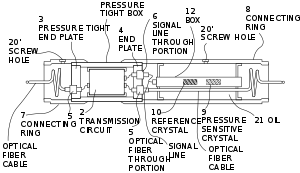

A cross section of the shore-end of a modern submarine communications cable.

1 – Polyethylene

2 – Mylar tape

3 – Stranded steel wires

4 – Aluminium water barrier

5 – Polycarbonate

6 – Copper or aluminium tube

7 – Petroleum jelly

8 – Optical fibers

1 – Polyethylene

2 – Mylar tape

3 – Stranded steel wires

4 – Aluminium water barrier

5 – Polycarbonate

6 – Copper or aluminium tube

7 – Petroleum jelly

8 – Optical fibers

Submarine cables are laid using special cable layer ships, such as the modern René Descartes (ship), operated by Orange Marine.

A submarine communications cable is a cable laid on the sea bed between land-based stations to carry telecommunication signals across stretches of ocean and sea. The first submarine communications cables laid beginning in the 1850s carried telegraphy traffic, establishing the first instant telecommunications links between continents, such as the first transatlantic telegraph cable which became operational on 16 August 1858. Subsequent generations of cables carried telephone traffic, then data communications traffic. Modern cables use optical fiber technology to carry digital data, which includes telephone, Internet and private data traffic.

Modern cables are typically about 1 inch (25 mm) in diameter and

weigh around 2.5 tons per mile (1.4 tonnes per km) for the deep-sea

sections which comprise the majority of the run, although larger and

heavier cables are used for shallow-water sections near shore. Submarine cables first connected all the world's continents (except Antarctica) when Java was connected to Darwin, Northern Territory, Australia in 1871 in anticipation of the completion of the Australian Overland Telegraph Line in 1872 connecting to Adelaide, South Australia, and thence to the rest of Australia.

Early history: telegraph and coaxial cables

First successful trials

After William Cooke and Charles Wheatstone had introduced their working telegraph in 1839, the idea of a submarine line across the Atlantic Ocean began to be thought of as a possible triumph of the future. Samuel Morse proclaimed his faith in it as early as 1840, and in 1842, he submerged a wire, insulated with tarred hemp and India rubber, in the water of New York Harbor, and telegraphed through it. The following autumn, Wheatstone performed a similar experiment in Swansea Bay. A good insulator

to cover the wire and prevent the electric current from leaking into

the water was necessary for the success of a long submarine line. India rubber had been tried by Moritz von Jacobi, the Prussian electrical engineer, as far back as the early 19th century.

Another insulating gum which could be melted by heat and readily applied to wire made its appearance in 1842. Gutta-percha, the adhesive juice of the Palaquium gutta tree, was introduced to Europe by William Montgomerie, a Scottish surgeon in the service of the British East India Company. Twenty years earlier, Montgomerie had seen whips made of gutta-percha in Singapore, and he believed that it would be useful in the fabrication of surgical apparatus. Michael Faraday

and Wheatstone soon discovered the merits of gutta-percha as an

insulator, and in 1845, the latter suggested that it should be employed

to cover the wire which was proposed to be laid from Dover to Calais. It was tried on a wire laid across the Rhine between Deutz and Cologne. In 1849, Charles Vincent Walker, electrician to the South Eastern Railway, submerged a two-mile wire coated with gutta-percha off the coast from Folkestone, which was tested successfully.

First commercial cables

A telegraph stamp of the British & Irish Magnetic Telegraph Co. Limited (c. 1862).

In August 1850, having earlier obtained a concession from the French government, John Watkins Brett's English Channel Submarine Telegraph Company laid the first line across the English Channel, using the converted tugboat Goliath. It was simply a copper wire coated with gutta-percha, without any other protection, and was not successful.

However, the experiment served to secure renewal of the concession,

and in September 1851, a protected core, or true, cable was laid by the

reconstituted Submarine Telegraph Company from a government hulk, Blazer, which was towed across the Channel.

In 1853, more successful cables were laid, linking Great Britain with Ireland, Belgium, and the Netherlands, and crossing The Belts in Denmark. The British & Irish Magnetic Telegraph Company completed the first successful Irish link on May 23 between Portpatrick and Donaghadee using the collier William Hutt. The same ship was used for the link from Dover to Ostend in Belgium, by the Submarine Telegraph Company. Meanwhile, the Electric & International Telegraph Company completed two cables across the North Sea, from Orford Ness to Scheveningen, the Netherlands. These cables were laid by Monarch, a paddle steamer which later became the first vessel with permanent cable-laying equipment.

In 1858, the steamship Elba was used to lay a telegraph cable from Jersey to Guernsey, on to Alderney and then to Weymouth,

the cable being completed successfully in September of that year.

Problems soon developed with eleven breaks occurring by 1860 due to

storms, tidal and sand movements, and wear on rocks. A report to the

Institution of Civil Engineers in 1860 set out the problems to assist in

future cable-laying operations.

Transatlantic telegraph cable

The first attempt at laying a transatlantic telegraph cable was promoted by Cyrus West Field, who persuaded British industrialists to fund and lay one in 1858.

However, the technology of the day was not capable of supporting the

project; it was plagued with problems from the outset, and was in

operation for only a month. Subsequent attempts in 1865 and 1866 with

the world's largest steamship, the SS Great Eastern, used a more advanced technology and produced the first successful transatlantic cable. Great Eastern later went on to lay the first cable reaching to India from Aden, Yemen, in 1870.

British dominance of early cable

Operators in the submarine telegraph cable room at the GPO's Central Telegraph Office in London c. 1898

From the 1850s until 1911, British submarine cable systems dominated the most important market, the North Atlantic Ocean.

The British had both supply side and demand side advantages. In terms

of supply, Britain had entrepreneurs willing to put forth enormous

amounts of capital necessary to build, lay and maintain these cables. In

terms of demand, Britain's vast colonial empire

led to business for the cable companies from news agencies, trading and

shipping companies, and the British government. Many of Britain's

colonies had significant populations of European settlers, making news

about them of interest to the general public in the home country.

British officials believed that depending on telegraph lines that

passed through non-British territory posed a security risk, as lines

could be cut and messages could be interrupted during wartime. They

sought the creation of a worldwide network within the empire, which

became known as the All Red Line, and conversely prepared strategies to quickly interrupt enemy communications. Britain's very first action after declaring war on Germany in World War I was to have the cable ship Alert (not the CS Telconia as frequently reported) cut the five cables linking Germany with France, Spain and the Azores, and through them, North America. Thereafter, the only way Germany could communicate was by wireless, and that meant that Room 40 could listen in.

The submarine cables were an economic benefit to trading

companies, because owners of ships could communicate with captains when

they reached their destination and give directions as to where to go

next to pick up cargo based on reported pricing and supply information.

The British government had obvious uses for the cables in maintaining

administrative communications with governors throughout its empire, as

well as in engaging other nations diplomatically and communicating with

its military units in wartime. The geographic location of British

territory was also an advantage as it included both Ireland on the east

side of the Atlantic Ocean and Newfoundland in North America on the west

side, making for the shortest route across the ocean, which reduced

costs significantly.

A few facts put this dominance of the industry in perspective. In

1896, there were 30 cable-laying ships in the world, 24 of which were

owned by British companies. In 1892, British companies owned and

operated two-thirds of the world's cables and by 1923, their share was

still 42.7 percent. During World War I,

Britain's telegraph communications were almost completely

uninterrupted, while it was able to quickly cut Germany's cables

worldwide.

Cable to India, Singapore, Far East and Australia

Eastern Telegraph Company network in 1901. Dotted lines across the Pacific indicate then-planned cables laid in 1902–03.

Throughout the 1860s and 1870s, British cable expanded eastward, into

the Mediterranean Sea and the Indian Ocean. An 1863 cable to Bombay

(now Mumbai), India, provided a crucial link to Saudi Arabia.

In 1870, Bombay was linked to London via submarine cable in a combined

operation by four cable companies, at the behest of the British

Government. In 1872, these four companies were combined to form the

mammoth globe-spanning Eastern Telegraph Company, owned by John Pender.

A spinoff from Eastern Telegraph Company was a second sister company,

the Eastern Extension, China and Australasia Telegraph Company, commonly

known simply as "the Extension". In 1872, Australia was linked by cable

to Bombay via Singapore and China and in 1876, the cable linked the

British Empire from London to New Zealand.

Submarine cables across the Pacific

The first trans-Pacific cables providing telegraph service were completed in 1902 and 1903, linking the U.S mainland to Hawaii in 1902 and Guam to the Philippines in 1903. Canada, Australia, New Zealand and Fiji were also linked in 1902 with the trans-Pacific segment of the All Red Line.

Japan was connected into the system in 1906. Service beyond Midway

Atoll was abandoned in 1941 due to World War II, but the remainder

remained in operation until 1951 when the FCC gave permission to cease

operations.

The first trans-Pacific telephone cable was laid from Hawaii to Japan in 1964, with an extension from Guam to The Philippines.

Also in 1964, the Commonwealth Pacific (COMPAC) cable, with 80

telephone channel capacity, opened for traffic from Sydney to Vancouver,

and in 1967, the South East Asia Commonwealth (SEACOM) system, with 160

telephone channel capacity, opened for traffic. This system used

microwave radio from Sydney to Cairns (Queensland), cable running from Cairns to Madang (Papua New Guinea), Guam, Hong Kong, Kota Kinabalu (capital of Sabah, Malaysia), Singapore, then overland by microwave radio to Kuala Lumpur. In 1991, the North Pacific Cable system was the first regenerative system (i.e., with repeaters)

to completely cross the Pacific from the U.S. mainland to Japan. The

U.S. portion of NPC was manufactured in Portland, Oregon, from 1989 to

1991 at STC Submarine Systems, and later Alcatel Submarine Networks. The

system was laid by Cable & Wireless Marine on the CS Cable Venture.

Construction

Transatlantic

cables of the 19th century consisted of an outer layer of iron and

later steel wire, wrapping India rubber, wrapping gutta-percha,

which surrounded a multi-stranded copper wire at the core. The portions

closest to each shore landing had additional protective armor wires.

Gutta-percha, a natural polymer similar to rubber, had nearly ideal

properties for insulating submarine cables, with the exception of a

rather high dielectric constant which made cable capacitance high. Gutta-percha was not replaced as a cable insulation until polyethylene

was introduced in the 1930s. Even then, the material was only available

to the military and the first submarine cable using it was not laid

until 1945 during World War II across the English Channel.

In the 1920s, the American military experimented with rubber-insulated

cables as an alternative to gutta-percha, since American interests

controlled significant supplies of rubber but did not have easy access

to gutta-percha manufacturers. The 1926 development by John T. Blake of deproteinized rubber improved the impermeability of cables to water.

Many early cables suffered from attack by sealife. The insulation could be eaten, for instance, by species of Teredo (shipworm) and Xylophaga. Hemp laid between the steel wire armouring gave pests a route to eat their way in. Damaged armouring, which was not uncommon, also provided an entrance. Cases of sharks biting cables and attacks by sawfish have been recorded. In one case in 1873, a whale damaged the Persian Gulf Cable between Karachi and Gwadar. The whale was apparently attempting to use the cable to clean off barnacles

at a point where the cable descended over a steep drop. The

unfortunate whale got its tail entangled in loops of cable and drowned.

The cable repair ship Amber Witch was only able to winch up the cable with difficulty, weighed down as it was with the dead whale's body.

Bandwidth problems

Early

long-distance submarine telegraph cables exhibited formidable

electrical problems. Unlike modern cables, the technology of the 19th

century did not allow for in-line repeater amplifiers in the cable. Large voltages were used to attempt to overcome the electrical resistance of their tremendous length but the cables' distributed capacitance and inductance combined to distort the telegraph pulses in the line, reducing the cable's bandwidth, severely limiting the data rate for telegraph operation to 10–12 words per minute.

As early as 1816, Francis Ronalds

had observed that electric signals were retarded in passing through an

insulated wire or core laid underground, and outlined the cause to be

induction, using the analogy of a long Leyden jar. The same effect was noticed by Latimer Clark (1853) on cores immersed in water, and particularly on the lengthy cable between England and The Hague. Michael Faraday showed that the effect was caused by capacitance between the wire and the earth

(or water) surrounding it. Faraday had noticed that when a wire is

charged from a battery (for example when pressing a telegraph key), the electric charge

in the wire induces an opposite charge in the water as it travels

along. In 1831, Faraday described this effect in what is now referred to

as Faraday's law of induction. As the two charges attract each other, the exciting charge is retarded. The core acts as a capacitor distributed along the length of the cable which, coupled with the resistance and inductance of the cable, limits the speed at which a signal travels through the conductor of the cable.

Early cable designs failed to analyze these effects correctly. Famously, E.O.W. Whitehouse

had dismissed the problems and insisted that a transatlantic cable was

feasible. When he subsequently became electrician of the Atlantic Telegraph Company, he became involved in a public dispute with William Thomson.

Whitehouse believed that, with enough voltage, any cable could be

driven. Because of the excessive voltages recommended by Whitehouse,

Cyrus West Field's first transatlantic cable never worked reliably, and

eventually short circuited to the ocean when Whitehouse increased the voltage beyond the cable design limit.

Thomson designed a complex electric-field generator that minimized current by resonating the cable, and a sensitive light-beam mirror galvanometer

for detecting the faint telegraph signals. Thomson became wealthy on

the royalties of these, and several related inventions. Thomson was

elevated to Lord Kelvin for his contributions in this area, chiefly an accurate mathematical model of the cable, which permitted design of the equipment for accurate telegraphy. The effects of atmospheric electricity and the geomagnetic field on submarine cables also motivated many of the early polar expeditions.

Thomson had produced a mathematical analysis of propagation of

electrical signals into telegraph cables based on their capacitance and

resistance, but since long submarine cables operated at slow rates, he

did not include the effects of inductance. By the 1890s, Oliver Heaviside had produced the modern general form of the telegrapher's equations, which included the effects of inductance and which were essential to extending the theory of transmission lines to higher frequencies required for high-speed data and voice.

Transatlantic telephony

While laying a transatlantic telephone cable was seriously considered

from the 1920s, the technology required for economically feasible

telecommunications was not developed until the 1940s. A first attempt to

lay a pupinized telephone cable failed in the early 1930s due to the Great Depression.

In 1942, Siemens Brothers of New Charlton, London, in conjunction with the United Kingdom National Physical Laboratory, adapted submarine communications cable technology to create the world's first submarine oil pipeline in Operation Pluto during World War II.

TAT-1 (Transatlantic No. 1) was the first transatlantic telephone cable system. Between 1955 and 1956, cable was laid between Gallanach Bay, near Oban, Scotland and Clarenville, Newfoundland and Labrador. It was inaugurated on September 25, 1956, initially carrying 36 telephone channels.

In the 1960s, transoceanic cables were coaxial cables that transmitted frequency-multiplexed voiceband signals.

A high-voltage direct current on the inner conductor powered repeaters

(two-way amplifiers placed at intervals along the cable). The

first-generation repeaters remain among the most reliable vacuum tube amplifiers ever designed.

Later ones were transistorized. Many of these cables are still usable,

but have been abandoned because their capacity is too small to be

commercially viable. Some have been used as scientific instruments to

measure earthquake waves and other geomagnetic events.

Modern history

Optical telephone cables

2007 map of submarine cables

In the 1980s, fiber optic cables were developed. The first transatlantic telephone cable to use optical fiber was TAT-8,

which went into operation in 1988. A fiber-optic cable comprises

multiple pairs of fibers. Each pair has one fiber in each direction.

TAT-8 had two operational pairs and one backup pair.

Modern optical fiber repeaters use a solid-state optical amplifier, usually an Erbium-doped fiber amplifier.

Each repeater contains separate equipment for each fiber. These

comprise signal reforming, error measurement and controls. A solid-state

laser dispatches the signal into the next length of fiber. The

solid-state laser excites a short length of doped fiber that itself acts

as a laser amplifier. As the light passes through the fiber, it is

amplified. This system also permits wavelength-division multiplexing, which dramatically increases the capacity of the fiber.

Repeaters are powered by a constant direct current passed down

the conductor near the center of the cable, so all repeaters in a cable

are in series. Power feed equipment is installed at the terminal

stations. Typically both ends share the current generation with one end

providing a positive voltage and the other a negative voltage. A virtual earth

point exists roughly halfway along the cable under normal operation.

The amplifiers or repeaters derive their power from the potential

difference across them.

The optic fiber used in undersea cables is chosen for its

exceptional clarity, permitting runs of more than 100 kilometres (62 mi)

between repeaters to minimize the number of amplifiers and the

distortion they cause.

Diagram of an optical submarine cable repeater

The rising demand for these fiber-optic cables outpaced the capacity of providers such as AT&T.

Having to shift traffic to satellites resulted in lower-quality

signals. To address this issue, AT&T had to improve its cable-laying

abilities. It invested $100 million in producing two specialized

fiber-optic cable laying vessels. These included laboratories in the

ships for splicing cable and testing its electrical properties. Such

field monitoring is important because the glass of fiber-optic cable is

less malleable than the copper cable that had been formerly used. The

ships are equipped with thrusters

that increase maneuverability. This capability is important because

fiber-optic cable must be laid straight from the stern, which was

another factor that copper-cable-laying ships did not have to contend

with.

Originally, submarine cables were simple point-to-point connections. With the development of submarine branching units

(SBUs), more than one destination could be served by a single cable

system. Modern cable systems now usually have their fibers arranged in a

self-healing ring to increase their redundancy, with the submarine sections following different paths on the ocean floor.

One reason for this development was that the capacity of cable systems

had become so large that it was not possible to completely backup a

cable system with satellite capacity, so it became necessary to provide

sufficient terrestrial backup capability. Not all telecommunications

organizations wish to take advantage of this capability, so modern cable

systems may have dual landing points

in some countries (where back-up capability is required) and only

single landing points in other countries where back-up capability is

either not required, the capacity to the country is small enough to be

backed up by other means, or having backup is regarded as too expensive.

A further redundant-path development over and above the

self-healing rings approach is the "Mesh Network" whereby fast switching

equipment is used to transfer services between network paths with

little to no effect on higher-level protocols if a path becomes

inoperable. As more paths become available to use between two points,

the less likely it is that one or two simultaneous failures will prevent

end-to-end service.

As of 2012, operators had "successfully demonstrated long-term,

error-free transmission at 100 Gbps across Atlantic Ocean" routes of up

to 6,000 km (3,700 mi), meaning a typical cable can move tens of terabits

per second overseas. Speeds improved rapidly in the previous few years,

with 40 Gbit/s having been offered on that route only three years

earlier in August 2009.

Switching and all-by-sea routing commonly increases the distance

and thus the round trip latency by more than 50%. For example, the round

trip delay (RTD) or latency of the fastest transatlantic connections is

under 60 ms, close to the theoretical optimum for an all-sea route.

While in theory, a great circle route (GCP) between London and New York City is only 5,600 km (3,500 mi), this requires several land masses (Ireland, Newfoundland, Prince Edward Island and the isthmus connecting New Brunswick to Nova Scotia) to be traversed, as well as the extremely tidal Bay of Fundy and a land route along Massachusetts' north shore from Gloucester to Boston and through fairly built up areas to Manhattan

itself. In theory, using this partial land route could result in round

trip times below 40 ms (which is the speed of light minimum time), and

not counting switching. Along routes with less land in the way, round

trip times can approach speed of light minimums in the long term.

Importance of submarine cables

Currently 99% of the data traffic that is crossing oceans is carried by undersea cables.

The reliability of submarine cables is high, especially when (as noted

above) multiple paths are available in the event of a cable break. Also,

the total carrying capacity of submarine cables is in the terabits per second, while satellites typically offer only 1,000 megabits per second and display higher latency. However, a typical multi-terabit, transoceanic submarine cable system costs several hundred million dollars to construct.

As a result of these cables' cost and usefulness, they are highly

valued not only by the corporations building and operating them for

profit, but also by national governments. For instance, the Australian government considers its submarine cable systems to be "vital to the national economy". Accordingly, the Australian Communications and Media Authority

(ACMA) has created protection zones that restrict activities that could

potentially damage cables linking Australia to the rest of the world.

The ACMA also regulates all projects to install new submarine cables.

Submarine cables are important to the modern military as well as private enterprise. The U.S. military,

for example, uses the submarine cable network for data transfer from

conflict zones to command staff in the United States. Interruption of

the cable network during intense operations could have direct

consequences for the military on the ground.

Investment in and financing of submarine cables

A map of active and anticipated submarine communications cables servicing the African continent.

Almost all fiber-optic cables from TAT-8 in 1988 until approximately

1997 were constructed by "consortia" of operators. For example, TAT-8

counted 35 participants including most major international carriers at

the time such as AT&T Corporation.

Two privately financed, non-consortium cables were constructed in the

late 1990s, which preceded a massive, speculative rush to construct

privately financed cables that peaked in more than $22 billion worth of

investment between 1999 and 2001. This was followed by the bankruptcy

and reorganization of cable operators such as Global Crossing, 360networks, FLAG, Worldcom, and Asia Global Crossing.

There has been an increasing tendency in recent years to expand submarine cable capacity in the Pacific Ocean

(the previous bias always having been to lay communications cable

across the Atlantic Ocean which separates the United States and Europe).

For example, between 1998 and 2003, approximately 70% of undersea

fiber-optic cable was laid in the Pacific. This is in part a response to

the emerging significance of Asian markets in the global economy.

Although much of the investment in submarine cables has been

directed toward developed markets such as the transatlantic and

transpacific routes, in recent years there has been an increased effort

to expand the submarine cable network to serve the developing world. For

instance, in July 2009, an underwater fiber-optic cable line plugged East Africa into the broader Internet. The company that provided this new cable was SEACOM, which is 75% owned by Africans. The project was delayed by a month due to increased piracy along the coast.

Antarctica

Antarctica

is the only continent not yet reached by a submarine telecommunications

cable. All phone, video, and e-mail traffic must be relayed to the rest

of the world via satellite links that have limited availability and capacity. Bases on the continent itself are able to communicate with one another via radio,

but this is only a local network. To be a viable alternative, a

fiber-optic cable would have to be able to withstand temperatures of

−80 °C (−112 °F) as well as massive strain from ice flowing up to 10

metres (33 ft) per year. Thus, plugging into the larger Internet

backbone with the high bandwidth afforded by fiber-optic cable is still

an as-yet infeasible economic and technical challenge in the Antarctic.

Cable repair

An animation showing a method used to repair submarine communications cables.

Cables can be broken by fishing trawlers, anchors, earthquakes, turbidity currents, and even shark bites.

Based on surveying breaks in the Atlantic Ocean and the Caribbean Sea,

it was found that between 1959 and 1996, fewer than 9% were due to

natural events. In response to this threat to the communications

network, the practice of cable burial has developed. The average

incidence of cable faults was 3.7 per 1,000 km (620 mi) per year from

1959 to 1979. That rate was reduced to 0.44 faults per 1,000 km per year

after 1985, due to widespread burial of cable starting in 1980. Still, cable breaks are by no means a thing of the past, with more than 50 repairs a year in the Atlantic alone, and significant breaks in 2006, 2008, and 2009.

The propensity for fishing trawler nets to cause cable faults may well have been exploited during the Cold War.

For example, in February 1959, a series of 12 breaks occurred in five

American trans-Atlantic communications cables. In response, a United

States naval vessel, the U.S.S. Roy O. Hale, detained and investigated the Soviet trawler Novorosiysk.

A review of the ship's log indicated it had been in the region of each

of the cables when they broke. Broken sections of cable were also found

on the deck of the Novorosiysk. It appeared that the cables had

been dragged along by the ship's nets, and then cut once they were

pulled up onto the deck to release the nets. The Soviet Union's stance

on the investigation was that it was unjustified, but the United States

cited the Convention for the Protection of Submarine Telegraph Cables

of 1884 to which Russia had signed (prior to the formation of the

Soviet Union) as evidence of violation of international protocol.

Shore stations can locate a break in a cable by electrical measurements, such as through spread-spectrum time-domain reflectometry

(SSTDR), a type of time-domain reflectometry that can be used in live

environments very quickly. Presently, SSTDR can collect a complete data

set in 20 ms.

Spread spectrum signals are sent down the wire and then the reflected

signal is observed. It is then correlated with the copy of the sent

signal and algorithms are applied to the shape and timing of the signals

to locate the break.

A cable repair ship will be sent to the location to drop a marker buoy near the break. Several types of grapples

are used depending on the situation. If the sea bed in question is

sandy, a grapple with rigid prongs is used to plough under the surface

and catch the cable. If the cable is on a rocky sea surface, the grapple

is more flexible, with hooks along its length so that it can adjust to

the changing surface.

In especially deep water, the cable may not be strong enough to lift as

a single unit, so a special grapple that cuts the cable soon after it

has been hooked is used and only one length of cable is brought to the

surface at a time, whereupon a new section is spliced in. The repaired cable is longer than the original, so the excess is deliberately laid in a "U" shape on the seabed. A submersible can be used to repair cables that lie in shallower waters.

A number of ports near important cable routes became homes to specialised cable repair ships. Halifax, Nova Scotia was home to a half dozen such vessels for most of the 20th century including long-lived vessels such as the CS Cyrus West Field, CS Minia and CS Mackay-Bennett. The latter two were contracted to recover victims from the sinking of the RMS Titanic. The crews of these vessels developed many new techniques and devices to repair and improve cable laying, such as the "plough".

Intelligence gathering

Underwater

cables, which cannot be kept under constant surveillance, have tempted

intelligence-gathering organizations since the late 19th century.

Frequently at the beginning of wars, nations have cut the cables of the

other sides to redirect the information flow into cables that were being

monitored. The most ambitious efforts occurred in World War I,

when British and German forces systematically attempted to destroy the

others' worldwide communications systems by cutting their cables with

surface ships or submarines. During the Cold War, the United States Navy and National Security Agency (NSA) succeeded in placing wire taps on Soviet underwater communication lines in Operation Ivy Bells.

Environmental impact

The main point of interaction of cables with marine life is in the benthic zone

of the oceans where the majority of cable lies. Studies in 2003 and

2006 indicated that cables pose minimal impacts on life in these

environments. In sampling sediment cores around cables and in areas

removed from cables, there were few statistically significant

differences in organism diversity or abundance. The main difference was

that the cables provided an attachment point for anemones that typically

could not grow in soft sediment areas. Data from 1877 to 1955 showed a

total of 16 cable faults caused by the entanglement of various whales.

Such deadly entanglements have entirely ceased with improved techniques

for placement of modern coaxial and fiber-optic cables which have less

tendency to self-coil when lying on the seabed.

Security implications

Submarine

cables are problematic from the security perspective because maps of

submarine cables are widely available. Publicly available maps are

necessary so that shipping can avoid damaging vulnerable cables by

accident. However, the availability of the locations of easily damaged

cables means the information is also easily accessible to criminal

agents. Governmental wiretapping also presents cybersecurity issues.

Legal issues

Submarine

cables are suffering from the inherent issue stemming from the

historically established practice of cable laying. Since the cable

connection is usually done by the private consortiums, there is a

problem with responsibility in the beginning. Firstly, deciding the

responsibility inside consortium can prove tricky on itself, since there

is not a one clearly leading company which could be designed as

responsible it could lead to confusion when it is needed to decide who

should be taking care about the cable. Secondly, it is hard to navigate

the issue of cable damage through the international legal regime, since

the regime was signed by and design for the states, not for private

companies. Thus it is hard to decide who should be responsible for the

damage costs and repairs, the company who built the cable, the company

who paid the cable, the government from where the cable originated, or

the government where the cable ends.

Another legal issue from which is the internal submarine cable

regime suffering is the ageing of the legal system, for example,

Australia still uses the fines which were priced during the signing of

the 1884 submarine cable treaty and sides which commits transgressions

over the cables are fined with, for today almost irrelevant, 2000

Australian dollars.

Influence of cable networks on modern history

Submarine

communication cables have had a wide variety of influences over

society. As well as allowing effective intercontinental trading and

supporting stock exchanges, they greatly influenced international

diplomatic conduct. Before the existence of submarine communication

connection diplomats had much more power in their hands since their

direct supervisors (governments of the countries which they represented)

could not immediately check on them. Getting instructions to the

diplomats in a foreign country often took weeks or even months.

Diplomats had to use their own initiative in negotiations with foreign

countries with only an occasional check from their government. This slow

connection resulted in diplomats engaging in leisure activities while

they waited for orders. The expansion of telegraph cables greatly

reduced the response time needed to instruct diplomats. Over time, this

led to a general decrease in prestige and power of individual diplomats

within international politics and signaled a professionalization of the

diplomatic corps who had to abandon their leisure activities.

Notable events

During testing of the TAT-8 fibre cable conducted by AT&T in the Canary Islands

area, shark bite damage to the cable occurred. This revealed that

sharks will dive to depths of one kilometre, a depth which surprised

marine biologists who until then thought that sharks were not active at

such depths.

The Newfoundland earthquake of 1929 broke a series of transatlantic cables by triggering a massive undersea mudslide. The sequence of breaks helped scientists chart the progress of the mudslide.

In July 2005, a portion of the SEA-ME-WE 3 submarine cable located 35 kilometres (22 mi) south of Karachi that provided Pakistan's

major outer communications became defective, disrupting almost all of

Pakistan's communications with the rest of the world, and affecting

approximately 10 million Internet users. On 26 December 2006, the 2006 Hengchun earthquake rendered numerous cables between Taiwan and Philippines inoperable.

In March 2007, pirates stole an 11-kilometre (7 mi) section of the T-V-H submarine cable that connected Thailand, Vietnam, and Hong Kong, afflicting Vietnam's Internet users with far slower speeds. The thieves attempted to sell the 100 tons of cable as scrap.

The 2008 submarine cable disruption was a series of cable outages, two of the three Suez Canal cables, two disruptions in the Persian Gulf, and one in Malaysia. It caused massive communications disruptions to India and the Middle East.

In April 2010, the undersea cable SEA-ME-WE 4

was under an outage. The Southeast Asia – Middle East – Western Europe 4

(SEA-ME-WE 4) submarine communications cable system, which connects

Southeast Asia and Europe, was reportedly cut in three places, off Palermo, Italy.

The 2011 Tōhoku earthquake and tsunami damaged a number of undersea cables that make landings in Japan, including:

- APCN-2, an intra-Asian cable that forms a ring linking China, Hong Kong, Japan, the Republic of Korea, Malaysia, the Philippines, Singapore, and Taiwan

- Pacific Crossing West and Pacific Crossing North

- Segments of the East Asia Crossing network (reported by PacNet)

- A segment of the Japan–U.S. Cable Network (reported by Korea Telecom)

- PC-1 submarine cable system (reported by NTT)

In February 2012, breaks in the EASSy and TEAMS cables disconnected about half of the networks in Kenya and Uganda from the global Internet.

In March 2013, the SEA-ME-WE-4 connection from France to Singapore was cut by divers near Egypt.

In November 2014 the SEA-ME-WE 3 stopped all traffic from Perth, Australia, to Singapore due to an unknown cable fault.

In August 2017, a fault in IMEWE (India-Middle East-Western Europe) undersea cable near Jeddah, Saudi Arabia,

disrupted the internet in Pakistan. The IMEWE submarine cable is an

ultra-high capacity fiber optic undersea cable system which links India

and Europe via the Middle East. The 12,091 km long cable has nine

terminal stations, operated by leading telecom carriers from eight

countries.

AAE-1, spanning over 25,000 kilometers, connects Southeast Asia to Europe via Egypt. Construction was finished in 2017.