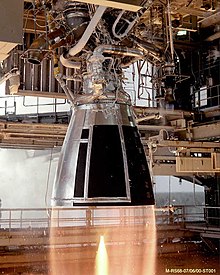

RS-68 being tested at NASA's Stennis Space Center. The nearly transparent exhaust is due to this engine's exhaust being mostly superheated steam (water vapour from its propellants, hydrogen and oxygen), plus some unburned hydrogen.

A rocket engine uses stored rocket propellant mass for forming its high-speed propulsive jet. Rocket engines are reaction engines, obtaining thrust in accordance with Newton's third law. Most rocket engines use combustion, although non-combusting forms (such as cold gas thrusters and nuclear thermal rockets) also exist. Vehicles propelled by rocket engines are commonly called rockets. Since they need no external material to form their jet, rocket engines can perform in a vacuum and thus can be used to propel spacecraft and ballistic missiles.

Compared to other types of jet engines, rocket engines are by far

the lightest, and have the highest thrust, but are the least

propellant-efficient (they have the lowest specific impulse). The ideal exhaust is hydrogen,

the lightest of all gases, but chemical rockets produce a mix of

heavier species, reducing the exhaust velocity. Rocket engines become

more efficient at high velocities, due to greater propulsive efficiency and the Oberth effect. Since they do not require an atmosphere, they are well suited for uses at very high altitudes and in space.

Terminology

Here, "rocket" is used as an abbreviation for "rocket engine".

Thermal rockets use an inert propellant, heated by a power source such as electric or nuclear power.

Chemical rockets are powered by exothermic chemical reactions of the propellant:

- Solid-fuel rockets (or solid-propellant rockets or motors) are chemical rockets which use propellant in a solid state.

- Liquid-propellant rockets use one or more liquid propellants fed from tanks.

- Hybrid rockets use a solid propellant in the combustion chamber, to which a second liquid or gas oxidiser or propellant is added to permit combustion.

- Monopropellant rockets use a single propellant decomposed by a catalyst. The most common monopropellants are hydrazine and hydrogen peroxide.

Principle of operation

A simplified diagram of a liquid-fuel rocket.

1. Liquid rocket fuel.

2. Oxidizer.

3. Pumps carry the fuel and oxidizer.

4. The combustion chamber mixes and burns the two liquids.

5. The hot exhaust is choked at the throat, which, among other things, dictates the amount of thrust produced.

6. Exhaust exits the rocket.

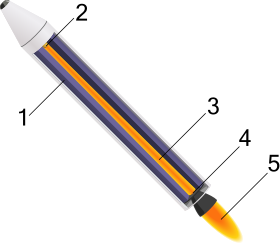

A simplified diagram of a solid-fuel rocket.

1. A solid fuel-oxidizer mixture (propellant) is packed into the rocket, with a cylindrical hole in the middle.

2. An igniter combusts the surface of the propellant.

3. The cylindrical hole in the propellant acts as a combustion chamber.

4. The hot exhaust is choked at the throat, which, among other things, dictates the amount of thrust produced.

5. Exhaust exits the rocket.

1. A solid fuel-oxidizer mixture (propellant) is packed into the rocket, with a cylindrical hole in the middle.

2. An igniter combusts the surface of the propellant.

3. The cylindrical hole in the propellant acts as a combustion chamber.

4. The hot exhaust is choked at the throat, which, among other things, dictates the amount of thrust produced.

5. Exhaust exits the rocket.

Rocket engines produce thrust by the expulsion of an exhaust fluid which has been accelerated to a high speed through a propelling nozzle.

The fluid is usually a gas created by high pressure

(150-to-2,900-pound-per-square-inch (10 to 200 bar)) combustion of solid

or liquid propellants, consisting of fuel and oxidiser components, within a combustion chamber. The nozzle uses the heat energy released by expansion of the gas to accelerate the exhaust to very high (supersonic)

speed, and the reaction to this pushes the engine in the opposite

direction. Combustion is most frequently used for practical rockets, as

high temperatures and pressures are desirable for the best performance,

permitting a longer nozzle, giving higher exhaust speeds and better

thermodynamic efficiency.

An alternative to combustion is the water rocket, which uses water pressurised by compressed air, carbon dioxide, nitrogen, or manual pumping, for model rocketry.

Propellant

Rocket

propellant is mass that is stored, usually in some form of propellant

tank, or within the combustion chamber itself, prior to being ejected

from a rocket engine in the form of a fluid jet to produce thrust.

Chemical rocket propellants are most commonly used, which undergo

exothermic chemical reactions which produce hot gas which is used by a

rocket for propulsive purposes. Alternatively, a chemically inert reaction mass can be heated using a high-energy power source via a heat exchanger, and then no combustion chamber is used.

Solid rocket

propellants are prepared as a mixture of fuel and oxidising components

called 'grain' and the propellant storage casing effectively becomes the

combustion chamber.

Injection

Liquid-fuelled rockets force separate fuel and oxidiser components into the combustion chamber, where they mix and burn. Hybrid rocket engines use a combination of solid and liquid or gaseous propellants. Both liquid and hybrid rockets use injectors to introduce the propellant into the chamber. These are often an array of simple jets

– holes through which the propellant escapes under pressure; but

sometimes may be more complex spray nozzles. When two or more

propellants are injected, the jets usually deliberately cause the

propellants to collide as this breaks up the flow into smaller droplets

that burn more easily.

Combustion chamber

For chemical rockets the combustion chamber is typically just a cylinder, and flame holders are rarely used. The dimensions of the cylinder are such that the propellant is able to combust thoroughly; different rocket propellants require different combustion chamber sizes for this to occur.

This leads to a number called :

where:

- is the volume of the chamber

- is the area of the throat

L* is typically in the range of 25–60 inches (0.64–1.52 m).

The combination of temperatures and pressures typically reached

in a combustion chamber is usually extreme by any standard. Unlike in airbreathing jet engines, no atmospheric nitrogen is present to dilute and cool the combustion, and the propellant mixture can reach true stoichiometric ratios. This, in combination with the high pressures, means that the rate of heat conduction through the walls is very high.

In order for fuel and oxidizer to flow into the chamber, the

pressure of the propellant fluids entering the combustion chamber must

exceed the pressure inside the combustion chamber itself. This may be

accomplished by a variety of design approaches including turbopumps or, in simpler engines, via sufficient tank pressure to advance fluid flow. Tank pressure may be maintained by several means, including a high-pressure helium

pressurization system common to many large rocket engines or, in some

newer rocket systems, by a bleed-off of high-pressure gas from the

engine cycle to autogenously pressurize the propellant tanks For example, the self-pressurization gas system of the BFR

is a critical part of SpaceX strategy to reduce launch vehicle fluids

from five in their legacy Falcon 9 vehicle family to just two in BFR,

eliminating not only the helium tank pressurant but all hypergolic propellants as well as nitrogen for cold-gas reaction-control thrusters.

Nozzle

Rocket

thrust is caused by pressures acting in the combustion chamber and

nozzle. From Newton's third law, equal and opposite pressures act on the

exhaust, and this accelerates it to high speeds.

The hot gas produced in the combustion chamber is permitted to escape

through an opening (the "throat"), and then through a diverging

expansion section. When sufficient pressure is provided to the nozzle

(about 2.5-3 times ambient pressure), the nozzle chokes

and a supersonic jet is formed, dramatically accelerating the gas,

converting most of the thermal energy into kinetic energy. Exhaust

speeds vary, depending on the expansion ratio the nozzle is designed

for, but exhaust speeds as high as ten times the speed of sound

in air at sea level are not uncommon. About half of the rocket engine's

thrust comes from the unbalanced pressures inside the combustion

chamber, and the rest comes from the pressures acting against the inside

of the nozzle (see diagram). As the gas expands (adiabatically) the pressure against the nozzle's walls forces the rocket engine in one direction while accelerating the gas in the other.

The four expansion regimes of a de Laval nozzle:

• under-expanded

• perfectly expanded

• over-expanded

• grossly over-expanded

• under-expanded

• perfectly expanded

• over-expanded

• grossly over-expanded

The most commonly used nozzle is the de Laval nozzle,

a fixed geometry nozzle with a high expansion-ratio. The large bell- or

cone-shaped nozzle extension beyond the throat gives the rocket engine

its characteristic shape.

The exit static pressure

of the exhaust jet depends on the chamber pressure and the ratio of

exit to throat area of the nozzle. As exit pressure varies from the

ambient (atmospheric) pressure, a choked nozzle is said to be

- under-expanded (exit pressure greater than ambient),

- perfectly expanded (exit pressure equals ambient),

- over-expanded (exit pressure less than ambient; shock diamonds form outside the nozzle), or

- grossly over-expanded (a shock wave forms inside the nozzle extension).

In practice, perfect expansion is only achievable with a

variable-exit area nozzle (since ambient pressure decreases as altitude

increases), and is not possible above a certain altitude as ambient

pressure approaches zero. If the nozzle is not perfectly expanded, then

loss of efficiency occurs. Grossly over-expanded nozzles lose less

efficiency, but can cause mechanical problems with the nozzle.

Fixed-area nozzles become progressively more under-expanded as they gain

altitude. Almost all de Laval nozzles will be momentarily grossly

over-expanded during startup in an atmosphere.

Nozzle efficiency is affected by operation in the atmosphere

because atmospheric pressure changes with altitude; but due to the

supersonic speeds of the gas exiting from a rocket engine, the pressure

of the jet may be either below or above ambient, and equilibrium between

the two is not reached at all altitudes.

Back pressure and optimal expansion

For

optimal performance, the pressure of the gas at the end of the nozzle

should just equal the ambient pressure: if the exhaust's pressure is

lower than the ambient pressure, then the vehicle will be slowed by the

difference in pressure between the top of the engine and the exit; on

the other hand, if the exhaust's pressure is higher, then exhaust

pressure that could have been converted into thrust is not converted,

and energy is wasted.

To maintain this ideal of equality between the exhaust's exit

pressure and the ambient pressure, the diameter of the nozzle would need

to increase with altitude, giving the pressure a longer nozzle to act

on (and reducing the exit pressure and temperature). This increase is

difficult to arrange in a lightweight fashion, although is routinely

done with other forms of jet engines. In rocketry a lightweight

compromise nozzle is generally used and some reduction in atmospheric

performance occurs when used at other than the 'design altitude' or when

throttled. To improve on this, various exotic nozzle designs such as

the plug nozzle, stepped nozzles, the expanding nozzle and the aerospike

have been proposed, each providing some way to adapt to changing

ambient air pressure and each allowing the gas to expand further against

the nozzle, giving extra thrust at higher altitudes.

When exhausting into a sufficiently low ambient pressure (vacuum)

several issues arise. One is the sheer weight of the nozzle—beyond a

certain point, for a particular vehicle, the extra weight of the nozzle

outweighs any performance gained. Secondly, as the exhaust gases

adiabatically expand within the nozzle they cool, and eventually some of

the chemicals can freeze, producing 'snow' within the jet. This causes

instabilities in the jet and must be avoided.

On a de Laval nozzle,

exhaust gas flow detachment will occur in a grossly over-expanded

nozzle. As the detachment point will not be uniform around the axis of

the engine, a side force may be imparted to the engine. This side force

may change over time and result in control problems with the launch

vehicle.

Advanced altitude-compensating designs, such as the aerospike or plug nozzle, attempt to minimize performance losses by adjusting to varying expansion ratio caused by changing altitude.

Propellant efficiency

Typical temperature (T), pressure (p), and velocity (v) profiles in a de Laval Nozzle

For a rocket engine to be propellant efficient, it is important that

the maximum pressures possible be created on the walls of the chamber

and nozzle by a specific amount of propellant; as this is the source of

the thrust. This can be achieved by all of:

- heating the propellant to as high a temperature as possible (using a high energy fuel, containing hydrogen and carbon and sometimes metals such as aluminium, or even using nuclear energy)

- using a low specific density gas (as hydrogen rich as possible)

- using propellants which are, or decompose to, simple molecules with few degrees of freedom to maximise translational velocity

Since all of these things minimise the mass of the propellant used,

and since pressure is proportional to the mass of propellant present to

be accelerated as it pushes on the engine, and since from Newton's third law

the pressure that acts on the engine also reciprocally acts on the

propellant, it turns out that for any given engine, the speed that the

propellant leaves the chamber is unaffected by the chamber pressure

(although the thrust is proportional). However, speed is significantly

affected by all three of the above factors and the exhaust speed is an

excellent measure of the engine propellant efficiency. This is termed exhaust velocity, and after allowance is made for factors that can reduce it, the effective exhaust velocity

is one of the most important parameters of a rocket engine (although

weight, cost, ease of manufacture etc. are usually also very important).

For aerodynamic reasons the flow goes sonic ("chokes") at the narrowest part of the nozzle, the 'throat'. Since the speed of sound

in gases increases with the square root of temperature, the use of hot

exhaust gas greatly improves performance. By comparison, at room

temperature the speed of sound in air is about 340 m/s while the speed

of sound in the hot gas of a rocket engine can be over 1700 m/s; much of

this performance is due to the higher temperature, but additionally

rocket propellants are chosen to be of low molecular mass, and this also

gives a higher velocity compared to air.

Expansion in the rocket nozzle then further multiplies the speed, typically between 1.5 and 2 times, giving a highly collimated

hypersonic exhaust jet. The speed increase of a rocket nozzle is mostly

determined by its area expansion ratio—the ratio of the area of the

throat to the area at the exit, but detailed properties of the gas are

also important. Larger ratio nozzles are more massive but are able to

extract more heat from the combustion gases, increasing the exhaust

velocity.

Thrust vectoring

Vehicles typically require the overall thrust to change direction

over the length of the burn. A number of different ways to achieve this

have been flown:

- The entire engine is mounted on a hinge or gimbal and any propellant feeds reach the engine via low pressure flexible pipes or rotary couplings.

- Just the combustion chamber and nozzle is gimballed, the pumps are fixed, and high pressure feeds attach to the engine.

- Multiple engines (often canted at slight angles) are deployed but throttled to give the overall vector that is required, giving only a very small penalty.

- High-temperature vanes protrude into the exhaust and can be tilted to deflect the jet.

Overall performance

Rocket technology can combine very high thrust (meganewtons),

very high exhaust speeds (around 10 times the speed of sound in air at

sea level) and very high thrust/weight ratios (>100) simultaneously

as well as being able to operate outside the atmosphere, and while

permitting the use of low pressure and hence lightweight tanks and

structure.

Rockets can be further optimised to even more extreme performance along one or more of these axes at the expense of the others.

Specific impulse

The most important metric for the efficiency of a rocket engine is impulse per unit of propellant, this is called specific impulse (usually written ). This is either measured as a speed (the effective exhaust velocity in metres/second or ft/s) or as a time (seconds). An engine that gives a large specific impulse is normally highly desirable.

The specific impulse that can be achieved is primarily a function

of the propellant mix (and ultimately would limit the specific

impulse), but practical limits on chamber pressures and the nozzle

expansion ratios reduce the performance that can be achieved.

Net thrust

Below is an approximate equation for calculating the net thrust of a rocket engine:

where: = exhaust gas mass flow = effective exhaust velocity = effective jet velocity when Pa = Pe = flow area at nozzle exit plane (or the plane where the jet leaves the nozzle if separated flow) = static pressure at nozzle exit plane = ambient (or atmospheric) pressure

Since, unlike a jet engine, a conventional rocket motor lacks an air

intake, there is no 'ram drag' to deduct from the gross thrust.

Consequently, the net thrust of a rocket motor is equal to the gross

thrust (apart from static back pressure).

The term represents the momentum thrust, which remains constant at a given throttle setting, whereas the

term represents the pressure thrust term. At full throttle, the net

thrust of a rocket motor improves slightly with increasing altitude,

because as atmospheric pressure decreases with altitude, the pressure

thrust term increases. At the surface of the Earth the pressure thrust

may be reduced by up to 30%,depending on the engine design. This

reduction drops roughly exponentially to zero with increasing altitude.

Maximum efficiency for a rocket engine is achieved by maximising

the momentum contribution of the equation without incurring penalties

from over expanding the exhaust. This occurs when . Since ambient pressure changes with altitude, most rocket engines spend very little time operating at peak efficiency.

Vacuum specific impulse, Isp

Due

to the specific impulse varying with pressure, a quantity that is easy

to compare and calculate with is useful. Because rockets choke

at the throat, and because the supersonic exhaust prevents external

pressure influences travelling upstream, it turns out that the pressure

at the exit is ideally exactly proportional to the propellant flow ,

provided the mixture ratios and combustion efficiencies are maintained.

It is thus quite usual to rearrange the above equation slightly:

and so define the vacuum Isp to be:

where:

- = the speed of sound constant at the throat

- = the thrust coefficient constant of the nozzle (typically about 2)

And hence:

Throttling

Rockets can be throttled by controlling the propellant combustion rate

(usually measured in kg/s or lb/s). In liquid and hybrid rockets, the

propellant flow entering the chamber is controlled using valves, in solid rockets

it is controlled by changing the area of propellant that is burning and

this can be designed into the propellant grain (and hence cannot be

controlled in real-time).

Rockets can usually be throttled down to an exit pressure of about one-third of ambient pressure

(often limited by flow separation in nozzles) and up to a maximum limit

determined only by the mechanical strength of the engine.

In practice, the degree to which rockets can be throttled varies

greatly, but most rockets can be throttled by a factor of 2 without

great difficulty;

the typical limitation is combustion stability, as for example,

injectors need a minimum pressure to avoid triggering damaging

oscillations (chugging or combustion instabilities); but injectors can

be optimised and tested for wider ranges.

For example, some more recent liquid-propellant engine designs that have

been optimised for greater throttling capability (BE-3, Raptor) can be throttled to as low as 18–20 percent of rated thrust.

Solid rockets can be throttled by using shaped grains that will vary their surface area over the course of the burn.

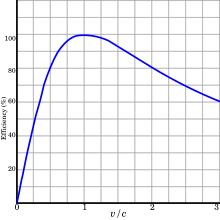

Energy efficiency

Rocket

vehicle mechanical efficiency as a function of vehicle instantaneous

speed divided by effective exhaust speed. These percentages need to be

multiplied by internal engine efficiency to get overall efficiency.

Rocket engine nozzles are surprisingly efficient heat engines for generating a high speed jet, as a consequence of the high combustion temperature and high compression ratio. Rocket nozzles give an excellent approximation to adiabatic expansion which is a reversible process, and hence they give efficiencies which are very close to that of the Carnot cycle. Given the temperatures reached, over 60% efficiency can be achieved with chemical rockets.

For a vehicle employing a rocket engine the energetic

efficiency is very good if the vehicle speed approaches or somewhat

exceeds the exhaust velocity (relative to launch); but at low speeds the

energy efficiency goes to 0% at zero speed (as with all jet propulsion.) See Rocket energy efficiency for more details.

Thrust-to-weight ratio

Rockets, of all the jet engines, indeed of essentially all engines,

have the highest thrust to weight ratio. This is especially true for

liquid rocket engines.

This high performance is due to the small volume of pressure vessels

that make up the engine—the pumps, pipes and combustion chambers

involved. The lack of inlet duct and the use of dense liquid propellant

allows the pressurisation system to be small and lightweight, whereas

duct engines have to deal with air which has a density about one

thousand times lower.

Of the liquid propellants used, density is worst for liquid hydrogen.

Although this propellant is marvellous in many ways, it has a very low

density, about one fourteenth that of water. This makes the turbopumps

and pipework larger and heavier, and this is reflected in the

thrust-to-weight ratio of engines that use it (for example the SSME)

compared to those that do not (NK-33).

Cooling

For

efficiency reasons, higher temperatures are desirable, but materials

lose their strength if the temperature becomes too high. Rockets run

with combustion temperatures that can reach ~3,500 K (~3,200 °C or

~5,800 °F).

Most other jet engines have gas turbines in the hot exhaust. Due

to their larger surface area, they are harder to cool and hence there is

a need to run the combustion processes at much lower temperatures,

losing efficiency. In addition, duct engines use air as an oxidant, which contains 78% largely unreactive nitrogen, which dilutes the reaction and lowers the temperatures. Rockets have none of these inherent combustion temperature limiters.

The temperatures reached by rocket exhaust often substantially

exceed the melting points of the nozzle and combustion chamber materials

(~1,200 K for copper). Most construction materials will also combust if

exposed to high temperature oxidizer, which leads to a number of design

challenges. The nozzle and combustion temperature walls must not be

allowed to combust, melt, or vaporize (sometimes facetiously termed an

"engine-rich exhaust").

Rockets that use the common construction materials such as

aluminium, steel, nickel or copper alloys must employ cooling systems to

limit the temperatures that engine structures experience. Regenerative cooling,

where the propellant is passed through tubes around the combustion

chamber or nozzle, and other techniques, such as curtain cooling or film

cooling, are employed to give longer nozzle and chamber life. These

techniques ensure that a gaseous thermal boundary layer touching the material is kept below the temperature which would cause the material to catastrophically fail.

Two material exceptions that can directly sustain rocket exhaust temperatures are graphite and tungsten,

although both are subject to oxidation if not protected. Materials

technology, combined with the engine design, is a limiting factor of the

exhaust temperature of chemical rockets.

In rockets, the heat fluxes that can pass through the wall are

among the highest in engineering; fluxes are generally in the range of

1-200 MW/m2. The strongest heat fluxes are found at the

throat, which often sees twice that found in the associated chamber and

nozzle. This is due to the combination of high speeds (which gives a

very thin boundary layer), and although lower than the chamber, the high

temperatures seen there.

In rockets the coolant methods include:

- uncooled (used for short runs mainly during testing)

- ablative walls (walls are lined with a material that is continuously vaporised and carried away).

- radiative cooling (the chamber becomes almost white hot and radiates the heat away)

- dump cooling (a propellant, usually hydrogen, is passed around the chamber and dumped)

- regenerative cooling (liquid rockets use the fuel, or occasionally the oxidiser, to cool the chamber via a cooling jacket before being injected)

- curtain cooling (propellant injection is arranged so the temperature of the gases is cooler at the walls)

- film cooling (surfaces are wetted with liquid propellant, which cools as it evaporates)

In all cases the cooling effect that prevents the wall from being destroyed is caused by a thin layer of insulating fluid (a boundary layer)

that is in contact with the walls that is far cooler than the

combustion temperature. Provided this boundary layer is intact the wall

will not be damaged.

Disruption of the boundary layer may occur during cooling

failures or combustion instabilities, and wall failure typically occurs

soon after.

With regenerative cooling a second boundary layer is found in the

coolant channels around the chamber. This boundary layer thickness

needs to be as small as possible, since the boundary layer acts as an

insulator between the wall and the coolant. This may be achieved by

making the coolant velocity in the channels as high as possible.

In practice, regenerative cooling is nearly always used in conjunction with curtain cooling and/or film cooling.

Liquid-fuelled engines are often run fuel-rich,

which lowers combustion temperatures. This reduces heat loads on the

engine and allows lower cost materials and a simplified cooling system.

This can also increase performance by lowering the average

molecular weight of the exhaust and increasing the efficiency with which

combustion heat is converted to kinetic exhaust energy.

Mechanical issues

Rocket combustion chambers are normally operated at fairly high pressure, typically 10–200 bar (1–20 MPa, 150–3,000 psi).

When operated within significant atmospheric pressure, higher

combustion chamber pressures give better performance by permitting a

larger and more efficient nozzle to be fitted without it being grossly

overexpanded.

However, these high pressures cause the outermost part of the chamber to be under very large hoop stresses – rocket engines are pressure vessels.

Worse, due to the high temperatures created in rocket engines the

materials used tend to have a significantly lowered working tensile

strength.

In addition, significant temperature gradients are set up in the

walls of the chamber and nozzle, these cause differential expansion of

the inner liner that create internal stresses.

Acoustic issues

The

extreme vibration and acoustic environment inside a rocket motor

commonly result in peak stresses well above mean values, especially in

the presence of organ pipe-like resonances and gas turbulence.

Combustion instabilities

The

combustion may display undesired instabilities, of sudden or periodic

nature. The pressure in the injection chamber may increase until the

propellant flow through the injector plate decreases; a moment later the

pressure drops and the flow increases, injecting more propellant in the

combustion chamber which burns a moment later, and again increases the

chamber pressure, repeating the cycle. This may lead to high-amplitude

pressure oscillations, often in ultrasonic range, which may damage the

motor. Oscillations of ±200 psi at 25 kHz were the cause of failures of

early versions of the Titan II missile second stage engines. The other failure mode is a deflagration to detonation transition; the supersonic pressure wave formed in the combustion chamber may destroy the engine.

Combustion instability was also a problem during Atlas

development. The Rocketdyne engines used in the Atlas family were found

to suffer from this effect in several static firing tests, and three

missile launches exploded on the pad due to rough combustion in the

booster engines. In most cases, it occurred while attempting to start

the engines with a "dry start" method whereby the igniter mechanism

would be activated prior to propellant injection. During the process of

man-rating Atlas for Project Mercury,

solving combustion instability was a high priority, and the final two

Mercury flights sported an upgraded propulsion system with baffled

injectors and a hypergolic igniter.

The problem affecting Atlas vehicles was mainly the so-called

"racetrack" phenomenon, where burning propellant would swirl around in a

circle at faster and faster speeds, eventually producing vibration

strong enough to rupture the engine, leading to complete destruction of

the rocket. It was eventually solved by adding several baffles around

the injector face to break up swirling propellant.

More significantly, combustion instability was a problem with the

Saturn F-1 engines. Some of the early units tested exploded during

static firing, which led to the addition of injector baffles.

In the Soviet space program, combustion instability also proved a

problem on some rocket engines, including the RD-107 engine used in the

R-7 family and the RD-216 used in the R-14 family, and several failures

of these vehicles occurred before the problem was solved. Soviet

engineering and manufacturing processes never satisfactorily resolved

combustion instability in larger RP-1/LOX engines, so the RD-171 engine

used to power the Zenit family still used four smaller thrust chambers

fed by a common engine mechanism.

The combustion instabilities can be provoked by remains of

cleaning solvents in the engine (e.g. the first attempted launch of a

Titan II in 1962), reflected shock wave, initial instability after

ignition, explosion near the nozzle that reflects into the combustion

chamber, and many more factors. In stable engine designs the

oscillations are quickly suppressed; in unstable designs they persist

for prolonged periods. Oscillation suppressors are commonly used.

Periodic variations of thrust, caused by combustion instability

or longitudinal vibrations of structures between the tanks and the

engines which modulate the propellant flow, are known as "pogo oscillations" or "pogo", named after the pogo stick.

Chugging

This

is a low frequency oscillation at a few Hertz in chamber pressure

usually caused by pressure variations in feed lines due to variations in

acceleration of the vehicle.

This can cause cyclic variation in thrust, and the effects can vary from

merely annoying to actually damaging the payload or vehicle. Chugging

can be minimised by using gas-filled damping tubes on feed lines of high

density propellants.

Buzzing

This can be caused due to insufficient pressure drop across the injectors.

It generally is mostly annoying, rather than being damaging. However, in

extreme cases combustion can end up being forced backwards through the

injectors – this can cause explosions with monopropellants.

Screeching

This

is the most immediately damaging, and the hardest to control. It is due

to acoustics within the combustion chamber that often couples to the

chemical combustion processes that are the primary drivers of the energy

release, and can lead to unstable resonant "screeching" that commonly

leads to catastrophic failure due to thinning of the insulating thermal

boundary layer. Acoustic oscillations can be excited by thermal

processes, such as the flow of hot air through a pipe or combustion in a

chamber. Specifically, standing acoustic waves inside a chamber can be

intensified if combustion occurs more intensely in regions where the

pressure of the acoustic wave is maximal.

Such effects are very difficult to predict analytically during the

design process, and have usually been addressed by expensive, time

consuming and extensive testing, combined with trial and error remedial

correction measures.

Screeching is often dealt with by detailed changes to injectors,

or changes in the propellant chemistry, or vaporising the propellant

before injection, or use of Helmholtz dampers within the combustion chambers to change the resonant modes of the chamber.

Testing for the possibility of screeching is sometimes done by

exploding small explosive charges outside the combustion chamber with a

tube set tangentially to the combustion chamber near the injectors to

determine the engine's impulse response and then evaluating the time response of the chamber pressure- a fast recovery indicates a stable system.

Exhaust noise

For all but the very smallest sizes, rocket exhaust compared to other engines is generally very noisy. As the hypersonic exhaust mixes with the ambient air, shock waves are formed. The Space Shuttle generates over 200 dB(A) of noise around its base. To reduce this, and the risk of payload damage or injury to the crew atop the stack, the Mobile Launcher Platform was fitted with a Sound Suppression System

that sprayed 1,100,000 litres of water around the base of the rocket in

41 seconds at launch time. Using this system kept sound levels within

the payload bay to 142 dB.

The sound intensity

from the shock waves generated depends on the size of the rocket and on

the exhaust velocity. Such shock waves seem to account for the

characteristic crackling and popping sounds produced by large rocket

engines when heard live. These noise peaks typically overload

microphones and audio electronics, and so are generally weakened or

entirely absent in recorded or broadcast audio reproductions. For large

rockets at close range, the acoustic effects could actually kill.

More worryingly for space agencies, such sound levels can also

damage the launch structure, or worse, be reflected back at the

comparatively delicate rocket above. This is why so much water is

typically used at launches. The water spray changes the acoustic

qualities of the air and reduces or deflects the sound energy away from

the rocket.

Generally speaking, noise is most intense when a rocket is close

to the ground, since the noise from the engines radiates up away from

the jet, as well as reflecting off the ground. Also, when the vehicle is

moving slowly, little of the chemical energy input to the engine can go

into increasing the kinetic energy of the rocket (since useful power P transmitted to the vehicle is for thrust F and speed V).

Then the largest portion of the energy is dissipated in the exhaust's

interaction with the ambient air, producing noise. This noise can be

reduced somewhat by flame trenches with roofs, by water injection around

the jet and by deflecting the jet at an angle.

Testing

Rocket engines are usually statically tested at a test facility

before being put into production. For high altitude engines, either a

shorter nozzle must be used, or the rocket must be tested in a large

vacuum chamber.

Safety

Rocket

vehicles have a reputation for unreliability and danger; especially

catastrophic failures. Contrary to this reputation, carefully designed

rockets can be made arbitrarily reliable.

In military use, rockets are not unreliable. However, one of the main

non-military uses of rockets is for orbital launch. In this application,

the premium has typically been placed on minimum weight, and it is

difficult to achieve high reliability and low weight simultaneously. In

addition, if the number of flights launched is low, there is a very high

chance of a design, operations or manufacturing error causing

destruction of the vehicle.

Saturn family (1961–1975)

The Rocketdyne H-1 engine, used in a cluster of eight in the first stage of the Saturn I and Saturn IB launch vehicles, had no catastrophic failures in 152 engine-flights. The Pratt and Whitney RL10 engine, used in a cluster of six in the Saturn I second stage, had no catastrophic failures in 36 engine-flights. The Rocketdyne F-1 engine, used in a cluster of five in the first stage of the Saturn V, had no failures in 65 engine-flights. The Rocketdyne J-2

engine, used in a cluster of five in the Saturn V second stage, and

singly in the Saturn IB second stage and Saturn V third stage, had no

catastrophic failures in 86 engine-flights.

Space Shuttle (1981–2011)

The Space Shuttle Solid Rocket Booster, used in pairs, caused one notable catastrophic failure in 270 engine-flights.

The Space Shuttle Main Engine,

used in a cluster of three, flew in 46 refurbished engine units. These

made a total of 405 engine-flights with no catastrophic in-flight

failures. A single in-flight SSME failure occurred during Space Shuttle Challenger's STS-51-F mission.[32] This failure had no effect on mission objectives or duration.

Chemistry

Rocket propellants require a high specific energy

(energy per unit mass), because ideally all the reaction energy appears

as kinetic energy of the exhaust gases, and exhaust velocity is the

single most important performance parameter of an engine, on which

vehicle performance depends.

Aside from inevitable losses and imperfections in the engine,

incomplete combustion, etc., after specific reaction energy, the main

theoretical limit reducing the exhaust velocity obtained is that,

according to the laws of thermodynamics, a fraction of the chemical

energy may go into rotation of the exhaust molecules, where it is

unavailable for producing thrust. Monatomic gases like helium have only

three degrees of freedom, corresponding to the three dimensions of

space, {x,y,z}, and only such spherically symmetric molecules escape this kind of loss. A diatomic molecule like H2 can rotate about either of the two axes perpendicular to the one joining the two atoms, and as the equipartition

law of statistical mechanics demands that the available thermal energy

be divided equally among the degrees of freedom, for such a gas in

thermal equilibrium 3/5 of the energy can go into unidirectional motion,

and 2/5 into rotation (actually, the vibration of the molecule should

not be neglected).

A triatomic molecule like water has six degrees of freedom, so the

energy is divided equally among rotational and translational degrees of

freedom. For most chemical reactions the latter situation is the case.

This issue is traditionally described in terms of the ratio, gamma, of

the specific heat of the gas at constant volume to that at constant

pressure. The rotational energy loss is largely recovered in practice if

the expansion nozzle is large enough to allow the gases to expand and

cool sufficiently, the function of the nozzle being to convert the

random thermal motions of the molecules in the combustion chamber into

the unidirectional translation that produces thrust. As long as the

exhaust gas remains in equilibrium as it expands, the initial rotational

energy will be largely returned to translation in the nozzle.

Although the specific reaction energy per unit mass of reactants

is key, low mean molecular weight in the reaction products is also

important in practice in determining exhaust velocity. This is because

the high gas temperatures in rocket engines pose serious problems for

the engineering of survivable motors. Because temperature is

proportional to the mean energy per molecule, a given amount of

energy distributed among more molecules of lower mass permits a higher

exhaust velocity at a given temperature. This means low atomic mass

elements are favoured. Liquid hydrogen (LH2) and oxygen

(LOX, or LO2), are the most effective propellants in terms of exhaust

velocity that have been widely used to date, though a few exotic

combinations involving boron or liquid ozone are potentially somewhat

better in theory if various practical problems could be solved.

It is important to note in computing the specific reaction energy, that the entire mass of the propellants, including both fuel and oxidiser,

must be included. The fact that air-breathing engines are typically

able to obtain oxygen "for free" without having to carry it along,

accounts for one factor of why air-breathing engines are very much more

propellant-mass efficient, and one reason that rocket engines are far

less suitable for most ordinary terrestrial applications. Fuels for car

or turbojet engines,

use atmospheric oxygen and so have a much better effective energy

output per unit mass of propellant that must be carried, but are similar

per unit mass of fuel.

Computer programs that predict the performance of propellants in rocket engines are available.

Ignition

With liquid and hybrid rockets, immediate ignition of the propellant(s) as they first enter the combustion chamber is essential.

With liquid propellants (but not gaseous), failure to ignite

within milliseconds usually causes too much liquid propellant to be

inside the chamber, and if/when ignition occurs the amount of hot gas

created can exceed the maximum design pressure of the chamber, causing a

catastrophic failure of the pressure vessel.

This is sometimes called a hard start or a rapid unscheduled disassembly (RUD).

Ignition can be achieved by a number of different methods; a pyrotechnic charge can be used, a plasma torch can be used, or electric spark ignition may be employed. Some fuel/oxidiser combinations ignite on contact (hypergolic),

and non-hypergolic fuels can be "chemically ignited" by priming the

fuel lines with hypergolic propellants (popular in Russian engines).

Gaseous propellants generally will not cause hard starts,

with rockets the total injector area is less than the throat thus the

chamber pressure tends to ambient prior to ignition and high pressures

cannot form even if the entire chamber is full of flammable gas at

ignition.

Solid propellants are usually ignited with one-shot pyrotechnic devices.

Once ignited, rocket chambers are self-sustaining and igniters

are not needed.

Indeed, chambers often spontaneously reignite if they are restarted

after being shut down for a few seconds. However, when cooled, many

rockets cannot be restarted without at least minor maintenance, such as

replacement of the pyrotechnic igniter.

Jet physics

Armadillo aerospace's quad vehicle showing visible banding (shock diamonds) in the exhaust jet

Rocket jets vary depending on the rocket engine, design altitude, altitude, thrust and other factors.

Carbon rich exhausts from kerosene fuels are often orange in colour due to the black-body radiation of the unburnt particles, in addition to the blue Swan bands. Peroxide oxidizer-based rockets and hydrogen rocket jets contain largely steam and are nearly invisible to the naked eye but shine brightly in the ultraviolet and infrared. Jets from solid rockets

can be highly visible as the propellant frequently contains metals such

as elemental aluminium which burns with an orange-white flame and adds

energy to the combustion process.

Some exhausts, notably alcohol fuelled rockets, can show visible shock diamonds. These are due to cyclic variations in the jet pressure relative to ambient creating shock waves that form 'Mach disks'.

The shape of the jet varies by the design altitude: at high

altitude all rockets are grossly under-expanded, and a quite small

percentage of exhaust gases actually end up expanding forwards.