From Wikipedia, the free encyclopedia

| Ozone | |||

|---|---|---|---|

|

|||

|

|||

|

|||

| Identifiers | |||

| CAS number | 10028-15-6 |

||

| PubChem | 24823 | ||

| ChemSpider | 23208 |

||

| UNII | 66H7ZZK23N |

||

| EC number | 233–069–2 | ||

| MeSH | Ozone | ||

| ChEBI | CHEBI:25812 |

||

| RTECS number | RS8225000 | ||

| 1101 | |||

| Jmol-3D images | Image 1 Image 2 Image 3 |

||

| Properties | |||

| Molecular formula | O3 | ||

| Molar mass | 48.00 g mol−1 | ||

| Appearance | Pale blue gas | ||

| Density | 2.144 mg cm−3 (at 0 °C) | ||

| Melting point | −192.2 °C; −313.9 °F; 81.0 K | ||

| Boiling point | −112 °C; −170 °F; 161 K | ||

| Solubility in water | 1.05 g L−1 (at 0 °C) | ||

| Solubility | very soluble in CCl4, sulfuric acid | ||

Refractive index (nD)

|

1.2226 (liquid) | ||

| Structure | |||

| Space group | C2v | ||

| Digonal | |||

| Molecular shape | Dihedral | ||

| Hybridisation | sp2 for O1 | ||

| Dipole moment | 0.53 D | ||

| Thermochemistry | |||

Std molar

entropy (S |

238.92 J K−1 mol−1 | ||

Std enthalpy of

formation (ΔfH |

142.67 kJ mol−1 | ||

| Hazards | |||

| EU classification | |||

| NFPA 704 | |||

| Related compounds | |||

| Related compounds | Sulfur dioxide Trisulfur Disulfur monoxide Cyclic ozone |

||

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C (77 °F), 100 kPa) | |||

| |

|||

| Infobox references | |||

Ozone /ˈoʊzoʊn/ (systematically named 1λ1,3λ1-trioxidane and catena-trioxygen), or trioxygen, is an inorganic molecule with the chemical formula OO

2 (also written [O

3]). It is a pale blue gas with a distinctively pungent smell. It is an allotrope of oxygen that is much less stable than the diatomic allotrope O

2, breaking down in the lower atmosphere to normal dioxygen. Ozone is formed from dioxygen by the action of ultraviolet light and also atmospheric electrical discharges, and is present in low concentrations throughout the Earth's atmosphere. In total, ozone makes up only 0.6 ppm of the atmosphere.

Ozone's odor is sharp, reminiscent of chlorine, and detectable by many people at concentrations of as little as 10 ppb in air. Ozone's O3 formula was determined in 1865. The molecule was later proven to have a bent structure and to be diamagnetic. In standard conditions, ozone is a pale blue gas that condenses at progressively cryogenic temperatures to a dark blue liquid and finally a violet-black solid. Ozone's instability with regard to more common dioxygen is such that both concentrated gas and liquid ozone may decompose explosively.[1] It is therefore used commercially only in low concentrations.

Ozone is a powerful oxidant (far more so than dioxygen) and has many industrial and consumer applications related to oxidation. This same high oxidizing potential, however, causes ozone to damage mucous and respiratory tissues in animals, and also tissues in plants, above concentrations of about 100 ppb. This makes ozone a potent respiratory hazard and pollutant near ground level. However, the so-called ozone layer (a portion of the stratosphere with a higher concentration of ozone, from two to eight ppm) is beneficial, preventing damaging ultraviolet light from reaching the Earth's surface, to the benefit of both plants and animals.

Nomenclature

The trivial name ozone is the most commonly used and preferred IUPAC name. The systematic names 1λ1,3λ1-trioxidane and catena-trioxygen, valid IUPAC names, are constructed according to the substitutive and additive nomenclatures, respectively. The name ozone derives from ozein (ὄζειν), the Greek word for smell (verb), referring to ozone's distinctive smell.In appropriate contexts, ozone can be viewed as trioxidane with two hydrogen atoms removed, and as such, trioxidanylidene may be used as a context-specific systematic name, according to substitutive nomenclature. By default, these names pay no regard to the radicality of the ozone molecule. In even more specific context, this can also name the non-radical singlet ground state, whereas the diradical state is named trioxidanediyl.

Trioxidanediyl (or ozonide) is used, non-systematically, to refer to the substituent group (-OOO-). Care should be taken to avoid confusing the name of the group for the context-specific name for ozone given above.

History

In 1785, Dutch chemist Martinus van Marum was conducting experiments involving electrical sparking above water when he noticed an unusual smell, which he attributed to the electrical reactions, failing to realize he had in fact created ozone.[2] A half century later, Christian Friedrich Schönbein noticed the same pungent odor and recognized it as the smell often following a bolt of lightning. In 1839 he succeeded in isolating the gaseous chemical and named it "ozone", from the Greek word ozein (ὄζειν) meaning "to smell".[3][4] For this reason, Schönbein is generally credited with the discovery of ozone.[2][5] The formula for ozone, O3, was not determined until 1865 by Jacques-Louis Soret[6] and confirmed by Schönbein in 1867.[3][7]

For much of the second half of the nineteenth century and well into the twentieth, ozone was considered a healthy component of the environment by naturalists and health-seekers. The City of Beaumont in California had as its official slogan "Beaumont: Zone of Ozone," as evidenced on postcards and Chamber of Commerce letterhead.[8] Naturalists working outdoors often considered the higher elevations beneficial because of their ozone content. "There is quite a different atmosphere [at higher elevation] with enough ozone to sustain the necessary energy [to work]," wrote naturalist Henry Henshaw, working in Hawaii.[9] Seaside air was considered to be healthy because of its "ozone" content but the smell giving rise to this belief is in reality that of rotting seaweed.[10]

Physical properties

Ozone is colourless or slightly bluish gas (blue when liquified), slightly soluble in water and much more soluble in inert non-polar solvents such as carbon tetrachloride or fluorocarbons, where it forms a blue solution. At 161 K (−112 °C; −170 °F), it condenses to form a dark blue liquid. It is dangerous to allow this liquid to warm to its boiling point, because both concentrated gaseous ozone and liquid ozone can detonate. At temperatures below 80 K (−193.2 °C; −315.7 °F), it forms a violet-black solid.[11]Most people can detect about 0.01 μmol/mol of ozone in air where it has a very specific sharp odor somewhat resembling chlorine bleach. Exposure of 0.1 to 1 μmol/mol produces headaches, burning eyes and irritation to the respiratory passages.[12] Even low concentrations of ozone in air are very destructive to organic materials such as latex, plastics and animal lung tissue.

Ozone is diamagnetic, which means that its electrons are all paired. In contrast, O2 is paramagnetic, containing two unpaired electrons.

Structure

According to experimental evidence from microwave spectroscopy, ozone is a bent molecule, with C2v symmetry (similar to the water molecule). The O – O distances are 127.2 pm (1.272 Å). The O – O – O angle is 116.78°.[13] The central atom is sp² hybridized with one lone pair. Ozone is a polar molecule with a dipole moment of 0.53 D.[14] The bonding can be expressed as a resonance hybrid with a single bond on one side and double bond on the other producing an overall bond order of 1.5 for each side.

Reactions

Ozone is a powerful oxidizing agent, far stronger than O2. It is also unstable at high concentrations, decaying to ordinary diatomic oxygen. It has a varying half-life length, depending upon atmospheric conditions (temperature, humidity, and air movement). In a sealed chamber with a fan that moves the gas, ozone has a half-life of approximately a day at room temperature.[15] Some unverified claims imply that ozone can have a half life as short as a half an hour under atmospheric conditions.[16]- 2 O

3 → 3 O

2

With metals

Ozone will oxidize most metals (except gold, platinum, and iridium) to oxides of the metals in their highest oxidation state. For example:- 2 Cu+ + 2 H

3O+ + O

3 → 2 Cu2+ + 3 H

2O + O

2

With nitrogen and carbon compounds

Ozone also oxidizes nitric oxide to nitrogen dioxide:- NO + O

3 → NO

2 + O

2

2 can be further oxidized:

- NO

2 + O

3 → NO3 + O

2

3 formed can react with NO

2 to form N

2O

5.

Solid nitronium perchlorate can be made from NO2, ClO2, and O

3 gases:

- 2 NO

2 + 2 ClO2 + 2 O

3 → 2 NO2ClO4 + O

2

- 2 NH

3 + 4 O

3 → NH

4NO

3 + 4 O

2 + H

2O

- C + 2 O3 → CO2 + 2 O2

With sulfur compounds

Ozone oxidizes sulfides to sulfates. For example, lead(II) sulfide is oxidised to lead(II) sulfate:- PbS + 4 O3 → PbSO4 + 4 O2

- S + H2O + O3 → H2SO4

- 3 SO2 + 3 H2O + O3 → 3 H2SO4

- H2S + O3 → SO2 + H2O

- H2S + O3 → S + O2 + H2O

- 3 H2S + 4 O3 → 3 H2SO4

With alkenes and alkynes

Alkenes can be oxidatively cloven by ozone, in a process called ozonolysis, giving alcohols, aldehydes, ketones, and carboxylic acids, depending on the second step of the workup.

Usually ozonolysis is carried out in a solution of dichloromethane, at a temperature of −78oC. After a sequence of cleavage and rearrangement, an organic ozonide is formed. With reductive workup (e.g. zinc in acetic acid or dimethyl sulfide), ketones and aldehydes will be formed, with oxidative workup (e.g. aqueous or alcoholic hydrogen peroxide), carboxylic acids will be formed.[18]

Other substrates

All three atoms of ozone may also react, as in the reaction of tin(II) chloride with hydrochloric acid and ozone:- 3 SnCl2 + 6 HCl + O

3 → 3 SnCl4 + 3 H2O

- I2 + 6 HClO4 + O3 → 2 I(ClO4)3 + 3 H2O

Combustion

Ozone can be used for combustion reactions and combustible gases; ozone provides higher temperatures than burning in dioxygen (O2). The following is a reaction for the combustion of carbon subnitride which can also cause higher temperatures:- 3 C

4N

2 + 4 O

3 → 12 CO + 3 N

2

- H + O

3 → HO2 + O - 2 HO2 → H

2O

4

Reduction to ozonides

Reduction of ozone gives the ozonide anion, O−3. Derivatives of this anion are explosive and must be stored at cryogenic temperatures. Ozonides for all the alkali metals are known. KO3, RbO3, and CsO3 can be prepared from their respective superoxides:

- KO2 + O3 → KO3 + O2

- 2 KOH + 5 O3 → 2 KO3 + 5 O2 + H2O

- CsO3 + Na+ → Cs+ + NaO3

- 3 Ca + 10 NH3 + 6 O

3 → Ca·6NH3 + Ca(OH)2 + Ca(NO3)2 + 2 NH4O3 + 2 O2 + H2

Applications

Ozone can be used to remove manganese from water, forming a precipitate which can be filtered:- 2 Mn2+ + 2 O

3 + 4 H2O → 2 MnO(OH)2 (s) + 2 O2 + 4 H+

- CN− + O3 → CNO− + O2

- (NH2)2CO + O3 → N2 + CO2 + 2 H2O

Ozone in Earth's atmosphere

The standard way to express total ozone levels (the amount of ozone in a vertical column) in the atmosphere is by using Dobson units. Point measurements are reported as mole fractions in nmol/mol (parts per billion, ppb) or as concentrations in μg/m3. The study of ozone concentration in the atmosphere started in the 1920s.[23]

Ozone layer

Location and production

The highest levels of ozone in the atmosphere are in the stratosphere, in a region also known as the ozone layer between about 10 km and 50 km above the surface (or between about 6 and 31 miles). However, even in this "layer" the ozone concentrations are only two to eight parts per million, so most of the oxygen there remains of the dioxygen type.Ozone in the stratosphere is mostly produced from short-wave ultraviolet rays (in the UVC band) but it can be also produced from x-rays reacting with oxygen:

- O

2 + photon (radiation λ < 240 nm) → 2 O

- O + O

2 + M → O

3 + M

- α + β− + O

2 → He + O

3

- O

3 + O → 2 O

2

Importance to surface-dwelling life on Earth

Levels of ozone at various altitudes and blocking of different bands of ultraviolet radiation. Essentially all UVC (100–280 nm) is blocked by dioxygen (at 100–200 nm) or by ozone (at 200–280 nm) in the atmosphere. The shorter portion of this band and even more energetic UV causes the formation of the ozone layer, when single oxygen atoms produced by UV photolysis of dioxygen (below 240 nm) react with more dioxygen. The ozone layer itself then blocks most, but not quite all, sunburn-producing UVB (280–315 nm). The band of UV closest to visible light, UVA (315–400 nm), is hardly affected by ozone, and most of it reaches the ground.

Ozone in the ozone layer filters out sunlight wavelengths from about 200 nm UV rays to 315 nm, with ozone peak absorption at about 250 nm.[24] This ozone UV absorption is important to life, since it extends the absorption of UV by ordinary oxygen and nitrogen in air (which absorb all wavelengths < 200 nm) through the lower UV-C (200–280 nm) and the entire UV-B band (280–315 nm). The small unabsorbed part that remains of UV-B after passage through ozone causes sunburn in humans, and direct DNA damage in living tissues in both plants and animals. Ozone's effect on mid-range UV-B rays is illustrated by its effect on UV-B at 290 nm, which has a radiation intensity 350 million times as powerful at the top of the atmosphere as at the surface. Nevertheless, enough of UV-B radiation at similar frequency reaches the ground to cause some sunburn, and these same wavelengths are also among those responsible for the production of vitamin D in humans.

The ozone layer has little effect on the longer UV wavelengths called UV-A (315–400 nm), but this radiation does not cause sunburn or direct DNA damage, and while it probably does cause long-term skin damage in certain humans, it is not as dangerous to plants and to the health of surface-dwelling organisms on Earth in general (see ultraviolet for more information on near ultraviolet).

Low level ozone

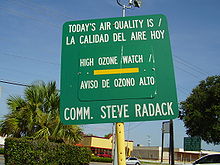

Low level ozone (or tropospheric ozone) is an atmospheric pollutant.[25] It is not emitted directly by car engines or by industrial operations, but formed by the reaction of sunlight on air containing hydrocarbons and nitrogen oxides that react to form ozone directly at the source of the pollution or many kilometers down wind.Ozone reacts directly with some hydrocarbons such as aldehydes and thus begins their removal from the air, but the products are themselves key components of smog. Ozone photolysis by UV light leads to production of the hydroxyl radical HO• and this plays a part in the removal of hydrocarbons from the air, but is also the first step in the creation of components of smog such as peroxyacyl nitrates, which can be powerful eye irritants. The atmospheric lifetime of tropospheric ozone is about 22 days; its main removal mechanisms are being deposited to the ground, the above-mentioned reaction giving HO•, and by reactions with OH and the peroxy radical HO2•.[26]

There is evidence of significant reduction in agricultural yields because of increased ground-level ozone and pollution which interferes with photosynthesis and stunts overall growth of some plant species.[27][28] The United States Environmental Protection Agency is proposing a secondary regulation to reduce crop damage, in addition to the primary regulation designed for the protection of human health.

Certain examples of cities with elevated ozone readings are Houston, Texas, and Mexico City, Mexico. Houston has a reading of around 41 nmol/mol, while Mexico City is far more hazardous, with a reading of about 125 nmol/mol.[28]

Ozone cracking

Ozone gas attacks any polymer possessing olefinic or double bonds within its chain structure, such as natural rubber, nitrile rubber, and styrene-butadiene rubber. Products made using these polymers are especially susceptible to attack, which causes cracks to grow longer and deeper with time, the rate of crack growth depending on the load carried by the rubber component and the concentration of ozone in the atmosphere. Such materials can be protected by adding antiozonants, such as waxes, which bond to the surface to create a protective film or blend with the material and provide long term protection. Ozone cracking used to be a serious problem in car tires for example, but the problem is now seen only in very old tires.[clarification needed][citation needed] On the other hand, many critical products like gaskets and O-rings may be attacked by ozone produced within compressed air systems. Fuel lines made of reinforced rubber are also susceptible to attack, especially within the engine compartment, where some ozone is produced by electrical components. Storing rubber products in close proximity to a DC electric motor can accelerate ozone cracking. The commutator of the motor generates sparks which in turn produce ozone.

Ozone as a greenhouse gas

Although ozone was present at ground level before the Industrial Revolution, peak concentrations are now far higher than the pre-industrial levels, and even background concentrations well away from sources of pollution are substantially higher.[29][30] Ozone acts as a greenhouse gas, absorbing some of the infrared energy emitted by the earth. Quantifying the greenhouse gas potency of ozone is difficult because it is not present in uniform concentrations across the globe. However, the most widely accepted scientific assessments relating to climate change (e.g. the Intergovernmental Panel on Climate Change Third Assessment Report)[31] suggest that the radiative forcing of tropospheric ozone is about 25% that of carbon dioxide.The annual global warming potential of tropospheric ozone is between 918–1022 tons carbon dioxide equivalent/tons tropospheric ozone. This means on a per-molecule basis, ozone in the troposphere has a radiative forcing effect roughly 1,000 times as strong as carbon dioxide. However, tropospheric ozone is a short-lived greenhouse gas, which decays in the atmosphere much more quickly than carbon dioxide. This means that over a 20 year span, the global warming potential of tropospheric ozone is much less, roughly 62 to 69 tons carbon dioxide equivalent / ton tropospheric ozone.[32]

Because of its short-lived nature, tropospheric ozone does not have strong global effects, but has very strong radiative forcing effects on regional scales. In fact, there are regions of the world where tropospheric ozone has a radiative forcing up to 150% of carbon dioxide.[33]

Health effects

Ozone air pollution

Ozone precursors are a group of pollutants, predominantly those emitted during the combustion of fossil fuels. Ground-level ozone pollution (tropospheric ozone) is created near the Earth's surface by the action of daylight UV rays on these precursors. The ozone at ground level is primarily from fossil fuel precursors, but methane is a natural precursor, and the very low natural background level of ozone at ground level is considered safe. This section examines health impacts of fossil fuel burning, which raises ground level ozone far above background levels.

There is a great deal of evidence to show that ground level ozone can harm lung function and irritate the respiratory system.[25][35] Exposure to ozone and the pollutants that produce it is linked to premature death, asthma, bronchitis, heart attack, and other cardiopulmonary problems.[36][37]

Long-term exposure to ozone has been shown to increase risk of death from respiratory illness. A study of 450,000 people living in United States cities showed a significant correlation between ozone levels and respiratory illness over the 18-year follow-up period. The study revealed that people living in cities with high ozone levels such as Houston or Los Angeles had an over 30% increased risk of dying from lung disease.[38][39]

Air quality guidelines such as those from the World Health Organization, the United States Environmental Protection Agency (EPA) and the European Union are based on detailed studies designed to identify the levels that can cause measurable ill health effects.

According to scientists with the US EPA, susceptible people can be adversely affected by ozone levels as low as 40 nmol/mol.[37][40][41] In the EU, the current target value for ozone concentrations is 120 µg/m³ which is about 60 nmol/mol. This target applies to all member states in accordance with Directive 2008/50/EC.[42] Ozone concentration is measured as a maximum daily mean of 8 hour averages and the target should not be exceeded on more than 25 calendar days per year, starting from January 2010. Whilst the directive requires in the future a strict compliance with 120 µg/m³ limit (i.e. mean ozone concentration not to be exceeded on any day of the year), there is no date set for this requirement and this is treated as a long-term objective. [43]

In the USA, the Clean Air Act directs the EPA to set National Ambient Air Quality Standards for several pollutants, including ground-level ozone, and counties out of compliance with these standards are required to take steps to reduce their levels. In May 2008, under a court order, the EPA lowered its ozone standard from 80 nmol/mol to 75 nmol/mol. The move proved controversial, since the Agency's own scientists and advisory board had recommended lowering the standard to 60 nmol/mol.[37] Many public health and environmental groups also supported the 60 nmol/mol standard,[44] and the World Health Organization recommends 51 nmol/mol.

On January 7, 2010, the U.S. Environmental Protection Agency (EPA) announced proposed revisions to the National Ambient Air Quality Standard (NAAQS) for the pollutant ozone, the principal component of smog:

- ... EPA proposes that the level of the 8-hour primary standard, which was set at 0.075 μmol/mol in the 2008 final rule, should instead be set at a lower level within the range of 0.060 to 0.070 μmol/mol, to provide increased protection for children and other ‘‘at risk’’ populations against an array of O

3 - related adverse health effects that range from decreased lung function and increased respiratory symptoms to serious indicators of respiratory morbidity including emergency department visits and hospital admissions for respiratory causes, and possibly cardiovascular-related morbidity as well as total non- accidental and cardiopulmonary mortality....[45]

Ozone can also be present in indoor air pollution, partly as a result of electronic equipment such as photocopiers. A connection has also been known to exist between the increased pollen, fungal spores, and ozone caused by thunderstorms and hospital admissions of asthma sufferers.[47]

In the Victorian era, one British folk myth held that the smell of the sea was caused by ozone. In fact, the characteristic "smell of the sea" is caused by dimethyl sulfide, a chemical generated by phytoplankton. Victorian British folk considered the resulting smell "bracing," but in high concentrations, dimethyl sulfide is actually toxic.[48]

Heat waves

Ozone production rises during heat waves, because plants absorb less ozone. It is estimated that curtailed ozone absorption by plants is responsible for the loss of 460 lives in the UK in the hot summer of 2006.[49] A similar investigation to assess the joint effects of ozone and heat during the European heat waves in 2003, concluded that these appear to be additive.[50]Physiology

Ozone, along with reactive forms of oxygen such as superoxide, singlet oxygen, hydrogen peroxide, and hypochlorite ions, is naturally produced by white blood cells and other biological systems (such as the roots of marigolds) as a means of destroying foreign bodies. Ozone reacts directly with organic double bonds. Also, when ozone breaks down to dioxygen it gives rise to oxygen free radicals, which are highly reactive and capable of damaging many organic molecules. Moreover, it is believed that the powerful oxidizing properties of ozone may be a contributing factor of inflammation. The cause-and-effect relationship of how the ozone is created in the body and what it does is still under consideration and still subject to various interpretations, since other body chemical processes can trigger some of the same reactions. A team headed by Dr. Paul Wentworth Jr. of the Department of Chemistry at the Scripps Research Institute has shown evidence linking the antibody-catalyzed water-oxidation pathway of the human immune response to the production of ozone. In this system, ozone is produced by antibody-catalyzed production of trioxidane from water and neutrophil-produced singlet oxygen.[51]When inhaled, ozone reacts with compounds lining the lungs to form specific, cholesterol-derived metabolites that are thought to facilitate the build-up and pathogenesis of atherosclerotic plaques (a form of heart disease). These metabolites have been confirmed as naturally occurring in human atherosclerotic arteries and are categorized into a class of secosterols termed atheronals, generated by ozonolysis of cholesterol's double bond to form a 5,6 secosterol[52] as well as a secondary condensation product via aldolization.[53]

Ozone has been implicated to have an adverse effect on plant growth: "... ozone reduced total chlorophylls, carotenoid and carbohydrate concentration, and increased 1-aminocyclopropane-1-carboxylic acid (ACC) content and ethylene production. In treated plants, the ascorbate leaf pool was decreased, while lipid peroxidation and solute leakage were significantly higher than in ozone-free controls. The data indicated that ozone triggered protective mechanisms against oxidative stress in citrus."[54]

Safety regulations

Due to the strongly oxidizing properties of ozone, ozone is a primary irritant, affecting especially the eyes and respiratory systems and can be hazardous at even low concentrations. The Canadian Center for Occupation Safety and Health reports that:"Even very low concentrations of ozone can be harmful to the upper respiratory tract and the lungs. The severity of injury depends on both by the concentration of ozone and the duration of exposure. Severe and permanent lung injury or death could result from even a very short-term exposure to relatively low concentrations."[55]To protect workers potentially exposed to ozone, U.S. Occupational Safety and Health Administration has established a permissible exposure limit (PEL) of 0.1 μmol/mol (29 CFR 1910.1000 table Z-1), calculated as an 8 hour time weighted average. Higher concentrations are especially hazardous and NIOSH has established an Immediately Dangerous to Life and Health Limit (IDLH) of 5 μmol/mol.[56] Work environments where ozone is used or where it is likely to be produced should have adequate ventilation and it is prudent to have a monitor for ozone that will alarm if the concentration exceeds the OSHA PEL. Continuous monitors for ozone are available from several suppliers.

Elevated ozone exposure can occur on passenger aircraft, with levels depending on altitude and atmospheric turbulence.[57] United States Federal Aviation Authority regulations set a limit of 250 nmol/mol with a maximum four-hour average of 100 nmol/mol.[58] Some planes are equipped with ozone converters in the ventilation system to reduce passenger exposure.[57]

Production

Ozone generators are used to produce ozone for cleaning air or remove smoke odors[59] in unoccupied rooms. These ozone generators can produce over 3 g of ozone per hour. Ozone often forms in nature under conditions where O2 will not react.[12] Ozone used in industry is measured in μmol/mol (ppm, parts per million), nmol/mol (ppb, parts per billion), μg/m3, mg/h (milligrams per hour) or weight percent. The regime of applied concentrations ranges from 1 to 5% in air and from 6 to 14% in oxygen for older generation methods. New electrolytic methods can achieve up 20 to 30% dissolved ozone concentrations in output water.

Temperature and humidity plays a large role in how much ozone is being produced using traditional generation methods such as corona discharge and ultraviolet light. Old generation methods will produce less than 50% its nominal capacity if operated with humid ambient air than when it operates in very dry air. New generators using electrolytic methods can achieve higher purity and dissolution through using water molecules as the source of ozone production.

Corona discharge method

This is the most common type of ozone generator for most industrial and personal uses. While variations of the "hot spark" coronal discharge method of ozone production exist, including medical grade and industrial grade ozone generators, these units usually work by means of a corona discharge tube.[60] They are typically cost-effective and do not require an oxygen source other than the ambient air to produce ozone concentrations of 3–6%. Fluctuations in ambient air, due to weather or other environmental conditions, cause variability in ozone production. However, they also produce nitrogen oxides as a by-product. Use of an air dryer can reduce or eliminate nitric acid formation by removing water vapor and increase ozone production. Use of an oxygen concentrator can further increase the ozone production and further reduce the risk of nitric acid formation by removing not only the water vapor, but also the bulk of the nitrogen.Ultraviolet light

UV ozone generators, or vacuum-ultraviolet (VUV) ozone generators, employ a light source that generates a narrow-band ultraviolet light, a subset of that produced by the Sun. The Sun's UV sustains the ozone layer in the stratosphere of Earth.[61]While standard UV ozone generators tend to be less expensive,[clarification needed] they usually produce ozone with a concentration of about 0.5% or lower. Another disadvantage of this method is that it requires the air (oxygen) to be exposed to the UV source for a longer amount of time, and any gas that is not exposed to the UV source will not be treated. This makes UV generators impractical for use in situations that deal with rapidly moving air or water streams (in-duct air sterilization, for example). Production of ozone is one of the potential dangers of ultraviolet germicidal irradiation. VUV ozone generators are used in swimming pool and spa applications ranging to millions of gallons of water. VUV ozone generators, unlike corona discharge generators, do not produce harmful nitrogen by-products and also unlike corona discharge systems, VUV ozone generators work extremely well in humid air environments. There is also not normally a need for expensive off-gas mechanisms, and no need for air driers or oxygen concentrators which require extra costs and maintenance.

Cold plasma

In the cold plasma method, pure oxygen gas is exposed to a plasma created by dielectric barrier discharge. The diatomic oxygen is split into single atoms, which then recombine in triplets to form ozone.Cold plasma machines utilize pure oxygen as the input source and produce a maximum concentration of about 5% ozone. They produce far greater quantities of ozone in a given space of time compared to ultraviolet production. However, because cold plasma ozone generators are very expensive, they are found less frequently than the previous two types.

The discharges manifest as filamentary transfer of electrons (micro discharges) in a gap between two electrodes. In order to evenly distribute the micro discharges, a dielectric insulator must be used to separate the metallic electrodes and to prevent arcing.

Some cold plasma units also have the capability of producing short-lived allotropes of oxygen which include O4, O5, O6, O7, etc. These species are even more reactive than ordinary O

3.[citation needed]

Electrolytic

Electrolytic ozone generation (EOG) splits water molecules into H2, O2, and O3. In most EOG methods, the hydrogen gas will be removed to leave oxygen and ozone as the only reaction products. Therefore, EOG can achieve higher dissolution in water without other competing gases found in corona discharge method, such as nitrogen gases present in ambient air. This method of generation can achieve concentrations of 20–30% and is independent of air quality because water is used as the source material. Production of ozone electrolytically is typically unfavorable because of the high overpotential required to produce ozone as compared to oxygen. This is why ozone is not produced during typical water electrolysis. However, it is possible to increase the overpotential of oxygen by careful catalyst selection such that ozone is preferentially produced under electrolysis. Catalysts typically chosen for this approach are lead dioxide[62] or boron-doped diamond.[63]Special considerations

Ozone cannot be stored and transported like other industrial gases (because it quickly decays into diatomic oxygen) and must therefore be produced on site. Available ozone generators vary in the arrangement and design of the high-voltage electrodes. At production capacities higher than 20 kg per hour, a gas/water tube heat-exchanger may be utilized as ground electrode and assembled with tubular high-voltage electrodes on the gas-side. The regime of typical gas pressures is around 2 bars (200 kPa) absolute in oxygen and 3 bars (300 kPa) absolute in air. Several megawatts of electrical power may be installed in large facilities, applied as one phase AC current at 50 to 8000 Hz and peak voltages between 3,000 and 20,000 volts. Applied voltage is usually inversely related to the applied frequency.The dominating parameter influencing ozone generation efficiency is the gas temperature, which is controlled by cooling water temperature and/or gas velocity. The cooler the water, the better the ozone synthesis. The lower the gas velocity, the higher the concentration (but the lower the net ozone produced). At typical industrial conditions, almost 90% of the effective power is dissipated as heat and needs to be removed by a sufficient cooling water flow.

Because of the high reactivity of ozone, only a few materials may be used like stainless steel (quality 316L), titanium, aluminium (as long as no moisture is present), glass, polytetrafluorethylene, or polyvinylidene fluoride. Viton may be used with the restriction of constant mechanical forces and absence of humidity (humidity limitations apply depending on the formulation). Hypalon may be used with the restriction that no water come in contact with it, except for normal atmospheric levels. Embrittlement or shrinkage is the common mode of failure of elastomers with exposure to ozone. Ozone cracking is the common mode of failure of elastomer seals like O-rings.

Silicone rubbers are usually adequate for use as gaskets in ozone concentrations below 1 wt%, such as in equipment for accelerated aging of rubber samples.

Incidental production

Ozone may be formed from O2 by electrical discharges and by action of high energy electromagnetic radiation. Unsuppressed arcing breaks down the chemical bonds of the atmospheric oxygen surrounding the contacts [O

2 → 2O]. Free radicals of oxygen in and around the arc recombine to create ozone [O

3].[64] Certain electrical equipment generate significant levels of ozone. This is especially true of devices using high voltages, such as ionic air purifiers, laser printers, photocopiers, tasers and arc welders. Electric motors using brushes can generate ozone from repeated sparking inside the unit. Large motors that use brushes, such as those used by elevators or hydraulic pumps, will generate more ozone than smaller motors. Ozone is similarly formed in the Catatumbo lightning storms phenomenon on the Catatumbo River in Venezuela, which helps to replenish ozone in the upper troposphere. It is the world's largest single natural generator of ozone, lending calls for it to be designated a UNESCO World Heritage Site.[65]

Laboratory production

In the laboratory, ozone can be produced by electrolysis using a 9 volt battery, a pencil graphite rod cathode, a platinum wire anode and a 3 molar sulfuric acid electrolyte.[66] The half cell reactions taking place are:- 3 H2O → O3 + 6 H+ + 6 e− (ΔEo = −1.53 V)

- 6 H+ + 6 e− → 3 H2 (ΔEo = 0 V)

- 2 H2O → O2 + 4 H+ + 4 e− (ΔEo = −1.23 V)

It can also be "prepared" by high voltage arc. This can be done with an apparatus consisting of two concentric glass tubes sealed together at the top, with in and out spigots at the top and bottom of the outer tube. The inner core should have a length of metal foil inserted into it connected to one side of the power source. The other side of the power source should be connected to another piece of foil wrapped around the outer tube. Dry O

2 should be run through the tube in one spigot. As the O

2 is run through one spigot into the apparatus and high voltage is applied to the foil leads, electricity will discharge between the dry dioxygen in the middle and form O

3 and O

2 out the other spigot. The reaction can be summarized as follows:[12]

- 3 O

2 — electricity → 2 O

3

Applications

Industry

The largest use of ozone is in the preparation of pharmaceuticals, synthetic lubricants, and many other commercially useful organic compounds, where it is used to sever carbon-carbon bonds.[12] It can also be used for bleaching substances and for killing microorganisms in air and water sources.[67] Many municipal drinking water systems kill bacteria with ozone instead of the more common chlorine.[68] Ozone has a very high oxidation potential.[69] Ozone does not form organochlorine compounds, nor does it remain in the water after treatment. Ozone can form the suspected carcinogen bromate in source water with high bromide concentrations. The Safe Drinking Water Act mandates that these systems introduce an amount of chlorine to maintain a minimum of 0.2 μmol/mol residual free chlorine in the pipes, based on results of regular testing. Where electrical power is abundant, ozone is a cost-effective method of treating water, since it is produced on demand and does not require transportation and storage of hazardous chemicals. Once it has decayed, it leaves no taste or odor in drinking water.Although low levels of ozone have been advertised to be of some disinfectant use in residential homes, the concentration of ozone in dry air required to have a rapid, substantial effect on airborne pathogens exceeds safe levels recommended by the U.S. Occupational Safety and Health Administration and Environmental Protection Agency. Humidity control can vastly improve both the killing power of the ozone and the rate at which it decays back to oxygen (more humidity allows more effectiveness). Spore forms of most pathogens are very tolerant of atmospheric ozone in concentrations where asthma patients start to have issues.

Industrially, ozone is used to:

- Disinfect laundry in hospitals, food factories, care homes etc.;[70]

- Disinfect water in place of chlorine[12]

- Deodorize air and objects, such as after a fire. This process is extensively used in fabric restoration

- Kill bacteria on food or on contact surfaces;[71]

- Sanitize swimming pools and spas

- Kill insects in stored grain[72]

- Scrub yeast and mold spores from the air in food processing plants;

- Wash fresh fruits and vegetables to kill yeast, mold and bacteria;[71]

- Chemically attack contaminants in water (iron, arsenic, hydrogen sulfide, nitrites, and complex organics lumped together as "colour");

- Provide an aid to flocculation (agglomeration of molecules, which aids in filtration, where the iron and arsenic are removed);

- Manufacture chemical compounds via chemical synthesis[73]

- Clean and bleach fabrics (the former use is utilized in fabric restoration; the latter use is patented);[citation needed]

- Assist in processing plastics to allow adhesion of inks;

- Age rubber samples to determine the useful life of a batch of rubber;

- Eradicate water borne parasites such as Giardia lamblia and Cryptosporidium in surface water treatment plants.

Many hospitals around the world use large ozone generators to decontaminate operating rooms between surgeries. The rooms are cleaned and then sealed airtight before being filled with ozone which effectively kills or neutralizes all remaining bacteria.[74]

Ozone is used as an alternative to chlorine or chlorine dioxide in the bleaching of wood pulp.[75] It is often used in conjunction with oxygen and hydrogen peroxide to eliminate the need for chlorine-containing compounds in the manufacture of high-quality, white paper.[76]

Ozone can be used to detoxify cyanide wastes (for example from gold and silver mining) by oxidizing cyanide to cyanate and eventually to carbon dioxide.[77]

Consumers

Devices generating high levels of ozone, some of which use ionization, are used to sanitize and deodorize uninhabited buildings, rooms, ductwork, woodsheds, and boats and other vehicles.One company has been successfully selling a CPAP sanitizer for the CPAP gear used by sleep apnea patients. This sanitizer works by pumping high concentration levels of electrically-generated ozone into the unit's humidification water tank (with or without water in it) and out through the hose into the mask, which is enclosed and sealed in an ozone-capturing receptacle (that also contains the ozone generator and pump that pushes it into the water tank), which completes a closed-loop system. This closed-loop system prevents the high levels of ozone from escaping while effectively sanitizing the CPAP equipment, as the CPAP equipment is prone to developing bacterial infestations and harboring viruses and other pathogens because of the constant moisture generated by the CPAP system's humidifier. The sanitizing unit has a two-hour cycle, it pumps the ozone for 6–10 minutes (user-designated) and then resting for two hours while maintaining the sealed closed-circuit loop as the ozone decays back into oxygen and finishes the sanitizing effect.[78]

In the U.S., air purifiers emitting low levels of ozone have been sold. This kind of air purifier is sometimes claimed to imitate nature's way of purifying the air without filters and to sanitize both it and household surfaces. The United States Environmental Protection Agency (EPA) has declared that there is "evidence to show that at concentrations that do not exceed public health standards, ozone is not effective at removing many odor-causing chemicals" or "viruses, bacteria, mold, or other biological pollutants." Furthermore, its report states that "results of some controlled studies show that concentrations of ozone considerably higher than these [human safety] standards are possible even when a user follows the manufacturer’s operating instructions."[79] A couple kept repeating health claims for the generator they sold, without supporting scientific studies. In 1998 a federal jury convicted them, among others things, of illegally distributing an ozone generator and of wire fraud.[80]

Ozonated water is used to launder clothes and to sanitize food, drinking water, and surfaces in the home. According to the U.S. Food and Drug Administration (FDA), it is "amending the food additive regulations to provide for the safe use of ozone in gaseous and aqueous phases as an antimicrobial agent on food, including meat and poultry." Studies at California Polytechnic University demonstrated that 0.3 μmol/mol levels of ozone dissolved in filtered tapwater can produce a reduction of more than 99.99% in such food-borne microorganisms as salmonella, E. coli 0157:H7 and Campylobacter. This quantity is 20,000 times the WHO-recommended limits stated above.[71][81] Ozone can be used to remove pesticide residues from fruits and vegetables.[82][83]

Ozone is used in homes and hot tubs to kill bacteria in the water and to reduce the amount of chlorine or bromine required by reactivating them to their free state. Since ozone does not remain in the water long enough, ozone by itself is ineffective at preventing cross-contamination among bathers and must be used in conjunction with halogens. Gaseous ozone created by ultraviolet light or by corona discharge is injected into the water.[84]

Ozone is also widely used in treatment of water in aquariums and fish ponds. Its use can minimize bacterial growth, control parasites, eliminate transmission of some diseases, and reduce or eliminate "yellowing" of the water. Ozone must not come in contact with fish's gill structures. Natural salt water (with life forms) provides enough "instantaneous demand" that controlled amounts of ozone activate bromide ion to hypobromous acid, and the ozone entirely decays in a few seconds to minutes. If oxygen fed ozone is used, the water will be higher in dissolved oxygen, fish's gill structures will atrophy and they will become dependent on higher dissolved oxygen levels.

Aquaculture

Ozonation - a process of infusing water with ozone - can be used in aquaculture to facilitate organic breakdown. Ozone is also added to recirculating systems to reduce nitrite levels[85] through conversion into nitrate. If nitrite levels in the water are high, nitrites will also accumulate in the blood and tissues of fish, where it interferes with oxygen transport (it causes oxidation of the heme-group of haemoglobin from ferrous (Fe2+) to ferric (Fe3+), making haemoglobin unable to bind O2).[86]

Despite these apparent positive effects, ozone use in recirculation systems has been linked to reducing the level of bioavailable iodine in salt water systems, resulting in iodine deficiency symptoms such as goitre and decreased growth in Senegalese sole (Solea senegalensis) larvae.[87]

Ozonate seawater is used for surface disinfection of haddock and Atlantic halibut eggs against nodavirus. Nodavirus is a lethal and vertically transmitted virus which causes severe mortality in fish. Haddock eggs should not be treated with high ozone level as eggs so treated did not hatch and died after 3–4 days.[88]

Agriculture

Ozone application on freshly cut pineapple and banana shows increase in flavonoids and total phenol contents when exposure is up to 20 minutes. Decrease in ascorbic acid (one form of vitamin C) content is observed but the positive effect on total phenol content and flavonoids can overcome the negative effect.[89] Tomatoes upon treatment with ozone shows an increase in β-carotene, lutein and lycopene.[90] However, ozone application on strawberries in pre-harvest period shows decrease in ascorbic acid content.[91]Ozone facilitates the extraction of some heavy metals from soil using EDTA. EDTA forms strong, water-soluble coordination compounds with some heavy metals (Pb, Zn) thereby making it possible to dissolve them out from contaminated soil. If contaminated soil is pre-treated with ozone, the extraction efficacy of Pb, Am and Pu increases by 11.0–28.9%,[92] 43.5%[93] and 50.7%[93] respectively.