The use of energy is considered sustainable if it meets the needs of the present without compromising the needs of future generations. Definitions of sustainable energy typically include environmental aspects such as greenhouse gas emissions, and social and economic aspects such as energy poverty.

Meeting the world's need for energy in a sustainable way is one of the greatest challenges facing humanity in the 21st century. The global energy system, which is 85% based on fossil fuels, is responsible for over 70% of the greenhouse gas emissions that cause climate change. Burning fossil fuels and biomass is a major contributor to air pollution, which causes an estimated 7 million deaths each year. More than 750 million people lack access to electricity and over 2.6 billion rely on polluting fuels such as wood or charcoal to cook.

Renewable energy sources such as wind, hydroelectric power, solar, and geothermal energy are generally far more sustainable than fossil fuel sources. However, some renewable energy projects, such as the clearing of forests to produce biofuels, can cause severe environmental damage. The role of non-renewable energy sources has been controversial. For example, nuclear power is a low-carbon source and has a safety record comparable to wind and solar, but its sustainability has been debated because of concerns about nuclear proliferation, radioactive waste and accidents. Switching from coal to natural gas has environmental benefits but may lead to a delay in switching to more sustainable options. Carbon capture and storage technology can be built into power plants to remove their carbon dioxide emissions but is expensive and has seldom been implemented.

Reducing greenhouse gas emissions to levels consistent with the Paris Agreement will require a system-wide transformation of the way energy is produced, distributed, stored, and consumed. To accommodate larger shares of variable renewable energy, electrical grids require flexibility through infrastructure such as energy storage. A sustainable energy system is likely to see a shift towards far more electricity use in sectors such as transport and heating, energy conservation, and the use of hydrogen produced from low-emission energy sources. Some critical technologies for eliminating energy-related greenhouse gas emissions are not yet mature.

Wind and solar energy sources generated 8.5% of worldwide electricity in 2019, a share that has grown rapidly while costs have fallen and are projected to continue falling. The IPCC estimates that to limit global warming to 1.5 °C, US$2.4 trillion, equivalent to 2.5 percent of world GDP, would need to be invested in the energy system each year between 2016 and 2035. Pathways exist to provide universal access to electricity and clean cooking technologies in ways that are compatible with climate goals while bringing major health and economic benefits to developing countries. Well-designed government policies that promote energy system transformation can lower greenhouse gas emissions and improve air quality simultaneously, and in many cases can also increase energy security. Policy approaches can include carbon-pricing and energy-specific policies such as renewable portfolio standards and phase-outs of fossil fuel subsidies.

Definitions and background

UN Secretary-General Ban Ki-moon

Definitions

The United Nations Brundtland Commission in its 1987 report, Our Common Future, described the concept of sustainable development, for which energy is a key component. It defined sustainable development as development that "meets the needs of the present without compromising the ability of future generations to meet their own needs". This description of sustainable development has since been referenced in many definitions and explanations of sustainable energy.

No single interpretation of how the concept of sustainability applies to energy has gained worldwide acceptance. Working definitions of sustainable energy encompass multiple dimensions of sustainability, such as environmental, economic, and social dimensions.

The environmental dimension includes greenhouse gas emissions, impacts on biodiversity and ecosystems, the production of hazardous waste and toxic emissions, water consumption, and depletion of non-renewable resources. Energy sources with low environmental impact are sometimes referred to as 'green energy' or 'clean energy'. Definitions of sustainable energy also cover social issues such as having reliable energy be affordable for all people, and economic issues such as energy security to ensure that each country has constant access to sufficient energy.

Sustainable development goals

Meeting the world's need for energy in a sustainable way is one of the greatest challenges facing humanity in the 21st century, both to meet the needs of the present and in terms of effects on future generations. Improving energy access in the least-developed countries and making energy cleaner are key to achieving most of the United Nations 2030 Sustainable Development Goals, which cover issues ranging from climate action to gender equality. Sustainable Development Goal 7 calls for "access to affordable, reliable, sustainable and modern energy for all" by 2030.

Environmental issues

The current energy system contributes to many environmental problems, including climate change, air pollution, biodiversity loss, the release of toxins into the environment, and water scarcity. Energy production and consumption are responsible for 72% of annual human-caused greenhouse gas emissions as of 2014.

The burning of fossil fuels and biomass is a major source of air pollutants harmful to human health. Coal combustion releases sulphur dioxide and volatile organic compounds which form into ground-level ozone, both of which can cause respiratory disease. The World Health Organization (WHO) estimates that outdoor air pollution causes 4.2 million deaths per year, and indoor air pollution causes 3.8 million deaths per year. Air pollution is the second-leading cause of death from non-communicable disease. Around 91% of the world's population lives with levels of air pollution that exceed WHO recommended limits.

Multiple analyses of strategies to reduce greenhouse gas emissions have found that the quantified health benefits of reduced air pollution can significantly offset the costs of implementing these strategies. Efforts to limit global warming to 1.5 °C could save millions of lives per year from air pollution alone, while increasing energy security and reducing poverty.

Environmental impacts extend beyond the by-products of combustion. Oil spills at sea harm marine life and may cause fires which release toxic emissions. Around 10% of global water use goes to energy production, mainly for cooling in thermal energy plants. In dry regions, this contributes to water scarcity. Bioenergy production, coal mining and processing, and oil extraction also require large amounts of water.

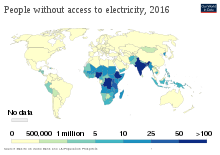

Energy poverty

As of 2019, 770 million people, three-quarters of whom live in sub-Saharan Africa, do not have access to electricity. As of 2020, more than 2.6 billion people in developing countries rely on burning polluting fuels such as wood, animal dung, coal, or kerosene for cooking. A large fraction of the world population, including many in richer countries, cannot afford sufficient heating or cooling for their homes.

Cooking with polluting fuels is responsible for nearly all indoor air pollution, which causes in an estimated 1.6 to 3.8 million deaths annually, and also contributes significantly to outdoor air pollution. Health effects are concentrated among women, who are likely to be responsible for cooking, and young children. The work of gathering fuel exposes women and children to safety risks and often consumes 15 or more hours per week, constraining their available time for education, rest and paid work. Excessive harvesting of wood and other combustible material can cause serious local environmental damage, including desertification.

Reliable and affordable energy, particularly electricity, is essential for health care, education, and economic development. Health clinics require electricity to operate medical equipment, refrigerate vaccines and medications, and for lighting, but a 2018 survey in six Asian and African countries found that half of health facilities had no or poor access to electricity. Households without electricity typically use kerosene lamps for lighting, which creates toxic fumes.

Energy conservation

The International Energy Agency (IEA) estimates that increasing energy efficiency can achieve 40% of greenhouse gas emission reductions needed to fulfil the Paris agreement. Climate change mitigation pathways that are in line with these goals show energy usage remaining around the same between 2010 and 2030, and then increasing slightly by 2050. Reducing overall energy demand would allow the growth in renewable energy sources to more rapidly displace fossil fuels.

One approach to conserving energy is increasing the technical efficiency of appliances, vehicles, industrial processes and buildings. Another approach is to reduce usage of materials, for example through better product lifecycle design and recycling. Behavioural changes such as using videoconferencing rather than business flights, or making urban trips by cycling, walking or public transport rather than by car, are another way to conserve energy. Consumer preferences for larger cars and SUVs, more air travel, and more Government policies to improve efficiency can include building codes, performance standards, carbon pricing, and the development of energy-efficient infrastructure to encourage changes in transport modes.

The energy intensity of the global economy (the amount of energy needed per unit of GDP) is a rough indicator of the energy efficiency of economic production. Energy intensity has been gradually decreasing for decades, however improvements have slowed in recent years, and faster rate of efficiency improvement would be necessary to meet global targets for 2030. Efficiency improvements often lead to a rebound effect in which consumers use the money they save to buy more energy-intensive goods and services. Recent technical efficiency improvements in transport and buildings have been largely offset by trends in consumer behaviour, such as purchasing larger vehicles and homes.

Energy sources

Renewable energy sources

Renewable energy technologies are essential contributors to sustainable energy, as they generally contribute to global energy security and reduce dependence on fossil fuel resources, thus mitigating greenhouse gas emissions. The terms sustainable energy and renewable energy are often used interchangeably. However, renewable energy projects sometimes raise significant sustainability concerns, such as risks to biodiversity when areas of high ecological value are converted to bioenergy production, wind or solar farms.

Hydropower is the largest source of renewable electricity while solar and wind energy have seen substantial growth over the last few years. Photovoltaic solar and onshore wind are the cheapest forms of new power generation capacity in most countries. For more than half of the 770 million people who currently lack access to electricity, decentralised renewable energy solutions such as solar-powered mini-grids are likely to be the cheapest method of providing access by 2030.

Solar

Solar energy is Earth's primary source of energy, a clean and abundantly available resource in many regions. In 2019, solar power provided around 3% of global electricity, mostly through solar panels based on photovoltaic cells (PV). The panels are mounted on top of buildings or used in solar parks connected to the electrical grid. Costs of solar photovoltaic cells have dropped rapidly, driving a strong growth in worldwide capacity. The cost of electricity from new solar farms is competitive with, or in many places, cheaper than electricity from existing coal plants. Various projections of future energy use identify solar PV as one of the main sources of energy generation in a sustainable mix.

Most components of solar panels can be easily recycled, but it is not always done in the absence of regulation. Panels typically contain heavy metals, so they pose environmental risks if put in landfill. Solar panels require energy for their production, equivalent to under two years of their own generation. Module recycling could reduce the energy payback time to around one month.

Concentrated solar power uses mirrors to produce heat, which drives a heat engine. Because the heat is typically stored, this type of solar power is dispatchable: it can be produced when needed. In addition to electricity production, solar energy is also used more directly; solar thermal heating systems are applied for hot water production, heating buildings, drying and desalination. Globally in 2018, solar energy fulfilled 1.5% of final energy demand for heating and cooling.

Wind power

As a clean energy source, wind has been an important driver of development over millennia, providing transportation on water and mechanical energy for industrial processes and land reclamation. In 2019, wind turbines provided approximately 6% of global electricity. Electricity from onshore wind farms is often cheaper than existing coal plants, and competitive with natural gas and nuclear. Wind turbines can be placed in the ocean where winds are steadier and stronger than on land but construction and maintenance costs are higher. According to some analyst forecasts, offshore wind power will become cheaper than onshore wind by the mid-2030s.

Onshore wind farms, often built in wild or rural areas, have a visual impact on the landscape. While collisions kill both bats and to a lesser extent birds, these impacts are fewer than from other infrastructure such as windows and transmission lines. The noise and flickering light created by the turbines can be annoying, and constrain construction near densely populated areas. Wind power, in contrast to nuclear and fossil fuel plants does not consume water to produce power. Little energy is needed for wind turbine construction compared to the energy produced by the wind power plant itself. Turbine blades are not fully recyclable and research into methods of manufacturing easier-to-recycle blades is ongoing.

Hydropower

Hydroelectric plants convert the energy of moving water into electricity. On average, hydropower ranks among the energy sources with the lowest levels of greenhouse gas emissions per unit of energy produced, but levels of emissions vary enormously between projects. In 2019, hydropower supplied 16% of the world's electricity, down from a high of nearly 20% in the mid-to-late 20th century. It produced 60% of the electricity used in Canada and nearly 80% in Brazil.

In conventional hydropower, a reservoir is created behind a dam. Conventional hydropower plants provide a highly flexible, dispatchable electricity supply and can be combined with wind and solar power to provide peak load and to compensate when wind and sun are less available.

In most conventional hydropower projects, the biological matter that becomes submerged in the reservoir's flooding decomposes, becoming a source of carbon dioxide and methane. Levels of these emissions are particularly high in tropical regions. Deforestation and climate change can reduce energy generation from hydroelectric dams. Depending on location, the implementing large-scale dams can displace residents and cause significant local environmental damage; potential dam failure could place the surrounding population at risk.

Run-of-the-river hydroelectricity facilities generally have less environmental impact than reservoir-based facilities, but their ability to generate power depends on river flow which can vary with daily and seasonal weather. Reservoirs provide water quantity controls that are used for flood control and flexible electricity generation output while also providing security during drought for drinking water supply and irrigation.

Geothermal

Geothermal energy is produced by tapping into the heat that exists below the earth's crust. Heat can be obtained by drilling into the ground and then carried by a heat-transfer fluid such as water, brine or steam. Geothermal energy can be harnessed for electricity generation and for heating. The use of geothermal energy is concentrated in regions where heat extraction is economical: a combination of heat, flow and high permeability is needed. Together with solar thermal, geothermal energy provided 2.2% of worldwide demand for heating in buildings in 2019.

Geothermal energy is a renewable resource because thermal energy is constantly replenished from neighbouring hotter regions and radioactive decay of naturally occurring isotopes. The median life-cycle greenhouse gas emissions of geothermal electric stations are 38 grams of carbon dioxide

equivalent per kilowatt-hour of electricity, less than 5% of carbon

intensity of coal, and in some geothermal plants it's as low as

6 grams gCO

2eq/kWh.

Geothermal energy carries a risk of inducing earthquakes, needs

effective protection to avoid water pollution, and emits toxic

emissions, which can be captured.

Bioenergy

Biomass is a versatile and common source of renewable energy. If the production of biomass is well-managed, carbon emissions can be significantly offset by the absorption of carbon dioxide by the plants during their lifespans. Biomass can either be burned to produce heat and to generate electricity or converted to modern biofuels such as biodiesel and ethanol. Biofuels are often produced from corn or sugar cane. They are used to power transport, often blended with liquid fossil fuels.

Use of farmland for growing biomass can result in less land being available for growing food. Since photosynthesis captures only a small fraction of the energy in sunlight and crops require significant amounts of energy to harvest, dry, and transport, a lot of land is needed to produce biomass. If biomass is harvested from crops such as tree plantations, the cultivation of these crops can displace natural ecosystems, degrade soils and consume water resources and synthetic fertilisers. Approximately one-third of all wood used for fuel is harvested unsustainably. In some cases, these impacts can actually result in higher overall carbon emissions compared to using petroleum-based fuels.

In the United States, corn-based ethanol has replaced around 10% of motor gasoline, which requires a significant proportion of the yearly corn harvest. In Malaysia and Indonesia, clearing forests to produce palm oil for biodiesel has led to serious social and environmental effects, as these forests are critical carbon sinks and habitats for endangered species.

More sustainable sources of biomass include crops grown on soil unsuitable for food production, algae and waste. If the biomass source is agricultural or municipal waste, burning it or converting it into biogas provides a way to dispose of this waste. Second-generation biofuels which are produced from non-food plants reduce competition with food production, but may have other negative effects including trade-offs with conservation areas and local air pollution.

Carbon capture and storage technology can be used to capture emissions from bioenergy power plants. This process is known as bioenergy with carbon capture and storage (BECCS) and can result in net carbon dioxide removal from the atmosphere. However, the BECCS process can also result in net positive emissions depending on how the biomass material is grown, harvested, and transported. Deployment of BECCS at scales described in some climate change mitigation pathways would also require converting large amounts of cropland.

Marine energy

Marine energy represents the smallest share of the energy market. It encompasses tidal power, which is approaching maturity and wave power, which is earlier in its development. Two tidal barrage systems, in France and in Korea make up 90% of total production. While single marine energy devices pose little risk to the environment, the impacts of multi-array devices are less well known.

Non-renewable energy sources

Fossil fuel switching and mitigation

For a given unit of energy produced, the life-cycle greenhouse-gas emissions of natural gas are around 40 times the emissions of wind or nuclear energy, but are much less than coal. Natural gas produces around half the emissions of coal when used to generate electricity and around two-thirds the emissions of coal when used to produce heat. Reducing methane leaks in the process of extracting and transporting natural gas could further decrease its climate impact. Natural gas produces less air pollution than coal.

Building gas-fired power plants and gas pipelines is promoted as a way to phase out coal and wood burning pollution and increase energy supply in some African countries with fast growing populations and economies, but this practice is controversial. Developing natural gas infrastructure risks the creation of carbon lock-in and stranded assets, where new fossil infrastructure either commits to decades of carbon emissions, or has to be written off prematurely.

The greenhouse gas emissions of fossil fuel and biomass power

plants can be significantly reduced through carbon capture and storage

(CCS), however deployment of this technology is still very limited, with

only 21 large-scale CCS plants in operation worldwide as of 2020. The CCS process is expensive, with costs depending considerably on the location's proximity to suitable geology for carbon dioxide storage. CCS can be retrofitted to existing power plants, but is more energy intensive. Most studies use a working assumption that CCS can capture 85–90% of the CO

2 emissions from a power plant. If 90% of emitted CO

2

is captured from a coal-fired power plant, its uncaptured emissions

would still be many times greater than the emissions of nuclear, solar

or wind energy per unit of electricity produced.

Since coal plants using CCS would be less efficient, they would require

more coal and thus increase the pollution associated with mining and

transporting coal.

Nuclear power

Nuclear power plants have been used since the 1950s as a low-carbon source of baseload electricity. Nuclear power plants in over 30 countries generate about 10% of global electricity, and as of 2019, over a quarter of all low-carbon energy, the second largest source after hydropower.

Nuclear power's lifecycle greenhouse gas emissions—including the mining and processing of uranium—are similar to the emissions from renewable energy sources. Nuclear power uses little land per unit of energy produced, compared to the major renewables, and does not create local air pollution. The uranium ore used to fuel nuclear fission plants is a non-renewable resource, but sufficient quantities exist to provide a supply for hundreds to thousands of years. Climate change mitigation pathways consistent with ambitious goals typically see an increase in power supply from nuclear.

There is controversy over whether nuclear power can be considered sustainable. The perceived risk of nuclear accidents has a major influence on public opinion of nuclear energy, although for each unit of energy produced, nuclear energy is far safer than fossil fuel energy and comparable to renewable sources. Radioactive nuclear waste must be managed over multi-generation timescales. Nuclear power plants can create fissile material that could be used for nuclear weapon proliferation. Reducing the time and the cost of building new nuclear plants have been goals for decades, but progress has been limited. Public opposition often makes nuclear plants politically difficult to implement. Experts from the Joint Research Centre (JRC), the scientific expert arm of the EU, stated in April 2021 that nuclear power is "sustainable". Two other groups of experts—SCHEER (Scientific Committee on Health, Environmental and Emerging Risks) and "Article 31"—largely confirmed JRC findings in July 2021.

Various new forms of nuclear energy are in development, hoping to address the drawbacks of conventional plants. Fast breeder reactors are capable of recycling nuclear waste and therefore can significantly reduce the amount of waste that requires geological disposal but have not yet been deployed on a large-scale commercial basis. Nuclear power based on thorium, rather than uranium, may be able to provide higher energy security for countries that do not have a large supply of uranium. Small modular reactors may have several advantages over current large reactors: it should be possible to build them faster, and their modularization would allow for cost reductions via learning-by-doing. Several countries are attempting to develop nuclear fusion reactors, which would generate small amounts of waste and no risk of explosions.

Energy system transformation

The emissions reductions necessary to keep global warming below 2 °C will require a system-wide transformation of the way energy is produced, distributed, stored, and consumed. As of 2019, 85% of the world's energy needs are met by burning fossil fuels. To maximize the use of renewable energy sources, energy usage technologies such as vehicles must become powered by electricity or hydrogen. Electricity systems will need to become more flexible to accommodate variable renewable energy sources.

The International Energy Agency states that further innovation in the energy sector, such as in battery technologies and carbon-neutral fuels, is needed to reach net-zero emissions in 2050. Development of new technologies requires research and development, demonstration and cost reductions via deployment.

Generation of electricity and heat contributes 31% of human-caused greenhouse gas emissions, use of energy in transport contributes 15%, and use of energy in manufacturing and construction contributes 12%. An additional 5% is released through processes associated with fossil fuel production and another 8% through various other forms of fuel combustion.

Electrification

Electrification is a key part of using energy sustainably. Many options exist to produce electricity sustainably, but producing fuels or heat on a large scale sustainably is relatively difficult. As of 2018, about a quarter of all electricity generation came from renewable sources other than biomass. Electricity generation has seen a much faster uptake of renewables than the heat and transport sectors.

Massive electrification in the heat and transport sector may be needed to make these sectors sustainable, with heat pumps and electric vehicles playing important roles. Ambitious climate policy would see a doubling of energy consumed as electricity by 2050, from 20% in 2020.

Infrastructure for generating and storing renewable electricity requires minerals and metals, such as cobalt and lithium for batteries and copper for solar panels. Recycling can meet some of this demand if product lifecycles are well-designed, however achieving net zero emissions would still require major increases in mining for 17 types of metals and minerals. A small group of countries or companies sometimes dominate the markets for these commodities raising geopolitical concerns. Cobalt, for instance, is mined in Congo, a politically unstable region where mining is often associated with human rights risks. More diverse geographical sourcing may ensure the stability of the supply chain.

Managing variable energy sources

Solar and wind are variable renewable energy sources that supply electricity intermittently depending on the weather and the time of day. Most electrical grids were constructed for non-intermittent energy sources such as coal-fired power plants. As larger amounts of solar and wind energy are integrated into the grid, changes have to be made to the energy system to ensure that the supply of electricity is matched to demand. In 2019, these sources generated 8.5% of worldwide electricity, a share that has grown rapidly.

There are various ways to make the electricity system more flexible. In many places, wind and solar production are complementary on a daily and a seasonal scale: There is more wind during the night and in winter when solar energy production is low. Linking different geographical regions through long-distance transmission lines allows for further cancelling out of variability. Energy demand can be shifted in time through energy demand management and the use of smart grids, matching the times when variable energy production is highest. With grid energy storage, energy produced in excess can be released when needed. Further flexibility could be provided from sector coupling, i.e. coupling the electricity sector to the heat and mobility sector via power-to-heat-systems and electric vehicles.

Building overcapacity for wind and solar generation can help to ensure that enough electricity is produced even during poor weather – during optimal weather energy generation may have to be curtailed, if excess electricity cannot be used or stored. The final demand-supply mismatch may be covered by using dispatchable energy sources such as hydropower, bioenergy, or natural gas.

Energy storage

Energy storage helps overcome barriers for intermittent renewable energy and is an important aspect of a sustainable energy system. The most commonly used storage method is pumped-storage hydroelectricity, which requires locations with large differences in height and access to water. Batteries, and specifically lithium-ion batteries whose costs have been coming down rapidly, are also deployed widely. Batteries typically store electricity for short periods; research is ongoing into technology with sufficient capacity to last through seasons. Pumped hydro storage and power-to-gas (converting electricity to gas, and back) with capacity for multi-month usage has been implemented in some locations.

Hydrogen

Hydrogen can be burned to produce heat or can power fuel cells to generate electricity, with zero emissions at the point of usage. The overall lifecycle emissions of hydrogen depend on how it is produced. Very little of the world's current supply of hydrogen is currently created from sustainable sources. The predominant reaction route is steam methane reforming in which hydrogen is produced from a chemical reaction between steam and methane. Producing one tonne of hydrogen through this process emits 6.6–9.3 tonnes of carbon dioxide. With carbon capture and storage technologies, a large fraction of these emissions could be removed.

Another more sustainable approach for hydrogen production is through electrolysis, by using electricity to split water molecules into hydrogen and oxygen; if the electricity is generated sustainably, the resultant fuel will also be sustainable. This process is currently more expensive than creating hydrogen from fossil fuels, and the efficiency of energy conversion is inherently low. Hydrogen can be produced when there is a surplus of intermittent renewable electricity, then stored and used to generate heat or to re-generate electricity. It can be further transformed into synthetic fuels such as ammonia and methanol, or into feedstock for the chemical industry, indirectly electrifying those applications. This dual character of hydrogen, both a chemical reagent and as an energy carrier, makes it likely hydrogen use will expand in the coming decades.

Innovation in hydrogen electrolysers could make large-scale production of hydrogen from electricity more cost-competitive. There is potential for hydrogen to play a significant role in decarbonising energy systems because in certain sectors, replacing fossil fuels with direct use of electricity would be very difficult. Hydrogen fuel can produce the intense heat required for industrial production of steel, cement, glass, and chemicals. For steelmaking, hydrogen can function as a clean energy carrier and simultaneously as a low-carbon catalyst replacing coal-derived coke.

Energy usage technologies

Transport

There are multiple ways to make transport more sustainable. Public transport frequently emits fewer greenhouse gases per passenger than personal vehicles, especially with high occupancy. High-speed rail journeys, which use much less fuel, can replace short-distance flights. Stimulating non-motorised transport such as walking and cycling, particularly in cities, can make transport cleaner and healthier.

The energy efficiency of cars has increased because of technological progress, but shifting to electric vehicles is an important further step towards decarbonising transport and reducing air pollution. A substantial proportion of traffic-related air pollution consists of particulate matter from road dust and the wearing-down of tyres and brake pads. Reducing pollution from these sources cannot be achieved by electrification; it requires measures such as making vehicles lighter and driving them less.

Making freight transport sustainable is challenging. Hydrogen vehicles may be an option for larger vehicles such as lorries which have not yet been widely electrified because of the weight of batteries needed for long-distance travel. Many of the techniques needed to lower emissions from shipping and aviation are still early in their development, with clean ammonia a promising candidate for shipping fuel. Aviation biofuel may be one of the better uses of bioenergy, providing some carbon is captured and stored during manufacture of the fuel.

Buildings

For heating buildings, alternatives to burning fossil fuels and biomass include electrification (heat pumps, or the less efficient electric heater), geothermal, solar thermal, and waste heat. Seasonal thermal energy storage has been implemented in some high-latitude regions for household heating. Heat pumps currently provide only 5% of space and water heating requirements globally, but the IEA estimates they could provide over 90%.

In densely populated urban areas, space for heat pumps may be limited and district heating may better meet demand. While traditionally using mostly fossil fuels, modern and cold district heating systems are designed to use lower temperatures, high shares of renewable energy such as central solar heating and geothermal energy and waste heat to provide low-carbon heating. The costs of all these technologies strongly depend on location, and uptake of the technology sufficient for deep decarbonisation requires stringent policy interventions.

Efficient cooling of buildings requires passive building design and urban planning, in addition to air conditioning, which requires electrification and additional power demand and is therefore not always accessible for poorer households. Some air conditioning units use refrigerants which warm the climate: replacing those with climate-friendly refrigerants, as required under the internationally agreed Kigali Amendment, would reduce the climate impacts of cooling.

Industry

Over one-third of energy use is by industry. Most of that energy is deployed in thermal processes: generating steam, drying, and refrigeration. The share of renewable energy in industry was 14.5% in 2017—mostly low-temperature heat supplied by bioenergy and electricity. The more energy-intensive activities in industry have the lowest shares of renewable energy, as they face limitations in generating heat at temperatures over 200 °C (390 °F).

For some industrial processes, such as steel production, commercialisation of technologies that have not yet been built or operated at full scale will be needed to eliminate greenhouse gas emissions. The production of plastic, cement and fertilizers also requires significant amounts of energy, with limited possibilities available to decarbonise. A switch to a circular economy would make industry more sustainable, as it involves recycling more and thereby using less energy compared to extracting new raw materials.

Universal access to energy

With responsible planning and management, pathways exist to provide universal access to electricity and clean cooking by 2030 in ways that are consistent with climate goals. Off-grid and mini-grid systems based on renewable energy, such as small solar PV installations that generate and store enough electricity for a village, are important solutions for rural areas. Wider access to reliable electricity would lead to less use of kerosene lighting and diesel generators, which are currently common in the developing world.

A goal in global sustainable development is to reduce the health and environmental problems caused by cooking with biomass, coal, and kerosene. Alternatives include electric stoves, solar cookers, stoves that use clean fuels, and improved cookstoves that burn biomass more efficiently and with less pollution. Depending on location, clean fuels for cooking are typically liquified petroleum gas (LPG), locally produced biogas, piped natural gas (PNG), or alcohol. The World Health Organization encourages further research into biomass stove technology, as no widely available biomass stoves meet recommended emissions limits.

Transitioning to cleaner cooking methods is expected to either raise greenhouse gas emissions by a minimal amount or decrease them, even if the replacement fuels are fossil gases. There is evidence that LPG and PNG have a smaller climate effect than the combustion of solid fuels, which emits methane and black carbon. The Intergovernmental Panel on Climate Change (IPCC) stated in 2018, "The costs of achieving nearly universal access to electricity and clean fuels for cooking and heating are projected to be between 72 and 95 billion USD per year until 2030 with minimal effects on GHG emissions."

According to a 2020 report by the IEA, current and planned policies would still leave over 660 million people without electricity by 2030. Efforts to improve access to clean cooking fuels and stoves have barely kept up with population growth, and current and planned policies would still leave 2.4 billion people without access in 2030. Historically, several countries have made rapid economic gains through coal usage, particularly in Asia. However, there remains a window of opportunity for many poor countries and regions to "leapfrog" fossil fuel dependency by developing their energy systems based on renewables, given adequate international investment and knowledge transfer.

Finance

Mobilising sufficient finance for innovation and investment is a prerequisite for the energy transition. The IPCC estimates that to limit global warming to 1.5 °C, US$2.4 trillion would need to be invested in the energy system each year between 2016 and 2035. Most studies project that these costs, equivalent to 2.5 percent of world GDP, would be small compared to the economic and health benefits. Average annual investment in low-carbon energy technologies and energy efficiency would need to be upscaled by roughly a factor of six by 2050 compared to 2015. Underfunding is particularly acute in the least developed countries.

The UNFCCC estimates that climate financing totalled $681 billion in 2016, with most of this being private-sector investment in renewable energy deployment, public-sector investment in sustainable transport and private-sector investment in energy efficiency. Fossil fuel funding and subsidies form a significant barrier to the energy transition. Direct global fossil fuel subsidies reached $319 billion in 2017, and $5.2 trillion when indirect costs such as air pollution are priced in. Ending these could lead to a 28% reduction in global carbon emissions and a 46% reduction in air pollution deaths. Funding for clean energy has been largely unaffected by the COVID-19 pandemic and required economic stimulus packages offer possibilities for a green recovery.

The International Labour Organization estimates that efforts to limit global warming to 2 °C would result in net job creation in most sectors of the economy. It predicts that 24 million new jobs would be created in areas such as renewable electricity generation, improving energy-efficiency in buildings and the transition to electric vehicles, while 6 million jobs in the fossil fuel industry would be lost.

Government policies

Well-designed government policies that promote energy system transformation can lower greenhouse gas emissions and improve air quality simultaneously, and in many cases can also increase energy security. Carbon pricing, energy-specific policies, or a mixture of both are necessary to limit global warming to 1.5 °C.

Carbon taxes provide a source of revenue that can be used to lower other taxes or to help lower-income households afford higher energy costs. Carbon taxes have encountered strong political pushback in some jurisdictions, whereas energy-specific policies tend to be politically safer. As of 2019, carbon pricing covers about 20% of global greenhouse gas emissions; in most of these cases the price on carbon is lower than what would be needed to achieve the goals of the Paris Agreement.

Energy-specific programs and regulations have historically been the mainstays of efforts to reduce fossil fuel emissions. Some governments have committed to dates for phasing out coal-fired power plants, ending new fossil fuel exploration, requiring that new passenger vehicles produce zero emissions, and requiring new buildings to be heated by electricity instead of gas. Renewable portfolio standards have been enacted in several countries requiring utilities to increase the percentage of electricity they generate from renewable sources.

Governments can accelerate energy system transformation by leading the development of infrastructure such as electrical distribution grids, smart grids and hydrogen pipelines. In transport, appropriate infrastructure and incentives can make travel more efficient and less car-dependent. Urban planning to discourage sprawl can reduce energy use in local transport and buildings while enhancing quality-of-life.

The scale and pace of policy reforms that have been initiated as of 2020 are far less than needed to fulfil the climate goals of the Paris Agreement. Governments can make the transition to sustainable energy more politically and socially feasible by ensuring a just transition for workers and regions that depend on the fossil fuel industry to ensure they have alternative economic opportunities. In addition to domestic policies, greater international cooperation will be required to accelerate innovation and to assist poorer countries in establishing a sustainable path to full energy access.