From Wikipedia, the free encyclopedia

An electric car is an automobile that is propelled by one or more electric motors, using electrical energy stored in batteries or another energy storage device. Electric motors give electric cars instant torque, creating strong and smooth acceleration.

The first electric cars were produced in the 1880s.[1] Electric cars were popular in the late 19th century and early 20th century, until advances in internal combustion engines and mass production of cheaper gasoline vehicles led to a decline in the use of electric drive vehicles. The energy crises of the 1970s and 1980s brought a short-lived interest in electric cars; although, those cars did not reach the mass marketing stage, as is the case in the 21st century. Since 2008, a renaissance in electric vehicle manufacturing has occurred due to advances in batteries and power management, concerns about increasing oil prices, and the need to reduce greenhouse gas emissions.[2][3] Several national and local governments have established tax credits, subsidies, and other incentives to promote the introduction and adoption in the mass market of new electric vehicles depending on battery size and their all-electric range.

Benefits of electric cars over conventional internal combustion engine automobiles include a significant reduction of local air pollution, as they do not emit tailpipe pollutants,[4] in many cases, a large reduction in total greenhouse gas and other emissions (dependent on the fuel used for electricity generation[2][3]), and less dependence on foreign oil, which in several countries is cause for concern about vulnerability to oil price volatility and supply disruption.[2][5][6] But widespread adoption of electric cars faces several hurdles and limitations, including their higher cost, lack of recharging infrastructure (other than home charging) and range anxiety (the driver's fear that the electric energy stored in the batteries will run out before the driver reaches their destination, due to the limited range of most existing electric cars).[2][3]

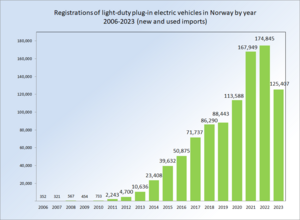

As of November 2014[update], the number of mass production highway-capable all-electric passenger cars and utility vans available in the market is limited to over 30 models, mainly in the United States, Japan, Western European countries and China. Pure electric car sales in 2012 were led by Japan with a 28% market share of global sales, followed by the United States with a 26% share, China with 16%, France with 11%, and Norway with 7%.[7] The world's top selling highway-capable electric car ever is the Nissan Leaf, released in December 2010 and sold in 35 countries, with global sales of over 158,000 units up until December 2014.[8][9][10]

Terminology

Electric cars are a variety of electric vehicle (EV). The term "electric vehicle" refers to any vehicle that uses electric motors for propulsion, while "electric car" generally refers to highway-capable automobiles powered by electricity. Low-speed electric vehicles, classified as neighborhood electric vehicles (NEVs) in the United States,[11] and as electric motorised quadricycles in Europe,[12] are plug-in electric-powered microcars or city cars with limitations in terms of weight, power and maximum speed that are allowed to travel on public roads and city streets up to a certain posted speed limit, which varies by country.While an electric car's power source is not explicitly an on-board battery, electric cars with motors powered by other energy sources are generally referred to by a different name: an electric car powered by sunlight is a solar car, and an electric car powered by a gasoline generator is a form of hybrid car. Thus, an electric car that derives its power from an on-board battery pack is a form of battery electric vehicle (BEV). Most often, the term "electric car" is used to refer to battery electric vehicles.

History

Invention

Rechargeable batteries that provided a viable means for storing electricity on board a vehicle did not come into being until 1859, with the invention of the lead-acid battery by French physicist Gaston Planté.[13][14]

Thomas Parker, responsible for innovations such as electrifying the London Underground, overhead tramways in Liverpool and Birmingham, built the first practical production electric car in London in 1884, using his own specially designed high-capacity rechargeable batteries.[15][16] Parker's long-held interest in the construction of more fuel-efficient vehicles led him to experiment with electric vehicles. He also may have been concerned about the malign effects smoke and pollution were having in London.[17]

An alternative contender as the world's first electric car was the German Flocken Elektrowagen, built in 1888.[1]

Golden age

Electric cars were reasonably popular in the late 19th century and early 20th century, when electricity was among the preferred methods for automobile propulsion, providing a level of comfort and ease of operation that could not be achieved by the gasoline cars of the time.[18] In 1900, 40% of American automobiles were powered by steam, 38% by electricity, and 22% by gasoline.[19] The electric vehicle stock peaked at approximately 30,000 vehicles at the turn of the 20th century.[20]Advances in internal combustion engines, especially the electric starter, soon lessened the relative advantages of the electric car. The greater range of gasoline cars, and their much quicker refueling times, encouraged a rapid expansion of petroleum infrastructure, which quickly proved decisive. The mass production of gasoline-powered vehicles, by companies such as Ford, reduced prices of gasoline-engined cars to less than half that of equivalent electric cars, and that inevitably led to a decline in the use of electric propulsion, effectively removing it from the automobile market by the early 1930s.[19] Out of the 568,000 vehicles produced by American automobile manufacturers in 1914, 99% were powered by internal combustion engines.[21] Electric cars went out of production in the U.S. in 1920.[19]

Electric battery-powered taxis became available at the end of the 19th century. In London, Walter C. Bersey designed a fleet of such cabs and introduced them to the streets of London in 1897. They were soon nicknamed "Hummingbirds" due to the idiosyncratic noise they made.[22] In the same year in New York City, the Samuel's Electric Carriage and Wagon Company began running 12 electric hansom cabs.[23] The company operated until 1898 with up to 62 cabs in service, until it was reformed by its financiers to form the Electric Vehicle Company.[24]

In 1911, the New York Times stated that the electric car has long been recognized as "ideal" because it was cleaner, quieter and much more economical than gasoline-powered cars.[25] However an article in the Washington Post in 2010, quoting that comment, asserted that "the same unreliability of electric car batteries that flummoxed Thomas Edison persists today."[26]

Mid to late 20th century: stops and starts

Some European nations during World War II experimented with electric cars, but the technology stagnated. Several ventures were established to build electric cars, such as the Henney Kilowatt. In 1955, the U.S. Air Pollution Control Act helped address the growing emissions problems and this law was later amended to establish regulatory standards for automobiles.[27] In 1959, American Motors Corporation (AMC) and Sonotone Corporation planned a car to be powered by a "self-charging" battery.[28] It was to have sintered plate nickel-cadmium batteries.[29] Nu-Way Industries also showed an experimental electric car with a one-piece plastic body that was to begin production in early 1960.[28]

Concerns with rapidly decreasing air quality caused by automobiles prompted the U.S. Congress to pass the Electric Vehicle Development Act of 1966 that provided for electric car research by universities and laboratories.[27] Meanwhile, the Enfield Thunderbolt, an electric car produced after a competition run by the Electrical Board, was won by Enfield Auto, and 100 cars were produced at their factory on the Isle of Wight.[30] By the late-1960s, the U.S. and Canada Big Three automakers each had electric car development programs. The much smaller AMC partnered with Gulton Industries to develop a new battery based on lithium and use an advanced speed controller.[31] Although a nickel-cadmium battery was used for an all-electric 1969 Rambler American station wagon, other "plug-in" vehicles were developed with Gulton that included the Amitron and the similar Electron.

The energy crises of the 1970s and 80s brought about renewed interest in the perceived independence that electric cars had from the fluctuations of the hydrocarbon energy market. In the early 1990s, the California Air Resources Board (CARB) began a push for more fuel-efficient, lower-emissions vehicles, with the ultimate goal being a move to zero-emissions vehicles such as electric vehicles.[2][32] In response, automakers developed electric models, including the Chrysler TEVan, Ford Ranger EV pickup truck, GM EV1, and S10 EV pickup, Honda EV Plus hatchback, Nissan Altra EV miniwagon, and Toyota RAV4 EV. These cars were eventually withdrawn from the U.S. market.[33]

1990s to present: Revival of interest

The global economic recession in the late 2000s led to increased calls for automakers to abandon fuel-inefficient SUVs, which were seen as a symbol of the excess that caused the recession, in favor of small cars, hybrid cars, and electric cars. California electric automaker Tesla Motors began development in 2004 on the Tesla Roadster, which was first delivered to customers in 2008. As of March 2012[update], Tesla had sold more than 2,250 Roadsters in at least 31 countries.[34] The Mitsubishi i MiEV was launched for fleet customers in Japan in July 2009, and for individual customers in April 2010,[35][36][37] followed by sales to the public in Hong Kong in May 2010,[38] and Australia in July 2010 via leasing.[39] Retail customer deliveries of the Nissan Leaf in Japan and the United States began in December 2010,[40][41] followed in 2011 by several European countries and Canada.[42][43]

In the 2011 State of the Union address, U.S. President Barack Obama expressed an ambitious goal of putting 1 million plug-in electric vehicles on the roads in the U.S. by 2015.[45] The objectives include "reducing dependence on oil and ensuring that America leads in the growing electric vehicle manufacturing industry."[46]

The Smart electric drive, Wheego Whip LiFe, Mia electric, Volvo C30 Electric, and the Ford Focus Electric were launched for retail customers during 2011. The BYD e6, released initially for fleet customers in 2010, began retail sales in Shenzhen, China in October, 2011.[47] The Bolloré Bluecar was released in December 2011 and deployed for use in the Autolib' carsharing service in Paris.[48] Leasing to individual and corporate customers began in October 2012 and is limited to the Île-de-France area.[49]

In February 2011, the Mitsubishi i MiEV became the first electric car to sell more than 10,000 units, including the models badged in Europe as the Citroën C-Zero and Peugeot iOn. Several months later, the Nissan Leaf overtook the i MiEV as the best selling all-electric car ever.[50]

Models released to the market between 2012 and 2014 include the BMW ActiveE, Coda, Renault Fluence Z.E., Tesla Model S, Honda Fit EV, Toyota RAV4 EV, Renault Zoe, Roewe E50, Mahindra e2o, Chevrolet Spark EV, Fiat 500e, Volkswagen e-Up!, BMW i3, BMW Brilliance Zinoro 1E, Kia Soul EV, Volkswagen e-Golf, Mercedes-Benz B-Class Electric Drive, and Venucia e30. The Nissan Leaf passed the milestone of 50,000 units sold worldwide in February 2013,[51] and the 100,000 unit mark in mid January 2014.[52] In June 2014 Tesla Motors announced it was making its patents open source freely available to speed up production of electric cars and spur competition, at a time that electric cars comprised less than 1% of all automobiles sold in the United States.[53]

Many countries are introducing CO

2 average emissions targets across all cars sold by a manufacturer, with financial penalties on manufacturers that fail to meet these targets. This has created an incentive for manufacturers, especially those selling many heavy or high-performance cars, to introduce electric cars as a means of reducing average fleet CO2 emissions.[54]

Comparison with internal combustion engine vehicles

An important goal for electric vehicles is overcoming the disparity between their costs of development, production, and operation, with respect to those of equivalent internal combustion engine vehicles (ICEVs). As of 2013[update], electric cars are significantly more expensive than conventional internal combustion engine vehicles and hybrid electric vehicles due to the additional cost of their lithium-ion battery pack.[55] However, battery prices are coming down with mass production and are expected to drop further.[56]Electric cars have several benefits over conventional internal combustion engine automobiles, including a significant reduction of local air pollution, as they have no tailpipe, and therefore do not emit harmful tailpipe pollutants from the onboard source of power at the point of operation;[57][58][59] reduced greenhouse gas emissions from the onboard source of power, depending on the fuel used for electricity generation to charge the batteries.[2][3] Electric vehicles generally, compared to gasoline vehicles show significant reductions in overall well-wheel global carbon emissions due to the highly carbon intensive production in mining, pumping, refining, transportation and the efficiencies obtained with gasoline.[60] While there is some technical superiority of electric propulsion compared with conventional technology, one should be aware that, in many countries, the effect of electrification of vehicles' fleet emissions will predominantly be due to regulation rather than technology.[61] Indeed electricity production is submitted to emission quotas, while vehicles' fuel propulsion is not, thus electrification shifts demand from a non-capped sector to a capped sector. In this context, technical efficiency of EV engine is not the driver of emission reduction.

Electric vehicles provide for less dependence on foreign oil, which for the United States and other developed or emerging countries is cause for concern about vulnerability to oil price volatility and supply disruption.[2][5][6] Also for many developing countries, and particularly for the poorest in Africa, high oil prices have an adverse impact on their balance of payments, hindering their economic growth.[62][63]

Price

Sales of the Mitsubishi i MiEV to the public began in Japan and in China in April 2010, in Hong Kong in May 2010 and in Australia in July 2010.

The up-front purchase price of electric cars is significantly higher than conventional internal combustion engine cars, even after considering government incentives for plug-in electric vehicles available in several countries. The primary reason is the high cost of car batteries.[64] The high purchase price is hindering the mass transition from gasoline cars to electric cars. According to a survey taken by Nielsen for the Financial Times in 2010, around three quarters of American and British car buyers have or would consider buying an electric car, but they are unwilling to pay more for an electric car. The survey showed that 65% of Americans and 76% of Britons are not willing to pay more for an electric car than the price of a conventional car.[65]

The electric car company Tesla Motors uses laptop -size cells for the battery packs of its electric cars, which are 3 to 4 times cheaper than dedicated electric car battery packs of other auto makers. Dedicated battery packs cost $700–$800 per kilowatt hour, while battery packs using small laptop cells cost about $200. This could drive down the cost of electric cars that use Tesla's battery technology such as the Toyota RAV4 EV, Smart ED and Tesla Model X which announced for 2014.[66][67][68] As of June 2012[update], and based on the three battery size options offered for the Tesla Model S, the New York Times estimated the cost of automotive battery packs between US$400 to US$500 per kilowatt-hour.[69]

A 2013 study by the American Council for an Energy-Efficient Economy reported that battery costs came down from US$1,300 per kilowatt hour in 2007 to US$500 per kilowatt hour in 2012. The U.S. Department of Energy has set cost targets for its sponsored battery research of US$300 per kilowatt hour in 2015 and US$125 per kilowatt hour by 2022. Cost reductions of batteries and higher production volumes will allow plug-in electric vehicles to be more competitive with conventional internal combustion engine vehicles.[70]

Several governments have established policies and economic incentives to overcome existing barriers, promote the sales of electric cars, and fund further development of electric vehicles, batteries and components. Several national and local governments have established tax credits, subsidies, and other incentives to reduce the net purchase price of electric cars and other plug-ins.[71][72][73][74]

Maintenance

Electric cars have expensive batteries that must be replaced if they become defective, however the lifetime of said batteries can be very long (many years). Otherwise, electric cars incur very low maintenance costs, particularly in the case of current lithium-based designs. The documentary film Who Killed the Electric Car?[75] shows a comparison between the parts that require replacement in gasoline powered cars and EV1s, with the garages stating that they bring the electric cars in every 5,000 mi (8,000 km), rotate the tires, fill the windshield washer fluid and send them back out again.

Running costs

The cost of charging the battery depends on the price paid per kWh of electricity - which varies with location. As of November 2012, a Nissan Leaf driving 500 mi (800 km) per week is estimated to cost US$600 per year in charging costs in Illinois, U.S.,[76] as compared to US$2,300 per year in fuel costs for an average new car using regular gasoline.[77][78]The EV1 energy use was about 11 kW·h/100 km (0.40 MJ/km; 0.18 kW·h/mi).[79] The 2011/12 Nissan Leaf uses 21.25 kW·h/100 km (0.765 MJ/km; 0.3420 kW·h/mi) according to the US Environmental Protection Agency.[80] These differences reflect the different design and utility targets for the vehicles, and the varying testing standards. The energy use greatly depends on the driving conditions and driving style. Nissan estimates that the Leaf's 5-year operating cost will be US$1,800 versus US$6,000 for a gasoline car in the US[81] According to Nissan, the operating cost of the Leaf in the UK is 1.75 pence per mile (1.09p per km) when charging at an off-peak electricity rate, while a conventional petrol-powered car costs more than 10 pence per mile (6.25p per km). These estimates are based on a national average of British Petrol Economy 7 rates as of January 2012, and assumed 7 hours of charging overnight at the night rate and one hour in the daytime charged at the Tier-2 daytime rate.[82]

The following table compares out-of-pocket fuel costs estimated by the U.S. Environmental Protection Agency according to its official ratings for fuel economy (miles per gallon gasoline equivalent in the case of plug-in electric vehicles) for series production all-electric passenger vehicles rated by the EPA as of January 2015[update], versus EPA rated most fuel efficient plug-in hybrid with long distance range (Chevrolet Volt), gasoline-electric hybrid car (Toyota Prius third generation),[83][84] and EPA's average new 2013/14 vehicle, which has a fuel economy of 23 mpg-US (10 L/100 km; 28 mpg-imp).[77][85]

| Comparison of fuel efficiency and costs for all the electric cars rated by the EPA for the U.S. market as of January 2015[update] against EPA rated most fuel efficient plug-in hybrid, hybrid electric vehicle and 2013 average gasoline-powered car in the U.S. (Fuel economy and operating costs as displayed in the Monroney label)[77][86] |

||||||||

|---|---|---|---|---|---|---|---|---|

| Vehicle | Model year |

EPA rated Combined fuel economy |

EPA rated City fuel economy |

EPA rated Highway fuel economy |

Cost to drive 25 miles |

Annual fuel cost |

Notes | |

| BMW i3[87] | 2014 | 124 mpg-e (27 kW-hrs/100 mi) |

137 mpg-e (25 kW-hrs/100 mi) |

111 mpg-e (30 kW-hrs/100 mi) |

$0.81 | $500 | See (1) and (3) The 2014 BMW i3 is the most fuel efficient EPA-certified vehicle of all fuel types considered in all years.[88] The i3 REx has a combined fuel economy in all-electric mode of 117 mpg-e (29 kW-hrs/100 mi).[89] |

|

| Scion iQ EV[90] | 2013 | 121 mpg-e (28 kW-hrs/100 mi) |

138 mpg-e (24 kW-hrs/100 mi) |

105 mpg-e (32 kW-hrs/100 mi) |

$0.84 | $500 | See (1) | |

| Chevrolet Spark EV[91] | 2014 | 119 mpg-e (28 kW-hrs/100 mi) |

128 mpg-e (26 kW-hrs/100 mi) |

109 mpg-e (31 kW-hrs/100 mi) |

$0.84 | $500 | See (1) | |

| Honda Fit EV[92] | 2013 | 118 mpg-e (29 kW-hrs/100 mi) |

132 mpg-e (26 kW-hrs/100 mi) |

105 mpg-e (32 kW-hrs/100 mi) |

$0.87 | $500 | See (1) | |

| Fiat 500e[93] | 2013/14 | 116 mpg-e (29 kW-hrs/100 mi) |

122 mpg-e (28 kW-hrs/100 mi) |

108 mpg-e (31 kW-hrs/100 mi) |

$0.87 | $500 | See (1) | |

| Nissan Leaf[94] | 2013 | 115 mpg-e (29 kW-hrs/100 mi) |

129 mpg-e (26 kW-hrs/100 mi) |

102 mpg-e (33 kW-hrs/100 mi) |

$0.87 | $500 | See (1) | |

| Volkswagen e-Golf[95] | 2015 | 116 mpg-e (29 kW-hrs/100 mi) |

126 mpg-e | 105 mpg-e | $0.87 | $550 | See (1) | |

| Nissan Leaf[94] | 2014/15 | 114 mpg-e (30 kW-hrs/100 mi) |

126 mpg-e (27 kW-hrs/100 mi) |

101 mpg-e (33 kW-hrs/100 mi) |

$0.90 | $550 | See (1) | |

| Mitsubishi i[96] | 2012/13 | 112 mpg-e (30 kW-hrs/100 mi) |

126 mpg-e (27 kW-hrs/100 mi) |

99 mpg-e (34 kW-hrs/100 mi) |

$0.90 | $550 | See (1) | |

| Smart electric drive[97] | 2013 | 107 mpg-e (32 kW-hrs/100 mi) |

122 mpg-e (28 kW-hrs/100 mi) |

93 mpg-e (36 kW-hrs/100 mi) |

$0.96 | $600 | See (1) Ratings correspond to both convertible and coupe models. |

|

| Kia Soul EV[98] | 2015 | 105 mpg-e (32 kW-hrs/100 mi) |

120 mpg-e | 92 mpg-e | $0.96 | $600 | See (1) | |

| Ford Focus Electric[99] | 2012/13 | 105 mpg-e (32 kW-hrs/100 mi) |

110 mpg-e (31 kW-hrs/100 mi) |

99 mpg-e (34 kW-hrs/100 mi) |

$0.96 | $600 | See (1) | |

| BMW ActiveE[100] | 2011 | 102 mpg-e (33 kW-hrs/100 mi) |

107 mpg-e | 96 mpg-e | $0.99 | $600 | See (1) | |

| Tesla Model S AWD - 85D[86] | 2015 | 100 mpg-e (34 kWh/100 mi) |

95 mpg-e | 106 mpg-e | $1.02 | $600 | See (1) Model with 85kWh battery pack |

|

| Nissan Leaf[101] | 2011/12 | 99 mpg-e (34 kW-hrs/100 mi) |

106 mpg-e (32 kW-hrs/100 mi) |

92 mpg-e (37 kW-hrs/100 mi) |

$1.02 | $600 | See (1) | |

| Tesla Model S[102] | 2013/14 | 95 mpg-e (35 kW-hrs/100 mi) |

94 mpg-e (36 kW-hrs/100 mi) |

97 mpg-e (35 kW-hrs/100 mi) |

$1.05 | $650 | See (1) Model with 60kWh battery pack |

|

| Tesla Model S AWD - P85D[86] | 2015 | 93 mpg-e (36 kWh/100 mi) |

89 mpg-e | 98 mpg-e | $1.08 | $650 | See (1) Model with 85kWh battery pack |

|

| Tesla Model S[103] | 2012/15 | 89 mpg-e (38 kW-hrs/100 mi) |

88 mpg-e (38 kW-hrs/100 mi) |

90 mpg-e (37 kW-hrs/100 mi) |

$1.14 | $700 | See (1) Model with 85kWh battery pack |

|

| Tesla Model S AWD[86] | 2014 | 89 (38 kWh/100 mi) |

86 | 94 | $1.14 | $700 | See (1) Model with 85kWh battery pack |

|

| Mercedes-Benz B-Class Electric Drive[104] | 2014 | 84 mpg-e (40 kW-hrs/100 mi) |

85 mpg-e (40 kW-hrs/100 mi) |

83 mpg-e (41 kW-hrs/100 mi) |

$1.20 | $700 | See (1) | |

| Toyota RAV4 EV[105] | 2012/13 | 76 mpg-e (44 kW-hrs/100 mi) |

78 mpg-e (43 kW-hrs/100 mi) |

74 mpg-e (46 kW-hrs/100 mi) |

$1.32 | $850 | See (1) | |

| Chevrolet Volt[106] (PHEV) |

Electricity only | 2013/15 | 98 mpg-e (35 kW-hrs/100 mi) |

- | - | $1.05 | $900 | See (1) and (2) Most fuel efficient PHEV capable of long distance travel. The 2013/14 Volt has a rating of 62 mpg-e for combined gasoline/electricity operation.[83] |

| Gasoline only | 37 mpg | 35 mpg | 40 mpg | $2.57 | ||||

| Toyota Prius[107] (HEV) |

Gasoline-electric hybrid |

2010/13 | 50 mpg | 51 mpg | 48 mpg | $1.74 | $1,050 | See (2) Most fuel efficient hybrid electric car, together with the Prius c.[83][108] |

| Ford Taurus FWD FFV[77][78] (Average new car using regular gasoline) |

Gasoline only | 2013/14 | 23 mpg | 19 mpg | 29 mpg | $3.79 | $2,300 | See (2) Other 2013 models achieving 23 mpg include the Chrysler 200, and the Toyota Venza.[78] |

| Notes: All estimated fuel costs based on 15,000 miles annual driving, 45% highway and 55% city. (1) Values rounded to the nearest $50. Electricity cost of $0.12/kw-hr (as of 26 January 2015). Conversion 1 gallon of gasoline=33.7 kW-hr. (2) Premium gasoline price of US$3.81 per gallon (used by the Volt), and regular gasoline price of US$3.49 per gallon (as of 30 March 2014). (3) The 2014 i3 REx is classified by EPA as a series plug-in hybrid, while for CARB is a range-extended battery-electric vehicle (BEVx). The i3 REx is the most fuel efficient EPA-certified current year vehicle with a gasoline engine with a combined gasoline/electricity rating of 88 mpg-e, but its total range is limited to 150 mi (240 km).[83][88][update][update] |

||||||||

Mileage costs

Most of the mileage-related cost of an electric vehicle can be attributed to the maintenance of the battery pack, and its eventual replacement, because an electric vehicle has only around 5 moving parts in its motor, compared to a gasoline car that has hundreds of parts in its internal combustion engine.[109] To calculate the cost per kilometer of an electric vehicle it is therefore necessary to assign a monetary value to the wear incurred on the battery. With use, the capacity of a battery decreases. However, even an 'end of life' battery which has insufficient capacity has market value as it can be re-purposed, recycled or used as a spare.[citation needed]The Tesla Roadster's very large battery pack is expected to last seven years with typical driving and costs US$12,000 when pre-purchased today.[110][111] Driving 40 miles (64 km) per day for seven years or 102,200 miles (164,500 km) leads to a battery consumption cost of US$0.1174 per 1 mile (1.6 km) or US$4.70 per 40 miles (64 km). The company Better Place provided another cost comparison as they anticipate meeting contractual obligations to deliver batteries as well as clean electricity to recharge the batteries at a total cost of US$0.08 per 1 mile (1.6 km) in 2010, US$0.04 per mile by 2015 and US$0.02 per mile by 2020.[112] 40 miles (64 km) of driving would initially cost US$3.20 and fall over time to US$0.80.

In 2010 the U.S. government estimated that a battery with a 100 miles (160 km) range would cost about US$33,000. Concerns remain about durability and longevity of the battery.[113]

Total cost of ownership

A 2010 report by J.D. Power and Associates states that it is not entirely clear to consumers the total cost of ownership of battery electric vehicles over the life of the vehicle, and "there is still much confusion about how long one would have to own such a vehicle to realize cost savings on fuel, compared with a vehicle powered by a conventional internal combustion engine (ICE). The resale value of HEVs and BEVs, as well as the cost of replacing depleted battery packs, are other financial considerations that weigh heavily on consumers’ minds."[114]A study published in 2011 by the Belfer Center, Harvard University, found that the gasoline costs savings of plug-in electric cars over their lifetimes do not offset their higher purchase prices. The study compared the lifetime net present value at 2010 purchase and operating costs for the US market with no government subsidies.[115][116] The study estimated that a PHEV-40 is US$5,377 more expensive than a conventional internal combustion engine, while a battery electric vehicle is US$4,819 more expensive. But assuming that battery costs will decrease and gasoline prices increase over the next 10 to 20 years, the study found that BEVs will be significantly cheaper than conventional cars (US$1,155 to US$7,181 cheaper). PHEVs, will be more expensive than BEVs in almost all comparison scenarios, and more expensive than conventional cars unless battery costs are very low and gasoline prices high. Savings differ because BEVs are simpler to build and do not use liquid fuel, while PHEVs have more complicated power trains and still have gasoline-powered engines.[115]

Range and recharging time

Most cars with internal combustion engines can be considered to have indefinite range, as they can be refueled very quickly. Electric cars often have less maximum range on one charge than cars powered by fossil fuels, and they can take considerable time to recharge. However, they can be charged at home overnight, which fossil fueled cars cannot. 71% of all car drivers in America drive less than 40 miles (64 km) per day,.[117] Nevertheless, people can be concerned that they would run out of energy from their battery before reaching their destination, a worry known as range anxiety.The Tesla Roadster can travel 245 miles (394 km) per charge;[118] more than double that of prototypes and evaluation fleet cars currently on the roads.[119] The Roadster can be fully recharged in about 3.5 hours from a 220-volt, 70-amp outlet which can be installed in a home.[120] But using a European standard 220-volt, 16-amp outlet a full charge will take more than 15 hours.

However, most vehicles also support much faster charging, where a suitable power supply is

available. Therefore for long distance travel, in the US and elsewhere, there has been the installation of DC Fast Charging stations with high-speed charging capability from three-phase industrial outlets so that consumers could recharge the 100-200+ mile battery of their electric vehicle to 80 percent in about 30 minutes.[121][122]

As of December 2013[update], Estonia is the first and only country that had deployed an EV charging network with nationwide coverage, with fast chargers available along highways at a minimum distance of between 40 to 60 km (25 to 37 mi), and a higher density in urban areas.[123][124][125] A nationwide fast charging infrastructure is currently being deployed in the US that by 2013 will cover the entire nation.[126] DC Fast Chargers are going to be installed at 45 BP and ARCO locations and will be made available to the public as early as March 2011.[127] The EV Project will deploy charge infrastructure in 16 cities and major metropolitan areas in six states.[128][129] Nissan has announced that 200 of its dealers in Japan will install fast chargers for the December 2010 launch of its Leaf EV, with the goal of having fast chargers everywhere in Japan within a 25-mile radius.[130] Although charging at these stations is still relatively time consuming compared to refueling, in practice it often meshes well with a normal driving pattern, where driving is usually done for a few hours before stopping and resting and drink or eating; this gives the car a chance to be charged.[131]

Another way to extend the limited range of electric vehicles is by battery swapping. An EV can go to a battery switch station and swap a depleted battery with a fully charged one in a few minutes. In 2011 Better Place deployed the first modern commercial application of the battery switching model, but due to financial difficulties, the company filed for bankruptcy in May 2013.[132][133][134][135]

A similar idea is that of the range-extension trailer which is attached only when going on long trips. The trailers can either be owned or rented only when necessary.[136] BMW i is offering a gasoline-powered range extender engine as an option for its BMW i3 all-electric car.[137] The company is also planning to offer additional mobility packages for trips where the range of an BMW i3 would not be enough to allow customers to cover longer distances, by providing a conventional BMW vehicle on a given number of days per year.[138] The i3 performance in range-extending mode may be more limited than when it is running on battery power, as BMW clarified that the range extender is designed not for long-distance travel but purely as an emergency backup to keep the electric system going until the next recharging location.[139] The range-extender option will cost an additional US$3,850 in the United States,[140] an additional €4,710 (~ US$6,300) in France,[141] and €4,490 (~ US$6,000) in the Netherlands.[142]

Air pollution and carbon emissions

Electric cars contribute to cleaner air in cities because they produce no harmful pollution at the tailpipe from the onboard source of power, such as particulates (soot), volatile organic compounds, hydrocarbons, carbon monoxide, ozone, lead, and various oxides of nitrogen. The clean air benefit is usually local because, depending on the source of the electricity used to recharge the batteries, air pollutant emissions are shifted to the location of the generation plants.[2] Nevertheless, introducing EV would come with a major environmental benefits in most (EU) countries, except those relying on old coal fired power plants.[143] The amount of carbon dioxide emitted depends on the emission intensity of the power source used to charge the vehicle, the efficiency of the said vehicle and the energy wasted in the charging process. This is referred to as the long tailpipe of electric vehicles.For mains electricity the emission intensity varies significantly per country and within a particular country it will vary depending on demand,[144] the availability of renewable sources and the efficiency of the fossil fuel-based generation used at a given time.[143][145]

Charging a vehicle using renewable energy yields very low carbon footprint (only that to produce and install the generation system e.g. wind power).

- United States

2 emissions estimated by the U.S.

Environmental Protection Agency for all series production model year 2014 all-electric passenger vehicles available in the U.S. market. Since all-electric cars do not produce tailpipe emissions, for comparison purposes the two most fuel efficient plug-in hybrids and the typical gasoline-powered car are included in the table. Total emissions include the emissions associated with the production and distribution of electricity used to charge the vehicle, and for plug-in hybrid electric vehicles, it also includes emissions associated with tailpipe emissions produced from the internal combustion engine. These figures were published by the EPA in October in its 2014 report "Light-Duty Automotive Technology, Carbon Dioxide Emissions, and Fuel Economy Trends."[147]

In order to account for the upstream CO

2 emissions associated with the production and distribution of electricity, and since electricity production in the United States varies significantly from region to region, the EPA considered three scenarios/ranges with the low end scenario corresponding to the California powerplant emissions factor, the middle of the range represented by the national average powerplant emissions factor, and the upper end of the range corresponding to the powerplant emissions factor for the Rocky Mountains. The EPA estimates that the electricity GHG emission factors for various regions of the country vary from 346 g CO

2/kWh in California to 986 g CO

2/kWh in the Rockies, with a national average of 648 g CO

2/kWh.[147] In the case of plug-in hybrids, and since their all-electric range depends on the size of the battery pack, the analysis introduced a utility factor as a projection of the share of miles that will be driven using electricity by an average driver.[147]

| Comparison of tailpipe and upstream CO 2 emissions(1) estimated by EPA for the MY 2014 all-electric vehicles available in the U.S. market[147] |

||||||

|---|---|---|---|---|---|---|

| Vehicle | Overall fuel economy (mpg-e) |

Utility factor(2) (share EV miles) |

Tailpipe CO 2 (g/mi) |

Tailpipe + Total Upstream CO2 | ||

| Low (g/mi) |

Avg (g/mi) |

High (g/mi) |

||||

| BMW i3 | 124 | 1 | 0 | 93 | 175 | 266 |

| Chevrolet Spark EV | 119 | 1 | 0 | 97 | 181 | 276 |

| Honda Fit EV | 118 | 1 | 0 | 99 | 185 | 281 |

| Fiat 500e | 116 | 1 | 0 | 101 | 189 | 288 |

| Nissan Leaf | 114 | 1 | 0 | 104 | 194 | 296 |

| Mitsubishi i | 112 | 1 | 0 | 104 | 195 | 296 |

| Smart electric drive | 107 | 1 | 0 | 109 | 204 | 311 |

| Ford Focus Electric | 105 | 1 | 0 | 111 | 208 | 316 |

| Tesla Model S (60 kWh) | 95 | 1 | 0 | 122 | 229 | 348 |

| Tesla Model S (85 kWh) | 89 | 1 | 0 | 131 | 246 | 374 |

| BMW i3 REx(3) | 88 | 0.83 | 40 | 134 | 207 | 288 |

| Mercedes-Benz B-Class ED | 84 | 1 | 0 | 138 | 259 | 394 |

| Toyota RAV4 EV | 76 | 1 | 0 | 153 | 287 | 436 |

| BYD e6 | 63 | 1 | 0 | 187 | 350 | 532 |

| Chevrolet Volt plug-in hybrid | 62 | 0.66 | 81 | 180 | 249 | 326 |

| Average 2014 gasoline-powered car | 24.2 | 0 | 367 | 400 | 400 | 400 |

| Notes: (1) Based on 45% highway and 55% city driving. (2) The utility factor represents, on average, the percentage of miles that will be driven using electricity (in electric only and blended modes) by an average driver. (3) The EPA classifies the i3 REx as a series plug-in hybrid.[77][147] |

||||||

2 emissions than plug-in electric cars, and the best fuel efficient gasoline-powered subcompact car produces slightly less emissions than a plug-in car. In the worst-case scenario, the study estimated that for a region where all energy is generated from coal, a plug-in electric car would emit greenhouse gas emissions equivalent to a gasoline car rated at a combined city/highway fuel economy of 30 mpg-US (7.8 L/100 km; 36 mpg-imp). In contrast, in a region that is completely reliant on natural gas, the plug-in would be equivalent to a gasoline-powered car rated at 50 mpg-US (4.7 L/100 km; 60 mpg-imp) combined.[148][149]

The study found that for 45% of the U.S. population, a plug-in electric car will generate lower CO

2 emissions than a gasoline-powered car capable of a combined fuel economy of 50 mpg-US (4.7 L/100 km; 60 mpg-imp), such as the Toyota Prius. Cities in this group included Portland, Oregon, San Francisco, Los Angeles, New York City, and Salt Lake City, and the cleanest cities achieved well-to-wheel emissions equivalent to a fuel economy of 79 mpg-US (3.0 L/100 km; 95 mpg-imp). The study also found that for 37% of the population, the electric car emissions will fall in the range of a gasoline-powered car rated at a combined fuel economy between 41 to 50 mpg-US (5.7 to 4.7 L/100 km; 49 to 60 mpg-imp), such as the Honda Civic Hybrid and the Lexus CT200h. Cities in this group include Phoenix, Arizona, Houston, Miami, Columbus, Ohio and Atlanta, Georgia. An 18% of the population lives in areas where the power supply is more dependent on burning carbon, and emissions will be equivalent to a car rated at a combined fuel economy between 31 to 40 mpg-US (7.6 to 5.9 L/100 km; 37 to 48 mpg-imp), such as the Chevrolet Cruze and Ford Focus. This group includes Denver, Minneapolis, Saint Louis, Missouri, Detroit, and Oklahoma City.[149][150][151] The study found that there are no regions in the U.S. where plug-in electric cars will have higher greenhouse gas emissions than the average new compact gasoline engine automobile, and the area with the dirtiest power supply produces CO

2 emissions equivalent to a gasoline-powered car rated 33 mpg-US (7.1 L/100 km; 40 mpg-imp).[148]

In September 2014 the UCS published an updated analysis of its 2012 report. The 2014 analysis found that 60% of Americans, up from 45% in 2012, live in regions where an all-electric car produce fewer CO

2 equivalent emissions per mile than the most efficient hybrid. The UCS study found two reasons for the improvement. First, electric utilities have adopted cleaner sources of electricity to their mix between the two analysis. Second, electric vehicles have become more efficient, as the average 2013 all-electric vehicle used 0.33 kWh per mile, representing a 5% improvement over 2011 models. Also, some new models are cleaner than the average, such as the BMW i3, which is rated at 0.27 kWh by the EPA. In states with a cleaner mix generation, the gains were larger. The average all-electric car in California went up to 95 mpg-US (2.5 L/100 km) equivalent from 78 mpg-US (3.0 L/100 km) in the 2012 study. States with dirtier generation that rely heavily on coal still lag, such as Colorado, where the average BEV only achieves the same emissions as a 34 mpg-US (6.9 L/100 km; 41 mpg-imp) gasoline-powered car. The author of the 2014 analysis noted that the benefits are not distributed evenly across the U.S. because electric car adoptions is concentrated in the states with cleaner power.[152][153]

One criticism to the UCS analysis and several other that have analyze the benefits of PEVs is that these analysis were made using average emissions rates across regions instead of marginal generation at different times of the day. The former approach does not take into account the generation mix within interconnected electricity markets and shifting load profiles throughout the day.[154][155] An analysis by three economist affiliated with the National Bureau of Economic Research (NBER), published in November 2014, developed a methodology to estimate marginal emissions of electricity demand that vary by location and time of day across the United States. The marginal analysis, applied to plug-in electric vehicles, found that the emissions of charging PEVs vary by region and hours of the day. In some regions, such as the Western U.S. and Texas, CO

2 emissions per mile from driving PEVs are less than those from driving a hybrid car. However, in other regions, such as the Upper Midwest, charging during the recommended hours of midnight to 4 a.m. implies that PEVs generate more emissions per mile than the average car currently on the road. The results show a fundamental tension between electricity load management and environmental goals as the hours when electricity is the least expensive to produce tend to be the hours with the greatest emissions. This occurs because coal-fired units, which have higher emission rates, are most commonly used to meet base-level and off-peak electricity demand; while natural gas units, which have relatively low emissions rates, are often brought online to meet peak demand.[155]

- United Kingdom

The savings are questionable relative to hybrid or diesel cars (according to official British government testing, the most efficient European market cars are well below 115 grams of CO

2 per kilometer driven, although a study in Scotland gave 149.5gCO

2/km as the average for new cars in the UK[157]), but since UK consumers can select their energy suppliers, it also will depend on how 'green' their chosen supplier is in providing energy into the grid. In contrast to other countries, in the UK a stable part of the electricity is produced by nuclear, coal and gas plants. Therefore there are only minor differences in the environmental impact over the year.[143]

- Germany

2 emissions by 0.1%, if nothing is done to upgrade the electricity infrastructure or manage demand.[158] A more reasonable estimate, relaxing the coal assumption, was provided by Massiani and Weinmann taking into account that the source of energy used for electricity generation would be determined based on the temporal pattern of the additional electricity demand (in other words an increase in electricity consumption at peak hour will activate the marginal technology, while an off peak increase would typically activate other technologies). Their conclusion is that natural gas will provide most of the energy used to reaload EV, while renewable energy will not represent more than a few percent of the energy used.[159]

Volkswagen conducted a life-cycle assessment of its electric vehicles certified by an independent inspection agency. The study found that CO

2 emissions during the use phase of its all-electric VW e-Golf are 99% lower than those of the Golf 1.2 TSI when powers comes from exclusively hydroelectricity generated in Germany, Austria and Switzerland. Accounting for the electric car entire life-cycle, the e-Golf reduces emissions by 61%. When the actual EU-27 electricity mix is considered, the e-Golf emissions are still 26% lower than those of the conventional Golf 1.2 TSI.[160]

- France and Belgium

2 emissions from electric car use would be about 12g per km (19.2g per US mile).[161] Because of the stable nuclear production, the timing of charging electric cars has almost no impact on their environmental footprint.[143]

- Emissions during production

Environmental impact of manufacturing

Electric cars are not completely environmentally friendly, and have impacts arising from manufacturing the vehicle. Since battery packs are heavy, manufacturers work to lighten the rest of the vehicle. As a result, electric car components contain many lightweight materials that require a lot of energy to produce and process, such as aluminium and carbon-fiber-reinforced polymers. Electric motors and batteries also add to the energy of electric-car manufacture.[163] Additionally, the magnets in the motors of electric vehicles contain precious metals. In a study released in 2012, a group of MIT researchers calculated that global mining of two rare Earth metals, neodymium and dysprosium, would need to increase 700% and 2600%, respectively, over the next 25 years to keep pace with various green-tech plans.[164] Substitute strategies do exist, but deploying them introduces trade-offs in efficiency and cost.[163] The same MIT study noted that the materials used in batteries are also harmful to the environment.[165] Compounds such as lithium, copper, and nickel are mined from the Earth and processed in a manner that demands energy and can release toxic components. In regions with poor legislature, mineral exploitation can even further extend risks. The local population may be exposed to toxic substances through air and groundwater contamination.[163][clarification needed]A paper published in the Journal of Industrial Ecology named "Comparative environmental life cycle assessment of conventional and electric vehicles" begins by stating that it is important to address concerns of problem-shifting.[166] The study highlighted in particular the toxicity of the electric car's manufacturing process compared to conventional petrol/diesel cars. It concludes that the global warming potential of the process used to make electric cars is twice that of conventional cars. The study also finds that electric cars do not make sense if the electricity they consume is produced predominately by coal-fired power plants.[167]

Acceleration and drivetrain design

Electric motors can provide high power-to-weight ratios, and batteries can be designed to supply the large currents to support these motors.Although some electric vehicles have very small motors, 15 kW (20 hp) or less and therefore have modest acceleration, many electric cars have large motors and brisk acceleration. In addition, the relatively constant torque of an electric motor, even at very low speeds tends to increase the acceleration performance of an electric vehicle relative to that of the same rated motor power internal combustion engine. Another early solution was American Motors’ experimental Amitron piggyback system of batteries with one type designed for sustained speeds while a different set boosted acceleration when needed.[168]

Electric vehicles can also use a direct motor-to-wheel configuration which increases the amount of available power. Having multiple motors connected directly to the wheels allows for each of the wheels to be used for both propulsion and as braking systems, thereby increasing traction. In some cases, the motor can be housed directly in the wheel, such as in the Whispering Wheel design, which lowers the vehicle's center of gravity and reduces the number of moving parts.[169][170][171] When not fitted with an axle, differential, or transmission, electric vehicles have less drivetrain rotational inertia. Housing the motor within the wheel can increase the unsprung weight of the wheel, which can have an adverse effect on the handling of the vehicle.[citation needed]

Transmission

A gearless or single gear design in some EVs eliminates the need for gear shifting, giving such vehicles both smoother acceleration and smoother braking. Because the torque of an electric motor is a function of current, not rotational speed, electric vehicles have a high torque over a larger range of speeds during acceleration, as compared to an internal combustion engine. As there is no delay in developing torque in an EV, EV drivers report generally high satisfaction with acceleration.[citation needed]The gearless design is the least complex, but high acceleration requires high torque from the motor, which requires high current and results in Joule heating. This is because the internal wiring of the motor has electrical resistance, which dissipates power as heat when a current is put through it, in accordance to Ohm's Law. While the torque of the electric motor is not dependent on its rotational speed, the output power of the motor is the product of both the torque and the rotational speed, which means that more power is lost in proportion to the output power when the motor is turning slowly. In effect, the drive train becomes less efficient the slower the vehicle moves.[citation needed]

In the single gear design, this problem is mitigated by using a gear ratio that allows the motor to turn faster than the wheel, which translates low torque and high rotational speed of the motor into high torque and low rotational speed of the wheels, giving equal or better acceleration without compromising efficiency as much. However, since the motor does have a top speed at which it can operate, the trade-off is lower top speed for the vehicle. If a higher top speed is desired, the trade-off is lower acceleration and lower efficiency at slow speeds. One solution is to use multiple motors. The Tesla Model S offers a dual motor option, where the second motor has a gear ratio which turns slower than the first. It adds a little to the start acceleration, allows a higher top speed, and by using it less at low speeds and the other less a high speeds (and the first motor more at low and less a high speeds), the overall efficiency is increased, translating into more range. The use of a multiple-speed transmission allows the vehicle to operate efficiently at both high and low speeds, but comes with more complexity and cost.[citation needed]

For example, the Venturi Fetish delivers supercar acceleration despite a relatively modest 220 kW (295 hp), and top speed of around 160 km/h (100 mph). Some DC-motor-equipped drag racer EVs, have simple two-speed manual transmissions to improve top speed.[172] The Tesla Roadster 2.5 Sport can accelerate from 0 to 97 km/h (0 to 60 mph) in 3.7 seconds with a motor rated at 215 kW (288 hp).[173] The Tesla Model S Performance currently holds the world record for the quickest production electric car to do 402 m (1⁄4 mi), which it did in 12.37 seconds at 178.3 km/h (110.8 mph).[174] And the Wrightspeed X1 prototype created by Wrightspeed Inc is the worlds fastest street legal electric car to accelerate from 0 to 97 km/h (0 to 60 mph), which it does in 2.9 seconds.[175][176]

Energy efficiency

Internal combustion engines are relatively inefficient at converting on-board fuel energy to propulsion as most of the energy is wasted as heat. On the other hand, electric motors are more efficient in converting stored energy into driving a vehicle, and electric drive vehicles do not consume energy while at rest or coasting, and some of the energy lost when braking is captured and reused through regenerative braking, which captures as much as one fifth of the energy normally lost during braking.[2][177] Typically, conventional gasoline engines effectively use only 15% of the fuel energy content to move the vehicle or to power accessories, and diesel engines can reach on-board efficiencies of 20%, while electric drive vehicles have on-board efficiency of around 80%.[177]Production and conversion electric cars typically use 10 to 23 kW·h/100 km (0.17 to 0.37 kW·h/mi).[79][178] Approximately 20% of this power consumption is due to inefficiencies in charging the batteries. Tesla Motors indicates that the vehicle efficiency (including charging inefficiencies) of their lithium-ion battery powered vehicle is 12.7 kW·h/100 km (0.21 kW·h/mi) and the well-to-wheels efficiency (assuming the electricity is generated from natural gas) is 24.4 kW·h/100 km (0.39 kW·h/mi).[179]

Cabin heating and cooling

Electric vehicles generate very little waste heat and resistance electric heat may have to be used to heat the interior of the vehicle if heat generated from battery charging/discharging cannot be used to heat the interior.While heating can be simply provided with an electric resistance heater, higher efficiency and integral cooling can be obtained with a reversible heat pump (this is currently implemented in the hybrid Toyota Prius). Positive Temperature Coefficient (PTC) junction cooling[180] is also attractive for its simplicity — this kind of system is used for example in the Tesla Roadster.

Because electric cars' cabin climate control system does not depend on an internal combustion engine running, to avoid impacting the electric car range some models allow the cabin to be already at the correct temperature at the time the car is next to be used. For example, the Nissan Leaf and the Mistubishi i-MiEV can be pre-heated when the vehicle is plugged in to reduce the impact on range due to cabin heating.[181][182]

Some electric cars, for example the Citroën Berlingo Electrique, use an auxiliary heating system (for example gasoline-fueled units manufactured by Webasto or Eberspächer) but sacrifice "green" and "Zero emissions" credentials. Cabin cooling can be augmented with solar power, most simply and effectively by inducting outside air to avoid extreme heat buildup when the vehicle is closed and parked in the sunlight (such cooling mechanisms are available as aftermarket kits for conventional vehicles). Two models of the 2010 Toyota Prius include this feature as an option.[183]

Safety

The safety issues of BEVs are largely dealt with by the international standard ISO 6469. This document is divided in three parts dealing with specific issues:- On-board electrical energy storage, i.e. the battery

- Functional safety means and protection against failures

- Protection of persons against electrical hazards.

Risk of fire

Lithium-ion batteries may suffer thermal runaway and cell rupture if overheated or overcharged, and in extreme cases this can lead to combustion.[184] Several plug-in electric vehicle fire incidents have taken place since the introduction of mass-production plug-in electric vehicles in 2008. Most of them have been thermal runaway incidents related to their lithium-ion battery packs, and have involved the Zotye M300 EV, Chevrolet Volt, Fisker Karma, BYD e6, Dodge Ram 1500 Plug-in Hybrid, Toyota Prius Plug-in Hybrid, Mitsubishi i-MiEV and Outlander P-HEV. As of November 2013[update], four post-crash fires associated with the batteries of all-electric cars—involving one BYD e6 and three Tesla Model S cars—have been reported.[citation needed]

The first modern crash-related fire was reported in China in May 2012, after a high-speed car crashed into a BYD e6 taxi in Shenzhen.[185] The second reported incident occurred in the United States in October 1, 2013, when a Tesla Model S caught fire after the electric car hit metal debris on a highway in Kent, Washington state, and the debris punctured one of 16 modules within the battery pack.[186][187] A second reported fire occurred on October 18, 2013 in Merida, Mexico. In this case the vehicle was being driven at high speed through a roundabout and crashed through a wall and into a tree. On November 6, 2013, a Tesla Model S being driven on Interstate 24 near Murfreesboro, Tennessee caught fire after it struck a tow hitch on the roadway, causing damage beneath the vehicle.[188]

In the United States, General Motors ran in several cities a training program for firefighters and first responders to demonstrate the sequence of tasks required to safely disable the Chevrolet Volt’s powertrain and its 12 volt electrical system, which controls its high-voltage components, and then proceed to extricate injured occupants. The Volt's high-voltage system is designed to shut down automatically in the event of an airbag deployment, and to detect a loss of communication from an airbag control module.[189][190] GM also made available an Emergency Response Guide for the 2011 Volt for use by emergency responders. The guide also describes methods of disabling the high voltage system and identifies cut zone information.[191] Nissan also published a guide for first responders that details procedures for handling a damaged 2011 Leaf at the scene of an accident, including a manual high-voltage system shutdown, rather than the automatic process built-in the car's safety systems.[192][193]

Vehicle safety

Great effort is taken to keep the mass of an electric vehicle as low as possible to improve its range and endurance. However, the weight and bulk of the batteries themselves usually makes an EV heavier than a comparable gasoline vehicle, reducing range and leading to longer braking distances.However, in a collision, the occupants of a heavy vehicle will, on average, suffer fewer and less serious injuries than the occupants of a lighter vehicle; therefore, the additional weight brings safety benefits[194] despite having a negative effect on the car's performance. [195] They also use up interior space if packeaged ineffectively. If stored under the passanger cell, not only is this not the case, they also lower the vehicles's center of gravity, increasing driving stability, thereby lowering the risk of an accident through loss of control. An accident in a 2,000 lb (900 kg) vehicle will on average cause about 50% more injuries to its occupants than a 3,000 lb (1,400 kg) vehicle.[196] In a single car accident,[citation needed] and for the other car in a two car accident, the increased mass causes an increase in accelerations and hence an increase in the severity of the accident.

Some electric cars use low rolling resistance tires, which typically offer less grip than normal tires.[197][198][199] Many electric cars have a small, light and fragile body, though, and therefore offer inadequate safety protection. The Insurance Institute for Highway Safety in America had condemned the use of low speed vehicles and "mini trucks," referred to as neighborhood electric vehicles (NEVs) when powered by electric motors, on public roads.[200] Mindful of this, several companies (Tesla Motors, BMW) have succeeded in keeping the body light, while making it very strong.[citation needed]

Hazard to pedestrians

At low speeds, electric cars produced less roadway noise as compared to vehicles propelled by internal combustion engines. Blind people or the visually impaired consider the noise of combustion engines a helpful aid while crossing streets, hence electric cars and hybrids could pose an unexpected hazard.[201][202] Tests have shown that this is a valid concern, as vehicles operating in electric mode can be particularly hard to hear below 20 mph (30 km/h) for all types of road users and not only the visually impaired. At higher speeds, the sound created by tire friction and the air displaced by the vehicle start to make sufficient audible noise.[202]The Government of Japan, the U.S. Congress, and the European Parliament passed legislation to regulate the minimum level of sound for hybrids and plug-in electric vehicles when operating in electric mode, so that blind people and other pedestrians and cyclists can hear them coming and detect from which direction they are approaching.[202][203][204][205] The Nissan Leaf was the first electric car to use Nissan's Vehicle Sound for Pedestrians system, which includes one sound for forward motion and another for reverse.[72][206] As of January 2014[update], most of the hybrids and plug-in electric and hybrids available in the United States, Japan and Europe make warning noises using a speaker system. The Tesla Model S is one of the few electric cars without warning sounds, because Tesla Motors will await until regulations are enacted.[207] Volkswagen and BMW also decided to add artificial sounds to their electric drive cars only when required by regulation.[208]

Several anti-noise and electric car advocates have opposed the introduction of artificial sounds as warning for pedestrians, as they argue that the proposed system will only increase noise pollution.[citation needed]

Differences in controls

Presently most EV manufacturers do their best to emulate the driving experience as closely as possible to that of a car with a conventional automatic transmission that motorists are familiar with. Most models therefore have a PRNDL selector traditionally found in cars with automatic transmission despite the underlying mechanical differences. Push buttons are the easiest to implement as all modes are implemented through software on the vehicle's controller.Even though the motor may be permanently connected to the wheels through a fixed-ratio gear and no parking pawl may be present the modes "P" and "N" will still be provided on the selector. In this case the motor is disabled in "N" and an electrically actuated hand brake provides the "P" mode.

In some cars the motor will spin slowly to provide a small amount of creep in "D", similar to a traditional automatic.[209]

When the foot is lifted from the accelerator of an ICE, engine braking causes the car to slow. An EV would coast under these conditions, and applying mild regenerative braking instead provides a more familiar response. Selecting the L mode will increase this effect for sustained downhill driving, analogous to selecting a lower gear.

Batteries

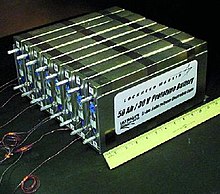

Prototypes of 75 watt-hour/kilogram lithium-ion polymer battery. Newer lithium-ion cells can provide up to 130 W·h/kg and last through thousands of charging cycles.

While most current highway-speed electric vehicle designs focus on lithium-ion and other lithium-based variants a variety of alternative batteries can also be used. Lithium-based batteries are often chosen for their high power and energy density but have a limited shelf life and cycle lifetime which can significantly increase the running costs of the vehicle. Variants such as Lithium iron phosphate and Lithium-titanate attempt to solve the durability issues with traditional lithium-ion batteries.

Other battery types include:

- Lead acid batteries are still the most used form of power for most of the electric vehicles used today. The initial construction costs are significantly lower than for other battery types, and while power output to weight is poorer than other designs, range and power can be easily added by increasing the number of batteries.[210]

- NiCd - Largely superseded by NiMH

- Nickel metal hydride (NiMH)

- Nickel iron battery - Known for its comparatively long lifetime and low power density

- Zinc-air battery

- Molten salt battery

- Zinc-bromine flow batteries or Vanadium redox batteries can be refilled, instead of recharged, saving time. The depleted electrolyte can be recharged at the point of exchange, or taken away to a remote station.

[211]

Travel range before recharging

The range of an electric car depends on the number and type of batteries used. The weight and type of vehicle, and the performance demands of the driver, also have an impact just as they do on the range of traditional vehicles. The range of an electric vehicle conversion depends on the battery type:Battery swapping

An alternative to quick recharging is to exchange a discharged battery or battery pack for a fully charged one, saving the delay of waiting for the vehicle's battery to charge. Battery swapping is common in warehouses using electric forklift trucks.[212] The concept of exchangeable battery service was first proposed as early as 1896 in order to overcome the limited operating range of electric cars and trucks.[21] The concept was first put into practice by Hartford Electric Light Company through the GeVeCo battery service and was initially available for electric trucks. Both vehicles and batteries were modified to facilitate a fast battery exchange. The service was provided between 1910 to 1924 and during that period covered more than 6 million miles.[21] A rapid battery replacement system was implemented to keep running 50 electric buses at the 2008 Summer Olympics.[213]Better Place

After implementing the first modern commercial deployment of the battery swapping model in Israel and Denmark, Better Place filed for bankruptcy in Israel in May 2013. The company's financial difficulties were caused by the high investment required to develop the charging and swapping infrastructure, about US$850 million in private capital, and a market penetration significantly lower than originally expected by the company's founder, Shai Agassi, who had predicted that 100,000 electric cars would be on Israeli roads by 2010. Fewer than 1,000 Fluence Z.E. cars were deployed in Israel and only around 400 units in Denmark.[134][218][219] Under Better Place's business model, the company owned the batteries, so the court liquidator had to decide what to do with customers who did not have ownership of the battery and risked being left with a useless car.[220] In July 2013 is was announced that Better Place would be acquired by the Sunrise group, which was to pay ₪18 million (US$5 million) for Better Place’s assets in Israel, and ₪25 million (US$7 million) for its intellectual property, held by Better Place Switzerland.[221] However the deal fell through a month later when the Sunrise group failed to make its first court-ordered payment for Better Place's operational assets and intellectual property.[222]

Tesla Motors

Tesla Motors designed its Model S to allow fast battery swapping.[223] In June 2013, Tesla announced their goal to deploy a battery swapping station in each of its supercharging stations. At a demonstration event Tesla showed that a battery swap operation with the Model S takes just over 90 seconds, about half the time it takes to refill a gasoline-powered car.[224][225]The first stations are planned to be deployed along Interstate 5 in California where, according to Tesla, a large number of Model S sedans make the San Francisco-Los Angeles trip regularly. These will be followed by the Washington, DC to Boston corridor. Each swapping station will cost US$500,000 and will have about 50 batteries available without requiring reservations. The service would be offered for the price of about 15 US gallons (57 l; 12 imp gal) of gasoline at the current local rate, around US$60 to US$80 at June 2013 prices.[224]

Vehicle-to-grid: uploading and grid buffering

A Smart grid allows BEVs to provide power to the grid, specifically:- During peak load periods, when the cost of electricity can be very high. These vehicles can then be recharged during off-peak hours at cheaper rates while helping to absorb excess night time generation. Here the batteries in the vehicles serve as a distributed storage system to buffer power.

- During blackouts, as an emergency backup supply.

Lifespan

Battery life should be considered when calculating the extended cost of ownership, as all batteries eventually wear out and must be replaced. The rate at which they expire depends on the type of battery and how they are used — many types of batteries are damaged by depleting them beyond a certain level. Lithium-ion batteries degrade faster when stored at higher temperatures.Future

- Lithium availability

- Other methods of energy storage

- Solar cars

Charging

Main article: Charging station

Batteries in BEVs must be periodically recharged.Unlike vehicles powered by fossil fuels, BEVs are most commonly and conveniently charged from the power grid overnight at home, without the inconvenience of having to go to a filling station. Charging can also be done using a street or shop charging station.

The electricity on the grid is in turn generated from a variety of sources; such as coal, hydroelectricity, nuclear and others. Power sources such as roof top photovoltaic solar cell panels, micro hydro or wind may also be used and are promoted because of concerns regarding global warming.

As part of its commitment to environmental sustainability, the Dutch government initiated a plan to establish over 200 recharging stations for electric vehicles across the country by 2015. The rollout will be undertaken by Switzerland-based power and automation company ABB and Dutch startup Fastned, and will aim to provide at least one station every 50 kilometres (31 miles) for the Netherlands' 16 million residents.[235]

Reports emerged in late July 2013 of a significant conflict between the companies responsible for the two types of charging machines. The Japanese-developed CHAdeMO standard is favored by Nissan, Mitsubishi, and Toyota, while the Society of Automotive Engineers’ (SAE) International J1772 Combo standard is backed by GM, Ford, Volkswagen, and BMW. Both are direct-current quick-charging systems designed to charge the battery of an electric vehicle to 80 percent in approximately 20 minutes, but the two systems are completely incompatible. In light of an ongoing feud between the two companies, experts in the field warned that the momentum of the electric vehicle market will be severely affected.[236][237] Richard Martin, editorial director for clean technology marketing and consultant firm Navigant Research, stated:

Fast charging, however and whenever it gets built out, is going to be key for the development of a mainstream market for plug-in electric vehicles. The broader conflict between the CHAdeMO and SAE Combo connectors, we see that as a hindrance to the market over the next several years that needs to be worked out.[237]Newer cars and prototypes are looking at ways of dramatically reducing the charging times for electric cars. The BMW i3 for example, can charge 0-80% of the battery in under 30 minutes in rapid charging mode.[238] The superchargers developed by Tesla Motors provided up to 130 kW of charging, allowing a 50% charge in 20 minutes. Considering the size of the battery, that translated to approx. 212 km of range.[citation needed]

US Charging Standards

Around 1998 the California Air Resources Board classified levels of charging power that have been codified in title 13 of the California Code of Regulations, the U.S. 1999 National Electrical Code section 625 and SAE International standards.[citation needed] Three standards were developed, termed Level 1, Level 2, and Level 3 charging.| Level | Original definition[239] | Coulomb Technologies' definition[240] | Connectors |

|---|---|---|---|

| Level 1 | AC energy to the vehicle's on-board charger; from the most common U.S. grounded household receptacle, commonly referred to as a 120 volt outlet. | 120 V AC; 16 A (= 1.92 kW) | SAE J1772 (16.8 kW), NEMA 5-15 |

| Level 2 | AC energy to the vehicle's on-board charger; 208 - 240 volt, single phase. The maximum current specified is 32 amps (continuous) with a branch circuit breaker rated at 40 amps. Maximum continuous input power is specified as 7.68 kW (= 240V x 32A*). | 208-240 V AC; 12 A - 80 A (= 2.5 - 19.2 kW) |

SAE J1772 (16.8 kW), IEC 62196 (44 kW), Magne Charge (Obsolete), Avcon, IEC 60309 16 A (3.8 kW) IEC 62198-2 Type 2 same as VDE-AR-E 2623-2-2, colloquially known as the "Mennekes connector" (43.5 kW) IEC 62198-2 Type 3 colloquially known as "Scame" |

| Level 3 | DC energy from an off-board charger; there is no minimum energy requirement but the maximum current specified is 400 amps and 240 kW continuous power supplied. | very high voltages (300-600 V DC); very high currents (hundreds of Amperes) | Magne Charge (Obsolete) CHAdeMO (62.5 kW), SAE J1772 Combo, IEC 62196 "Mennekes Combo" |

- * or potentially 208V x 37 A, out of the strict specification but within circuit breaker and connector/cable power limits. Alternatively, this voltage would impose a lower power rating of 6.7 kW at 32 A.

As of June 2012[update], some electric cars provide charging options that do not fit within the older California "Level 1, 2, and 3 charging" standard, with its top charging rate of 40 Amps. For example, the Tesla Roadster may be charged at a rate up to 70 Amps (16.8 kW) with a wall-mounted charger.[243]

For comparison in Europe the IEC 61851-1 charging modes are used to classify charging equipment. The provisions of IEC 62196 charging modes for conductive charging of electric vehicles include Mode 1 (max. 16 A / max. 250 V a.c. or 480 V three-phase), Mode 2 (max. 32 A / max. 250 V a.c. or 480 V three-phase), Mode 3 (max. 63A (70A U.S.) / max. 690 V a.c. or three-phase) and Mode 4 (max. 400 A / max. 600 V d.c.).[244]

Connectors

Most electric cars have used conductive coupling to supply electricity for recharging after the California Air Resources Board settled on the SAE J1772-2001 standard[245] as the charging interface for electric vehicles in California in June 2001.[246] In Europe the ACEA has decided to use the Type 2 connector from the range of IEC_62196 plug types for conductive charging of electric vehicles in the European Union as the Type 1 connector (SAE J1772-2009) does not provide for three-phase charging.[247]Another approach is inductive charging using a non-conducting "paddle" inserted into a slot in the car. Delco Electronics developed the Magne Charge inductive charging system around 1998 for the General Motors EV1 and it was also used for the Chevrolet S-10 EV and Toyota RAV4 EV vehicles.

Regenerative braking

Using regenerative braking, a feature which is present on many hybrid electric vehicles as well as pure electric vehicles, approximately 20% of the energy usually lost in the brakes is recovered to recharge the batteries.[2]

Charging time

More electrical power to the car reduces charging time. Power is limited by the capacity of the grid connection, and, for level 1 and 2 charging, by the power rating of the car's on-board charger. A normal household outlet is between 1.5 kW (in the US, Canada, Japan, and other countries with 110 volt supply) to 3 kW (in countries with 230V supply). The main connection to a house may sustain 10, 15 or even 20 kW in addition to "normal" domestic loads—although, it would be unwise to use all the apparent capability—and special wiring can be installed to use this.

As examples of on-board chargers, the Nissan Leaf at launch has a 3.3 kW charger[248] and the Tesla Roadster can accept up to 16.8 kW (240V at 70A) from the High Power Wall Connector.[243] These power numbers are small compared to the effective power delivery rate of an average petrol pump, about 5,000 kW.[citation needed]

Even if the electrical supply power can be increased, most batteries do not accept charge at greater than their charge rate ("1C"), because high charge rates have an adverse effect on the discharge capacities of batteries. Despite these power limitations, plugging in to even the least-powerful conventional home outlet provides more than 15 kilowatt-hours of energy overnight, sufficient to propel most electric cars more than 70 km (43 mi).[citation needed]

Hobbyists, conversions, and racing

Hobbyists often build their own EVs by converting existing production cars to run solely on electricity. There is a cottage industry supporting the conversion and construction of BEVs by hobbyists.[249] Universities such as the University of California, Irvine even build their own custom electric or hybrid-electric cars from scratch.

Short-range battery electric vehicles can offer the hobbyist comfort, utility, and quickness, sacrificing only range. Short-range EVs may be built using high-performance lead–acid batteries, using about half the mass needed for a 100 to 130 km (60 to 80 mi) range. The result is a vehicle with about a 50 km (30 mi) range, which, when designed with appropriate weight distribution (40/60 front to rear), does not require power steering, offers exceptional acceleration in the lower end of its operating range, and is freeway capable and legal. But their EVs are expensive due to the higher cost for these higher-performance batteries. By including a manual transmission, short-range EVs can obtain both better performance and greater efficiency than the single-speed EVs developed by major manufacturers. Unlike the converted golf carts used for neighborhood electric vehicles, short-range EVs may be operated on typical suburban throughways (where 60–80 km/h / 35-50 mph speed limits are typical) and can keep up with traffic typical on such roads and the short "slow-lane" on-and-off segments of freeways common in suburban areas.

Faced with chronic fuel shortage on the Gaza Strip, Palestinian electrical engineer Waseem Othman al-Khozendar invented in 2008 a way to convert his car to run on 32 electric batteries. According to al-Khozendar, the batteries can be charged with US$2 worth of electricity to drive from 180 to 240 km (110 to 150 mi). After a 7-hour charge, the car should also be able to run up to a speed of 100 km/h (60 mph).[250][251]

Japanese Professor Hiroshi Shimizu from Faculty of Environmental Information of the Keio University created an electric limousine: the Eliica (Electric Lithium-Ion Car) has eight wheels with electric 55 kW hub motors (8WD) with an output of 470 kW and zero emissions, a top speed of 370 km/h (230 mph), and a maximum range of 320 km (200 mi) provided by lithium-ion batteries.[252] However, current models cost approximately US$300,000, about one third of which is the cost of the batteries.

In 2008, several Chinese manufacturers began marketing lithium iron phosphate (LiFePO