Nanoparticles are particles between 1 and 100 nanometres (nm) in size with a surrounding interfacial layer. The interfacial layer is an integral part of nanoscale

matter, fundamentally affecting all of its properties. The interfacial

layer typically consists of ions, inorganic and organic molecules.

Organic molecules coating inorganic nanoparticles are known as

stabilizers, capping and surface ligands, or passivating agents. In nanotechnology, a particle is defined as a small object that behaves as a whole unit with respect to its transport and properties. Particles are further classified according to diameter.

Definition

IUPAC definition

Particle of any shape with dimensions in the 1 × 10−9 and 1 × 10−7 m range.

Note 1: Modified from definitions of nanoparticle and nanogel.

Note 2: The basis of the 100-nm limit is the fact that novel properties that

differentiate particles from the bulk material typically develop at a critical

length scale of under 100 nm.

Note 3: Because other phenomena (transparency or turbidity, ultrafiltration,

stable dispersion, etc.) that extend the upper limit are occasionally considered,

the use of the prefix nano is accepted for dimensions smaller than 500 nm,

provided reference to the definition is indicated.

Note 2: The basis of the 100-nm limit is the fact that novel properties that

differentiate particles from the bulk material typically develop at a critical

length scale of under 100 nm.

Note 3: Because other phenomena (transparency or turbidity, ultrafiltration,

stable dispersion, etc.) that extend the upper limit are occasionally considered,

the use of the prefix nano is accepted for dimensions smaller than 500 nm,

provided reference to the definition is indicated.

Note 4: Tubes and fibers with only two dimensions below 100 nm are also

nanoparticles.

nanoparticles.

The term "nanoparticle" is not usually applied to individual molecules; it usually refers to inorganic materials.

Ultrafine particles are the same as nanoparticles and between 1

and 100 nm in size, as opposed to fine particles are sized between 100

and 2,500 nm, and coarse particles cover a range between 2,500 and

10,000 nm. The reason for the synonymous definition of nanoparticles

and ultrafine particles is that, during the 1970s and 80s, when the

first thorough fundamental studies with "nanoparticles" were underway in

the USA (by Granqvist and Buhrman) and Japan, (within an ERATO Project) they were called "ultrafine particles" (UFP). However, during the 1990s before the National Nanotechnology Initiative

was launched in the USA, the new name, "nanoparticle," had become more

common (for example, see the same senior author's paper 20 years later

addressing the same issue, lognormal distribution of sizes).

Nanoparticles can exhibit size-related properties significantly

different from those of either fine particles or bulk materials.

Nanoclusters have at least one dimension between 1 and 10 nanometers and a narrow size distribution. Nanopowders are agglomerates of ultrafine particles, nanoparticles, or nanoclusters. Nanometer-sized single crystals, or single-domain ultrafine particles, are often referred to as nanocrystals.

According to ISO Technical Specification 80004,

a nanoparticle is defined as a nano-object with all three external

dimensions in the nanoscale, whose longest and shortest axes do not

differ significantly, with a significant difference typically being a

factor of at least 3.

The terms colloid

and nanoparticle are not interchangeable. A colloid is a mixture which

has solid particles dispersed in a liquid medium. The term applies only

if the particles are larger than atomic dimensions but small enough to

exhibit Brownian motion, with the critical size range (or particle diameter) typically ranging from nanometers (10−9 m) to micrometers (10−6 m).

Colloids can contain particles too large to be nanoparticles, and

nanoparticles can exist in non-colloidal form, for examples as a powder

or in a solid matrix.

History

Although nanoparticles are associated with modern science, they have a long history. Nanoparticles were used by artisans as far back as Rome in the fourth century in the famous Lycurgus cup made of dichroic glass as well as the ninth century in Mesopotamia for creating a glittering effect on the surface of pots. In modern times, pottery from the Middle Ages and Renaissance often retains a distinct gold- or copper-colored metallic glitter. This luster is caused by a metallic film that was applied to the transparent surface of a glazing. The luster can still be visible if the film has resisted atmospheric oxidation and other weathering.

The luster originates within the film itself, which contains

silver and copper nanoparticles dispersed homogeneously in the glassy

matrix of the ceramic glaze. These nanoparticles are created by the

artisans by adding copper and silver salts and oxides together with vinegar, ochre, and clay on the surface of previously-glazed pottery. The object is then placed into a kiln and heated to about 600 °C in a reducing atmosphere. In heat the glaze softens, causing the copper and silver ions

to migrate into the outer layers of the glaze. There the reducing

atmosphere reduced the ions back to metals, which then came together

forming the nanoparticles that give the color and optical effects.

Luster technique showed that ancient craftsmen had a sophisticated

empirical knowledge of materials. The technique originated in the Muslim world.

As Muslims were not allowed to use gold in artistic representations,

they sought a way to create a similar effect without using real gold.

The solution they found was using luster.

Michael Faraday

provided the first description, in scientific terms, of the optical

properties of nanometer-scale metals in his classic 1857 paper. In a

subsequent paper, the author (Turner) points out that: "It is well known

that when thin leaves of gold or silver are mounted upon glass and

heated to a temperature that is well below a red heat (~500 °C), a

remarkable change of properties takes place, whereby the continuity of

the metallic film is destroyed. The result is that white light is now

freely transmitted, reflection is correspondingly diminished, while the

electrical resistivity is enormously increased."

Properties

Silicon nanopowder

1 kg of particles of 1 mm3 has the same surface area as 1 mg of particles of 1 nm3

Nanoparticles are of great scientific interest as they are, in effect, a bridge between bulk materials and atomic or molecular

structures. A bulk material should have constant physical properties

regardless of its size, but at the nano-scale size-dependent properties

are often observed. Thus, the properties of materials change as their

size approaches the nanoscale and as the percentage of the surface in

relation to the percentage of the volume of a material becomes

significant. For bulk materials larger than one micrometer (or micron),

the percentage of the surface is insignificant in relation to the volume

in the bulk of the material. The interesting and sometimes

unexpected properties of nanoparticles are therefore largely due to the

large surface area of the material, which dominates the contributions

made by the small bulk of the material.

Nanoparticles often possess unexpected optical properties as they

are small enough to confine their electrons and produce quantum

effects. For example, gold

nanoparticles appear deep-red to black in solution. Nanoparticles of

yellow gold and grey silicon are red in color. Gold nanoparticles melt

at much lower temperatures (~300 °C for 2.5 nm size) than the gold slabs

(1064 °C);.

Absorption of solar radiation is much higher in materials composed of

nanoparticles than it is in thin films of continuous sheets of material.

In both solar PV and solar thermal applications, controlling the size,

shape, and material of the particles, it is possible to control solar

absorption.

Recently, the core (metal)-shell (dielectric) nanoparticle has

demonstrated a zero backward scattering with enhanced forward scattering

on Si substrate when surface plasmon is located in front of a solar

cell.

The core-shell nanoparticles can support simultaneously both electric

and magnetic resonances, demonstrating entirely new properties when

compared with bare metallic nanoparticles if the resonances are properly

engineered.

Other size-dependent property changes include quantum confinement in semiconductor particles, surface plasmon resonance in some metal particles and superparamagnetism in magnetic materials. What would appear ironic is that the changes in physical properties are not always desirable. Ferromagnetic materials

smaller than 10 nm can switch their magnetisation direction using room

temperature thermal energy, thus making them unsuitable for memory

storage.

Suspensions of nanoparticles are possible since the interaction of the particle surface with the solvent is strong enough to overcome density differences, which otherwise usually result in a material either sinking or floating in a liquid.

The high surface area to volume ratio of nanoparticles provides a tremendous driving force for diffusion, especially at elevated temperatures. Sintering

can take place at lower temperatures, over shorter time scales than for

larger particles. In theory, this does not affect the density of the

final product, though flow difficulties and the tendency of

nanoparticles to agglomerate complicates matters. Moreover,

nanoparticles have been found to impart some extra properties to various

day to day products. For example, the presence of titanium dioxide

nanoparticles imparts what we call the self-cleaning effect, and, the

size being nano-range, the particles cannot be observed. Zinc oxide

particles have been found to have superior UV blocking properties

compared to its bulk substitute. This is one of the reasons why it is

often used in the preparation of sunscreen lotions, is completely photostable, and toxic [DJS -- ??].

Clay nanoparticles when incorporated into polymer matrices

increase reinforcement, leading to stronger plastics, verifiable by a

higher glass transition temperature

and other mechanical property tests. These nanoparticles are hard, and

impart their properties to the polymer (plastic). Nanoparticles have

also been attached to textile fibers in order to create smart and

functional clothing.

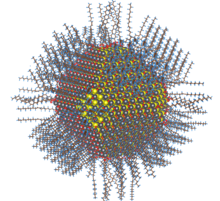

Metal, dielectric, and semiconductor nanoparticles have been formed, as well as hybrid structures (e.g., core–shell nanoparticles). Nanoparticles made of semiconducting material may also be labeled quantum dots if they are small enough (typically sub 10 nm) that quantization of electronic energy levels occurs. Such nanoscale particles are used in biomedical applications as drug carriers or imaging agents with work being done to try to understand the fluid dynamic properties (e.g. drag forces) in nanoscale applications. This has shown the relationship between the fluid forces on nanoparticles and the fluid Reynolds and Knudsen numbers.

Semiconductor nanoparticle (quantum dot) of lead sulfide with complete passivation by oleic acid, oleyl amine and hydroxyl ligands (size ~5nm)

Semi-solid and soft nanoparticles have been manufactured. A prototype nanoparticle of semi-solid nature is the liposome. Various types of liposome nanoparticles are currently used clinically as delivery systems for anticancer drugs and vaccines.

Nanoparticles with one half hydrophilic and the other half hydrophobic are termed Janus particles and are particularly effective for stabilizing emulsions. They can self-assemble at water/oil interfaces and act as solid surfactants.

Hydrogel nanoparticles made of N-isopropylacrylamide hydrogel core shell can be dyed with affinity baits, internally. These affinity baits allow the nanoparticles to isolate and remove undesirable proteins while enhancing the target analytes.

Variation in properties

The

chemical processing and synthesis of high-performance technological

components for the private, industrial, and military sectors requires

the use of high-purity ceramics (oxide ceramics, such as aluminium oxide or copper(II) oxide), polymers, glass-ceramics, and composite materials, as metal carbides (SiC), nitrides (Aluminum nitrides, Silicon nitride), metals (Al, Cu), non-metals (graphite, carbon nanotubes) and layered (Al + Aluminium carbonate,

Cu + C). In condensed bodies formed from fine powders, the irregular

particle sizes and shapes in a typical powder often lead to non-uniform

packing morphologies that result in packing density variations in the

powder compact.

Uncontrolled agglomeration of powders due to attractive van der Waals forces

can also give rise to microstructural heterogeneity. Differential

stresses that develop as a result of non-uniform drying shrinkage are

directly related to the rate at which the solvent can be removed, and thus highly dependent upon the distribution of porosity. Such stresses have been associated with a plastic-to-brittle transition in consolidated bodies, and can yield to crack propagation in the unfired body if not relieved.

In addition, any fluctuations in packing density in the compact as it is prepared for the kiln are often amplified during the sintering

process, yielding inhomogeneous densification. Some pores and other

structural defects associated with density variations have been shown to

play a detrimental role in the sintering process by growing and thus

limiting end-point densities. Differential stresses arising from

inhomogeneous densification have also been shown to result in the

propagation of internal cracks, thus becoming the strength-controlling

flaws.

Inert gas evaporation and inert gas deposition

are free many of these defects due to the distillation (cf.

purification) nature of the process and having enough time to form

single crystal particles, however even their non-aggreated deposits have

lognormal size distribution, which is typical with nanoparticles.

The reason why modern gas evaporation techniques can produce a

relatively narrow size distribution is that aggregation can be avoided.

However, even in this case, random residence times in the growth zone,

due to the combination of drift and diffusion, result in a size

distribution appearing lognormal.

It would, therefore, appear desirable to process a material in

such a way that it is physically uniform with regard to the distribution

of components and porosity, rather than using particle size

distributions that will maximize the green density. The containment of a

uniformly dispersed assembly of strongly interacting particles in

suspension requires total control over interparticle forces. Monodisperse nanoparticles and colloids provide this potential.

Monodisperse powders of colloidal silica, for example, may therefore be stabilized sufficiently to ensure a high degree of order in the colloidal crystal or polycrystalline

colloidal solid that results from aggregation. The degree of order

appears to be limited by the time and space allowed for longer-range

correlations to be established. Such defective polycrystalline colloidal

structures would appear to be the basic elements of submicrometer

colloidal materials science and, therefore, provide the first step in

developing a more rigorous understanding of the mechanisms involved in

microstructural evolution in high performance materials and components.

Synthesis

There are several methods for creating nanoparticles, including gas condensation, attrition, chemical precipitation, ion implantation, pyrolysis and hydrothermal synthesis. In attrition, macro- or micro-scale particles are ground in a ball mill, a planetary ball mill, or other size-reducing mechanism. The resulting particles are air classified

to recover nanoparticles. In pyrolysis, a vaporous precursor (liquid or

gas) is forced through an orifice at high pressure and burned. The

resulting solid (a version of soot) is air classified to recover oxide

particles from by-product gases. Traditional pyrolysis often results in

aggregates and agglomerates rather than single primary particles. Ultrasonic nozzle spray pyrolysis (USP) on the other hand aids in preventing agglomerates from forming.

A thermal plasma

can deliver the energy to vaporize small micrometer-size particles. The

thermal plasma temperatures are in the order of 10,000 K, so that solid

powder easily evaporates. Nanoparticles are formed upon cooling while

exiting the plasma region. The main types of the thermal plasma torches

used to produce nanoparticles are dc plasma jet, dc arc plasma, and

radio frequency (RF) induction plasmas. In the arc plasma reactors, the

energy necessary for evaporation and reaction is provided by an electric

arc formed between the anode and the cathode. For example, silica sand

can be vaporized with an arc plasma at atmospheric pressure, or thin

aluminum wires can be vaporized by exploding wire method.

The resulting mixture of plasma gas and silica vapour can be rapidly

cooled by quenching with oxygen, thus ensuring the quality of the fumed

silica produced.

In RF induction plasma torches, energy coupling to the plasma is

accomplished through the electromagnetic field generated by the

induction coil. The plasma gas does not come in contact with electrodes,

thus eliminating possible sources of contamination and allowing the

operation of such plasma torches with a wide range of gases including

inert, reducing, oxidizing, and other corrosive atmospheres. The working

frequency is typically between 200 kHz and 40 MHz. Laboratory units run

at power levels in the order of 30–50 kW, whereas the large-scale

industrial units have been tested at power levels up to 1 MW. As the

residence time of the injected feed droplets in the plasma is very

short, it is important that the droplet sizes are small enough in order

to obtain complete evaporation. The RF plasma method has been used to

synthesize different nanoparticle materials, for example synthesis of

various ceramic nanoparticles such as oxides, carbours/carbides, and

nitrides of Ti and Si.

Inert gas condensation

Inert-gas condensation

is frequently used to produce metallic nanoparticles. The metal is

evaporated in a vacuum chamber containing a reduced atmosphere of an

inert gas.

Condensation of the supersaturated metal vapor results in creation of

nanometer-size particles, which can be entrained in the inert gas stream

and deposited on a substrate or studied in situ. Early studies were

based on thermal evaporation. Using magnetron sputtering to create the metal vapor allows to achieve higher yields.

The method can easily be generalized to alloy nanoparticles by choosing

appropriate metallic targets. The use of sequential growth schemes,

where the particles travel through a second metallic vapor, results in

growth of core-shell (CS) structures.

Radiolysis method

Left) Transmission electron microscopy (TEM) image of Hf nanoparticles grown by magnetron-sputtering inert-gas condensation (inset: size distribution) and right) energy dispersive x-ray (EDX) mapping of Ni and Ni@Cu core@shell nanoparticles.

Nanoparticles can also be formed using radiation chemistry. Radiolysis from gamma rays can create strongly active free radicals

in solution. This relatively simple technique uses a minimum number of

chemicals. These including water, a soluble metallic salt, a radical

scavenger (often a secondary alcohol), and a surfactant (organic capping

agent). High gamma doses on the order of 104 Gray

are required. In this process, reducing radicals will drop metallic

ions down to the zero-valence state. A scavenger chemical will

preferentially interact with oxidizing radicals to prevent the

re-oxidation of the metal. Once in the zero-valence state, metal atoms

begin to coalesce into particles. A chemical surfactant surrounds the

particle during formation and regulates its growth. In sufficient

concentrations, the surfactant molecules stay attached to the particle.

This prevents it from dissociating or forming clusters with other

particles. Formation of nanoparticles using the radiolysis method allows

for tailoring of particle size and shape by adjusting precursor

concentrations and gamma dose.

Sol–gel

The sol–gel process is a wet-chemical technique (also known as chemical solution deposition) widely used recently in the fields of materials science and ceramic engineering. Such methods are used primarily for the fabrication of materials (typically a metal oxide) starting from a chemical solution (sol, short for solution), which acts as the precursor for an integrated network (or gel) of either discrete particles or network polymers.

Typical precursors are metal alkoxides and metal chlorides, which undergo hydrolysis and polycondensation reactions to form either a network "elastic solid" or a colloidal suspension (or dispersion) – a system composed of discrete (often amorphous)

submicrometer particles dispersed to various degrees in a host fluid.

Formation of a metal oxide involves connecting the metal centers with

oxo (M-O-M) or hydroxo (M-OH-M) bridges, therefore generating metal-oxo

or metal-hydroxo polymers in solution. Thus, the sol evolves toward the

formation of a gel-like diphasic system containing both a liquid phase and solid phase whose morphologies range from discrete particles to continuous polymer networks.

In the case of the colloid, the volume fraction of particles (or

particle density) may be so low that a significant amount of fluid may

need to be removed initially for the gel-like properties to be recognized. This can be accomplished in a number of ways. The most simple method is to allow time for sedimentation to occur, and then pour off the remaining liquid. Centrifugation can also be used to accelerate the process of phase separation.

Removal of the remaining liquid (solvent) phase requires a drying process, which typically causes shrinkage and densification. The rate at which the solvent can be removed is ultimately determined by the distribution of porosity

in the gel. The ultimate microstructure of the final component will

clearly be strongly influenced by changes implemented during this phase

of processing. Afterward, a thermal treatment, or firing process, is

often necessary in order to favor further polycondensation and enhance

mechanical properties and structural stability via final sintering,

densification, and grain growth. One of the distinct advantages of using

this methodology as opposed to the more traditional processing

techniques is that densification is often achieved at a much lower

temperature.

The precursor sol can be either deposited on a substrate to form a film (e.g., by dip-coating or spin-coating), cast into a suitable container with the desired shape (e.g., to obtain a monolithic ceramics, glasses, fibers, membranes, aerogels), or used to synthesize powders (e.g., microspheres, nanospheres).

The sol–gel approach is a cheap and low-temperature technique that

allows for the fine control of the product’s chemical composition. Even

small quantities of dopants, such as organic dyes and rare earth metals,

can be introduced in the sol and end up uniformly dispersed in the

final product. It can be used in ceramics processing and manufacturing as an investment casting material, or as a means of producing very thin films of metal oxides for various purposes. Sol–gel derived materials have diverse applications in optics, electronics, energy, space, (bio)sensors, medicine (e.g., controlled drug release) and separation (e.g., chromatography) technology.

Ion implantation

Ion

implantation may be used to treat the surfaces of dielectric materials

such as sapphire and silica to make composites with near-surface

dispersions of metal or oxide nanoparticles.

Morphology

Nanostars of vanadium(IV) oxide

Scientists have taken to naming their particles after the real-world shapes that they might represent. Nanospheres, nanochains, nanoreefs, nanoboxes,

and more have appeared in the literature. These morphologies sometimes

arise spontaneously as an effect of a templating or directing agent

present in the synthesis such as miscellar emulsions or anodized alumina pores, or from the innate crystallographic growth patterns of the materials themselves. Some of these morphologies may serve a purpose, such as long carbon nanotubes used to bridge an electrical junction, or just a scientific curiosity like the stars shown at right.

Amorphous particles usually adopt a spherical shape (due to their

microstructural isotropy), whereas the shape of anisotropic

microcrystalline whiskers corresponds to their particular crystal habit.

At the small end of the size range, nanoparticles are often referred to

as clusters. Spheres, rods, fibers, and cups are just a few of the shapes that have been grown. The study of fine particles is called micromeritics.

Characterization

Nanoparticles have different analytical requirements than

conventional chemicals, for which chemical composition and concentration

are sufficient metrics. Nanoparticles have other physical properties

that must be measured for a complete description, such as size, shape, surface properties, crystallinity, and dispersion state.

Additionally, sampling and laboratory procedures can perturb their

dispersion state or bias the distribution of other properties.

In environmental contexts, an additional challenge is that many

methods cannot detect low concentrations of nanoparticles that may still

have an adverse effect.

For some applications, nanoparticles may be characterized in complex

matrices such as water, soil, food, polymers, inks, complex mixtures of

organic liquids such as in cosmetics, or blood.

There are several overall categories of methods used to characterize nanoparticles. Microscopy methods generate images of individual nanoparticles to characterize their shape, size, and location. Electron microscopy and scanning probe microscopy are the dominant methods. Because nanoparticles have a size below the diffraction limit of visible light, conventional optical microscopy is not useful. Electron microscopes can be coupled to spectroscopic methods that can perform elemental analysis. Microscopy methods are destructive, and can be prone to undesirable artifacts

from sample preparation, or from probe tip geometry in the case of

scanning probe microscopy. Additionally, microscopy is based on single-particle measurements, meaning that large numbers of individual particles must be characterized to estimate their bulk properties.

Spectroscopy, which measures the particles' interaction with electromagnetic radiation as a function of wavelength, is useful for some classes of nanoparticles to characterize concentration, size, and shape. X-ray, ultraviolet–visible, infrared, and nuclear magnetic resonance spectroscopy can be used with nanoparticles. Light scattering methods using laser light, X-rays, or neutron scattering are used to determine particle size, with each method suitable for different size ranges and particle compositions. Some miscellaneous methods are electrophoresis for surface charge, the Brunauer–Emmett–Teller method for surface area, and X-ray diffraction for crystal structure, as well as mass spectrometry for particle mass, and particle counters for particle number. Chromatography, centrifugation, and filtration techniques can be used to separate nanoparticles by size or other physical properties before or during characterization.

Functionalization

Functionalization is the introduction of organic molecules or polymers on the surface of the nanoparticle. The surface coating

of nanoparticles determines many of their physical and chemical

properties, notably stability, solubility, and targeting. A coating that

is multivalent or polymeric confers high stability. Functionalized nanomaterial-based catalysts can be used for catalysis of many known organic reactions.

Surface coating for biological applications

For biological applications, the surface coating should be polar to

give high aqueous solubility and prevent nanoparticle aggregation. In

serum or on the cell surface, highly charged coatings promote

non-specific binding, whereas polyethylene glycol linked to terminal hydroxyl or methoxy groups repel non-specific interactions.

Nanoparticles can be linked to biological molecules that can act as

address tags, to direct the nanoparticles to specific sites within the

body, specific organelles within the cell, or to follow specifically the movement of individual protein or RNA molecules in living cells. Common address tags are monoclonal antibodies, aptamers, streptavidin or peptides.

These targeting agents should ideally be covalently linked to the

nanoparticle and should be present in a controlled number per

nanoparticle. Multivalent nanoparticles, bearing multiple targeting

groups, can cluster receptors, which can activate cellular signaling

pathways, and give stronger anchoring. Monovalent nanoparticles, bearing

a single binding site, avoid clustering and so are preferable for tracking the behavior of individual proteins.

Red blood cell coatings can help nanoparticles evade the immune system.

Health and safety

Nanoparticles present possible dangers, both medically and environmentally. Most of these are due to the high surface to volume ratio, which can make the particles very reactive or catalytic. They are also able to pass through cell membranes in organisms, and their interactions with biological systems are relatively unknown.

However, it is unlikely the particles would enter the cell nucleus,

Golgi complex, endoplasmic reticulum or other internal cellular

components due to the particle size and intercellular agglomeration. A recent study looking at the effects of ZnO nanoparticles on human immune cells has found varying levels of susceptibility to cytotoxicity.

There are concerns that pharmaceutical companies, seeking regulatory

approval for nano-reformulations of existing medicines, are relying on

safety data produced during clinical studies of the earlier,

pre-reformulation version of the medicine. This could result in

regulatory bodies, such as the FDA, missing new side effects that are

specific to the nano-reformulation.

Whether cosmetics and sunscreens containing nanomaterials pose health risks remains largely unknown at this stage. However considerable research has demonstrated that zinc nanoparticles are not absorbed into the bloodstream in vivo.

Concern has also been raised over the health effects of respirable nanoparticles from certain combustion processes. As of 2013 the U.S. Environmental Protection Agency was investigating the safety of the following nanoparticles:

- Carbon Nanotubes: Carbon materials have a wide range of uses, ranging from composites for use in vehicles and sports equipment to integrated circuits for electronic components. The interactions between nanomaterials such as carbon nanotubes and natural organic matter strongly influence both their aggregation and deposition, which strongly affects their transport, transformation, and exposure in aquatic environments. In past research, carbon nanotubes exhibited some toxicological impacts that will be evaluated in various environmental settings in current EPA chemical safety research. EPA research will provide data, models, test methods, and best practices to discover the acute health effects of carbon nanotubes and identify methods to predict them.

- Cerium oxide: Nanoscale cerium oxide is used in electronics, biomedical supplies, energy, and fuel additives. Many applications of engineered cerium oxide nanoparticles naturally disperse themselves into the environment, which increases the risk of exposure. There is ongoing exposure to new diesel emissions using fuel additives containing CeO2 nanoparticles, and the environmental and public health impacts of this new technology are unknown. EPA’s chemical safety research is assessing the environmental, ecological, and health implications of nanotechnology-enabled diesel fuel additives.

- Titanium dioxide: Nano titanium dioxide is currently used in many products. Depending on the type of particle, it may be found in sunscreens, cosmetics, and paints and coatings. It is also being investigated for use in removing contaminants from drinking water.

- Nano Silver: Nano silver is being incorporated into textiles, clothing, food packaging, and other materials to eliminate bacteria. EPA and the U.S. Consumer Product Safety Commission are studying certain products to see whether they transfer nano-size silver particles in real-world scenarios. EPA is researching this topic to better understand how much nano-silver children come in contact with in their environments.

- Iron: While nano-scale iron is being investigated for many uses, including “smart fluids” for uses such as optics polishing and as a better-absorbed iron nutrient supplement, one of its more prominent current uses is to remove contamination from groundwater. This use, supported by EPA research, is being piloted at a number of sites across the United States.

Regulation

As

of 2016, the U.S. Environmental Protection Agency had conditionally

registered, for a period of four years, only two nanomaterial pesticides

as ingredients. The EPA differentiates nanoscale ingredients from

non-nanoscale forms of the ingredient, but there is little scientific

data about potential variation in toxicity. Testing protocols still need

to be developed.

Applications

As

the most prevalent morphology of nanomaterials used in consumer

products, nanoparticles have potential and actual applications in all

industries. Table below summarizes the most common nanoparticles used in

various product types available on the global markets.

Scientific research on nanoparticles is intense as they have many potential applications in medicine, physics, optics, and electronics. The U.S. National Nanotechnology Initiative offers government funding focused on nanoparticle research.|The use of nanoparticles in laser dye-doped poly(methyl methacrylate) (PMMA) laser gain media was demonstrated in 2003 and it has been shown to improve conversion efficiencies and to decrease laser beam divergence.

Researchers attribute the reduction in beam divergence to improved

dn/dT characteristics of the organic-inorganic dye-doped nanocomposite.

The optimum composition reported by these researchers is 30% w/w of SiO2 (~ 12 nm) in dye-doped PMMA.|Nanoparticles are being investigated as potential drug delivery system. Drugs, growth factors or other biomolecules can be conjugated to nano particles to aid targeted delivery.

This nanoparticle-assisted delivery allows for spatial and temporal

controls of the loaded drugs to achieve the most desirable biological

outcome.|Nanoparticles are also studied for possible applications as dietary supplements for delivery of biologically active substances, for example mineral elements.