From Wikipedia, the free encyclopedia

Energy harvesting (also known as

power harvesting or

energy scavenging or

ambient power) is the process by which

energy is derived from external sources (e.g.,

solar power,

thermal energy,

wind energy,

salinity gradients, and

kinetic energy, also known as

ambient energy), captured, and stored for small, wireless autonomous devices, like those used in

wearable electronics and wireless

sensor networks.[1]

Energy harvesters provide a very small amount of power for low-energy

electronics. While the input fuel to some large-scale generation costs

resources (oil, coal, etc.), the energy source for energy harvesters is

present as ambient background. For example, temperature gradients exist

from the operation of a combustion engine and in urban areas, there is a

large amount of electromagnetic energy in the environment because of

radio and television broadcasting.

One of the earliest applications of ambient power collected from ambient

electromagnetic radiation (EMR) is the

crystal radio.

The principles of energy harvesting from ambient EMR can be demonstrated with basic components.

[2]

Operation

Energy

harvesting devices converting ambient energy into electrical energy

have attracted much interest in both the military and commercial

sectors. Some systems convert motion, such as that of ocean waves, into

electricity to be used by oceanographic monitoring sensors for

autonomous operation. Future applications may include high power output

devices (or arrays of such devices) deployed at remote locations to

serve as reliable power stations for large systems. Another application

is in wearable electronics, where energy harvesting devices can power or

recharge cellphones, mobile computers, radio communication equipment,

etc. All of these devices must be sufficiently robust to endure

long-term exposure to hostile environments and have a broad range of

dynamic sensitivity to exploit the entire spectrum of wave motions.

Accumulating energy

Energy can also be harvested to power small autonomous sensors such as those developed using

MEMS technology.

These systems are often very small and require little power, but their

applications are limited by the reliance on battery power. Scavenging

energy from ambient vibrations, wind, heat or light could enable smart

sensors to be functional indefinitely. Several academic and commercial

groups have been involved in the analysis and development of

vibration-powered energy harvesting technology, including the Control

and Power Group and Optical and Semiconductor Devices Group at

Imperial College London,

IMEC and the partnering Holst Centr,

[3] AdaptivEnergy, LLC, ARVENI,

MIT Boston, Victoria University of Wellington,

[4] Georgia Tech,

UC Berkeley,

Southampton University,

University of Bristol,

[5] Micro Energy System Lab at The University of Tokyo,

Nanyang Technological University,

[6] PMG Perpetuum,

ReVibe Energy,

Vestfold University College,

National University of Singapore,

[7] NiPS Laboratory at the University of Perugia,

[8] Columbia University,

[9] Universidad Autónoma de Barcelona and USN & Renewable Energy Lab at the University of Ulsan (Ulsan, South Korea). The

National Science Foundation also supports an Industry/University Cooperative Research Center led by

Virginia Tech and

The University of Texas at Dallas called the Center for Energy Harvesting Materials and Systems.

Typical power densities available from energy harvesting devices are

highly dependent upon the specific application (affecting the

generator's size) and the design itself of the harvesting generator. In

general, for motion powered devices, typical values are a few µW/cm³ for

human body powered applications and hundreds of µW/cm³ for generators

powered from machinery.

[10] Most energy scavenging devices for wearable electronics generate very little power.

[11][verification needed]

Storage of power

In general, energy can be stored in a

capacitor,

super capacitor, or

battery.

Capacitors are used when the application needs to provide huge energy

spikes. Batteries leak less energy and are therefore used when the

device needs to provide a steady flow of energy.

Use of the power

Current

interest in low power energy harvesting is for independent sensor

networks. In these applications an energy harvesting scheme puts power

stored into a capacitor then boosted/regulated to a second storage

capacitor or battery for the use in the

microprocessor [12] or in the data transmission.

[13] The power is usually used in a

sensor application and the data stored or is

transmitted possibly through a wireless method.

[14]

Motivation

The

history of energy harvesting dates back to the windmill and the

waterwheel. People have searched for ways to store the energy from heat

and vibrations for many decades. One driving force behind the search for

new energy harvesting devices is the desire to power sensor networks

and mobile devices without batteries. Energy harvesting is also

motivated by a desire to address the issue of climate change and global

warming.

Devices

There are many small-scale energy sources that generally cannot be scaled up to industrial size:

- Some wristwatches are powered by kinetic energy (called automatic watches), in this case movement of the arm is used. The arm movement causes winding of its mainspring. A newer design introduced by Seiko

("Kinetic") uses movement of a magnet in the electromagnetic generator

instead to power the quartz movement. The motion provides a rate of

change of flux, which results in some induced emf on the coils. The concept is related to Faraday's Law.

- Photovoltaics

is a method of generating electrical power by converting solar

radiation (both indoors and outdoors) into direct current electricity

using semiconductors that exhibit the photovoltaic effect. Photovoltaic

power generation employs solar panels composed of a number of cells

containing a photovoltaic material. Note that photovoltaics have been

scaled up to industrial size and that large solar farms exist.

- Thermoelectric

generators (TEGs) consist of the junction of two dissimilar materials

and the presence of a thermal gradient. Large voltage outputs are

possible by connecting many junctions electrically in series and

thermally in parallel. Typical performance is 100-300 μV/K per junction.

These can be utilized to capture mW.s of energy from industrial

equipment, structures, and even the human body. They are typically

coupled with heat sinks to improve temperature gradient.

- Micro wind turbine

are used to harvest wind energy readily available in the environment in

the form of kinetic energy to power the low power electronic devices

such as wireless sensor nodes. When air flows across the blades of the

turbine, a net pressure difference is developed between the wind speeds

above and below the blades. This will result in a lift force generated

which in turn rotate the blades. Similar to photovoltaics, wind farms

have been constructed on an industrial scale and are being used to

generate substantial amounts of electrical energy.

- Piezoelectric crystals or fibers generate a small voltage whenever they are mechanically deformed. Vibration from engines can stimulate piezoelectric materials, as can the heel of a shoe, or the pushing of a button.

- Special antennas can collect energy from stray radio waves,[15] this can also be done with a Rectenna and theoretically at even higher frequency EM radiation with a Nantenna.

- Power from keys pressed during use of a portable electronic device

or remote controller, using magnet and coil or piezoelectric energy

converters, may be used to help power the device.[16]

Ambient-radiation sources

A

possible source of energy comes from ubiquitous radio transmitters.

Historically, either a large collection area or close proximity to the

radiating

wireless energy source is needed to get useful power levels from this source. The

nantenna is one proposed development which would overcome this limitation by making use of the abundant

natural radiation (such as

solar radiation).

One idea is to deliberately broadcast RF energy to power and collect information from remote devices:

[13] This is now commonplace in passive

radio-frequency identification (RFID) systems, but the Safety and US

Federal Communications Commission

(and equivalent bodies worldwide) limit the maximum power that can be

transmitted this way to civilian use. This method has been used to power

individual nodes in a wireless sensor network

[17]

Fluid flow

Airflow

can be harvested by various turbine and non-turbine generator

technologies. For example, Zephyr Energy Corporation’s patented Windbeam

micro generator captures energy from airflow to recharge batteries and

power electronic devices. The Windbeam’s novel design allows it to

operate silently in wind speeds as low as 2 mph. The generator consists

of a lightweight beam suspended by durable long-lasting springs within

an outer frame. The beam oscillates rapidly when exposed to airflow due

to the effects of multiple fluid flow phenomena. A linear alternator

assembly converts the oscillating beam motion into usable electrical

energy. A lack of bearings and gears eliminates frictional

inefficiencies and noise. The generator can operate in low-light

environments unsuitable for solar panels (e.g. HVAC ducts) and is

inexpensive due to low cost components and simple construction. The

scalable technology can be optimized to satisfy the energy requirements

and design constraints of a given application.

[18]

The flow of blood can also be used to power devices. For instance,

the pacemaker developed at the University of Bern, uses blood flow to

wind up a spring which in turn drives an electrical micro-generator.

[19]

Photovoltaic

Photovoltaic

(PV) energy harvesting wireless technology offers significant

advantages over wired or solely battery-powered sensor solutions:

virtually inexhaustible sources of power with little or no adverse

environmental effects. Indoor PV harvesting solutions have to date been

powered by specially tuned amorphous silicon (aSi)a technology most used

in Solar Calculators. In recent years new PV technologies have come to

the forefront in Energy Harvesting such as Dye Sensitized Solar Cells (

DSSC). The dyes absorbs light much like

chlorophyll does in plants. Electrons released on impact escape to the layer of TiO

2

and from there diffuse, through the electrolyte, as the dye can be

tuned to the visible spectrum much higher power can be produced. At

200 lux a DSSC can provide over

10 µW per cm².

picture of a batteryless and wireless wallswitch

Piezoelectric

The

piezoelectric effect converts mechanical

strain

into electric current or voltage. This strain can come from many

different sources. Human motion, low-frequency seismic vibrations, and

acoustic noise are everyday examples. Except in rare instances the

piezoelectric effect operates in AC requiring time-varying inputs at

mechanical resonance to be efficient.

Most piezoelectric electricity sources produce power on the order of

milliwatts, too small for system application, but enough for hand-held

devices such as some commercially available self-winding wristwatches.

One proposal is that they are used for micro-scale devices, such as in a

device harvesting micro-hydraulic energy. In this device, the flow of

pressurized hydraulic fluid drives a reciprocating piston supported by

three piezoelectric elements which convert the pressure fluctuations

into an alternating current.

As piezo energy harvesting has been investigated only since the late 1990s,

[20][21]

it remains an emerging technology. Nevertheless, some interesting

improvements were made with the self-powered electronic switch at INSA

school of engineering, implemented by the spin-off Arveni. In 2006, the

proof of concept of a battery-less wireless doorbell push button was

created, and recently, a product showed that classical wireless

wallswitch can be powered by a piezo harvester. Other industrial

applications appeared between 2000 and 2005,

[22] to harvest energy from vibration and supply sensors for example, or to harvest energy from shock.

Piezoelectric systems can convert motion from the human body into electrical power.

DARPA has funded efforts to harness energy from leg and arm motion, shoe impacts, and

blood pressure

for low level power to implantable or wearable sensors. The nanobrushes

are another example of a piezoelectric energy harvester.

[23]

They can be integrated into clothing. Multiple other nanostructures

have been exploited to build an energy-harvesting device, for example, a

single crystal PMN-PT nanobelt was fabricated and assembled into a

piezoelectric energy harvester in 2016.

[24]

Careful design is needed to minimise user discomfort. These energy

harvesting sources by association affect the body. The Vibration Energy

Scavenging Project

[25]

is another project that is set up to try to scavenge electrical energy

from environmental vibrations and movements. Microbelt can be used to

gather electricity from respiration.

[26]

Besides, as the vibration of motion from human comes in three

directions, a single piezoelectric cantilever based omni-directional

energy harvester is created by using 1:2 internal resonance.

[27] Finally, a millimeter-scale piezoelectric energy harvester has also already been created.

[28]

The use of

piezoelectric

materials to harvest power has already become popular. Piezoelectric

materials have the ability to transform mechanical strain energy into

electrical charge. Piezo elements are being embedded in walkways

[29][30][31] to recover the "people energy" of footsteps. They can also be embedded in shoes

[32]

to recover "walking energy". Researchers at MIT developed the first

micro-scale piezoelectric energy harvester using thin film PZT in 2005.

[33]

Arman Hajati and Sang-Gook Kim invented the Ultra Wide-Bandwidth

micro-scale piezoelectric energy harvesting device by exploiting the

nonlinear stiffness of a doubly clamped microelectromechanical systems (

MEMSs)

resonator. The stretching strain in a doubly clamped beam shows a

nonlinear stiffness, which provides a passive feedback and results in

amplitude-stiffened Duffing mode resonance.

[34]

Typically, piezoelectric cantilevers are adopted for the

above-mentioned energy harvesting system. One drawback is that the

piezoelectric cantilever has gradient strain distribution, i.e., the

piezoelectric transducer is not fully utilized. To address this issue,

triangle shaped and L-shaped cantilever are proposed for uniform strain

distribution.

[35][36][37]

In 2018, Soochow University researchers reported hybridizing a

triboelectric nanogenerator and a silicon solar cell by sharing a mutual electrode. This device can collect solar energy

or convert the mechanical energy of falling raindrops into electricity.

[38]

Energy from smart roads and piezoelectricity

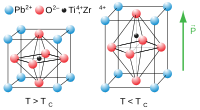

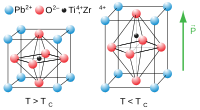

Tetragonal unit cell of lead titanate

A piezoelectric disk generates a voltage when deformed (change in shape is greatly exaggerated)

Brothers

Pierre Curie and

Jacques Curie gave the concept of piezoelectric effect in 1880.

[39] Piezoelectric effect converts mechanical strain into voltage or

electric current and generates electric energy from motion, weight, vibration and temperature changes as shown in the figure.

Considering piezoelectric effect in thin film lead zirconate titanate

PZT, microelectromechanical systems (

MEMS) power generating device has been developed. During recent improvement in piezoelectric technology, Aqsa Abbasi

(also known as Aqsa Aitbar, General secretory at IMS, IEEE MUET Chapter and Director Media at HYD MUN [40][41][42][43][44]) diffentiated two modes called

and

in vibration converters and re-designed to resonate at specific

frequencies from an external vibration energy source, thereby creating

electrical energy via the piezoelectric effect using electromechanical

damped mass.

[45][46] However, Aqsa further developed beam-structured

electrostatic devices that are more difficult to fabricate than PZT MEMS devices versus a similar because general

silicon processing involves many more mask steps that do not require PZT film. Piezoelectric

type

sensors and

actuators have a cantilever beam structure that consists of a membrane bottom

electrode, film, piezoelectric film, and top electrode. More than

(3~5 masks)

mask steps are required for patterning of each layer while have very

low induced voltage. Pyroelectric crystals that have a unique polar axis

and have spontaneous polarization, along which the spontaneous

polarization exists. These are the

crystals of classes

6mm,

4mm,

mm2,

6,

4,

3m,

3,

2,

m. The special polar axis—crystallophysical axis

X3 — coincides with the axes

L6,

L4,

L3, and

L2 of the crystals or lies in the unique straight plane

P (class “m”).

Consequently, the electric centers of positive and negative charges are

displaced of an elementary cell from equilibrium positions, i.e., the

spontaneous polarization of the crystal changes. Therefore, all

considered crystals have spontaneous polarization

.

Since piezoelectric effect in pyroelectric crystals arises as a result

of changes in their spontaneous polarization under external effects (

electric fields, mechanical stresses). As a result of displacement, Aqsa Abbasi introduced change in the components

along all three axes

. Suppose that

is proportional to the

mechanical stresses causing in a first approximation, which results

where

Tkl represents the mechanical stress and

dikl represents the piezoelectric modules.

[45]

PZT thin films have attracted attention for applications such as force sensors,

accelerometers, gyroscopes actuators, tunable optics, micro pumps, ferroelectric RAM, display systems and smart roads,

[45]

when energy sources are limited, energy harvesting plays an important

role in the environment. Smart roads have the potential to play an

important role in power generation. Embedding piezoelectric material in

the road can convert pressure exerted by moving vehicles into voltage

and current.

[45]

Smart transportation intelligent system

Piezoelectric sensors are most useful in Smart-road technologies that

can be used to create systems that are intelligent and improve

productivity in the long run. Imagine highways that alert motorists of a

traffic jam before it forms. Or bridges that report when they are at

risk of collapse, or an electric grid that fixes itself when blackouts

hit. For many decades, scientists and experts have argued that the best

way to fight congestion is intelligent transportation systems, such as

roadside sensors to measure traffic and synchronized traffic lights to

control the flow of vehicles. But the spread of these technologies has

been limited by cost. There are also some other smart-technology

shovel ready

projects which could be deployed fairly quickly, but most of the

technologies are still at the development stage and might not be

practically available for five years or more.

[47]

Pyroelectric

The

pyroelectric effect converts a temperature change into electric current or voltage. It is analogous to the

piezoelectric effect, which is another type of

ferroelectric

behavior. Pyroelectricity requires time-varying inputs and suffers from

small power outputs in energy harvesting applications due to its low

operating frequencies. However, one key advantage of pyroelectrics over

thermoelectrics

is that many pyroelectric materials are stable up to 1200 ⁰C or higher,

enabling energy harvesting from high temperature sources and thus

increasing

thermodynamic efficiency.

One way to directly convert

waste heat

into electricity is by executing the Olsen cycle on pyroelectric

materials. The Olsen cycle consists of two isothermal and two

isoelectric field processes in the electric displacement-electric field

(D-E) diagram. The principle of the Olsen cycle is to charge a capacitor

via cooling under low electric field and to discharge it under heating

at higher electric field. Several pyroelectric converters have been

developed to implement the Olsen cycle using conduction,

[48] convection,

[49][50][51][52] or radiation.

[53]

It has also been established theoretically that pyroelectric conversion

based on heat regeneration using an oscillating working fluid and the

Olsen cycle can reach Carnot efficiency between a hot and a cold thermal

reservoir.

[54] Moreover, recent studies have established polyvinylidene fluoride trifluoroethylene [P(VDF-TrFE)] polymers

[55] and lead lanthanum zirconate titanate (PLZT) ceramics

[56]

as promising pyroelectric materials to use in energy converters due to

their large energy densities generated at low temperatures.

Additionally, a pyroelectric scavenging device that does not require

time-varying inputs was recently introduced. The energy-harvesting

device uses the edge-depolarizing electric field of a heated

pyroelectric to convert heat energy into mechanical energy instead of

drawing electric current off two plates attached to the crystal-faces.

[57]

Thermoelectrics

In 1821,

Thomas Johann Seebeck

discovered that a thermal gradient formed between two dissimilar

conductors produces a voltage. At the heart of the thermoelectric effect

is the fact that a temperature gradient in a conducting material

results in heat flow; this results in the diffusion of charge carriers.

The flow of charge carriers between the hot and cold regions in turn

creates a voltage difference. In 1834,

Jean Charles Athanase Peltier

discovered that running an electric current through the junction of two

dissimilar conductors could, depending on the direction of the current,

cause it to act as a heater or cooler. The heat absorbed or produced is

proportional to the current, and the proportionality constant is known

as the Peltier coefficient. Today, due to knowledge of the Seebeck and

Peltier effects, thermoelectric materials can be used as heaters, coolers and

generators (TEGs).

Ideal thermoelectric materials have a high Seebeck coefficient, high

electrical conductivity, and low thermal conductivity. Low thermal

conductivity is necessary to maintain a high thermal gradient at the

junction. Standard thermoelectric modules manufactured today consist of

P- and N-doped bismuth-telluride semiconductors sandwiched between two

metallized ceramic plates. The ceramic plates add rigidity and

electrical insulation to the system. The semiconductors are connected

electrically in series and thermally in parallel.

Miniature thermocouples have been developed that convert body heat into electricity and generate 40

μW at 3

V with a 5 degree temperature gradient, while on the other end of the scale, large thermocouples are used in nuclear

RTG batteries.

Practical examples are the finger-heartratemeter by the

Holst Centre and the thermogenerators by the Fraunhofer Gesellschaft.

[58][59]

Advantages to thermoelectrics:

- No moving parts allow continuous operation for many years. Tellurex Corporation[60] (a thermoelectric production company) claims that thermoelectrics are capable of over 100,000 hours of steady state operation.

- Thermoelectrics contain no materials that must be replenished.

- Heating and cooling can be reversed.

One downside to thermoelectric energy conversion is low efficiency

(currently less than 10%). The development of materials that are able to

operate in higher temperature gradients, and that can conduct

electricity well without also conducting heat (something that was until

recently thought impossible

[citation needed]), will result in increased efficiency.

Future work in thermoelectrics could be to convert wasted heat, such as in automobile engine combustion, into electricity.

[61]

Electrostatic (capacitive)

This

type of harvesting is based on the changing capacitance of

vibration-dependent capacitors. Vibrations separate the plates of a

charged variable capacitor, and mechanical energy is converted into

electrical energy. Electrostatic energy harvesters need a polarization

source to work and to convert mechanical energy from vibrations into

electricity. The polarization source should be in the order of some

hundreds of volts; this greatly complicates the power management

circuit. Another solution consists in using

electrets, that are electrically charged dielectrics able to keep the polarization on the capacitor for years.

[62]

It's possible to adapt structures from classical electrostatic

induction generators, which also extract energy from variable

capacitances, for this purpose. The resulting devices are self-biasing,

and can directly charge batteries, or can produce exponentially growing

voltages on storage capacitors, from which energy can be periodically

extracted by DC/DC converters.

[63]

Magnetic induction

Magnets

wobbling on a cantilever are sensitive to even small vibrations and

generate microcurrents by moving relative to conductors due to

Faraday's law of induction. By developing a miniature device of this kind in 2007, a team from the

University of Southampton

made possible the planting of such a device in environments that

preclude having any electrical connection to the outside world.

Sensors in inaccessible places can now generate their own power and transmit data to outside receivers.

[64]

One of the major limitations of the magnetic vibration energy harvester developed at

University of Southampton

is the size of the generator, in this case approximately one cubic

centimeter, which is much too large to integrate into today's mobile

technologies. The complete generator including circuitry is a massive

4 cm by 4 cm by 1 cm

[64]

nearly the same size as some mobile devices such as the iPod nano.

Further reductions in the dimensions are possible through the

integration of new and more flexible materials as the cantilever beam

component. In 2012, a group at

Northwestern University developed a vibration-powered generator out of polymer in the form of a spring.

[65]

This device was able to target the same frequencies as the University

of Southampton groups silicon based device but with one third the size

of the beam component.

A new approach to magnetic induction based energy harvesting has also

been proposed by using ferrofluids. The journal article,

"Electromagnetic ferrofluid-based energy harvester", discusses the use

of ferrofluids to harvest low frequency vibrational energy at 2.2 Hz

with a power output of ~80 mW per g.

[66]

Commercially successful vibration energy harvesters based on magnetic

induction are still relatively few in number. Examples include products

developed by Swedish company

ReVibe Energy, a technology spin-out from

Saab Group.

Another example is the products developed from the early University of

Southampton prototypes by Perpetuum. These have to be sufficiently large

to generate the power required by wireless sensor nodes (wsn)but in M2M

applications this is not normally an issue. These harvesters are now

being supplied in large volumes to power wsn's made by companies such as

GE and Emerson and also for train bearing monitoring systems made by

Perpetuum.

Overhead powerline sensors can use magnetic induction to harvest energy directly from the conductor they are monitoring.

[67][68]

Blood sugar

Another way of energy harvesting is through the oxidation of blood sugars. These energy harvesters are called

biobatteries.

They could be used to power implanted electronic devices (e.g.,

pacemakers, implanted biosensors for diabetics, implanted active RFID

devices, etc.). At present, the Minteer Group of Saint Louis University

has created enzymes that could be used to generate power from blood

sugars. However, the enzymes would still need to be replaced after a few

years.

[69] In 2012, a pacemaker was powered by implantable biofuel cells at Clarkson University under the leadership of Dr. Evgeny Katz.

[70]

Tree-based

Tree

metabolic energy harvesting is a type of bio-energy harvesting. Voltree

has developed a method for harvesting energy from trees. These energy

harvesters are being used to power remote sensors and mesh networks as

the basis for a long term deployment system to monitor forest fires and

weather in the forest. According to Voltree's website, the useful life

of such a device should be limited only by the lifetime of the tree to

which it is attached. A small test network was recently deployed in a US

National Park forest.

[71]

Other sources of energy from trees include capturing the physical

movement of the tree in a generator. Theoretical analysis of this source

of energy shows some promise in powering small electronic devices.

[72] A practical device based on this theory has been built and successfully powered a sensor node for a year.

[73]

Metamaterial

A metamaterial-based device wirelessly converts a 900 MHz

microwave signal to 7.3 volts of

direct current

(greater than that of a USB device). The device can be tuned to harvest

other signals including Wi-Fi signals, satellite signals, or even sound

signals. The experimental device used a series of five

fiberglass and

copper

conductors. Conversion efficiency reached 37 percent. When traditional

antennas are close to each other in space they interfere with each

other.

[74][75][76]

But since RF power goes down by the cube of the distance, the amount of

power is very very small. While the claim of 7.3 volts is grand, the

measurement is for an open circuit. Since the power is so low, there can

be almost no current when any load is attached.

Atmospheric pressure changes

The

change in air pressure due to temperature changes or weather patterns

vs. a sealed chamber has been used to provide power for mechanical

clocks such as the

Atmos clock.

What is an Atmospheric pressure change?

An Atmospheric change is a force exerted on a surface by air above as

gravity pulls it to Earth. This is often measured by the barometer, a

slight mercury in the glass tube rises and drops depending on changes in

altitude and pressure. Usually, atmosphere pressure drops as altitude

increases, also vice versa. Atmospheric pressure consists of molecules

in constant motion, colliding with each other about 10

10 collisions per molecule per second at 10 °C (50 °F), this is part of the kinetic energy of the atmosphere

[77].

With given devices/technology (Wind Turbine) in the contemporary era,

industries/individuals can harvest or convert atmospheric energy into

Electrical energy with low-cost efficient or even free! Overall an

Atmospheric pressure is a great utility that can be devised into our

economy for top-tier energy harvest and future solution for many other

issues

[78].

Ocean Energy

A

relatively new concept of generating energy is to generate energy from

oceans. Large masses of waters are present on the planet which carry

with them great amounts of energy.The energy in this case can be

generated by tidal streams, ocean waves, difference in salinity and also

difference in temperature. Efforts are underway to harvest energy this

way as it holds a great potential and would be a renewable form of

energy. United States Navy recently was able to generate electricity

using difference in temperatures present in the ocean. The project

didn't yielded that much energy but sure there is a lot of potential.

Another idea is to generate an artificial flow in ocean to generate

energy. If a flow of considerable magnitude could be generated it would

produce large amounts of energy.

Future directions

Electroactive polymers

(EAPs) have been proposed for harvesting energy. These polymers have a

large strain, elastic energy density, and high energy conversion

efficiency. The total weight of systems based on EAPs(electroactive

polymers) is proposed to be significantly lower than those based on

piezoelectric materials.

Nanogenerators, such as the one made by Georgia Tech, could provide a new way for powering devices without batteries.

[79] As of 2008, it only generates some dozen nanowatts, which is too low for any practical application.

Noise

has been the subject of a proposal by NiPS Laboratory in Italy to

harvest wide spectrum low scale vibrations via a nonlinear dynamical

mechanism that can improve harvester efficiency up to a factor 4

compared to traditional linear harvesters.

[80]

Combinations of different types

[81]

of energy harvesters can further reduce dependence on batteries,

particularly in environments where the available ambient energy types

change periodically. This type of complementary balanced energy

harvesting has the potential to increase reliability of wireless sensor

systems for structural health monitoring.

[82]

is the local voltage,[6] and

is the local voltage,[6] and  is the local conductivity. In general, the Seebeck effect is described locally by the creation of an electromotive field

is the local conductivity. In general, the Seebeck effect is described locally by the creation of an electromotive field is the Seebeck coefficient (also known as thermopower), a property of the local material, and

is the Seebeck coefficient (also known as thermopower), a property of the local material, and  is the temperature gradient.

is the temperature gradient. , then the voltage gradient is given simply by the emf:

, then the voltage gradient is given simply by the emf:  . This simple relationship, which does not depend on conductivity, is used in the thermocouple

to measure a temperature difference; an absolute temperature may be

found by performing the voltage measurement at a known reference

temperature. A metal of unknown composition can be classified by its

thermoelectric effect if a metallic probe of known composition is kept

at a constant temperature and held in contact with the unknown sample

that is locally heated to the probe temperature. It is used commercially

to identify metal alloys. Thermocouples in series form a thermopile. Thermoelectric generators are used for creating power from heat differentials.

. This simple relationship, which does not depend on conductivity, is used in the thermocouple

to measure a temperature difference; an absolute temperature may be

found by performing the voltage measurement at a known reference

temperature. A metal of unknown composition can be classified by its

thermoelectric effect if a metallic probe of known composition is kept

at a constant temperature and held in contact with the unknown sample

that is locally heated to the probe temperature. It is used commercially

to identify metal alloys. Thermocouples in series form a thermopile. Thermoelectric generators are used for creating power from heat differentials. and

and  are the Peltier coefficients of conductors A and B, and

are the Peltier coefficients of conductors A and B, and  is the electric current (from A to B). The total heat generated is not

determined by the Peltier effect alone, as it may also be influenced by

Joule heating and thermal-gradient effects (see below).

is the electric current (from A to B). The total heat generated is not

determined by the Peltier effect alone, as it may also be influenced by

Joule heating and thermal-gradient effects (see below). and

and  are different. The Peltier effect can be considered as the back-action counterpart to the Seebeck effect (analogous to the back-emf

in magnetic induction): if a simple thermoelectric circuit is closed,

then the Seebeck effect will drive a current, which in turn (by the

Peltier effect) will always transfer heat from the hot to the cold

junction. The close relationship between Peltier and Seebeck effects can

be seen in the direct connection between their coefficients:

are different. The Peltier effect can be considered as the back-action counterpart to the Seebeck effect (analogous to the back-emf

in magnetic induction): if a simple thermoelectric circuit is closed,

then the Seebeck effect will drive a current, which in turn (by the

Peltier effect) will always transfer heat from the hot to the cold

junction. The close relationship between Peltier and Seebeck effects can

be seen in the direct connection between their coefficients:  (see below).

(see below). is passed through a homogeneous conductor, the Thomson effect predicts a heat production rate per unit volume

is passed through a homogeneous conductor, the Thomson effect predicts a heat production rate per unit volume is the temperature gradient, and

is the temperature gradient, and  is the Thomson coefficient. The Thomson coefficient is related to the Seebeck coefficient as

is the Thomson coefficient. The Thomson coefficient is related to the Seebeck coefficient as  (see below). This equation, however, neglects Joule heating and ordinary thermal conductivity (see full equations below).

(see below). This equation, however, neglects Joule heating and ordinary thermal conductivity (see full equations below). , is[9]

, is[9] is the thermal conductivity. The first term is the Fourier's heat conduction law, and the second term shows the energy carried by currents. The third term,

is the thermal conductivity. The first term is the Fourier's heat conduction law, and the second term shows the energy carried by currents. The third term,  , is the heat added from an external source (if applicable).

, is the heat added from an external source (if applicable). and

and  . Using these facts and the second Thomson relation (see below), the heat equation then can be simplified to

. Using these facts and the second Thomson relation (see below), the heat equation then can be simplified to at junction) and Thomson (

at junction) and Thomson ( in thermal gradient) effects. Combined with the Seebeck equation for

in thermal gradient) effects. Combined with the Seebeck equation for  , this can be used to solve for the steady-state voltage and temperature profiles in a complicated system.

, this can be used to solve for the steady-state voltage and temperature profiles in a complicated system. is the absolute temperature,

is the absolute temperature,  is the Thomson coefficient,

is the Thomson coefficient,  is the Peltier coefficient, and

is the Peltier coefficient, and  is the Seebeck coefficient. This relationship is easily shown given

that the Thomson effect is a continuous version of the Peltier effect.

Using the second relation (described next), the first Thomson relation

becomes

is the Seebeck coefficient. This relationship is easily shown given

that the Thomson effect is a continuous version of the Peltier effect.

Using the second relation (described next), the first Thomson relation

becomes  .

.