Delta IV Medium launch carrying DSCS III-B6

| |

| Function | Orbital launch vehicle |

|---|---|

| Manufacturer | United Launch Alliance |

| Country of origin | United States |

| Cost per launch | US$164+ million |

| Size | |

| Height | 63–72 m (207–236 ft) |

| Diameter | 5 m (16 ft) |

| Mass | 249,500–733,400 kg (550,100–1,616,900 lb) |

| Stages | 2 |

| Capacity | |

| Payload to LEO | 11,470–28,790 kg (25,290–63,470 lb) |

| Payload to GTO | 4,440–14,220 kg (9,790–31,350 lb) |

| Associated rockets | |

| Family | Delta (rocket family) |

| Comparable | |

| Launch history | |

| Status | Delta IV Heavy is active; Delta IV Medium, M+(4,2), M+(5,2), and M+(5,4) retired. |

| Launch sites | SLC-37B, Cape Canaveral SLC-6, Vandenberg AFB |

| Total launches |

40

|

| Successes |

39

|

| Partial failures | 1 (Heavy) |

| First flight |

|

| Last flight | |

| Notable payloads | |

| Boosters (Medium+) – GEM 60 | |

| No. boosters | Medium+ (4,2), Medium+ (5,2): 2 Medium+ (5,4): 4 |

| Gross mass | 33,638 kg (74,158 lb) |

| Thrust | 826.6 kN (185,800 lbf) |

| Specific impulse | 245 s (2.40 km/s) (sea level) |

| Burn time | 91 seconds |

| Fuel | HTPB / Aluminum |

| Boosters (Heavy) – Common Booster Core (CBC) | |

| No. boosters | 2 |

| Gross mass | 226,400 kg (499,100 lb) |

| Engines | 1 RS-68A |

| Thrust | 3,140 kN (705,000 lbf) (sea level) |

| Specific impulse | Sea level: 360 s (3.5 km/s) Vacuum: 412 s (4.04 km/s) |

| Burn time | 242 seconds[2] |

| Fuel | LH2 / LOX |

| First stage – CBC | |

| Gross mass | 226,400 kg (499,100 lb) |

| Engines | 1 RS-68A |

| Thrust | 3,140 kN (705,000 lbf) (sea level) |

| Specific impulse | Sea level: 360 s (3.5 km/s) Vacuum: 412 s (4.04 km/s) |

| Burn time | 245 seconds (328 seconds in Heavy configuration) |

| Fuel | LH2 / LOX |

| Second stage – Delta Cryogenic Second Stage (DCSS) | |

| Gross mass | 4-m: 24,170 kg (53,290 lb) 5-m: 30,700 kg (67,700 lb) |

| Engines | 1 RL10-B-2 |

| Thrust | 110 kN (25,000 lbf) |

| Specific impulse | 462 s (4.53 km/s) |

| Burn time | 850-1,125 seconds |

| Fuel | LH2 / LOX |

Delta IV is a group of five expendable launch systems in the Delta rocket family introduced in the early 2000s. Originally designed by Boeing's Defense, Space & Security division for the Evolved Expendable Launch Vehicle (EELV) program, the Delta IV became a United Launch Alliance (ULA) product in 2006. The Delta IV was and is primarily a launch vehicle for United States Air Force military payloads, but has also been used to launch a number of U.S. government non-military payloads and a single commercial satellite.

The Delta IV originally had two main versions which allowed the family to cover a range of payload sizes and masses: the retired Medium (which had four configurations) and Heavy. As of 2019, only the Heavy remains active, with payloads that would previously fly on Medium moving to either the existing Atlas V or the forthcoming Vulcan. Retirement of the Delta IV is anticipated in 2024.

Delta IV vehicles are built in the ULA facility in Decatur, Alabama. Final assembly is completed at the launch site by ULA: at the Horizontal Integration Facility for launches from SLC-37B pad at Cape Canaveral and in a similar facility for launches from SLC-6 pad at Vandenberg Air Force Base.

History

The latest evolutionary development of the Delta rocket family, Delta IV was introduced to meet the requirements of the United States Air Force's (USAF's) Evolved Expendable Launch Vehicle

(EELV, now national security space launch/NSSL) program. While the

Delta IV retains the name of the Delta family of rockets, major changes

were incorporated. Perhaps the most significant change was the switch

from kerosene to liquid hydrogen fuel, with new tankage and a new engine required.

During the Delta IV's development, a Small variant was considered. This would have featured the Delta II second stage, an optional Thiokol Star 48B third stage, and the Delta II payload fairing, all atop a single Common Booster Core (CBC). The Small variant was dropped by 1999.

In 2002, the Delta IV was first launched, with the RS-68 becoming the first large liquid-propellant rocket engine designed in the U.S. since the Space Shuttle main engine (SSME) in the 1970s. The primary goal for the RS-68 was to reduce cost versus the SSME. Some sacrifice in chamber pressure and specific impulse

was made, hurting efficiency; however, development time, part count,

total cost, and assembly labor were reduced to a fraction of the SSME,

despite the RS-68's significantly larger size.

The L3 Technologies

Redundant Inertial Flight Control Assembly (RIFCA) guidance system

originally used on the Delta IV was common to that carried on the Delta II, although the software was different because of the differences between the Delta II and Delta IV. The RIFCA featured six ring laser gyroscopes and accelerometers each, to provide a higher degree of reliability.

Boeing

initially intended to market Delta IV commercial launch services.

However, the Delta IV entered the space launch market when global

capacity was already much higher than demand. Furthermore, as an

unproven design it had difficulty finding a market in commercial

launches, and Delta IV launch costs are higher than comparable vehicles

of the same era. In 2003, Boeing pulled the Delta IV from the commercial

market, citing low demand and high costs. In 2005, Boeing stated that

it sought to return the Delta IV to commercial service.

As of 2009, the USAF funded Delta IV EELV engineering,

integration, and infrastructure work through contracts with Boeing

Launch Services (BLS). On August 8, 2008, the USAF Space and Missile Systems Center

increased the "cost plus award fee" contract with BLS for $1.656

billion to extend the period of performance through the end of FY09. In addition a $557.1 million option was added to cover FY10. However, the Delta IV series was at that time launched by the United Launch Alliance (ULA), a joint venture between Boeing and Lockheed Martin.

In February 2010, naturalized citizen Dongfan Chung, an engineer working with Boeing, was the first person convicted under the Economic Espionage Act of 1996. Chung passed on classified information on designs including the Delta IV rocket and was sentenced to 15 years.

In March 2015, ULA announced plans to phase out the Delta IV Medium by 2018. The Delta IV will be replaced by the Atlas V in the near term and Vulcan in the far term. The Delta IV Medium was actually retired on 22 August 2019.

With the exception of the first launch, which carried the Eutelsat W5 commercial communications satellite, all Delta IV launches have been paid for by the US government. In 2015, ULA stated that a Delta IV Heavy is sold for nearly $400 million.

RS-68A booster engine upgrade

The

possibility of a higher performance Delta IV was first proposed in a

2006 RAND Corporation study of national security launch requirements out

to 2020. A single National Reconnaissance Office (NRO) payload required an increase in the lift capability of the Delta IV Heavy. Lift capacity was increased by developing the higher-performance RS-68A engine, which first flew on June 29, 2012.

ULA phased out the baseline RS-68 engine with the launch of Delta

flight 371 on March 25, 2015. All following launches have used the

RS-68A,

and the engine's higher thrust allowed the use of a single standardized

CBC design for all Delta IV Medium and M+ versions. This upgrade

reduced cost and increased flexibility, since any standardized CBC could

be configured for zero, two, or four solid boosters. However, the new

CBC led to a slight performance loss for most medium configurations. The Delta IV Heavy still requires non-standard CBCs for the core and boosters.

Payload capacities after RS-68A upgrade

| Version | Fairing | CBCs | SRBs | Payload to LEO

407 km x 51.6°

|

Payload to GTO

1800 m/s residual

|

Launches to date |

|---|---|---|---|---|---|---|

| Medium | 4 m | 1 | 0 | 8,510 kg | 4,440 kg | 0 |

| M+(4,2) | 4 m | 1 | 2 | 12,000 kg | 6,390 kg | 2 |

| M+(5,2) | 5 m | 1 | 2 | 10,220 kg | 5,490 kg | 2 |

| M+(5,4) | 5 m | 1 | 4 | 12,820 kg | 7,300 kg | 4 |

| Heavy | 5 m | 3 | 0 | 25,980 kg | 14,220 kg | 4 |

Payload capacities with original RS-68

|

Version

|

Fairing

|

CBCs

|

SRBs

|

Payload to LEO

407 km x 51.6° |

Payload to GTO

1800 m/s residual |

Launches to date

|

|---|---|---|---|---|---|---|

| Medium | 4 m | 1 | 0 | 8,800 kg | 4,540 kg | 3 |

| M+(4,2) | 4 m | 1 | 2 | 11,920 kg | 6,270 kg | 13 |

| M+(5,2) | 5 m | 1 | 2 | 10,580 kg | 5,430 kg | 1 |

| M+(5,4) | 5 m | 1 | 4 | 13,450 kg | 7,430 kg | 4 |

| Heavy | 5 m | 3 | 0 | 22,980 kg | 13,400 kg | 7 |

Proposed upgrades that were not implemented

Possible

future upgrades for the Delta IV included adding extra strap-on solid

motors, higher-thrust main engines, lighter materials, higher-thrust

second stages, more (up to six) strap-on CBCs, and a cryogenic

propellant cross feed from strap on boosters to the common core.

At one point NASA planned to use Delta IV or Atlas V to launch the proposed Orbital Space Plane, which eventually became the Crew Exploration Vehicle and then the Orion. Orion was intended to fly on the Ares I launch vehicle, then the Space Launch System after Ares I was cancelled.

In 2009 The Aerospace Corporation reported on NASA results of a study to determine the feasibility of modifying Delta IV to be human-rated for use in NASA human spaceflight missions. According to Aviation Week the study, "found that a Delta IV heavy [...] could meet NASA's requirements for getting humans to low Earth orbit."

A proposed upgrade to the Delta IV family was the addition of

extra solid motors. The Medium+(4,4) would have used existing mount

points to pair the four GEM-60s of the M+(5,4) with the upper stage and

fairing of the (4,2). An M+(4,4) would have had a GTO payload of

7,500 kg (16,600 lb), a LEO payload of 14,800 kg (32,700 lb), and could

have been available within 36 months of the first order. It was also

considered to add extra GEM-60s to the M+(5,4), which would have

required adding extra attachment points, structural changes to cope with

the different flight loads, and launch pad and infrastructure changes.

The Medium+(5,6) and (5,8) would have flown with six and eight SRBs

respectively, for a maximum of up to 9,200 kg/20,200 lb to GTO with the

M+(5,8). The Medium+(5,6) and (5,8) could have been available within 48

months of the first order.

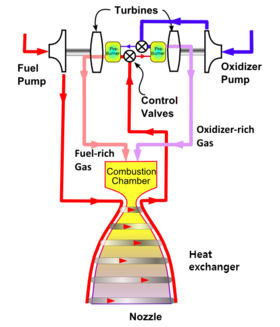

Planned successor

The Vulcan rocket is planned to replace the Atlas V and Delta IV rockets. Vulcan is projected to enter service by 2021, using the Blue Origin BE-4 methane-fueled rocket engine.

The Delta IV Heavy and Atlas V are expected to stay in service for a

few years after Vulcan's inaugural launch, and the Heavy is expected to

be discontinued by 2024.

Vehicle description

Delta IV evolution

Delta IV Medium

The Delta IV Medium was available in four configurations: Medium, Medium+ (4,2), Medium+ (5,2), and Medium+ (5,4).

The Delta IV Medium (Delta 9040) was the most basic Delta IV. It

featured a single CBC and a modified Delta III second stage, with

4-meter liquid hydrogen and liquid oxygen tanks and a 4-meter payload

fairing. The Delta IV Medium was capable of launching 4,200 kg to geosynchronous transfer orbit

(GTO). From Cape Canaveral, GTO is 1804 m/s away from GEO. The mass of

fairing and payload attach fittings have been subtracted from the gross

performance. It flew last time on 22 August 2019.

The Delta IV Medium+ (4,2) (Delta 9240) had the same CBC and DCSS as the Medium, but with the addition of two Orbital ATK-built 1.5-m (60-in) diameter solid rocket booster Graphite-Epoxy Motors (GEM-60s) strap-on boosters to increase payload capacity to 6,150 kg to GTO.

The Delta IV Medium+ (5,2) (Delta 9250) was similar to the

Medium+ (4,2), but had a 5-m–diameter DCSS and payload fairing for

larger payloads. Because of the extra weight of the larger payload

fairing and second stage, the Medium+ (5,2) could launch 5,072 kg to

GTO.

The Delta IV Medium+ (5,4) (Delta 9450) was similar to the

Medium+ (5,2), but used four GEM-60s instead of two, enabling it to lift

6,882 kg to GTO.

To encapsulate the satellite payload, a variety of different

payload fairings were available. A stretched Delta III 4 meter diameter

composite payload fairing was used on 4 meter Medium versions, while an

enlarged, 5 meter diameter composite fairing was used on 5 meter Medium

versions.

Delta IV Heavy

Delta IV Heavy launching

The Delta IV Heavy (Delta 9250H) combines a 5-meter (16 ft) diameter

DCSS and payload fairing with two additional CBCs. These are strap-on

boosters which are separated

earlier in the flight than the center CBC. As of 2007, a longer 5 meter

diameter composite fairing was standard on the Delta IV Heavy,

with an aluminum isogrid fairing also available. The aluminum trisector

(three-part) fairing was built by Boeing and derived from a Titan IV fairing. The trisector fairing was first used on the DSP-23 flight. The Delta IV with the extended fairing is over 62 m (205 ft) tall.

Common Booster Core

Each Delta IV consists of at least one Common Booster Core (CBC). Each CBC is powered by one Aerojet Rocketdyne RS-68 engine, which burns liquid hydrogen and liquid oxygen.

On flights of the Medium, the RS-68 ran at 102% rated thrust for

the first few minutes of flight, and then throttled down to 58% rated

thrust before main engine cutoff.

On the Heavy, the main CBC's engine throttles down to 58% rated thrust

around 50 seconds after liftoff, while the strap-on CBCs remain at 102%.

This conserves propellant and allows the main CBC to burn after booster

separation. After the strap-on CBCs separate, the main CBC's engine throttles back up to 102% before throttling back down to 58% prior to main engine cutoff.

The RS-68 engine is mounted to the lower thrust structure of the CBC by a four-legged (quadrapod) thrust frame and enclosed in a protective composite conical thermal shield. Above the thrust structure is an aluminum isogrid (a grid pattern machined out of the inside of the tank to reduce weight) liquid hydrogen tank, followed by a composite

cylinder called the centerbody, an aluminum isogrid liquid oxygen tank,

and a forward skirt. Along the back of the CBC is a cable tunnel to

hold electrical and signal lines, and a feedline to carry the liquid

oxygen to the RS-68 from the tank. The CBC is of a constant, 5-meter

(16.4 ft) diameter.

Delta Cryogenic Second Stage

Delta IV 4-Meter Second Stage

The upper stage of the Delta IV is the Delta Cryogenic Second Stage (DCSS). The DCSS is based on the Delta III

upper stage but has increased propellant capacity. Two versions have

been produced: a 4-meter (13.1 ft) diameter DCSS that was retired with

the Delta IV Medium and a 5-meter diameter DCSS that remains in service

with the Delta IV Heavy. The 4 m diameter version lengthened both Delta

III propellant tanks, while the 5-meter version has an extended diameter

liquid hydrogen tank and a further lengthened liquid oxygen tank.

Regardless of the diameter, each DCSS is powered by one RL10B2 engine, with an extendable carbon-carbon nozzle to improve specific impulse.

Two different interstages are used to mate the first stage and DCSS. A

tapering interstage that narrowed down from 5 m to 4 m diameter was used

to mate the 4 m DCSS to the CBC, while a cylindrical interstage is used

to mate the 5 m DCSS. Both interstages were built from composites and

enclosed the liquid oxygen tank, with the larger liquid hydrogen tank

making up part of the vehicle's outer mold line.

Launch sites

First Delta IV Heavy with three CBCs prior to launch

Delta IV launches occur from either of two rocket launch complexes. Launches on the East coast of the United States use Space Launch Complex 37 (SLC-37) at the Cape Canaveral Air Force Station. On the West coast, polar-orbit and high-inclination launches use Vandenberg Air Force Base's Space Launch Complex 6 (SLC-6).

Launch facilities at both sites are similar. A Horizontal Integration Facility

(HIF) is situated some distance from the pad. Delta IV CBCs and second

stages to be mated and tested in the HIF before they are moved to the

pad. The partial horizontal rocket assembly of the Delta IV is somewhat similar to the Soyuz launch vehicle, which is completely assembled horizontally. The Space Shuttles, the past Saturn launch vehicles, and the upcoming Space Launch System are assembled and rolled out to the launch pad entirely vertically.

Movement of the Delta IVs among the various facilities at the pad

is facilitated by rubber-tired Elevating Platform Transporters (EPTs)

and various transport jigs. Diesel engine

EPTs are used for moving the vehicles from the HIF to the pad, while

electric EPTs are used in the HIF, where precision of movement is

important.

The basic launchpad structure includes a flame trench to direct

the engine plume away from the rocket, lightning protection, and

propellant storage. In the case of Delta IV, the vehicle is completed on

the launch pad inside a building. This Mobile Service Tower (MST)

provides service access to the rocket and protection from the weather

and is rolled away from the rocket on launch day. A crane at the top of

the MST lifts the encapsulated payload to the vehicle and also attached

the GEM-60 solid motors for Delta IV Medium launches. The MST is rolled

away from the rocket several hours before launch. At Vandenberg, the

launch pad also has a Mobile Assembly Shelter (MAS), which completely

encloses the vehicle; at CCAFS, the vehicle is partly exposed near its

bottom.

Beside the vehicle is a Fixed Umbilical Tower (FUT), which has

two (VAFB) or three (CCAFS) swing arms. These arms carry telemetry

signals, electrical power, hydraulic

fluid, environmental control air flow, and other support functions to

the vehicle through umbilical lines. The swing arms retract at T-0

seconds once the vehicle is committed to launch.

Under the vehicle is a Launch Table, with six Tail Service Masts

(TSMs), two for each CBC. The Launch Table supports the vehicle on the

pad, and the TSMs provide further support and fueling functions for the

CBCs. The vehicle is mounted to the Launch Table by a Launch Mate Unit

(LMU), which is attached to the vehicle by bolts that sever at launch.

Behind the Launch Table is a Fixed Pad Erector (FPE), which uses two

long-stroke hydraulic pistons to raise the vehicle to the vertical

position after being rolled to the pad from the Horizontal Integration

Facility (HIF). Beneath the Launch Table is a flame duct, which deflects

the rocket's exhaust away from the rocket or facilities.

Vehicle processing

Delta IV CBCs and DCSSs are assembled at ULA's factory in Decatur, Alabama. They are then loaded onto the M/V Delta Mariner, a roll-on/roll-off cargo vessel, and shipped to either launch pad. There, they are offloaded and rolled into a Horizontal Integration Facility

(HIF). For Delta IV Medium launches, the CBC and DCSS were mated in the

HIF. For Delta IV Heavy launches, the port and starboard strap-on CBCs

are also mated in the HIF.

Various tests are performed, and then the vehicle is rolled

horizontally to the pad, where the Fixed Pad Erector (FPE) is used to

raise the vehicle to the vertical position. At this time, the GEM-60

solid motors, if any are required, are rolled to the pad and attached to

the vehicle. After further testing, the payload (which has already been

enclosed in its fairing) is transported to the pad, hoisted into the

MST by a crane, and attached to the vehicle. Finally, on launch day, the

MST is rolled away from the vehicle, and the vehicle is ready for

launch.

Notable launches

GOES-N launch on a Medium+ (4,2)

A unique aerial view of NROL-22 launch from SLC-6

The first payload launched with a Delta IV was the Eutelsat W5 communications satellite. A Medium+ (4,2) from Cape Canaveral carried the communications satellite into geostationary transfer orbit (GTO) on 20 November 2002.

Heavy Demo was the first launch of the Delta IV Heavy in December 2004 after significant delays due to bad weather. Due to cavitation

in the propellant lines, sensors on all three CBCs registered depletion

of propellant. The strap-on CBCs and then core CBC engines shut down

prematurely, even though sufficient propellant remained to continue the

burn as scheduled. The second stage attempted to compensate for the

shutdown and burned until it ran out of propellant. This flight was a

test launch carrying a payload of:

- DemoSat – 6020 kg; an aluminum cylinder filled with 60 brass rods – planned to be carried to GEO; however due to the sensor faults, the satellite did not reach this orbit.

- NanoSat-2, carried to low Earth orbit (LEO) – a set of two very small satellites of 24 and 21 kg, nicknamed Sparky and Ralphie – planned to orbit for one day. Given the under-burn, the two most likely did not reach a stable orbit.

NROL-22 was the first Delta IV launched from SLC-6 at

Vandenberg Air Force Base (VAFB). It was launched aboard a Medium+ (4,2)

in June 2006 carrying a classified satellite for the U.S. National Reconnaissance Office (NRO).

DSP-23 was the first launch of a valuable payload aboard a Delta IV Heavy. This was also the first Delta IV launch contracted by the United Launch Alliance, a joint venture between Boeing and Lockheed Martin. The main payload was the 23rd and final Defense Support Program missile-warning satellite, DSP-23. Launch from Cape Canaveral occurred on November 10, 2007.

NROL-26 was the first Delta IV Heavy EELV launch for the NRO. USA 202, a classified reconnaissance satellite, lifted off 18 January 2009.

NROL-32

was a Delta IV Heavy launch, carrying a satellite for NRO. The payload

is speculated to be the largest satellite sent into space. After a delay

from 19 October 2010, the rocket lifted off on 21 November 2010.

NROL-49 lifted off from Vandenberg AFB on January 20, 2011.

It was the first Delta IV Heavy mission to be launched out of

Vandenberg. This mission was for the NRO and its details are classified.

On October 4, 2012, a Delta IV M+ (4,2) experienced an anomaly in

the upper stage's RL10-B-2 engine which resulted in lower than expected

thrust. While the vehicle had sufficient fuel margins to successfully

place the payload, a GPS Block IIF satellite, into its targeted orbit,

investigation into the glitch delayed subsequent Delta IV launches and

the next Atlas V launch (AV-034) due to commonality between the engines

used on both vehicles' upper stages.

By December 2012, ULA had determined the cause of the anomaly to be a

fuel leak, and Delta IV launches resumed in May 2013. After two more

successful launches, further investigation led to the delay of Delta

flight 365 with the GPS IIF-5 satellite. Originally scheduled to launch in October 2013, the vehicle lifted off on February 21, 2014.

A Delta IV Heavy launched the Orion spacecraft on an uncrewed test flight, EFT-1, on December 5, 2014.

The launch was originally planned for December 4, but high winds and

valve issues caused the launch to be rescheduled for December 5.

The second GPS Block III satellite was launched with the final Delta IV Medium in the +(4,2) configuration on 22 August 2019.