Hybrid nuclear fusion–fission (hybrid nuclear power) is a proposed means of generating power by use of a combination of nuclear fusion and fission processes. The basic idea is to use high-energy fast neutrons from a fusion reactor to trigger fission in otherwise nonfissile fuels like U-238 or Th-232. Each neutron can trigger several fission events, multiplying the energy released by each fusion reaction hundreds of times. This would not only make fusion designs more economical in power terms, but also be able to burn fuels that were not suitable for use in conventional fission plants, even their nuclear waste.

The concept dates to the 1950s, and was strongly advocated by Hans Bethe

during the 1970s. At that time the first powerful fusion experiments

were being built, but it would still be many years before they could be

economically competitive. Hybrids were proposed as a way of greatly

accelerating their market introduction, producing energy even before the

fusion systems reached break-even. However, detailed studies of the economics of the systems suggested they could not compete with existing fission reactors.

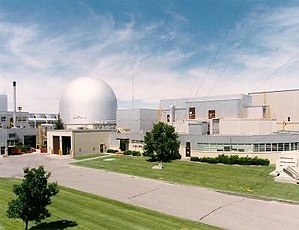

The idea was abandoned and lay dormant until the 2000s, when the continued delays in reaching break-even led to a brief revival around 2009, notably as the basis of the LIFE program. This program was cancelled when the underlying technology, from the National Ignition Facility, failed to reach its design performance goals. Apollo Fusion, a company founded by Google executive Mike Cassidy in 2017, was also reported to be focused on using the subcritical nuclear fusion-fission hybrid method.

In general terms, the hybrid is similar in concept to the fast breeder reactor, which uses a compact high-energy fission core in place of the hybrid's fusion core. Another similar concept is the accelerator-driven subcritical reactor, which uses a particle accelerator to provide the neutrons instead of nuclear reactions.

The idea was abandoned and lay dormant until the 2000s, when the continued delays in reaching break-even led to a brief revival around 2009, notably as the basis of the LIFE program. This program was cancelled when the underlying technology, from the National Ignition Facility, failed to reach its design performance goals. Apollo Fusion, a company founded by Google executive Mike Cassidy in 2017, was also reported to be focused on using the subcritical nuclear fusion-fission hybrid method.

In general terms, the hybrid is similar in concept to the fast breeder reactor, which uses a compact high-energy fission core in place of the hybrid's fusion core. Another similar concept is the accelerator-driven subcritical reactor, which uses a particle accelerator to provide the neutrons instead of nuclear reactions.

Fission basics

Conventional fission power plants rely on the chain reaction caused when nuclear fission events release neutrons that cause further fission events. Each fission event in uranium

releases two or three neutrons, so by careful arrangement and the use

of various absorber materials, you can balance the system so one of

those neutrons causes another fission event while the other one or two

are lost. This careful balance is known as criticality.

Natural uranium is a mix of several isotopes, mainly a trace amount of U-235 and over 99% U-238.

When they undergo fission, both of these elements release fast neutrons

with an energy distribution peaking around 1 to 2 MeV. This energy is

too low to cause fission in U-238, which means it cannot sustain a chain

reaction. U-235 will undergo fission when struck by neutrons of this

energy, so it is possible for U-235 to sustain a chain reaction, as is

the case in a nuclear bomb.

However, the probability of one neutron causing fission in another

U-235 atom before it escapes the fuel is too low to maintain criticality

in a mass of natural uranium, so the chain reaction can only occur in

fuels with increased amounts of U-235. This is accomplished by

concentrating, or enriching, the fuel, increasing the amount of U-235 to produce enriched uranium, while the leftover, now mostly U-238, is a waste product known as depleted uranium.

U-235 will undergo fission more easily if the neutrons are of lower energy, the so-called thermal neutrons. Neutrons can be slowed to thermal energies through collisions with a neutron moderator

material, the easiest to use being the hydrogen atoms found in water.

By placing the fission fuel in water, the probability that the neutrons

will cause fission in another U-235 is greatly increased, which means

the level of enrichment needed to reach criticality is greatly reduced.

This leads to the concept of reactor-grade enriched uranium, with

the amount of U-235 increased from just less than 1% to between 3 and

5% depending on the reactor design. This is in contrast to weapons-grade enrichment, which increases to the U-235 to at least 20%, and more commonly, over 90%.

In order to maintain criticality, the fuel has to retain that

extra concentration of U-235. However, a typical fission reactor burns

off enough of the U-235 to cause the reaction to stop over a period on

the order of a few months. A combination of burnup of the U-235 along

with the creation of neutron absorbers, or poisons, as part of

the fission process eventually results in the fuel mass not being able

to maintain criticality. This burned up fuel has to be removed and

replaced with fresh fuel. The result is nuclear waste that is highly radioactive and filled with long lived radionuclides that present a safety concern.

The waste contains most of the U-235 it started with, only 1% or

so of the energy in the fuel is extracted by the time it reaches the

point where it is no longer fissile. One solution to this problem is to reprocess

the fuel, which uses chemical processes to separate the U-235 (and

other non-poison elements) from the waste, and then uses that U-235 in

fresh fuel loads. This reduces the amount of new fuel that needs to be

mined, and also concentrates the unwanted portions of the waste into a

smaller load. Reprocessing is expensive, however, and has generally been

more expensive than simply buying fresh fuel from the mine.

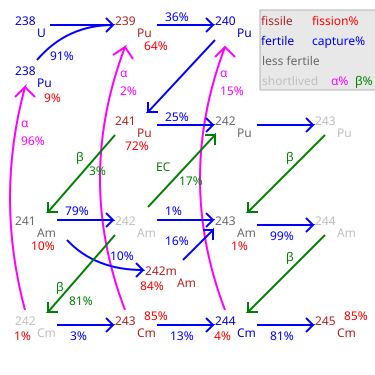

Another possibility is to breed Pu-239 from the U-238 through neutron capture,

or various other means. In order to do this, higher energy neutrons are

required, which means they cannot be moderated as in a conventional

reactor. The simplest way to achieve this is to further enrich the

original fuel well beyond what is needed for use in a moderated reactor,

to the point where the U-235 maintains criticality even with the fast

neutrons. The extra fast neutrons escaping the fuel load can then be

used to breed fuel in a U-238 assembly surrounding the reactor core,

most commonly taken from the stocks of depleted uranium. The Pu-239 is

then chemically separated and mixed into fresh fuel for conventional

reactors, in the same fashion as normal reprocessing, but the total

volume of fuel created in this process is much greater. In spite of

this, like reprocessing, the economics of breeder reactors has proven

unattractive, and commercial breeder plants have ceased operation.

Fusion basics

Fusion reactors typically burn a mixture of deuterium (D) and tritium (T). When heated to millions of degrees, the kinetic energy in the fuel begins to overcome the natural electrostatic repulsion between nuclei, the so-called coulomb barrier, and the fuel begins to undergo fusion. This reaction gives off an alpha particle and a high energy neutron

of 14 MeV. A key requirement to the economic operation of a fusion

reactor is that the alphas deposit their energy back into the fuel mix,

heating it so that additional fusion reactions take place. This leads to

a condition not unlike the chain reaction in the fission case, known as

ignition.

Deuterium can be obtained by the separation of hydrogen isotopes in sea water (see heavy water production).

Tritium has a short half life of just over a decade, so only trace

amounts are found in nature. To fuel the reactor, the neutrons from the

reaction are used to breed more tritium through a reaction in a blanket of lithium

surrounding the reaction chamber. Tritium breeding is key to the

success of a D-T fusion cycle, and to date this technique has not been

demonstrated. Predictions based on computer modeling suggests that the

breeding ratios are quite small and a fusion plant would barely be able

to cover its own use. Many years would be needed to breed enough surplus

to start another reactor.

Hybrid concepts

Fusion–fission

designs essentially replace the lithium blanket with a blanket of

fission fuel, either natural uranium ore or even nuclear waste. The

fusion neutrons have more than enough energy to cause fission in the

U-238, as well as many of the other elements in the fuel, including some

of the transuranic

waste elements. The reaction can continue even when all of the U-235 is

burned off; the rate is controlled not by the neutrons from the fission

events, but the neutrons being supplied by the fusion reactor.

Fission occurs naturally because each event gives off more than

one neutron capable of producing additional fission events. Fusion, at

least in D-T fuel, gives off only a single neutron, and that neutron is

not capable of producing more fusion events. When that neutron strikes

fissile material in the blanket, one of two reactions may occur. In many

cases, the kinetic energy of the neutron will cause one or two neutrons

to be struck out of the nucleus without causing fission. These neutrons

still have enough energy to cause other fission events. In other cases

the neutron will be captured and cause fission, which will release two

or three neutrons. This means that every fusion neutron in the

fusion–fission design can result in anywhere between two and four

neutrons in the fission fuel.

This is a key concept in the hybrid concept, known as fission multiplication.

For every fusion event, several fission events may occur, each of which

gives off much more energy than the original fusion, about 11 times.

This greatly increases the total power output of the reactor. This has

been suggested as a way to produce practical fusion reactors in spite of

the fact that no fusion reactor has yet reached break-even, by

multiplying the power output using cheap fuel or waste.

However, a number of studies have repeatedly demonstrated that this

only becomes practical when the overall reactor is very large, 2 to

3 GWt, which makes it expensive to build.

These processes also have the side-effect of breeding Pu-239 or

U-233, which can be removed and used as fuel in conventional fission

reactors. This leads to an alternate design where the primary purpose of

the fusion–fission reactor is to reprocess waste into new fuel.

Although far less economical than chemical reprocessing, this process

also burns off some of the nastier elements instead of simply physically

separating them out. This also has advantages for non-proliferation,

as enrichment and reprocessing technologies are also associated with

nuclear weapons production. However, the cost of the nuclear fuel

produced is very high, and is unlikely to be able to compete with

conventional sources.

Neutron economy

A key issue for the fusion–fission concept is the number and lifetime of the neutrons in the various processes, the so-called neutron economy.

In a pure fusion design, the neutrons are used for breeding

tritium in a lithium blanket. Natural lithium consists of about 92% Li-7

and the rest is mostly Li-6. Li-7 requires neutron energies even higher

than those released by fission, around 5 MeV, well within the range of

energies provided by fusion. This reaction produces Tritium and Helium-4,

and another slow neutron. Li-6 can react with high or low energy

neutrons, including those released by the Li-7 reaction. This means that

a single fusion reaction can produce several tritiums, which is a

requirement if the reactor is going to make up for natural decay and

losses in the fusion processes.

When the lithium blanket is replaced, or supplanted, by fission

fuel in the hybrid design, neutrons that do react with the fissile

material are no longer available for tritium breeding. The new neutrons

released from the fission reactions can be used for this purpose, but

only in Li-6. One could process the lithium to increase the amount of

Li-6 in the blanket, making up for these losses, but the downside to

this process is that the Li-6 reaction only produces one tritium atom.

Only the high-energy reaction between the fusion neutron and Li-7 can

create more than one tritium, and this is essential for keeping the

reactor running.

To address this issue, at least some of the fission neutrons must

also be used for tritium breeding in Li-6. Every one that does is no

longer available for fission, reducing the reactor output. This requires

a very careful balance if one wants the reactor to be able to produce

enough tritium to keep itself running, while also producing enough

fission events to keep the fission side energy positive. If these cannot

be accomplished simultaneously, there is no reason to build a hybrid.

Even if this balance can be maintained, it might only occur at a level

that is economically infeasible.

Overall economy

Through

the early development of the hybrid concept the question of overall

economics appeared difficult to handle. A series of studies starting in

the late 1970s provided a much clearer picture of the hybrid in a

complete fuel cycle, and allowed the economics to be better understood.

These studies appeared to indicate there was no reason to build a

hybrid.

One of the most detailed of these studies was published in 1980 by Los Alamos National Laboratory (LANL).

Their study noted that the hybrid would produce most of its energy

indirectly, both through the fission events in its own reactor, and much

more by providing Pu-239 to fuel conventional fission reactors. In this

overall picture, the hybrid is essentially identical to the breeder reactor,

which uses fast neutrons from plutonium fission to breed more fuel in a

fission blanket in largely the same fashion as the hybrid.

Both require chemical processing to remove the bred Pu-239, both

presented the same proliferation and safety risks as a result, and both

produced about the same amount of fuel. Since that fuel is the primary

source of energy in the overall cycle, the two systems were almost

identical in the end.

What was not identical, however, was the technical maturity of

the two designs. The hybrid would require considerable additional

research and development before it would be known if it could even work,

and even if that were demonstrated, the end result would be a system

essentially identical to breeders which were already being built at that

time. The report concluded:

The investment of time and money required to commercialize the hybrid cycle could only be justified by a real or perceived advantage of the hybrid over the classical FBR. Our analysis leads us to conclude that no such advantage exists. Therefore, there is not sufficient incentive to demonstrate and commercialize the fusion–fission hybrid.

Rationale

The

fusion process alone currently does not achieve sufficient gain (power

output over power input) to be viable as a power source. By using the

excess neutrons from the fusion reaction to in turn cause a high-yield

fission reaction (close to 100%) in the surrounding subcritical

fissionable blanket, the net yield from the hybrid fusion–fission

process can provide a targeted gain of 100 to 300 times the input energy

(an increase by a factor of three or four over fusion alone). Even

allowing for high inefficiencies on the input side (i.e. low laser efficiency in ICF and Bremsstrahlung losses

in Tokamak designs), this can still yield sufficient heat output for

economical electric power generation. This can be seen as a shortcut to

viable fusion power until more efficient pure fusion technologies can

be developed, or as an end in itself to generate power, and also consume

existing stockpiles of nuclear fissionables and waste products.

In the LIFE project at the Lawrence Livermore National Laboratory LLNL, using technology developed at the National Ignition Facility, the goal is to use fuel pellets of deuterium and tritium surrounded by a fissionable blanket to produce energy sufficiently greater than the input (laser) energy for electrical power generation. The principle involved is to induce inertial confinement fusion (ICF) in the fuel pellet which acts as a highly concentrated point source of neutrons which in turn converts and fissions the outer fissionable blanket. In parallel with the ICF approach, the University of Texas at Austin is developing a system based on the tokamak

fusion reactor, optimising for nuclear waste disposal versus power

generation. The principles behind using either ICF or tokamak reactors

as a neutron source are essentially the same (the primary difference

being that ICF is essentially a point-source of neutrons while Tokamaks

are more diffuse toroidal sources).

Use to dispose of nuclear waste

The surrounding blanket can be a fissile material (enriched uranium or plutonium) or a fertile material (capable of conversion to a fissionable material by neutron bombardment) such as thorium, depleted uranium or spent nuclear fuel. Such subcritical reactors (which also include particle accelerator-driven neutron spallation

systems) offer the only currently-known means of active disposal

(versus storage) of spent nuclear fuel without reprocessing. Fission by-products produced by the operation of commercial light water nuclear reactors (LWRs)

are long-lived and highly radioactive, but they can be consumed using

the excess neutrons in the fusion reaction along with the fissionable

components in the blanket, essentially destroying them by nuclear transmutation and producing a waste product which is far safer and less of a risk for nuclear proliferation. The waste would contain significantly reduced concentrations of long-lived, weapons-usable actinides

per gigawatt-year of electric energy produced compared to the waste

from a LWR. In addition, there would be about 20 times less waste per

unit of electricity produced. This offers the potential to efficiently

use the very large stockpiles of enriched fissile materials, depleted

uranium, and spent nuclear fuel.

Safety

In contrast to current commercial fission reactors, hybrid reactors potentially demonstrate what is considered inherently safe behavior because they remain deeply subcritical

under all conditions and decay heat removal is possible via passive

mechanisms. The fission is driven by neutrons provided by fusion

ignition events, and is consequently not self-sustaining. If the fusion

process is deliberately shut off or the process is disrupted by a

mechanical failure, the fission damps out

and stops nearly instantly. This is in contrast to the forced damping

in a conventional reactor by means of control rods which absorb neutrons

to reduce the neutron flux

below the critical, self-sustaining, level. The inherent danger of a

conventional fission reactor is any situation leading to a positive feedback, runaway, chain reaction such as occurred during the Chernobyl disaster.

In a hybrid configuration the fission and fusion reactions are

decoupled, i.e. while the fusion neutron output drives the fission, the

fission output has no effect whatsoever on the fusion reaction,

completely eliminating any chance of a positive feedback loop.

Fuel cycle

There are three main components to the hybrid fusion fuel cycle: deuterium, tritium, and fissionable elements. Deuterium can be derived by separation of hydrogen isotopes in sea water. Tritium may be generated in the hybrid process itself by

absorption of neutrons in lithium bearing compounds. This would entail

an additional lithium bearing blanket and a means of collection. The

third component is externally derived fissionable materials from

demilitarized supplies of fissionables, or commercial nuclear fuel and

waste streams. Fusion driven fission also offers the possibility of

using Thorium as a fuel, which would greatly increase the potential amount of fissionables available. The extremely energetic nature of the fast neutrons

emitted during the fusion events (up to 0.17 the speed of light) can

allow normally non-fissioning U-238 to undergo fission directly (without

conversion first to Pu-239), enabling refined natural Uranium to be

used with very low enrichment, while still maintaining a deeply

subcritical regime.

Engineering considerations

Practical

engineering designs must first take into account safety as the primary

goal. All designs should incorporate passive cooling in combination

with refractory materials to prevent melting and reconfiguration of

fissionables into geometries capable of un-intentional criticality.

Blanket layers of Lithium bearing compounds will generally be included

as part of the design to generate Tritium to allow the system to be

self-supporting for one of the key fuel element components. Tritium,

because of its relatively short half-life and extremely high

radioactivity, is best generated on site to obviate the necessity of

transportation from a remote location. D-T fuel can be manufactured on

site using Deuterium derived from heavy water production and Tritium

generated in the hybrid reactor itself. Nuclear spallation

to generate additional neutrons can be used to enhance the fission

output, with the caveat that this is a tradeoff between the number of

neutrons (typically 20-30 neutrons per spallation event) against a

reduction of the individual energy of each neutron. This is a

consideration if the reactor is to use natural Thorium as a fuel. While

high energy (0.17c) neutrons produced from fusion events are capable of

directly causing fission in both Thorium and U-238, the lower energy

neutrons produced by spallation generally cannot. This is a tradeoff

which affects the mixture of fuels against the degree of spallation used

in the design.