From Wikipedia, the free encyclopedia

The current logo, used since December 2005.

|

|

Headquarters in Santa Clara, California

|

|

| Public | |

| Traded as | NASDAQ: INTC Dow Jones Industrial Average Component NASDAQ-100 Component S&P 500 Component |

| Industry | Semiconductors |

| Founded | July 18, 1968 |

| Founder | Gordon Moore, Robert Noyce |

| Headquarters | Santa Clara, California, U.S.[1] |

Area served

|

Worldwide |

Key people

|

Andy Bryant (Chairman) Brian Krzanich (CEO) Renée James (President) |

| Products | Bluetooth chipsets, flash memory, microprocessors, motherboard chipsets, network interface cards, mobile phones |

| Revenue | |

| Total assets | |

| Total equity | |

Number of employees

|

106,700 (2014)[3] |

| Website | www |

Intel Corporation is an American multinational corporation headquartered in Santa Clara, California. Intel is one of the world's largest and highest valued semiconductor chip makers, based on revenue.[4] It is the inventor of the x86 series of microprocessors, the processors found in most personal computers.

Intel Corporation, founded on July 18, 1968, is a portmanteau of Integrated Electronics (the fact that "intel" is the term for intelligence information also made the name appropriate).[5] Intel also makes motherboard chipsets, network interface controllers and integrated circuits, flash memory, graphic chips, embedded processors and other devices related to communications and computing. Founded by semiconductor pioneers Robert Noyce and Gordon Moore and widely associated with the executive leadership and vision of Andrew Grove, Intel combines advanced chip design capability with a leading-edge manufacturing capability. Though Intel was originally known primarily to engineers and technologists, its "Intel Inside" advertising campaign of the 1990s made it a household name, along with its Pentium processors.

Intel was an early developer of SRAM and DRAM memory chips, and this represented the majority of its business until 1981. Although Intel created the world's first commercial microprocessor chip in 1971, it was not until the success of the personal computer (PC) that this became its primary business. During the 1990s, Intel invested heavily in new microprocessor designs fostering the rapid growth of the computer industry. During this period Intel became the dominant supplier of microprocessors for PCs, and was known for aggressive and sometimes illegal tactics in defense of its market position, particularly against Advanced Micro Devices (AMD), as well as a struggle with Microsoft for control over the direction of the PC industry.[6][7]

The 2013 rankings of the world's 100 most valuable brands published by Millward Brown Optimor showed the company's brand value at number 61.[8]

Intel has also begun research into electrical transmission and generation.[9][10] Intel has recently introduced a 3-D transistor that improves performance and energy efficiency.[11] Intel has begun mass-producing this 3-D transistor, named the Tri-Gate transistor, with their 22 nm process, which is currently used in their 3rd generation core processors initially released on April 29, 2012.[12] In 2011, SpectraWatt Inc., a solar cell spinoff of Intel, filed for bankruptcy under Chapter 11.[13] In June 2013, Intel unveiled its fourth generation of Intel Core processors (Haswell) in an event named Computex in Taipei.[14]

The Open Source Technology Center at Intel hosts PowerTOP and LatencyTOP, and supports other open-source projects such as Wayland, Intel Array Building Blocks, Threading Building Blocks (TBB), and Xen.[15][16]

Corporate history

Origins

Intel was originally founded in Mountain View, California in 1968 by Gordon E. Moore (of "Moore's Law" fame), a chemist, and Robert Noyce, a physicist and co-inventor of the integrated circuit. Arthur Rock (investor and venture capitalist) helped them find investors, while Max Palevsky was on the board from an early stage.[17] Moore and Noyce had left Fairchild Semiconductor to found Intel. Rock was not an employee, but he was an investor and was chairman of the board.[18][19] The total initial investment in Intel was $2.5 million convertible debentures and $10,000 from Rock. Just 2 years later, Intel completed their initial public offering (IPO), raising $6.8 million ($23.50 per share).[18] Intel's third employee was Andy Grove,[20] a chemical engineer, who later ran the company through much of the 1980s and the high-growth 1990s.

In deciding on a name, Moore and Noyce quickly rejected "Moore Noyce",[21] homophone for "more noise" – an ill-suited name for an electronics company, since noise in electronics is usually very undesirable and typically associated with bad interference. Instead they used the name NM Electronics before renaming their company Integrated Electronics or "Intel" for short.[22] Since "Intel" was already trademarked by the hotel chain Intelco, they had to buy the rights for the name.[18][23]

Early history

At its founding, Intel was distinguished by its ability to make semiconductors. Its first product, in 1969, was the 3101 Schottky TTL bipolar 64-bit static random-access memory (SRAM), which was nearly twice as fast as earlier Schottky diode implementations by Fairchild and the Electrotechnical Laboratory in Tsukuba, Japan.[24][25] In the same year Intel also produced the 3301 Schottky bipolar 1024-bit read-only memory (ROM)[26] and the first commercial metal–oxide–semiconductor field-effect transistor (MOSFET) silicon gate SRAM chip, the 256-bit 1101.[18][27][28] Intel's business grew during the 1970s as it expanded and improved its manufacturing processes and produced a wider range of products, still dominated by various memory devices.While Intel created the first commercially available microprocessor (Intel 4004) in 1971[18] and one of the first microcomputers in 1972,[27][29] by the early 1980s its business was dominated by dynamic random-access memory chips. However, increased competition from Japanese semiconductor manufacturers had, by 1983, dramatically reduced the profitability of this market. The growing success of the IBM personal computer, based on an Intel microprocessor, was among factors that convinced Gordon Moore (CEO since 1975) to shift the company's focus to microprocessors, and to change fundamental aspects of that business model. Moore's decision to sole-source Intel's 386 chip played into the company's continuing success.

By the end of the 1980s, buoyed by its fortuitous position as microprocessor supplier to IBM and IBM's competitors within the rapidly growing personal computer market, Intel embarked on a 10-year period of unprecedented growth as the primary (and most profitable) hardware supplier to the PC industry, part of the winning 'Wintel' combination. Moore handed over to Andy Grove in 1987. By launching its Intel Inside marketing campaign in 1991, Intel was able to associate brand loyalty with consumer selection, so that by the end of the 1990s, its line of Pentium processors had become a household name.

Slowing demand and challenges to dominance

After 2000, growth in demand for high-end microprocessors slowed. Competitors, notably AMD (Intel's largest competitor in its primary x86 architecture market), garnered significant market share, initially in low-end and mid-range processors but ultimately across the product range, and Intel's dominant position in its core market was greatly reduced.[30] In the early 2000s then-CEO Craig Barrett attempted to diversify the company's business beyond semiconductors, but few of these activities were ultimately successful.Intel had also for a number of years been embroiled in litigation. US law did not initially recognize intellectual property rights related to microprocessor topology (circuit layouts), until the Semiconductor Chip Protection Act of 1984, a law sought by Intel and the Semiconductor Industry Association (SIA).[31] During the late 1980s and 1990s (after this law was passed), Intel also sued companies that tried to develop competitor chips to the 80386 CPU.[32] The lawsuits were noted to significantly burden the competition with legal bills, even if Intel lost the suits.[32] Antitrust allegations had been simmering since the early 1990s and had been the cause of one lawsuit against Intel in 1991. In 2004 and 2005, AMD brought further claims against Intel related to unfair competition.

In 2005, CEO Paul Otellini reorganized the company to refocus its core processor and chipset business on platforms (enterprise, digital home, digital health, and mobility). In 2013, Intel partnered with Medopad, an enterprise mobile health solution provider to support the deployment of Medopad across the 60+ BMI Healthcare hospitals.[33]

Regaining of momentum

In 2007, Intel unveiled its Core microarchitecture to widespread critical acclaim;[34] the product range was perceived as an exceptional leap in processor performance that at a stroke regained much of its leadership of the field.[35][36] In 2008, Intel had another "tick," when it introduced the Penryn microarchitecture, which was 45 nm. Later that year, Intel released a processor with the Nehalem architecture. Nehalem had positive reviews.[37]Sale of XScale processor business

On June 27, 2006, the sale of Intel's XScale assets was announced. Intel agreed to sell the XScale processor business to Marvell Technology Group for an estimated $600 million and the assumption of unspecified liabilities. The move was intended to permit Intel to focus its resources on its core x86 and server businesses, and the acquisition completed on November 9, 2006.[38]Acquisitions

On August 19, 2010, Intel announced that it planned to purchase McAfee, a manufacturer of computer security technology. The purchase price was $7.68 billion, and the companies said that if the deal were approved, new products would be released early in 2011.[39] On January 26, 2011, the European Union approved the acquisition, after Intel agreed to provide rival security firms with all necessary information that would allow their products to use Intel's chips and personal computers.[40] After the acquisition, Intel had about 90,000 employees, including about 12,000 software engineers.[41]On August 30, 2010, Intel and Infineon Technologies announced that Intel would acquire Infineon's Wireless Solutions business.[42] Intel planned to use Infineon's technology in laptops, smart phones, netbooks, tablets and embedded computers in consumer products, eventually integrating its wireless modem into Intel's silicon chips.[43]

In March 2011, Intel bought most of the assets of Cairo-based SySDSoft.[44]

In July 2011, Intel announced that it had agreed to acquire Fulcrum Microsystems Inc., a company specializing in network switches.[45] The company was previously included on the EE Times list of 60 Emerging Startups.[45]

On October 1, 2011, Intel reached a deal to acquire Telmap, an Israeli-based navigation software company. The purchase price was not disclosed, but Israeli media reported values around $300 million to $350 million.[46]

In July 2012, Intel Corporation agreed to buy 10 percent shares of ASML Holding NV for $2.1 billion and another $1 billon for 5 percent shares that need shareholder approval to fund relevant research and development efforts, as part of a EUR3.3 billion ($4.1 billion) deal to accelerate the development of 450-millimeter wafer technology and extreme ultra-violet lithography by as much as two years.[47]

In July 2013, Intel confirmed the acquisition of Omek Interactive, an Israeli company that makes technology for gesture-based interfaces, without disclosing the monetary value of the deal. An official statement from Intel read: "The acquisition of Omek Interactive will help increase Intel's capabilities in the delivery of more immersive perceptual computing experiences." One report estimated the value of the acquisition between US$30 million and $50 million.[48]

The acquisition of a Spanish natural language recognition startup named Indisys was announced on September 13, 2013. The terms of the deal were not disclosed but an email from an Intel representative stated: "Intel has acquired Indisys, a privately held company based in Seville, Spain. The majority of Indisys employees joined Intel. We signed the agreement to acquire the company on May 31 and the deal has been completed." Indysis explains that its artificial intelligence (AI) technology "is a human image, which converses fluently and with common sense in multiple languages and also works in different platforms."[49]

In December 2014, Intel bought PasswordBox.[50]

In January 2015, Intel purchased a 30% stake in Vuzix, a smart glasses manufacturer. The deal was worth $24.8 million.[51]

In February 2015, Intel announced its agreement to purchase German network chipmaker Lantiq, to aid in its expansion of its range of chips in devices with Internet connection capability.[52]

Acquisition table

| Number | Acquisition date | Company | Business | Country | Price | Used as or integrated with | Ref(s). |

|---|---|---|---|---|---|---|---|

| 1 | June 4, 2009 | Wind River Systems | Embedded Systems | $884M | Software | [53] | |

| 2 | August 19, 2010 | McAfee | Security | $7.6B | Software | [54] | |

| 3 | August 30, 2010 | Infineon | Wireless | $1.4B | Mobile CPUs | [55] | |

| 4 | March 17, 2011 | Silicon Hive | DSP | N/A | Mobile CPUs | [56] | |

| 5 | September 29, 2011 | Telmap | Software | N/A | Location Services | [57] | |

| 6 | April 13, 2013 | Mashery | Cloud Software | $180M | Software | [58] | |

| 7 | May 3, 2013 | Aepona | SDN | N/A | Software | [59] | |

| 8 | May 6, 2013 | Stonesoft Corporation | Security | $389M | Software | [60] | |

| 9 | July 16, 2013 | Omek Interactive | Gesture | N/A | Software | [48] | |

| 10 | September 13, 2013 | Indisys | Natural language processing | N/A | Software | [49] | |

| 11 | March 25, 2014 | BASIS | Wearable | N/A | New Devices | [61] | |

| 12 | August 13, 2014 | Avago Technologies | Semiconductor | N/A | Communications Processors | [62] | |

| 13 | December 1, 2014 | PasswordBox | Security | N/A | Software | [63] | |

| 14 | January 5, 2015 | Vuzix | Wearable | $24.8M | New Devices | [64] |

Expansions

In 2008, Intel spun off key assets of a solar startup business effort to form an independent company, SpectraWatt Inc. However, as of 2011, SpectraWatt has filed for bankruptcy.[13]In February 2011, Intel announced plans to build a new microprocessor manufacturing facility in Chandler, Arizona, which is expected to be completed in 2013, at a cost of $5 billion.[65] It will accommodate 4,000 employees. The company produces three-quarters of their products in the United States, although three-quarters of their revenue comes from overseas.[66]

In April 2011, Intel began a pilot project with ZTE Corporation to produce smartphones using the Intel Atom processor for China's domestic market. This project is intended to challenge the domination of ARM processors in mobile phones.[67]

In December 2011, Intel announced that it reorganized several of its business units to form a new mobile and communications group.[68] This group will be responsible for the company's smartphone, tablet and wireless efforts, and will be headed by Hermann Eul and Mike Bell.

Opening up the foundries

Finding itself with excess fab capacity after the failure of the Ultrabook to gain market traction and with PC sales declining, in 2013 Intel reached a foundry agreement to produce chips for Altera using 14-nm process. General Manager of Intel's custom foundry division Sunit Rikhi indicated that Intel would pursue further such deals in the future.[69] This was after poor sales of Windows 8 hardware caused a major retrenchment for most of the major semiconductor manufacturers, except for Qualcomm, which continued to see healthy purchases from its largest customer, Apple.[70]As of July 2013, five companies will use Intel's fabs via the Intel Custom Foundry division: Achronix, Tabula, Netronome, Microsemi, and Altera—most are FPGA makers, but Netronome designs network processors. Only Achronix began shipping chips made by Intel using the 22-nm Tri-Gate process.[71][72] Several other customers also exist but were not announced at the time.[73]

The Alliance for Affordable Internet (A4AI) was launched in October 2013 and Intel is part of the coalition of public and private organisations that also includes Facebook, Google, and Microsoft. Led by Sir Tim Berners-Lee, the A4AI seeks to make Internet access more affordable so that access is broadened in the developing world, where only 31% of people are online. Google will help to decrease internet access prices so that they fall below the UN Broadband Commission's worldwide target of 5% of monthly income.[74]

Product and market history

SRAMS and the microprocessor

Intel's first products were shift register memory and random-access memory integrated circuits, and Intel grew to be a leader in the fiercely competitive DRAM, SRAM, and ROM markets throughout the 1970s. Concurrently, Intel engineers Marcian Hoff, Federico Faggin, Stanley Mazor and Masatoshi Shima invented Intel's first microprocessor. Originally developed for the Japanese company Busicom to replace a number of ASICs in a calculator already produced by Busicom, the Intel 4004 was introduced to the mass market on November 15, 1971, though the microprocessor did not become the core of Intel's business until the mid-1980s. (Note: Intel is usually given credit with Texas Instruments for the almost-simultaneous invention of the microprocessor)From DRAM to microprocessors

In 1983, at the dawn of the personal computer era, Intel's profits came under increased pressure from Japanese memory-chip manufacturers, and then-president Andy Grove focused the company on microprocessors. Grove described this transition in the book Only the Paranoid Survive. A key element of his plan was the notion, then considered radical, of becoming the single source for successors to the popular 8086 microprocessor.Until then, the manufacture of complex integrated circuits was not reliable enough for customers to depend on a single supplier,[clarification needed] but Grove began producing processors in three geographically distinct factories,[which?] and ceased licensing the chip designs to competitors such as Zilog and AMD.[citation needed] When the PC industry boomed in the late 1980s and 1990s, Intel was one of the primary beneficiaries.

Intel, x86 processors, and the IBM PC

Despite the ultimate importance of the microprocessor, the 4004 and its successors the 8008 and the 8080 were never major revenue contributors at Intel. As the next processor, the 8086 (and its variant the 8088) was completed in 1978, Intel embarked on a major marketing and sales campaign for that chip nicknamed "Operation Crush", and intended to win as many customers for the processor as possible. One design win was the newly created IBM PC division, though the importance of this was not fully realized at the time.

IBM introduced its personal computer in 1981, and it was rapidly successful. In 1982, Intel created the 80286 microprocessor, which, two years later, was used in the IBM PC/AT. Compaq, the first IBM PC "clone" manufacturer, produced a desktop system based on the faster 80286 processor in 1985 and in 1986 quickly followed with the first 80386-based system, beating IBM and establishing a competitive market for PC-compatible systems and setting up Intel as a key component supplier.

In 1975, the company had started a project to develop a highly advanced 32-bit microprocessor, finally released in 1981 as the Intel iAPX 432. The project was too ambitious and the processor was never able to meet its performance objectives, and it failed in the marketplace. Intel extended the x86 architecture to 32 bits instead.[75][76]

386 microprocessor

During this period Andrew Grove dramatically redirected the company, closing much of its DRAM business and directing resources to the microprocessor business. Of perhaps greater importance was his decision to "single-source" the 386 microprocessor. Prior to this, microprocessor manufacturing was in its infancy, and manufacturing problems frequently reduced or stopped production, interrupting supplies to customers. To mitigate this risk, these customers typically insisted that multiple manufacturers produce chips they could use to ensure a consistent supply. The 8080 and 8086-series microprocessors were produced by several companies, notably AMD. Grove made the decision not to license the 386 design to other manufacturers, instead producing it in three geographically distinct factories: Santa Clara, California; Hillsboro, Oregon; and Chandler, a suburb of Phoenix, Arizona. He convinced customers that this would ensure consistent delivery. As the success of Compaq's Deskpro 386 established the 386 as the dominant CPU choice, Intel achieved a position of near-exclusive dominance as its supplier. Profits from this funded rapid development of both higher-performance chip designs and higher-performance manufacturing capabilities, propelling Intel to a position of unquestioned leadership by the early 1990s.486, Pentium, and Itanium

Intel introduced the 486 microprocessor in 1989, and in 1990 formally established a second design team, designing the processors code-named "P5" and "P6" in parallel and committing to a major new processor every two years, versus the four or more years such designs had previously taken.Engineers Vinod Dham and Rajeev Chandrasekhar (Member of Parliament, India) were key figures on the core team that invented the 486 chip and later, Intel's signature Pentium chip. The P5 was earlier known as "Operation Bicycle," referring to the cycles of the processor. The P5 was introduced in 1993 as the Intel Pentium, substituting a registered trademark name for the former part number (numbers, such as 486, are hard to register as a trademark). The P6 followed in 1995 as the Pentium Pro and improved into the Pentium II in 1997. New architectures were developed alternately in Santa Clara, California and Hillsboro, Oregon.

The Santa Clara design team embarked in 1993 on a successor to the x86 architecture, codenamed "P7". The first attempt was dropped a year later, but quickly revived in a cooperative program with Hewlett-Packard engineers, though Intel soon took over primary design responsibility. The resulting implementation of the IA-64 64-bit architecture was the Itanium, finally introduced in June 2001. The Itanium's performance running legacy x86 code did not meet expectations, and it failed to compete effectively with x86-64, which was AMD's 64-bit extensions to the original x86 architecture (Intel uses the name Intel 64, previously EM64T). As of 2012, Intel continues to develop and deploy the Itanium; known planning continues into 2014.

The Hillsboro team designed the Willamette processors (initially code-named P68), which were marketed as the Pentium 4.[citation needed]

Pentium flaw

In June 1994, Intel engineers discovered a flaw in the floating-point math subsection of the P5 Pentium microprocessor. Under certain data-dependent conditions, the low-order bits of the result of a floating-point division would be incorrect. The error could compound in subsequent calculations. Intel corrected the error in a future chip revision.In October 1994, Thomas Nicely, Professor of Mathematics at Lynchburg College, independently discovered the bug. He contacted Intel, but received no response. On October 30, he posted a message on the Internet.[77] Word of the bug spread quickly and reached the industry press. The bug was easy to replicate; a user could enter specific numbers into the calculator on the operating system. Consequently, many users did not accept Intel's statements that the error was minor and "not even an erratum." During Thanksgiving, in 1994, The New York Times ran a piece by journalist John Markoff spotlighting the error. Intel changed its position and offered to replace every chip, quickly putting in place a large end-user support organization. This resulted in a $500 million charge against Intel's 1994 revenue.

The "Pentium flaw" incident, Intel's response to it, and the surrounding media coverage propelled Intel from being a technology supplier generally unknown to most computer users to a household name. Dovetailing with an uptick in the "Intel Inside" campaign, the episode is considered to have been a positive event for Intel, changing some of its business practices to be more end-user focused and generating substantial public awareness, while avoiding a lasting negative impression.[78]

"Intel Inside" and other 1990s programs

During this period, Intel undertook two major supporting programs. The first is widely known: the 1991 "Intel Inside" marketing and branding campaign. The idea of ingredient branding was new at the time with only Nutrasweet and a few others making attempts to do so.[79] This campaign established Intel, which had been a component supplier little-known outside the PC industry, as a household name.The second program is little-known: Intel's Systems Group began, in the early 1990s, manufacturing PC "motherboards", the main board component of a personal computer, and the one into which the processor (CPU) and memory (RAM) chips are plugged.[80] Shortly after, Intel began manufacturing fully configured "white box" systems for the dozens of PC clone companies that rapidly sprang up.[citation needed] At its peak in the mid-1990s, Intel manufactured over 15% of all PCs, making it the third-largest supplier at the time.[citation needed]

During the 1990s, Intel's Architecture Lab (IAL) was responsible for many of the hardware innovations of the personal computer, including the PCI Bus, the PCI Express (PCIe) bus, the Universal Serial Bus (USB). IAL's software efforts met with a more mixed fate; its video and graphics software was important in the development of software digital video,[citation needed] but later its efforts were largely overshadowed by competition from Microsoft. The competition between Intel and Microsoft was revealed in testimony by IAL Vice-President Steven McGeady at the Microsoft antitrust trial.

Solid-state drives (SSD)

On September 8, 2008, Intel began shipping its first mainstream solid-state drives, the X18-M and X25-M with 80GB and 160GB storage capacities.[81] Reviews measured high performance with these MLC-based drives.[82][83][84][85] Intel released their SLC-based Enterprise X25-E Extreme SSDs on October 15 that same year in capacities of 32GB and 64GB.[86]

In July 2009, Intel refreshed their X25-M and X18-M lines by moving from a 50-nanometer to a 34-nanometer process. These new drives, dubbed by the press as the X25-M and X18-M G2[87][88] (or generation 2), reduced prices by up to 60 percent while offering lower latency and improved performance.[89]

On February 1, 2010, Intel and Micron announced that they were gearing up for production of NAND flash memory using a new 25-nanometer process.[90] In March of that same year, Intel entered the budget SSD segment with their X25-V drives with an initial capacity of 40GB.[91] The SSD 310, Intel's first mSATA drive was released on December 2010, providing X25-M G2 performance in a much smaller package.[92][93]

March 2011 saw the introduction of two new SSD lines from Intel. The first, the SSD 510, used a SATA 6 Gigabit per second interface to reach speeds of up to 500 MegaBytes per second.[94] The drive, which uses a controller from Marvell Technology Group,[95] was released using 34 nm NAND Flash and came in capacities of 120GB and 250GB. The second product announcement, the SSD 320, is the successor to Intel's earlier X25-M. It uses the new 25 nm process that Intel and Micron announced in 2010, and was released in capacities of 40 GB, 80 GB, 120 GB, 160 GB, 300 GB and 600 GB.[96] Sequential read performance maxes out at 270 MB/s due to the older SATA 3 Gbit/s interface, and sequential write performance varies greatly based on the size of the drive with sequential write performance of the 40 GB model peaking at 45 MB/s and the 600 GB at 220 MB/s.[97]

Micron and Intel announced that they were producing their first 20 nm MLC NAND flash on April 14, 2011.[98]

In February 2012, Intel launched the SSD 520 series solid state drives using the SandForce SF-2200 controller with sequential read and write speeds of 550 and 520 MB/s respectively with random read and write IOPS as high as 80,000. These drives will replace the 510 series.[99] Intel has released the budget 330 series solid state drive in 60, 120, and 180GB capacities using 25 nm flash memory and a SandForce controller that have replaced the 320 series.[100][101]

| Model | Codename | Capacities (GB) | NAND type | Interface | Form factor | Controller | Seq. read/write MB/s | Rnd 4KB read/write IOPS (K) | Introduced | Comment / Source |

|---|---|---|---|---|---|---|---|---|---|---|

| X18-M/X25-M | Ephraim | 80/160 | 50 nm MLC | SATA 3 Gbit/s | 1.8"/2.5" | Intel | 250 / 70 | 35 / 3.300–0.35 | Sept 2008 (now EOL) | [81][102] |

| X25-E | Ephraim | 32/64 | 50 nm SLC | SATA 3 Gbit/s | 2.5" | Intel | 250 / 170 | 35 / 3.3 | Oct 2008 | [86][88] |

| X18-M G2 / X25-M G2 | Postville | 80/120/160 | 34 nm MLC | SATA 3 Gbit/s | 1.8"/2.5" | Intel | 250 / 100 | 35 / 6.6–0.3 | July 2009 | [87][88][103] |

| X25-V | Glenbrook | 40 | 34 nm MLC | SATA 3 Gbit/s | 2.5" | Intel | 170 / 35 | 25 / 2.5–? | Mar 2010 | [91][104] |

| 310 | Soda Creek | 40/80 | 34 nm MLC | SATA 3 Gbit/s | mSATA | Intel | 200/70 | 35/2.6 | Dec 2010 | [92][105][106] |

| 510 | Elmcrest | 120/250 | 34 nm MLC | SATA 6 Gbit/s | 2.5" | Marvell | 500/315 | 20/8 | Mar 2011 | [94][107] |

| 320 | Postville Refresh | 40/80/120/160/300/600 | 25 nm MLC | SATA 3 Gbit/s | 1.8"/2.5" | Intel[108] | 270/220 | 39.5/23 | Mar 2011 | Originally to be released Oct 2010, named X18-M G3 & X25-M G3, the 1.8" was released later in 2011[88][96][109] |

| 311 | Larsen Creek | 20 | 34 nm SLC | SATA 3 Gbit/s | 2.5"/mSATA | Intel | 200/105 | 37/3.3 | May 2011 | Special low capacity SLC SSD for use with Intel SRT[110][111][112] |

| 710 | Lyndonville | 100/200/300 | 25 nm MLC-HET | SATA 3 Gbit/s | 2.5" | Intel | 270/210 | 38.5/2.7 | Q3 2011 | [113][114] |

| 520 | Cherryville | 60/120/180/240/480 | 25 nm MLC | SATA 6 Gbit/s | 2.5" | SandForce | 550/520 | 50/80 | February 2012 | Replaces 510[99] |

| 313 | Hawley Creek | 20/24 | 25 nm SLC | SATA 3 Gbit/s | 2.5"/mSATA | Intel | 220/115 | 36/4 | April 2012 | Replaces 311; for use with SRT[115] |

| 330 | Maple Crest | 60/120/180/240 | 25 nm MLC | SATA 6 Gbit/s | 2.5" | SandForce | 500/450 | 22.5/33 | April 2012 | [100][101] |

| 910 | Ramsdale | 400/800 | 25 nm MLC-HET | PCIe 2.0 × 8 | PCIe | Intel/Hitachi | 2000/1000 | 180/75 | April 2012 | [116][117] |

| 335 | Jay Crest | 80/180/240 | 20 nm MLC | SATA 6 Gbit/s | 2.5" | SandForce | 500/450 | 42/52 | October 2012 | [118][119] |

| DC S3700 | Taylorsville | 100/200/400/800 | 25 nm MLC-HET | SATA 6 Gbit/s | 1.8"/2.5" | Intel | 500/450 | 72/34 | November 2012 | [120][121] |

| 525 | Lincoln Crest | 30/60/120/180/240 | 25 nm MLC | SATA 6 Gbit/s | mSATA | SandForce | 550/520 | 50/60 | January 2013 | [122][123] |

| DC S3500 | Wolfsville | 80/120/160/240/300/400/480/600/800 | 20 nm MLC | SATA 6 Gbit/s | 1.8"/2.5" | Intel | 475/450 | 75/11.5 | June 2013 | [124][125] |

| 530 | Dale Crest | 80/120/180/240/360/480 | 20 nm MLC | SATA 6 Gbit/s | M.2/mSATA/2.5" | SandForce | 540/490 | 41/80 | July 2013 | [126][127] |

| Pro 1500 | Sierra Star | 80/120/180/240/360/480 | 20 nm MLC | SATA 6 Gbit/s | M.2/2.5" | SandForce | 540/490 | 41/80 | Sept 2013 | [128][129][130] |

| Pro 2500 | Temple Star | 80/180/240/360/480 | 20 nm MLC | SATA 6 Gbit/s | M.2/2.5" | SandForce? | 540/490 | 42/52 | Q2 2014 | [131][132] |

| DC P3700 | Fultondale | 200/400/800/1600/2000 | 20 nm MLC-HET | PCIe | (2.5"/AIC) | Intel | 2800/1700 | 450/150 | Q2 2014 | Custom Intel NVMe controller[131][132] |

| DC P3500 | Pleasantdale | 250/500/1000/2000 | 20 nm MLC | PCIe | (2.5"/AIC) | Intel | 2800/1700 | 450/40 | Q2 2014 | Custom Intel NVMe controller[131][132] |

| 730 | Jackson Ridge | 240/480 | 20 nm MLC | SATA 6 Gbit/s | 2.5" | Intel | 550/470 | 89/74 | March 2014 | [133] |

| DC P3600 | 400/800/1200/1600/2000 | 20 nm MLC | PCIe | (2.5"/AIC) | Intel | 2600/1700 | 450/56 | June 2014 | [134][135] | |

| Model | Codename | Capacities (GB) | NAND type | Interface | Form factor | Controller | Seq. read/write MB/s | Rnd 4KB read/write IOPS (K) | Introduced | Comment / Source |

Supercomputers

The Intel Scientific Computers division was founded in 1984 by Justin Rattner, in order to design and produce parallel computers based on Intel microprocessors connected in hypercube topologies.[136] In 1992 the name was changed to the Intel Supercomputing Systems Division, and development of the iWarp architecture was also subsumed.[137] The division designed several supercomputer systems, including the Intel iPSC/1, iPSC/2, iPSC/860, Paragon and ASCI Red. In November 2014, Intel revealed that it is going to use light beams to speed up supercomputers.[138] The renowned chip maker has also disclosed that all its Supercomputer forms will use optical technology for data transfer from 2015.Competition, antitrust and espionage

Two factors combined to end this dominance: the slowing of PC demand growth beginning in 2000 and the rise of the low cost PC. By the end of the 1990s, microprocessor performance had outstripped software demand for that CPU power. Aside from high-end server systems and software, whose demand dropped with the end of the "dot-com bubble", consumer systems ran effectively on increasingly low-cost systems after 2000. Intel's strategy of producing ever-more-powerful processors and obsoleting their predecessors stumbled,[citation needed] leaving an opportunity for rapid gains by competitors, notably AMD. This in turn lowered the profitability[citation needed] of the processor line and ended an era of unprecedented dominance of the PC hardware by Intel.[citation needed]Intel's dominance in the x86 microprocessor market led to numerous charges of antitrust violations over the years, including FTC investigations in both the late 1980s and in 1999, and civil actions such as the 1997 suit by Digital Equipment Corporation (DEC) and a patent suit by Intergraph. Intel's market dominance (at one time[when?] it controlled over 85% of the market for 32-bit x86 microprocessors) combined with Intel's own hardball legal tactics (such as its infamous 338 patent suit versus PC manufacturers)[139] made it an attractive target for litigation, but few of the lawsuits ever amounted to anything.[clarification needed]

A case of industrial espionage arose in 1995 that involved both Intel and AMD. Bill Gaede, an Argentine formerly employed both at AMD and at Intel's Arizona plant, was arrested for attempting in 1993 to sell the i486 and P5 Pentium designs to AMD and to certain foreign powers.[140] Gaede videotaped data from his computer screen at Intel and mailed it to AMD, which immediately alerted Intel and authorities, resulting in Gaede's arrest. Gaede was convicted and sentenced to 33 months in prison in June 1996.[141][142]

Partnership with Apple

On June 6, 2005, Steve Jobs, then CEO of Apple, announced that Apple would be transitioning from its long favored PowerPC architecture to the Intel x86 architecture, because the future PowerPC road map was unable to satisfy Apple's needs. The first Macintosh computers containing Intel CPUs were announced on January 10, 2006, and Apple had its entire line of consumer Macs running on Intel processors by early August 2006. The Apple Xserve server was updated to Intel Xeon processors from November 2006, and was offered in a configuration similar to Apple's Mac Pro.[143]Core 2 Duo advertisement controversy

In 2007, the company released a print advertisement for its Core 2 Duo processor featuring six African American runners appearing to bow down to a Caucasian male inside of an office setting (due to the posture taken by runners on starting blocks). According to Nancy Bhagat, Vice President of Intel Corporate Marketing, the general public[clarification needed] found the ad to be "insensitive and insulting."[144] The campaign was quickly pulled and several Intel executives made public apologies on the corporate website.[145]Classmate PC

Intel's Classmate PC is the company's first low-cost netbook computer.[146] One of the models, designed by TEAMS Design [4] in their Shanghai office, won many design awards, such as the Appliance Design EID Award,[147] the 2008 Spark Award,[148] and the iF 2008 China Award.[149]Mobile processor

In June 2011, Intel introduced the first Pentium mobile processor based on the Sandy Bridge core. The B940, clocked at 2 GHz, is faster than existing or upcoming mobile Celerons, although it is almost identical to dual-core Celeron CPUs in all other aspects.[150] According to IHS iSuppli's report on September 28, 2011, Sandy Bridge chips have helped Intel increase its market share in global processor market to 81.8%, while AMD's market share dropped to 10.4%.[151]Intel planned to introduce Medfield – a processor for tablets and smartphones – to the market in 2012, as an effort to compete with ARM.[152] As a 32-nanometer processor, Medfield is designed to be energy-efficient, which is one of the core features in ARM's chips.[153]

At the Intel Developers Forum (IDF) 2011 in San Francisco, Intel's partnership with Google was announced. By January 2012, Google's Android 2.3 will use Intel's Atom microprocessor.[154][155][156]

Server chips

In July 2011, Intel announced that its server chips, the Xeon series, will use new sensors that can improve data center cooling efficiency.[157]22 nm processors

In 2011, Intel announced the Ivy Bridge processor family at the Intel Developer Forum.[158] Ivy Bridge supports both DDR3 memory and DDR3L chips.Personal Office Energy Monitor (POEM)

As part of its efforts in the Positive Energy Buildings Consortium, Intel has been developing an application, called Personal Office Energy Monitor (POEM), to help office buildings to be more energy-efficient. With this application, employees can get the power consumption info for their office machines, so that they can figure out a better way to save energy in their working environment.[159]IT Manager 3: Unseen Forces

IT Manager III: Unseen Forces is a web-based IT simulation game from Intel. In it you manage a company's IT department. The goal is to apply technology and skill to enable the company to grow from a small business into a global enterprise.[citation needed]Car Security System

In 2011, Intel announced that it is working on a car security system that connects to smartphones via an application. The application works by streaming video to a cloud service if your car is broken into.[160]High-Bandwidth Digital Content Protection

Intel also developed High-Bandwidth Digital Content Protection (HDCP) to prevent access of digital audio and video content as it travels across connections.Move from Wintel desktop to open mobile platforms

In 2013, Intel's Kirk Skaugen said that Intel's exclusive focus on Microsoft platforms was a thing of the past and that they would now support all "tier-one operating systems" such as Linux, Android, iOS, and Chrome.[161]In 2014, Intel cut thousands of employees in response to "evolving market trends",[162] and offered to subsidize manufacturers for the extra costs involved in using Intel chips in their tablets.[163]

Wearable fashion

On January 6, 2014, Intel announced that it was "teaming with the Council of Fashion Designers of America, Barneys New York and Opening Ceremony around the wearable tech field."[164]Intel has developed a reference design for wearable smart earbuds that provide biometric and fitness information. The Intel smart earbuds provide full stereo audio, and monitor heart rate, while the applications on the user’s phone keep track of run distance and calories burned.

Corporate affairs

In September 2006, Intel had nearly 100,000 employees and 200 facilities world wide. Its 2005 revenues were $38.8 billion and its Fortune 500 ranking was 49th. Its stock symbol is INTC, listed on the NASDAQ. As of February 2009, the biggest customers of Intel are Hewlett-Packard and Dell.[165]Leadership and corporate structure

Robert Noyce was Intel's CEO at its founding in 1968, followed by co-founder Gordon Moore in 1975. Andy Grove became the company's president in 1979 and added the CEO title in 1987 when Moore became chairman. In 1998, Grove succeeded Moore as Chairman, and Craig Barrett, already company president, took over. On May 18, 2005, Barrett handed the reins of the company over to Paul Otellini, who previously was the company president and COO and who was responsible for Intel's design win in the original IBM PC. The board of directors elected Otellini as President and CEO, and Barrett replaced Grove as Chairman of the Board. Grove stepped down as chairman, but is retained as a special adviser. In May 2009, Barrett stepped down as chairman of the Board and was succeeded by Jane Shaw. In May 2012, Intel vice chairman Andy Bryant, who had previously held the posts of CFO (1994) and Chief Administrative Officer (2007) at Intel, succeeded Shaw as executive chairman.[166]

In November 2012, president and CEO Paul Otellini announced that he would step down in May 2013 at the age of 62, three years before the company's mandatory retirement age. During a six-month transition period, Intel's board of directors commenced a search process for the next CEO, in which it considered both internal managers and external candidates such as Sanjay Jha and Patrick Gelsinger.[167] Financial results revealed that, under Otellini, Intel's revenue increased by 55.8 percent (US$34.2 to 53.3 billion), while its net income increased by 46.7% (US$7.5 billion to 11 billion).[168]

On May 2, 2013, Executive Vice President and COO Brian Krzanich was elected as Intel's sixth CEO,[169] a selection that became effective on May 16, 2013 at the company's annual meeting. Reportedly, the board concluded that an insider could proceed with the role and exert an impact more quickly, without the need to learn Intel's processes, and Krzanich was selected on such a basis.[170] Intel's software head Renée James was selected as president of the company, a role that is second to the CEO position.[171]

As of May 2013, Intel's board of directors consists of Andy Bryant, John Donahoe, Frank Yeary, Ambassador Charlene Barshefsky, Susan Decker, Reed Hundt, Paul Otellini, James Plummer, David Pottruck, and David Yoffie. The board was described by former Financial Times journalist Tom Foremski as "an exemplary example of corporate governance of the highest order" and received a rating of ten from GovernanceMetrics International, a form of recognition that has only been awarded to twenty-one other corporate boards worldwide.[172]

Employment

Intel microprocessor facility in Costa Rica was responsible in 2006 for 20% of Costa Rican exports and 4.9% of the country's GDP.[173]

The firm promotes very heavily from within, most notably in its executive suite. The company has resisted the trend toward outsider CEOs. Paul Otellini was a 30-year veteran of the company when he assumed the role of CEO. All of his top lieutenants have risen through the ranks after many years with the firm. In many cases, Intel's top executives have spent their entire working careers with Intel.[citation needed]

Intel has a mandatory retirement policy for its CEOs when they reach age 65. Andy Grove retired at 62, while both Robert Noyce and Gordon Moore retired at 58. Grove retired as Chairman and as a member of the board of directors in 2005 at age 68.

Intel's Headquarters are based in Santa Clara, California and has operations around the world. Its largest workforce concentration anywhere is in Washington County, Oregon (in the Portland metropolitan area's "Silicon Forest"), with about 17,000 employees at several facilities and major expansion under way.[174] Outside the United States, the company has facilities in China, Costa Rica, Malaysia, Israel, Ireland, India, Russia and Vietnam, 63 countries and regions internationally. In the U.S. Intel employs significant numbers of people in California, Colorado, Massachusetts, Arizona, New Mexico, Oregon, Texas, Washington and Utah. In Oregon, Intel is the state's largest private employer.[174][175] The company is the largest industrial employer in New Mexico while in Arizona the company has over 10,000 employees.[citation needed]

Intel invests heavily in research in China and about 100 researchers – or 10% of the total number of researchers from Intel – are located in Beijing.[176]

In 2011, the Israeli government offered Intel $290 million to expand in the country. As a condition, Intel will have to employ 1,500 more workers in Kiryat Gat and between 600–1000 workers in the north.[177]

In January 2014, it was reported that Intel would cut about 5,000 jobs from its work force of 107,000. The announcement was made a day after it reported earnings that missed analyst targets.[178]

In March 2014, it was reported that Intel would embark upon a $6 billion plan to expand its activities in Israel. The plan calls for continued investment in existing and new Intel plants until 2030. As of 2014 Intel employs 10,000 workers at four development centers and two production plants in Israel.[179]

Diversity

Intel has a Diversity Initiative, including employee diversity groups as well as supplier diversity programs.[180] Like many companies with employee diversity groups, they include groups based on race and nationality as well as sexual identity and religion. In 1994, Intel sanctioned one of the earliest corporate Gay, Lesbian, Bisexual, and Transgender employee groups,[181] and supports a Muslim employees group,[182] a Jewish employees group,[183] and a Bible-based Christian group.[184][185]Intel received a 100% rating on the first Corporate Equality Index released by the Human Rights Campaign in 2002. It has maintained this rating in 2003 and 2004. In addition, the company was named one of the 100 Best Companies for Working Mothers in 2005 by Working Mother magazine.[citation needed]

In January 2015, Intel announced the investment of $300 million over the next five years to enhance gender and racial diversity in their own company as well as the technology industry as a whole.[186][187][188][189][190]

Economic Impacts

In 2011, ECONorthwest conducted an economic impact analysis of Intel's economic contribution to the state of Oregon. The report found that in 2009 "the total economic impacts attributed to Intel's operations, capital spending, contributions and taxes amounted to almost $14.6 billion in activity, including $4.3 billion in personal income and 59,990 jobs."[191] Through multiplier effects, every 10 Intel jobs supported, on average, was found to create 31 jobs in other sectors of the economy.[192]Funding of a school

In Rio Rancho, New Mexico, Intel is the leading employer.[193] In 1997, a community partnership between Sandoval County and Intel Corporation funded and built Rio Rancho High School.[194][195]Ultrabook Fund

In 2011, Intel Capital announced a new fund to support startups working on technologies in line with the company's concept for next generation notebooks.[196] The company is setting aside a $300 million fund to be spent over the next three to four years in areas related to ultrabooks.[196] Intel announced the ultrabook concept at Computex in 2011. The ultrabook is defined as a thin (less than 0.8 inches [~2 cm] thick[197]) notebook that utilizes Intel processors[197] and also incorporates tablet features such as a touch screen and long battery life.[196][197]At the Intel Developers Forum in 2011, four Taiwan ODMs showed prototype ultrabooks that used Intel's Ivy Bridge chips.[198] Intel plans to improve power consumption of its chips for ultrabooks, like new Ivy Bridge processors in 2013, which will only have 10W default thermal design power.[199]

Intel's goal for Ultrabook's price is below $1000;[197] however, according to two presidents from Acer and Compaq, this goal will not be achieved if Intel does not lower the price of its chips.[200]

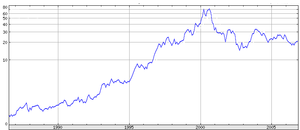

Finances

Intel's market capitalization is $162.97 billion (February 21, 2015). It publicly trades on NASDAQ with the symbol INTC. A widely held stock, the following indices include Intel shares: Dow Jones Industrial Average, S&P 500, NASDAQ-100, Russell 1000 Index, Russell 1000 Growth Index and SOX (PHLX Semiconductor Sector).

On July 15, 2008, Intel announced that it had achieved the highest earnings in the history of the company during Q2 2008.[201]

Advertising and brand management

Intel Inside

Intel has become one of the world's most recognizable computer brands following its long-running Intel Inside campaign. The campaign, which started in 1991, was created by Intel marketing manager Dennis Carter.[202] The five-note jingle was introduced in 1994 and by its tenth anniversary was being heard in 130 countries around the world. The initial branding agency for the Intel Inside campaign was DahlinSmithWhite Advertising of Salt Lake City. The Intel swirl logo was the work of DahlinSmithWhite art director Steve Grigg under the direction of Intel president and CEO Andy Grove.The Intel Inside advertising campaign sought public brand loyalty and awareness of Intel processors in consumer computers.[203] Intel paid some of the advertiser's costs for an ad that used the Intel Inside logo and xylomarimba jingle.[204]

In 2008, Intel planned to shift the emphasis of its Intel Inside campaign from traditional media such as television and print to newer media such as the Internet.[205] Intel required that a minimum of 35% of the money it provided to the companies in its co-op program be used for online marketing.[205] The Intel 2010 annual financial report indicated that $1.8 billion (6% of the gross margin and nearly 16% of the total net income) was allocated to all advertising with Intel Inside being part of that.[206]

Sonic logo

The famous D♭ D♭ G♭ D♭ A♭ xylophone/xylomarimba jingle, sonic logo, tag, audio mnemonic was produced by Musikvergnuegen and written by Walter Werzowa, once a member of the Austrian 1980s sampling band Edelweiss.[207] The sonic Intel logo has undergone substantial changes in tone since the introduction of the Pentium III, Pentium 4, and Core processors, yet keeps the same jingle.Naming strategy

In 2006, Intel expanded its promotion of open specification platforms beyond Centrino, to include the Viiv media center PC and the business desktop Intel vPro.In mid January 2006, Intel announced that they were dropping the long running Pentium name from their processors. The Pentium name was first used to refer to the P5 core Intel processors (Pent refers to the 5 in P5,) and was done to circumvent court rulings that prevent the trademarking of a string of numbers, so competitors could not just call their processor the same name, as had been done with the prior 386 and 486 processors (both of which had copies manufactured by IBM and AMD). They phased out the Pentium names from mobile processors first, when the new Yonah chips, branded Core Solo and Core Duo, were released. The desktop processors changed when the Core 2 line of processors were released. By 2009 Intel was using a good-better-best strategy with Celeron being good, Pentium better, and the Intel Core family representing the best the company has to offer.[208]

According to spokesman Bill Calder, Intel has maintained only the Celeron brand, the Atom brand for netbooks and the vPro lineup for businesses. Since late 2009, Intel's mainstream processors have been called Celeron, Pentium, Core i3, Core i5, and Core i7, in order of performance from lowest to highest. The first generation core products carry a 3 digit name, such as i5 750, and the second generation products carry a 4 digit name, such as the i5 2500. In both cases, a K at the end of it shows that it is an unlocked processor, enabling additional overclocking abilities (for instance, 2500K). vPro products will carry the Intel Core i7 vPro processor or the Intel Core i5 vPro processor name.[209] In October 2011, Intel started to sell its Core i7-2700K "Sandy Bridge" chip to customers worldwide.[210]

Beginning in 2010, "Centrino" will only be applied to Intel's WiMAX and Wi-Fi technologies; it won't be a PC brand anymore. This will be an evolutionary process taking place over time, Intel acknowledges that multiple brands will be in the market including older ones throughout the transition.[209]

Open source support

Intel has a significant participation in the open source communities since 1999.[211] For example, in 2006 Intel released MIT-licensed X.org drivers for their integrated graphic cards of the i965 family of chipsets. Intel released FreeBSD drivers for some networking cards,[212] available under a BSD-compatible license,[213] which were also ported to OpenBSD.[213] Binary firmware files for non-wireless Ethernet devices were also released under a BSD licence allowing free redistribution.[214] Intel ran the Moblin project until April 23, 2009, when they handed the project over to the Linux Foundation. Intel also runs the LessWatts.org campaigns.[215]However, after the release of the wireless products called Intel Pro/Wireless 2100, 2200BG/2225BG/2915ABG and 3945ABG in 2005, Intel was criticized for not granting free redistribution rights for the firmware that must be included in the operating system for the wireless devices to operate.[216] As a result of this, Intel became a target of campaigns to allow free operating systems to include binary firmware on terms acceptable to the open source community. Linspire-Linux creator Michael Robertson outlined the difficult position that Intel was in releasing to open source, as Intel did not want to upset their large customer Microsoft.[217] Theo de Raadt of OpenBSD also claimed that Intel is being "an Open Source fraud" after an Intel employee presented a distorted view of the situation at an open-source conference.[218] In spite of the significant negative attention Intel received as a result of the wireless dealings, the binary firmware still has not gained a license compatible with free software principles.[219]

Corporate responsibility record

Intel has been accused by some residents of Rio Rancho, New Mexico of allowing VOCs to be released in excess of their pollution permit. One resident claimed that a release of 1.4 tons of carbon tetrachloride was measured from one acid scrubber during the fourth quarter of 2003 but an emission factor allowed Intel to report no carbon tetrachloride emissions for all of 2003.[220]Another resident alleges that Intel was responsible for the release of other VOCs from their Rio Rancho site and that a necropsy of lung tissue from two deceased dogs in the area indicated trace amounts of toluene, hexane, ethylbenzene, and xylene isomers,[221] all of which are solvents used in industrial settings but also commonly found in gasoline, retail paint thinners and retail solvents. During a sub-committee meeting of the New Mexico Environment Improvement Board, a resident claimed that Intel's own reports documented more than 1,580 pounds (720 kg) of VOCs were released in June and July 2006.[222]

Intel's environmental performance is published annually in their corporate responsibility report.[223]

In its 2012 rankings on the progress of consumer electronics companies relating to conflict minerals, the Enough Project rated Intel the best of 24 companies, calling it a "Pioneer of progress".[224] In 2014, chief executive Brian Krzanich urged the rest of the industry to follow Intel's lead by also shunning conflict minerals.[225]

Religious controversy

Orthodox Jews have protested against Intel operating in Israel on Saturday, Shabbat. Intel ringed its office with barbed wire before the protest, but there was no violence.[226] As of December 2009, the situation has been stable for Intel Israel while some employees reported working overtime on Shabbat.Age discrimination

Intel has faced complaints of age discrimination in firing and layoffs. Intel was sued in 1993 by nine former employees, over allegations that they were laid off because they were over the age of 40.[227]A group called FACE Intel (Former and Current Employees of Intel) claims that Intel weeds out older employees. FACE Intel claims that more than 90 percent of people who have been laid off or fired from Intel are over the age of 40. Upside magazine requested data from Intel breaking out its hiring and firing by age, but the company declined to provide any.[228] Intel has denied that age plays any role in Intel's employment practices.[229] FACE Intel was founded by Ken Hamidi, who was fired from Intel in 1995 at the age of 47.[228] Hamidi was blocked in a 1999 court decision from using Intel's email system to distribute criticism of the company to employees,[230] which overturned in 2003 in Intel Corp. v. Hamidi.

Competition

In the 1980s, Intel was among the top ten sellers of semiconductors (10th in 1987) in the world. In 1991, Intel became the biggest chip maker by revenue and has held the position ever since. Other top semiconductor companies include TSMC, Advanced Micro Devices, Samsung, Texas Instruments, Toshiba and STMicroelectronics.Competitors in PC chip sets include AMD, VIA Technologies, SiS, and Nvidia. Intel's competitors in networking include Freescale, Infineon, Broadcom, Marvell Technology Group and AMCC, and competitors in flash memory include Spansion, Samsung, Qimonda, Toshiba, STMicroelectronics, and Hynix.

The only major competitor in the x86 processor market is Advanced Micro Devices (AMD), with which Intel has had full cross-licensing agreements since 1976: each partner can use the other's patented technological innovations without charge after a certain time.[231] However, the cross-licensing agreement is canceled in the event of an AMD bankruptcy or takeover.[232] Some smaller competitors such as VIA and Transmeta produce low-power x86 processors for small factor computers and portable equipment. However, the advent of such mobile computing devices, in particular, smartphones, has in recent years led to a decline in PC sales. This is seen as the main reason for Intel's 2013 Q1 net income drop of 25%.[233] As over 95% of the world's smartphones are currently powered by processors designed by ARM Holdings, this company has become a major competitor for Intel's processor market. ARM is also planning to make inroads into the PC and server market.[234]

Lawsuits

Intel has often been accused by competitors of using legal claims to thwart competition. Intel claims that it is defending its intellectual property. Intel has been plaintiff and defendant in numerous legal actions.In September 2005, Intel filed a response to an AMD lawsuit,[235] disputing AMD's claims, and claiming that Intel's business practices are fair and lawful. In a rebuttal, Intel deconstructed AMD's offensive strategy and argued that AMD struggled largely as a result of its own bad business decisions, including underinvestment in essential manufacturing capacity and excessive reliance on contracting out chip foundries.[236] Legal analysts predicted the lawsuit would drag on for a number of years, since Intel's initial response indicated its unwillingness to settle with AMD.[237][238] In 2008 a court date was finally set,[239] but in 2009 Intel settled with a $1.25 billion payout to AMD (see below).[240]

In October 2006, a Transmeta lawsuit was filed against Intel for patent infringement on computer architecture and power efficiency technologies.[241] The lawsuit was settled in October 2007, with Intel agreeing to pay US$150 million initially and US$20 million per year for the next five years. Both companies agreed to drop lawsuits against each other, while Intel was granted a perpetual non-exclusive license to use current and future patented Transmeta technologies in its chips for 10 years.[242]

On November 4, 2009, New York's attorney general filed an antitrust lawsuit against Intel Corp, claiming the company used "illegal threats and collusion" to dominate the market for computer microprocessors.

On November 12, 2009, AMD agreed to drop the antitrust lawsuit against Intel in exchange for $1.25 billion.[240] A joint press release published by the two chip makers stated "While the relationship between the two companies has been difficult in the past, this agreement ends the legal disputes and enables the companies to focus all of our efforts on product innovation and development."[243][244]

An antitrust lawsuit[245] and a class-action suit relating to cold calling employees of other companies is still pending. [246]

Anti-competitive allegations

Japan

In 2005, the local Fair Trade Commission found that Intel violated the Japanese Antimonopoly Act. The commission ordered Intel to eliminate discounts that had discriminated against AMD. To avoid a trial, Intel agreed to comply with the order.[247][248][249][250]European Union

In July 2007, the European Commission accused Intel of anti-competitive practices, mostly against AMD.[251] The allegations, going back to 2003, include giving preferential prices to computer makers buying most or all of their chips from Intel, paying computer makers to delay or cancel the launch of products using AMD chips, and providing chips at below standard cost to governments and educational institutions.[252] Intel responded that the allegations were unfounded and instead qualified its market behavior as consumer-friendly.[252] General counsel Bruce Sewell responded that the Commission had misunderstood some factual assumptions as to pricing and manufacturing costs.[253]In February 2008, Intel stated that its office in Munich had been raided by European Union regulators. Intel reported that it was cooperating with investigators.[254] Intel faced a fine of up to 10% of its annual revenue, if found guilty of stifling competition.[255] AMD subsequently launched a website promoting these allegations.[256][257] In June 2008, the EU filed new charges against Intel.[258] In May 2009, the EU found that Intel had engaged in anti-competitive practices and subsequently fined Intel €1.06 billion (US$1.44 billion), a record amount. Intel was found to have paid companies, including Acer, Dell, HP, Lenovo and NEC,[259] to exclusively use Intel chips in their products, and therefore harmed other companies including AMD.[259][260][261] The European Commission said that Intel had deliberately acted to keep competitors out of the computer chip market and in doing so had made a "serious and sustained violation of the EU's antitrust rules".[259] In addition to the fine, Intel was ordered by the Commission to immediately cease all illegal practices.[259] Intel has stated that they will appeal against the Commission's verdict. In June 2014, the General Court, which sits below the European Court of Justice, rejected the appeal.[259]

South Korea

In September 2007, South Korean regulators accused Intel of breaking antitrust law. The investigation began in February 2006, when officials raided Intel's South Korean offices. The company risked a penalty of up to 3% of its annual sales, if found guilty.[262] In June 2008, the Fair Trade Commission ordered Intel to pay a fine of US$25.5 million for taking advantage of its dominant position to offer incentives to major Korean PC manufacturers on the condition of not buying products from AMD.[263]United States

New York started an investigation of Intel in January 2008 on whether the company violated antitrust laws in pricing and sales of its microprocessors.[264] In June 2008, the Federal Trade Commission also began an antitrust investigation of the case.[265] In December 2009, the FTC announced it would initiate an administrative proceeding against Intel in September 2010.[266][267][268][269]In November 2009, following a two-year investigation, New York Attorney General Andrew Cuomo sued Intel, accusing them of bribery and coercion, claiming that Intel bribed computer makers to buy more of their chips than those of their rivals, and threatened to withdraw these payments if the computer makers were perceived as working too closely with its competitors. Intel has denied these claims.[270]

On July 22, 2010, Dell agreed to a settlement with the U.S. Securities and Exchange Commission (SEC) to pay $100M in penalties resulting from charges that Dell did not accurately disclose accounting information to investors. In particular, the SEC charged that from 2002 to 2006, Dell had an agreement with Intel to receive rebates in exchange for not using chips manufactured by AMD. These substantial rebates were not disclosed to investors, but were used to help meet investor expectations regarding the company's financial performance; "These exclusivity payments grew from 10 percent of Dell's operating income in FY 2003 to 38 percent in FY 2006, and peaked at 76 percent in the first quarter of FY 2007.".[271] Dell eventually did adopt AMD as a secondary supplier in 2006, and Intel subsequently stopped their rebates, causing Dell's financial performance to fall.[272][273][274]

According to IDC, while Intel still enjoys the biggest market share in both the overall worldwide PC microprocessor market (79.3%) and the mobile PC microprocessor (84.4%) in the second quarter of 2011, the numbers decreased by 1.5% and 1.9% compared to the first quarter.[275][276]

Per Passmark's (?) CPU benchmark, which takes into account individual benchmarking of their software and each system results are reported with, Intel has retained 70% and more of the active market versus AMD since Q1 2008.[277]