From Wikipedia, the free encyclopedia

|

|

Photovoltaic power systems and components:

Top: solar string inverter and other BOS components · Solar array on rooftop in Hong Kong, China · BIPV on balcony in Helsinki, Finland

Middle: rooftop system in Boston, United States · Westmill solar park in the United Kingdom · Dual axis tracker with CPV modules · Topaz, one of the world's largest solar power station, as seen from space

Bottom: commercial rooftop PV system of about 400 kWp · Power plant on Mt. Komekura, Japan · Solar PV system on Zugspitze, Germany's highest mountain-top

|

A photovoltaic system, also PV system or solar power system, is an electric power system designed to supply usable solar power by means of photovoltaics. It consists of an arrangement of several components, including solar panels to absorb and convert sunlight into electricity, a solar inverter to convert the output from direct to alternating current, as well as mounting, cabling, and other electrical accessories to set up a working system. It may also use a solar tracking system to improve the system's overall performance and include an integrated battery.

PV systems convert light directly into electricity, and are not to be confused with other solar technologies, such as concentrated solar power or solar thermal, used for heating and cooling. A solar array

only encompasses the ensemble of solar panels, the visible part of the

PV system, and does not include all the other hardware, often summarized

as balance of system (BOS). PV systems range from small, rooftop-mounted or building-integrated systems with capacities from a few to several tens of kilowatts, to large utility-scale power stations of hundreds of megawatts. Nowadays, most PV systems are grid-connected, while off-grid or stand-alone systems account for a small portion of the market.

Operating silently and without any moving parts or environmental emissions,

PV systems have developed from being niche market applications into a

mature technology used for mainstream electricity generation. A rooftop

system recoups the invested energy for its manufacturing and installation within 0.7 to 2 years and produces about 95 percent of net clean renewable energy over a 30-year service lifetime.

Due to the growth of photovoltaics,

prices for PV systems have rapidly declined since their introduction;

however, they vary by market and the size of the system. In 2014, prices

for residential 5-kilowatt systems in the United States were around $3.29 per watt, while in the highly penetrated German market, prices for rooftop systems of up to 100 kW declined to €1.24 per watt. Nowadays, solar PV modules account for less than half of the system's overall cost,

leaving the rest to the remaining BOS-components and to soft costs,

which include customer acquisition, permitting, inspection and

interconnection, installation labor and financing costs.

Modern system

Overview

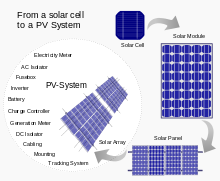

Diagram of the possible components of a photovoltaic system

A photovoltaic system converts the Sun's radiation, in the form of light, into usable electricity. It comprises the solar array and the balance of system components. PV systems can be categorized by various aspects, such as, grid-connected vs. stand alone systems, building-integrated vs. rack-mounted systems, residential vs. utility systems, distributed vs. centralized systems, rooftop vs. ground-mounted systems, tracking vs. fixed-tilt systems, and new constructed vs. retrofitted systems. Other distinctions may include, systems with microinverters vs. central inverter, systems using crystalline silicon vs. thin-film technology, and systems with modules.

About 99 percent of all European and 90 percent of all U.S. solar power systems are connected to the electrical grid, while off-grid systems are somewhat more common in Australia and South Korea.

PV systems rarely use battery storage. This may change, as government

incentives for distributed energy storage are implemented and

investments in storage solutions gradually become economically viable

for small systems.

A typical residential solar array is rack-mounted on the roof, rather

than integrated into the roof or facade of the building, which is

significantly more expensive. Utility-scale solar power stations

are ground-mounted, with fixed tilted solar panels rather than using

expensive tracking devices. Crystalline silicon is the predominant

material used in 90 percent of worldwide produced solar modules, while

its rival thin-film has lost market-share. About 70 percent of all solar cells and modules are produced in China and Taiwan, only 5 percent by European and US-manufacturers.

The installed capacity for both small rooftop systems and large solar

power stations is growing rapidly and in equal parts, although there is a

notable trend towards utility-scale systems, as the focus on new

installations is shifting away from Europe to sunnier regions, such as

the Sunbelt in the U.S., which are less opposed to ground-mounted solar farms and cost-effectiveness is more emphasized by investors.

Driven by advances in technology and increases in manufacturing

scale and sophistication, the cost of photovoltaics is declining

continuously.

There are several million PV systems distributed all over the world,

mostly in Europe, with 1.4 million systems in Germany alone – as well as North America with 440,000 systems in the United States. The energy conversion efficiency of a conventional solar module increased from 15 to 20 percent since 2004

and a PV system recoups the energy needed for its manufacture in about 2

years. In exceptionally irradiated locations, or when thin-film

technology is used, the so-called energy payback time decreases to one year or less.

Net metering and financial incentives, such as preferential feed-in tariffs for solar-generated electricity, have also greatly supported installations of PV systems in many countries. The levelised cost of electricity

from large-scale PV systems has become competitive with conventional

electricity sources in an expanding list of geographic regions, and grid parity has been achieved in about 30 countries.

As of 2015, the fast-growing global PV market is rapidly approaching the 200 GW mark – about 40 times the installed capacity in 2006. These systems currently contribute about 1 percent to worldwide electricity generation. Top installers of PV systems

in terms of capacity are currently China, Japan and the United States,

while half of the world's capacity is installed in Europe, with Germany

and Italy supplying 7% to 8% of their respective domestic electricity

consumption with solar PV. The International Energy Agency expects solar power to become the world's largest source of electricity by 2050, with solar photovoltaics and concentrated solar thermal contributing 16% and 11% to the global demand, respectively.

Solar grid-connection

Schematics of a typical residential PV system

A grid connected system is connected to a larger independent grid

(typically the public electricity grid) and feeds energy directly into

the grid. This energy may be shared by a residential or commercial

building before or after the revenue measurement point, depending on

whether the credited energy production is calculated independently of

the customer's energy consumption (feed-in tariff) or only on the difference of energy (net metering). These systems vary in size from residential (2–10 kWp) to solar power stations (up to 10s of MWp). This is a form of decentralized electricity generation. Feeding electricity into the grid requires the transformation of DC into AC by a special, synchronising grid-tie inverter.

In kilowatt-sized installations the DC side system voltage is as high

as permitted (typically 1000 V except US residential 600 V) to limit

ohmic losses. Most modules (60 or 72 crystalline silicon cells) generate

160 W to 300 W at 36 volts. It is sometimes necessary or desirable to

connect the modules partially in parallel rather than all in series. An

individual set of modules connected in series is known as a 'string'.

Scale of system

Photovoltaic

systems are generally categorized into three distinct market segments:

residential rooftop, commercial rooftop, and ground-mount utility-scale

systems. Their capacities range from a few kilowatts to hundreds of

megawatts. A typical residential system is around 10 kilowatts and

mounted on a sloped roof, while commercial systems may reach a

megawatt-scale and are generally installed on low-slope or even flat

roofs. Although rooftop mounted systems are small and have a higher cost per watt

than large utility-scale installations, they account for the largest

share in the market. There is, however, a growing trend towards bigger

utility-scale power plants, especially in the "sunbelt" region of the

planet.

Utility-scale

Large utility-scale solar parks or farms are power stations and capable of providing an energy supply to large numbers of consumers. Generated electricity

is fed into the transmission grid powered by central generation plants

(grid-connected or grid-tied plant), or combined with one, or many,

domestic electricity generators to feed into a small electrical grid (hybrid plant). In rare cases generated electricity is stored or used directly by island/standalone plant.

PV systems are generally designed in order to ensure the highest energy

yield for a given investment. Some large photovoltaic power stations

such as Solar Star, Waldpolenz Solar Park and Topaz Solar Farm cover tens or hundreds of hectares and have power outputs up to hundreds of megawatts.

Rooftop, mobile, and portable

A small PV system is capable of providing enough AC electricity to

power a single home, or an isolated device in the form of AC or DC

electric. Military and civilian Earth observation satellites, street lights, construction and traffic signs, electric cars, solar-powered tents, and electric aircraft may contain integrated photovoltaic systems to provide a primary or auxiliary power

source in the form of AC or DC power, depending on the design and power

demands. In 2013, rooftop systems accounted for 60 percent of worldwide

installations. However, there is a trend away from rooftop and towards

utility-scale PV systems, as the focus of new PV installations is also

shifting from Europe to countries in the sunbelt region of the planet

where opposition to ground-mounted solar farms is less accentuated.

Portable and mobile PV systems provide electrical power independent of

utility connections, for "off the grid" operation. Such systems are so

commonly used on recreational vehicles

and boats that there are retailers specializing in these applications

and products specifically targeted to them. Since recreational vehicles

(RV) normally carry batteries and operate lighting and other systems on

nominally 12-volt DC power, RV systems normally operate in a voltage

range that can charge 12-volt batteries directly, so addition of a PV

system requires only panels, a charge controller, and wiring. Solar

systems on recreation vehicles are usually constrained in wattage by the

physical size of the RV's roof space.

Building-integrated

BAPV wall near Barcelona, Spain

In urban and suburban areas, photovoltaic arrays are often used on

rooftops to supplement power use; often the building will have a

connection to the power grid, in which case the energy produced by the PV array can be sold back to the utility in some sort of net metering agreement. Some utilities use the rooftops of commercial customers and telephone poles to support their use of PV panels. Solar trees are arrays that, as the name implies, mimic the look of trees, provide shade, and at night can function as street lights.

Performance

Uncertainties in revenue over time relate mostly to the evaluation of

the solar resource and to the performance of the system itself. In the

best of cases, uncertainties are typically 4% for year-to-year climate

variability, 5% for solar resource estimation (in a horizontal plane),

3% for estimation of irradiation in the plane of the array, 3% for power

rating of modules, 2% for losses due to dirt and soiling,

1.5% for losses due to snow, and 5% for other sources of error.

Identifying and reacting to manageable losses is critical for revenue

and O&M efficiency. Monitoring of array performance may be part of

contractual agreements between the array owner, the builder, and the

utility purchasing the energy produced. A method to create "synthetic days" using readily available weather data and verification using the Open Solar Outdoors Test Field make it possible to predict photovoltaic systems performance with high degrees of accuracy. This method can be used to then determine loss mechanisms on a local scale - such as those from snow or the effects of surface coatings (e.g. hydrophobic or hydrophilic) on soiling or snow losses. (Although in heavy snow environments with severe ground interference can result in annual losses from snow of 30%.)

Access to the Internet has allowed a further improvement in energy

monitoring and communication. Dedicated systems are available from a

number of vendors. For solar PV systems that use microinverters

(panel-level DC to AC conversion), module power data is automatically

provided. Some systems allow setting performance alerts that trigger

phone/email/text warnings when limits are reached. These solutions

provide data for the system owner and the installer. Installers are able

to remotely monitor multiple installations, and see at-a-glance the

status of their entire installed base.

Components

The

balance of system

components of a PV system (BOS) balance the power-generating subsystem

of the solar array (left side) with the power-using side of the

AC-household devices and the utility grid (right side).

A photovoltaic system for residential, commercial, or industrial

energy supply consists of the solar array and a number of components

often summarized as the balance of system (BOS). This term is synonymous with "Balance of plant" q.v. BOS-components include power-conditioning equipment and structures for mounting, typically one or more DC to AC power converters, also known as inverters,

an energy storage device, a racking system that supports the solar

array, electrical wiring and interconnections, and mounting for other

components.

Optionally, a balance of system may include any or all of the following: renewable energy credit revenue-grade meter, maximum power point tracker (MPPT), battery system and charger, GPS solar tracker, energy management software, solar irradiance sensors, anemometer, or task-specific accessories designed to meet specialized requirements for a system owner. In addition, a CPV system requires optical lenses or mirrors and sometimes a cooling system.

The terms "solar array" and "PV system" are often incorrectly

used interchangeably, despite the fact that the solar array does not

encompass the entire system. Moreover, "solar panel" is often used as a

synonym for "solar module", although a panel consists of a string of

several modules. The term "solar system" is also an often used misnomer for a PV system.

Solar array

The building blocks of a photovoltaic system are solar cells. A solar

cell is the electrical device that can directly convert photons energy

into electricity. There are three technological generations of solar

cells: the first generation (1G) of crystalline silicon cells (c-Si), the second generation (2G) of thin-film cells (such as CdTe, CIGS, Amorphous Silicon, and GaAs), and the third generation (3G) of organic, dye-sensitized, Perovskite and multijunction cells.

Conventional c-Si solar cells, normally wired in series, are encapsulated in a solar module to protect them from the weather. The module consists of a tempered glass as cover, a soft and flexible encapsulant, a rear backsheet made of a weathering and fire-resistant material

and an aluminium frame around the outer edge. Electrically connected

and mounted on a supporting structure, solar modules build a string of

modules, often called solar panel. A solar array consists of one or many

such panels.

A photovoltaic array, or solar array, is a linked collection of solar

modules. The power that one module can produce is seldom enough to meet

requirements of a home or a business, so the modules are linked together

to form an array. Most PV arrays use an inverter to convert the DC power produced by the modules into alternating current that can power lights, motors, and other loads. The modules in a PV array are usually first connected in series to obtain the desired voltage; the individual strings are then connected in parallel to allow the system to produce more current. Solar panels are typically measured under STC (standard test conditions) or PTC (PVUSA test conditions), in watts. Typical panel ratings range from less than 100 watts to over 400 watts. The array rating consists of a summation of the panel ratings, in watts, kilowatts, or megawatts.

Module and efficiency

A typical 150 watt PV module is about a square meter in size. Such a module may be expected to produce 0.75 kilowatt-hour

(kWh) every day, on average, after taking into account the weather and

the latitude, for an insolation of 5 sun hours/day. Module output and

life degraded by increased temperature. Allowing ambient air to flow

over, and if possible behind, PV modules reduces this problem. Effective

module lives are typically 25 years or more.

The payback period for an investment in a PV solar installation varies

greatly and is typically less useful than a calculation of return on investment. While it is typically calculated to be between 10 and 20 years, the financial payback period can be far shorter with incentives.

The temperature effect on photovoltaic modules is usually

quantified by means of some coefficients relating the variations of the

open‐circuit voltage, of the short‐circuit current, and of the maximum

power to temperature changes. In this paper, comprehensive experimental

guidelines to estimate the temperature coefficients.

Due to the low voltage of an individual solar cell (typically ca. 0.5V), several cells are wired (also see copper used in PV systems)

in series in the manufacture of a "laminate". The laminate is assembled

into a protective weatherproof enclosure, thus making a photovoltaic

module or solar panel.

Modules may then be strung together into a photovoltaic array. In 2012,

solar panels available for consumers have an efficiency of up to about

17%, while commercially available panels can go as far as 27%. It has been recorded that a group from The Fraunhofer Institute for Solar Energy Systems

have created a cell that can reach 44.7% efficiency, which makes

scientists' hopes of reaching the 50% efficiency threshold a lot more

feasible.

Shading and dirt

Photovoltaic cell electrical output is extremely sensitive to shading ("Christmas light effect"). When even a small portion of a cell, module, or array is shaded, with

the remainder is in sunlight, the output falls dramatically due to

internal 'short-circuiting' (the electrons reversing course through the

shaded portion of the p-n junction).

If the current drawn from the series string of cells is no greater than

the current that can be produced by the shaded cell, the current (and

so power) developed by the string is limited. If enough voltage is

available from the other cells in a string, current will be forced

through the cell by breaking down the junction in the shaded portion.

This breakdown voltage in common cells is between 10 and 30 volts.

Instead of adding to the power produced by the panel, the shaded cell

absorbs power, turning it into heat. Since the reverse voltage of a

shaded cell is much greater than the forward voltage of an illuminated

cell, one shaded cell can absorb the power of many other cells in the

string, disproportionately affecting panel output. For example, a shaded

cell may drop 8 volts, instead of adding 0.5 volts, at a particular

current level, thereby absorbing the power produced by 16 other cells. It is thus important that a PV installation is not shaded by trees or other obstructions.

Several methods have been developed to determine shading losses from trees to PV systems over both large regions using LiDAR, but also at an individual system level using 3D modeling software.

Most modules have bypass diodes between each cell or string of cells

that minimize the effects of shading and only lose the power of the

shaded portion of the array. The main job of the bypass diode is to

eliminate hot spots that form on cells that can cause further damage to

the array, and cause fires.

Sunlight can be absorbed by dust, snow, or other impurities at the surface of the module (collectively referred to as soiling).

Soiling reduces the light that strikes the cells, which in turn reduces

the power output of the PV system. Soiling losses aggregate over time,

and can become large without adequate cleaning. In 2018, the global

annual energy loss due to soiling was estimated to at least 3–4%.

However, soiling losses varies largely from region to region, and within regions.

Maintaining a clean module surface will increase output performance over

the life of the PV system. In one study performed in a snow-rich area (Ontario),

cleaning flat mounted solar panels after 15 months increased their

output by almost 100%. However, 5° tilted arrays were adequately cleaned

by rainwater.

In many cases, especially in arid

regions, or in locations in close proximity to deserts, roads,

industry, or agriculture, regular cleaning of the solar panels is cost-effective. In 2018, the estimated soiling-induced revenue loss was estimated to between 5 and 7 billion euros.

The long‐term reliability of photovoltaic modules is crucial to

ensure the technical and economic viability of PV as a successful energy

source. The analysis of degradation mechanisms of PV modules is key to

ensure current lifetimes exceeding 25 years.

Insolation and energy

Solar insolation is made up of direct, diffuse, and reflected radiation. The absorption factor of a PV cell is defined as the fraction of incident solar irradiance that is absorbed by the cell. At high noon on a cloudless day at the equator, the power of the sun is about 1 kW/m2, on the Earth's surface, to a plane that is perpendicular to the sun's rays. As such, PV arrays can track the sun

through each day to greatly enhance energy collection. However,

tracking devices add cost, and require maintenance, so it is more common

for PV arrays to have fixed mounts that tilt the array and face solar noon

(approximately due south in the Northern Hemisphere or due north in the

Southern Hemisphere). The tilt angle, from horizontal, can be varied

for season,

but if fixed, should be set to give optimal array output during the

peak electrical demand portion of a typical year for a stand-alone

system. This optimal module tilt angle is not necessarily identical to

the tilt angle for maximum annual array energy output.

The optimization of the photovoltaic system for a specific environment

can be complicated as issues of solar flux, soiling, and snow losses

should be taken into effect. In addition, later work has shown that

spectral effects can play a role in optimal photovoltaic material

selection. For example, the spectral albedo can play a significant role in output depending on the surface around the photovoltaic system and the type of solar cell material. For the weather and latitudes of the United States and Europe, typical insolation ranges from 4 kWh/m2/day in northern climes to 6.5 kWh/m2/day

in the sunniest regions. A photovoltaic installation in the northern

latitudes of Europe or the United States may expect to produce 1 kWh/m2/day.

A typical 1 kW photovoltaic installation in Australia or the southern

latitudes of Europe or United States, may produce 3.5–5 kWh per day,

dependent on location, orientation, tilt, insolation and other factors.

In the Sahara desert, with less cloud cover and a better solar angle, one could ideally obtain closer to 8.3 kWh/m2/day

provided the nearly ever present wind would not blow sand onto the

units. The area of the Sahara desert is over 9 million km2. 90,600 km2, or about 1%, could generate as much electricity as all of the world's power plants combined.

Mounting

A 23-year-old ground mounted PV system from the 1980s on a

North Frisian Island, Germany. The modules conversion efficiency was only 12%.

Modules are assembled into arrays on some kind of mounting system,

which may be classified as ground mount, roof mount or pole mount. For solar parks

a large rack is mounted on the ground, and the modules mounted on the

rack.

For buildings, many different racks have been devised for pitched roofs.

For flat roofs, racks, bins and building integrated solutions are used.

Solar panel racks mounted on top of poles can be stationary or moving,

see Trackers below. Side-of-pole mounts are suitable for situations

where a pole has something else mounted at its top, such as a light

fixture or an antenna. Pole mounting raises what would otherwise be a

ground mounted array above weed shadows and livestock, and may satisfy

electrical code requirements regarding inaccessibility of exposed

wiring. Pole mounted panels are open to more cooling air on their

underside, which increases performance. A multiplicity of pole top racks

can be formed into a parking carport or other shade structure. A rack

which does not follow the sun from left to right may allow seasonal

adjustment up or down.

Cabling

Due to their outdoor usage, solar cables are designed to be resistant against UV

radiation and extremely high temperature fluctuations and are generally

unaffected by the weather. Standards specifying the usage of electrical wiring in PV systems include the IEC 60364 by the International Electrotechnical Commission, in section 712 "Solar photovoltaic (PV) power supply systems", the British Standard BS 7671, incorporating regulations relating to microgeneration and photovoltaic systems, and the US UL4703 standard, in subject 4703 "Photovoltaic Wire".

Tracker

A 1998 model of a passive solar tracker, viewed from underneath

A solar tracking system

tilts a solar panel throughout the day. Depending on the type of

tracking system, the panel is either aimed directly at the Sun or the

brightest area of a partly clouded sky. Trackers greatly enhance early

morning and late afternoon performance, increasing the total amount of

power produced by a system by about 20–25% for a single axis tracker and

about 30% or more for a dual axis tracker, depending on latitude.

Trackers are effective in regions that receive a large portion of

sunlight directly. In diffuse light (i.e. under cloud or fog), tracking

has little or no value. Because most concentrated photovoltaics

systems are very sensitive to the sunlight's angle, tracking systems

allow them to produce useful power for more than a brief period each

day.

Tracking systems improve performance for two main reasons. First, when a

solar panel is perpendicular to the sunlight, it receives more light on

its surface than if it were angled. Second, direct light is used more

efficiently than angled light. Special anti-reflective coatings can improve solar panel efficiency for direct and angled light, somewhat reducing the benefit of tracking.

Trackers and sensors to optimise the performance are often seen as optional, but they can increase viable output by up to 45%.

Arrays that approach or exceed one megawatt often use solar trackers.

Considering clouds, and the fact that most of the world is not on the

equator, and that the sun sets in the evening, the correct measure of

solar power is insolation

– the average number of kilowatt-hours per square meter per day. For

the weather and latitudes of the United States and Europe, typical

insolation ranges from 2.26 kWh/m2/day in northern climes to 5.61 kWh/m2/day in the sunniest regions.

For large systems, the energy gained by using tracking systems can outweigh the added complexity. For very large systems, the added maintenance of tracking is a substantial detriment. Tracking is not required for flat panel and low-concentration photovoltaic systems. For high-concentration photovoltaic systems, dual axis tracking is a necessity. Pricing trends affect the balance between adding more stationary solar panels versus having fewer panels that track.

As pricing, reliability and performance of single-axis trackers

have improved, the systems have been installed in an increasing

percentage of utility-scale projects. According to data from

WoodMackenzie/GTM Research, global solar tracker shipments hit a record

14.5 gigawatts in 2017. This represents growth of 32 percent

year-over-year, with similar or greater growth projected as large-scale

solar deployment accelerates.

Inverter

Central inverter with AC and DC disconnects (on the side), monitoring gateway, transformer isolation and interactive LCD

String inverter (left), generation meter, and AC disconnect (right). A modern 2013 installation in

Vermont, United States.

Systems designed to deliver alternating current (AC), such as grid-connected applications need an inverter to convert the direct current

(DC) from the solar modules to AC. Grid connected inverters must supply

AC electricity in sinusoidal form, synchronized to the grid frequency,

limit feed in voltage to no higher than the grid voltage and disconnect

from the grid if the grid voltage is turned off.

Islanding inverters need only produce regulated voltages and

frequencies in a sinusoidal waveshape as no synchronisation or

co-ordination with grid supplies is required.

A solar inverter may connect to a string of solar panels. In some installations a solar micro-inverter is connected at each solar panel.

For safety reasons a circuit breaker is provided both on the AC and DC

side to enable maintenance. AC output may be connected through an electricity meter into the public grid. The number of modules

in the system determines the total DC watts capable of being generated

by the solar array; however, the inverter ultimately governs the amount

of AC watts that can be distributed for consumption. For example, a PV

system comprising 11 kilowatts DC (kWDC) worth of PV modules, paired with one 10-kilowatt AC (kWAC)

inverter, will be limited to the inverter's output of 10 kW. As of

2019, conversion efficiency for state-of-the-art converters reached more

than 98 percent. While string inverters are used in residential to

medium-sized commercial PV systems, central inverters cover the large

commercial and utility-scale market. Market-share for central and string

inverters are about 44 percent and 52 percent, respectively, with less

than 1 percent for micro-inverters.

Maximum power point tracking

(MPPT) is a technique that grid connected inverters use to get the

maximum possible power from the photovoltaic array. In order to do so,

the inverter's MPPT system digitally samples the solar array's ever

changing power output and applies the proper resistance to find the

optimal maximum power point.

Anti-islanding

is a protection mechanism to immediately shut down the inverter,

preventing it from generating AC power when the connection to the load

no longer exists. This happens, for example, in the case of a blackout.

Without this protection, the supply line would become an "island" with

power surrounded by a "sea" of unpowered lines, as the solar array

continues to deliver DC power during the power outage. Islanding is a

hazard to utility workers, who may not realize that an AC circuit is

still powered, and it may prevent automatic re-connection of devices. Anti-Islanding feature is not required for complete Off-Grid Systems.

Inverter/Converter market in 2019

| Type

|

Power

|

Efficiency(a)

|

Market

Share(b)

|

Remarks

|

| String inverter

|

up to 150 kWp(c)

|

98%

|

61.6%

|

Cost(b) €0.05-0.17 per watt-peak. Easy to replace.

|

| Central inverter

|

above 80 kWp

|

98.5%

|

36.7%

|

€0.04 per watt-peak. High reliability. Often sold along with a service contract.

|

| Micro-inverter

|

module power range

|

90%–97%

|

1.7%

|

€0.29 per watt-peak. Ease-of-replacement concerns.

|

DC/DC converter

(Power optimizer)

|

module power range

|

99.5%

|

5.1%

|

€0.08 per watt-peak. Ease-of-replacement concerns. Inverter is still needed.

|

Source: data by IHS Markit 2020, remarks by Fraunhofer ISE 2020, from: Photovoltaics Report 2020, p. 39, PDF

Notes: (a)best efficiencies displayed, (b)market-share and cost per watt are estimated, (c)kWp = kilowatt-peak, (d) Total Market Share is greater than 100% because DC/DC converters are required to be paired with string inverters

|

Battery

Although still expensive, PV systems increasingly use rechargeable batteries to store a surplus to be later used at night. Batteries used for grid-storage also stabilize the electrical grid by leveling out peak loads, and play an important role in a smart grid, as they can charge during periods of low demand and feed their stored energy into the grid when demand is high.

Common battery technologies used in today's PV systems include the valve regulated lead-acid battery – a modified version of the conventional lead–acid battery – nickel–cadmium and lithium-ion

batteries. Compared to the other types, lead-acid batteries have a

shorter lifetime and lower energy density. However, due to their high

reliability, low self discharge as well as low investment and

maintenance costs, they are currently the predominant technology used in

small-scale, residential PV systems, as lithium-ion batteries are still

being developed and about 3.5 times as expensive as lead-acid

batteries. Furthermore, as storage devices for PV systems are

stationary, the lower energy and power density and therefore higher

weight of lead-acid batteries are not as critical as, for example, in electric transportation Other rechargeable batteries considered for distributed PV systems include sodium–sulfur and vanadium redox batteries, two prominent types of a molten salt and a flow battery, respectively. In 2015, Tesla Motors launched the Powerwall, a rechargeable lithium-ion battery with the aim to revolutionize energy consumption.

PV systems with an integrated battery solution also need a charge controller, as the varying voltage and current from the solar array requires constant adjustment to prevent damage from overcharging.

Basic charge controllers may simply turn the PV panels on and off, or

may meter out pulses of energy as needed, a strategy called PWM or pulse-width modulation. More advanced charge controllers will incorporate MPPT

logic into their battery charging algorithms. Charge controllers may

also divert energy to some purpose other than battery charging. Rather

than simply shut off the free PV energy when not needed, a user may

choose to heat air or water once the battery is full.

Monitoring and metering

The metering must be able to accumulate energy units in both directions,

or two meters must be used. Many meters accumulate bidirectionally,

some systems use two meters, but a unidirectional meter (with detent)

will not accumulate energy from any resultant feed into the grid. In some countries, for installations over 30 kWp

a frequency and a voltage monitor with disconnection of all phases is

required. This is done where more solar power is being generated than

can be accommodated by the utility, and the excess can not either be

exported or stored.

Grid operators historically have needed to provide transmission lines

and generation capacity. Now they need to also provide storage. This is

normally hydro-storage, but other means of storage are used. Initially

storage was used so that baseload generators could operate at full

output. With variable renewable energy, storage is needed to allow power generation whenever it is available, and consumption whenever needed.

A Canadian electricity meter

The two variables a grid operator has are storing electricity for when it is needed, or transmitting it to where

it is needed. If both of those fail, installations over 30kWp can

automatically shut down, although in practice all inverters maintain

voltage regulation and stop supplying power if the load is inadequate.

Grid operators have the option of curtailing excess generation from

large systems, although this is more commonly done with wind power than

solar power, and results in a substantial loss of revenue.

Three-phase inverters have the unique option of supplying reactive

power which can be advantageous in matching load requirements.

Photovoltaic systems need to be monitored to detect breakdown and optimize operation. There are several photovoltaic monitoring

strategies depending on the output of the installation and its nature.

Monitoring can be performed on site or remotely. It can measure

production only, retrieve all the data from the inverter or retrieve all

of the data from the communicating equipment (probes, meters, etc.).

Monitoring tools can be dedicated to supervision only or offer

additional functions. Individual inverters and battery charge

controllers may include monitoring using manufacturer specific protocols

and software.

Energy metering of an inverter may be of limited accuracy and not

suitable for revenue metering purposes. A third-party data acquisition

system can monitor multiple inverters, using the inverter manufacturer's

protocols, and also acquire weather-related information. Independent smart meters

may measure the total energy production of a PV array system. Separate

measures such as satellite image analysis or a solar radiation meter (a pyranometer) can be used to estimate total insolation for comparison.

Data collected from a monitoring system can be displayed remotely over the World Wide Web, such as OSOTF.

Other systems

This

section includes systems that are either highly specialized and

uncommon or still an emerging new technology with limited significance.

However, standalone

or off-grid systems take a special place. They were the most common

type of systems during the 1980s and 1990s, when PV technology was still

very expensive and a pure niche market of small scale applications.

Only in places where no electrical grid was available, they were

economically viable. Although new stand-alone systems are still being

deployed all around the world, their contribution to the overall

installed photovoltaic capacity is decreasing. In Europe, off-grid

systems account for 1 percent of installed capacity. In the United

States, they account for about 10 percent. Off-grid systems are still

common in Australia and South Korea, and in many developing countries.

CPV

Concentrator photovoltaics (CPV) and high concentrator photovoltaic (HCPV) systems use optical lenses

or curved mirrors to concentrate sunlight onto small but highly

efficient solar cells. Besides concentrating optics, CPV systems

sometime use solar trackers and cooling systems and are more expensive.

Especially HCPV systems are best suited in location with high

solar irradiance, concentrating sunlight up to 400 times or more, with

efficiencies of 24–28 percent, exceeding those of regular systems.

Various designs of systems are commercially available but not very

common. However, ongoing research and development is taking place.

CPV is often confused with CSP (concentrated solar power)

that does not use photovoltaics. Both technologies favor locations that

receive much sunlight and directly compete with each other.

Hybrid

A hybrid system combines PV with other forms of generation, usually a

diesel generator. Biogas is also used. The other form of generation may

be a type able to modulate power output as a function of demand.

However more than one renewable form of energy may be used e.g. wind.

The photovoltaic power generation serves to reduce the consumption of

non renewable fuel. Hybrid systems are most often found on islands. Pellworm island in Germany and Kythnos island in Greece are notable examples (both are combined with wind). The Kythnos plant has reduced diesel consumption by 11.2%.

In 2015, a case-study conducted in seven countries concluded that

in all cases generating costs can be reduced by hybridising mini-grids

and isolated grids. However, financing costs for such hybrids are

crucial and largely depend on the ownership structure of the power

plant. While cost reductions for state-owned utilities can be

significant, the study also identified economic benefits to be

insignificant or even negative for non-public utilities, such as independent power producers.

There has also been work showing that the PV penetration limit

can be increased by deploying a distributed network of PV+CHP hybrid

systems in the U.S.

The temporal distribution of solar flux, electrical and heating

requirements for representative U.S. single family residences were

analyzed and the results clearly show that hybridizing CHP with PV can

enable additional PV deployment above what is possible with a

conventional centralized electric generation system. This theory was

reconfirmed with numerical simulations using per second solar flux data

to determine that the necessary battery backup to provide for such a

hybrid system is possible with relatively small and inexpensive battery

systems.

In addition, large PV+CHP systems are possible for institutional

buildings, which again provide back up for intermittent PV and reduce

CHP runtime.

- PVT system

(hybrid PV/T), also known as photovoltaic thermal hybrid solar

collectors, convert solar radiation into thermal and electrical energy.

Such a system combines a solar (PV) module with a solar thermal collector in a complementary way.

- CPVT system. A concentrated photovoltaic thermal hybrid (CPVT) system is similar to a PVT system. It uses concentrated photovoltaics (CPV) instead of conventional PV technology, and combines it with a solar thermal collector.

- CPV/CSP system is a proposed novel solar hybrid system, combining concentrator photovoltaics with the non-PV technology of concentrated solar power (CSP), or also known as concentrated solar thermal.

- PV diesel system combines a photovoltaic system with a diesel generator. Combinations with other renewables are possible and include wind turbines.

Floating solar arrays

Floating solar arrays are PV systems that float on – or are built over – the surface of drinking water reservoirs, quarry lakes, irrigation canals

or remediation and tailing ponds. These systems are called

"floatovoltaics" when used only for electrical production or

"aquavoltaics" when such systems are used to synergistically enhance aquaculture. A small number of such systems exist in France, India, Japan, South Korea, the United Kingdom, Singapore and the United States.

The systems are said to have advantages over photovoltaics on

land. The cost of land is more expensive, and there are fewer rules and

regulations for structures built on bodies of water not used for

recreation. Unlike most land-based solar plants, floating arrays can be

unobtrusive because they are hidden from public view. They achieve

higher efficiencies than PV panels on land, because water cools the

panels. The panels have a special coating to prevent rust or corrosion.

In May 2008, the Far Niente Winery in Oakville, California,

pioneered the world's first floatovoltaic system by installing 994 solar

PV modules with a total capacity of 477 kW on to 130 pontoons and

floating them on the winery's irrigation pond.

The primary benefit of such a system is that it avoids the need to

sacrifice valuable land area that could be used for another purpose. In

the case of the Far Niente Winery, it saved 0.75 acres (0.30 ha) that

would have been required for a land-based system.

Another benefit of a floatovoltaic system is that the panels are kept

at a cooler temperature than they would be on land, leading to a higher

efficiency of solar energy conversion. The floating PV array also

reduces the amount of water lost through evaporation and inhibits the

growth of algae.

Utility-scale floating PV farms are starting to be built. The multinational electronics and ceramics manufacturer Kyocera will develop the world's largest, a 13.4 MW farm on the reservoir above Yamakura Dam in Chiba Prefecture using 50,000 solar panels. Salt-water resistant floating farms are also being considered for ocean use, with experiments in Thailand. The largest so far announced floatovoltaic project is a 350 MW power station in the Amazon region of Brazil.

Direct current grid

DC

grids are found in electric powered transport: railways trams and

trolleybuses. A few pilot plants for such applications have been built,

such as the tram depots in Hannover Leinhausen, using photovoltaic

contributors and Geneva (Bachet de Pesay). The 150 kWp

Geneva site feeds 600 V DC directly into the tram/trolleybus

electricity network whereas before it provided about 15% of the

electricity at its opening in 1999.

Standalone

A stand-alone or off-grid system is not connected to the electrical grid. Standalone systems vary widely in size and application from wristwatches or calculators to remote buildings or spacecraft. If the load is to be supplied independently of solar insolation, the generated power is stored and buffered with a battery. In non-portable applications where weight is not an issue, such as in buildings, lead acid batteries are most commonly used for their low cost and tolerance for abuse.

A charge controller may be incorporated in the system to avoid

battery damage by excessive charging or discharging. It may also help to

optimize production from the solar array using a maximum power point

tracking technique (MPPT).

However, in simple PV systems where the PV module voltage is matched to

the battery voltage, the use of MPPT electronics is generally

considered unnecessary, since the battery voltage is stable enough to

provide near-maximum power collection from the PV module.

In small devices (e.g. calculators, parking meters) only direct current

(DC) is consumed. In larger systems (e.g. buildings, remote water

pumps) AC is usually required. To convert the DC from the modules or

batteries into AC, an inverter is used.

In agricultural settings, the array may be used to directly power DC pumps, without the need for an inverter.

In remote settings such as mountainous areas, islands, or other places

where a power grid is unavailable, solar arrays can be used as the sole

source of electricity, usually by charging a storage battery. Stand-alone systems closely relate to microgeneration and distributed generation.

Costs and economy

The cost of producing photovoltaic cells has dropped because of economies of scale

in production and technological advances in manufacturing. For

large-scale installations, prices below $1.00 per watt were common by

2012.

A price decrease of 50% had been achieved in Europe from 2006 to 2011,

and there was a potential to lower the generation cost by 50% by 2020. Crystal silicon solar cells

have largely been replaced by less expensive multicrystalline silicon

solar cells, and thin film silicon solar cells have also been developed

at lower costs of production. Although they are reduced in energy

conversion efficiency from single crystalline "siwafers", they are also

much easier to produce at comparably lower costs.

The table below shows the total (average) cost in US cents per kWh of electricity generated by a photovoltaic system. The row headings on the left show the total cost, per peak kilowatt (kWp),

of a photovoltaic installation. Photovoltaic system costs have been

declining and in Germany, for example, were reported to have fallen to

USD 1389/kWp by the end of 2014. The column headings across the top refer to the annual energy output in kWh expected from each installed kWp. This varies by geographic region because the average insolation

depends on the average cloudiness and the thickness of atmosphere

traversed by the sunlight. It also depends on the path of the sun

relative to the panel and the horizon.

Panels are usually mounted at an angle based on latitude, and often they

are adjusted seasonally to meet the changing solar declination. Solar tracking can also be utilized to access even more perpendicular sunlight, thereby raising the total energy output.

The calculated values in the table reflect the total (average)

cost in cents per kWh produced. They assume a 10% total capital cost

(for instance 4% interest rate, 1% operating and maintenance cost, and depreciation of the capital outlay over 20 years). Normally, photovoltaic modules have a 25-year warranty.

Cost of generated kilowatt-hour by a PV system (US¢/kWh)

depending on solar radiation and installation cost during 20 years of operation

|

|---|

Installation

cost in

$ per watt |

Insolation annually generated kilowatt-hours per installed kW-capacity (kWh/(kWp•y))

|

| 2,400 |

2,200 |

2,000 |

1,800 |

1,600 |

1,400 |

1,200 |

1,000 |

800

|

| $0.20

|

0.8

|

0.9

|

1.0

|

1.1

|

1.3

|

1.4

|

1.7

|

2.0

|

2.5

|

| $0.60

|

2.5

|

2.7

|

3.0

|

3.3

|

3.8

|

4.3

|

5.0

|

6.0

|

7.5

|

| $1.00

|

4.2

|

4.5

|

5.0

|

5.6

|

6.3

|

7.1

|

8.3

|

10.0

|

12.5

|

| $1.40

|

5.8

|

6.4

|

7.0

|

7.8

|

8.8

|

10.0

|

11.7

|

14.0

|

17.5

|

| $1.80

|

7.5

|

8.2

|

9.0

|

10.0

|

11.3

|

12.9

|

15.0

|

18.0

|

22.5

|

| $2.20

|

9.2

|

10.0

|

11.0

|

12.2

|

13.8

|

15.7

|

18.3

|

22.0

|

27.5

|

| $2.60

|

10.8

|

11.8

|

13.0

|

14.4

|

16.3

|

18.6

|

21.7

|

26.0

|

32.5

|

| $3.00

|

12.5

|

13.6

|

15.0

|

16.7

|

18.8

|

21.4

|

25.0

|

30.0

|

37.5

|

| $3.40

|

14.2

|

15.5

|

17.0

|

18.9

|

21.3

|

24.3

|

28.3

|

34.0

|

42.5

|

| $3.80

|

15.8

|

17.3

|

19.0

|

21.1

|

23.8

|

27.1

|

31.7

|

38.0

|

47.5

|

| $4.20

|

17.5

|

19.1

|

21.0

|

23.3

|

26.3

|

30.0

|

35.0

|

42.0

|

52.5

|

| $4.60

|

19.2

|

20.9

|

23.0

|

25.6

|

28.8

|

32.9

|

38.3

|

46.0

|

57.5

|

| $5.00

|

20.8

|

22.7

|

25.0

|

27.8

|

31.3

|

35.7

|

41.7

|

50.0

|

62.5

|

| USA

|

Japan

|

Germany

|

Small rooftop system cost and average insolation applied to data table in 2013

|

Notes:

- Cost per watt for rooftop system in 2013: Japan $4.64, United States $4.92, and Germany $2.05

- Generated kilowatt-hour per installed watt-peak, based on average insolation for Japan (1500 kWh/m2/year), United States (5.0 to 5.5 kWh/m2/day), and Germany (1000 to 1200 kWh/m2/year).

- A 2013 study by the Fraunhofer ISE concludes LCOE cost for a small PV system to be $0.16 (€0.12) rather than $0.22 per kilowatt-hour as shown in table (Germany).

|

Learning curve

Photovoltaic systems demonstrate a learning curve in terms of levelized cost of electricity (LCOE), reducing its cost per kWh by 32.6% for every doubling of capacity. From the data of LCOE and cumulative installed capacity from International Renewable Energy Agency (IRENA) from 2010 to 2017, the learning curve equation for photovoltaic systems is given as

- LCOE : levelized cost of electricity (in USD/kWh)

- Capacity : cumulative installed capacity of photovoltaic systems (in MW)

Regulation

Standardization

Increasing

use of photovoltaic systems and integration of photovoltaic power into

existing structures and techniques of supply and distribution increases

the need for general standards and definitions for photovoltaic

components and systems.[citation needed] The standards are compiled at the International Electrotechnical Commission

(IEC) and apply to efficiency, durability and safety of cells, modules,

simulation programs, plug connectors and cables, mounting systems,

overall efficiency of inverters etc.

National regulations

United Kingdom

In

the UK, PV installations are generally considered permitted development

and do not require planning permission. If the property is listed or in

a designated area (National Park, Area of Outstanding Natural Beauty,

Site of Special Scientific Interest or Norfolk Broads) then planning

permission is required.

United States

In

the United States, article 690 of the National Electric Code provides

general guidelines for the installation of photovoltaic systems; these

may be superseded by local laws and regulations. Often a permit is

required necessitating plan submissions and structural calculations

before work may begin. Additionally, many locales require the work to be

performed under the guidance of a licensed electrician.

The Authority Having Jurisdiction

(AHJ) will review designs and issue permits, before construction can

lawfully begin. Electrical installation practices must comply with

standards set forth within the National Electrical Code (NEC) and be inspected by the AHJ to ensure compliance with building code, electrical code, and fire safety code. Jurisdictions may require that equipment has been tested, certified, listed, and labeled by at least one of the Nationally Recognized Testing Laboratories (NRTL).

Many localities require a permit to install a photovoltaic system. A

grid-tied system normally requires a licensed electrician to connect

between the system and the grid-connected wiring of the building. Installers who meet these qualifications are located in almost every state. Several states prohibit homeowners' associations from restricting solar devices.

Spain

Although Spain generates around 40%

of its electricity via photovoltaic and other renewable energy sources,

and cities such as Huelva and Seville boast nearly 3,000 hours of

sunshine per year, in 2013 Spain issued a solar tax to account for the

debt created by the investment done by the Spanish government. Those who

do not connect to the grid can face up to a fine of 30 million euros

(US$40 million).

Such measures were finally withdrawn by 2018, when new legislation was

introduced banning any taxes on renewable energy self-consumption.

Limitations

Impact on electricity network

With

the increasing levels of rooftop photovoltaic systems, the energy flow

becomes two-way. When there is more local generation than consumption,

electricity is exported to the grid. However, electricity network

traditionally is not designed to deal with the two-way energy transfer.

Therefore, some technical issues may occur. For example, in Queensland,

Australia, there have been more than 30% of households with rooftop PV

by the end of 2017. The famous Californian 2020 duck curve

appears very often for a lot of communities from 2015 onwards. An

over-voltage issue may come out as the electricity flows back to the

network.

There are solutions to manage the over voltage issue, such as

regulating PV inverter power factor, new voltage and energy control

equipment at electricity distributor level, re-conductor the electricity

wires, demand side management, etc. There are often limitations and

costs related to these solutions.

Implication onto electricity bill management and energy investment

Customers

have different specific situations, e.g. different comfort/convenience

needs, different electricity tariffs, or different usage patterns. An

electricity tariff may have a few elements, such as daily access and

metering charge, energy charge (based on kWh, MWh) or peak demand charge

(e.g. a price for the highest 30min energy consumption in a month). PV

is a promising option for reducing energy charge when electricity price

is reasonably high and continuously increasing, such as in Australia and

Germany. However, for sites with peak demand charge in place, PV may be

less attractive if peak demands mostly occur in the late afternoon to

early evening, for example residential communities. Overall, energy

investment is largely an economic decision and investment decisions are

based on systematical evaluation of options in operational improvement,

energy efficiency, onsite generation and energy storage.