenerative Studies incorporates cradle to cradle systems throughout the center. The use of the term C2C is replaced with Regenerative.

- The Chinese Government is constructing many cities like Huangbaiyu based on C2C principles, utilising the rooftops for agriculture.

- The Ford River Rouge Complex redevelopment. Cleaning 20 billion US gallons (76,000,000 m3) of rainwater annually.

- The Netherlands Institute of Ecology (NIOO-KNAW) will make its laboratory and office complex completely cradle to cradle compliant

- Several private houses and communal buildings in the Netherlands

- Fashion Positive, an initiative to assist the fashion world in implementing the cradle-to-cradle model in five areas: material health, material reuse, renewable energy, water stewardship and social fairness.

Coordination with other models

The Cradle to Cradle model can be viewed as a framework that considers systems as a whole or holistically. It can be applied to many aspects of human society, and is related to Life cycle assessment. See for instance the LCA based model of the Eco-costs, which has been designed to cope with analyses of recycle systems. The Cradle to Cradle model in some implementations is closely linked with the Car-free movement,

such as in the case of large-scale building projects or the

construction or redevelopment of urban environments. It is closely

linked with passive solar design in the building industry and with permaculture in agriculture within or near urban environments. An earthship is a perfect example where different re-use models are used, cradle to cradle and permaculture.

In 2005, IE Business School in Madrid launched the Center for

Eco-Intelligent Innovation in collaboration with William McDonough to

study the implementation of Cradle to Cradle design approaches in

pioneering businesses. The academic research of companies lead to the

elaboration of the Biosphere Rules, a set of five principles derived from nature that guide the implementation of circular models in production.

Constraints

A

major constraint in the optimal recycling of materials is that at civic

amenity sites, products are not disassembled by hand and have each

individual part sorted into a bin, but instead have the entire product

sorted into a certain bin.

This makes the extraction of rare earth elements and other

materials uneconomical (at recycling sites, products typically get

crushed after which the materials are extracted by means of magnets,

chemicals, special sorting methods, ...) and thus optimal recycling of,

for example metals is impossible (an optimal recycling method for metals

would require to sort all similar alloys together rather than mixing

plain iron with alloys).

Obviously, disassembling products is not feasible at currently

designed civic amenity sites, and a better method would be to send back

the broken products to the manufacturer, so that the manufacturer can

disassemble the product. These disassembled product can then be used for

making new products or at least to have the components sent separately

to recycling sites (for proper recycling, by the exact type of

material). At present though, few laws are put in place in any country

to oblige manufacturers to take back their products for disassembly,

nor are there even such obligations for manufacturers of

cradle-to-cradle products. One process where this is happening is in the

EU with the Waste Electrical and Electronic Equipment Directive.

Criticism and response

Criticism has been advanced

on the fact that McDonough and Braungart previously kept C2C

consultancy and certification in their inner circle. Critics argued that

this lack of competition prevented the model from fulfilling its

potential. Many critics pleaded for a public-private partnership

overseeing the C2C concept, thus enabling competition and growth of

practical applications and services.

McDonough and Braungart responded to this criticism by giving

control of the certification protocol to a non-profit, independent

Institute called the Cradle to Cradle Products Innovation Institute.

McDonough said the new institute "will enable our protocol to become a

public certification program and global standard."

The new Institute announced the creation of a Certification Standards

Board in June 2012. The new board, under the auspices of the Institute,

will oversee the certification moving forward.

Experts in the field of environment protection have questioned the practicability of the concept. Friedrich Schmidt-Bleek, head of the German Wuppertal Institute

called his assertion, that the "old" environmental movement had

hindered innovation with its pessimist approach "pseudo-psychological

humbug".

I can feel very nice on Michael's seat covers in the airplane. Nevertheless I am still waiting for a detailed proposal for a design of the other 99.99 percent of the Airbus 380 after his principles.

In 2009 Schmidt-Bleek stated that it is out of the question that the concept can be realized on a bigger scale.

Some claim that C2C certification may not be entirely sufficient in all eco-design

approaches. Quantitative methodologies (LCAs) and more adapted tools

(regarding the product type which is considered) could be used in

tandem. The C2C concept ignores the use phase of a product. According to

the Variants of Life Cycle Assessment

the entire life cycle of a product or service has to be evaluated, not

only the material itself. For many goods e.g. in transport, the use

phase has the most influence on the environmental footprint. E.g. the

more lightweight a car or a plane the less fuel it consumes and

consequently the less impact it has. Braungart fully ignores the use

phase.

It is safe to say that every production step or resource-transformation step needs a certain amount of energy.

The C2C concept foresees an own certification of its analysis and therefore is in contradiction to international ISO standards 14040 and 14044 for Life Cycle Assessment

whereas an independent and critical review is needed in order to obtain

comparative and resilient results. Independent external review.