Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, straw, woodchips, food waste, etc. Bioplastic can be made from agricultural by-products and also from used plastic bottles and other containers using microorganisms. Common plastics, such as fossil-fuel plastics (also called petrobased polymers) are derived from petroleum or natural gas. Not all bioplastics are biodegradable nor biodegrade more readily than commodity fossil-fuel derived plastics. Bioplastics are usually derived from sugar derivatives, including starch, cellulose, and lactic acid. As of 2014, bioplastics represented approximately 0.2% of the global polymer market (300 million tons).

IUPAC definition

Biobased polymer derived from the biomass or issued from monomers derived from the biomass and which, at some stage in its processing into finished products, can be shaped by flow.

- Note 1: Bioplastic is generally used as the opposite of polymer derived from

fossil resources.

- Note 2: Bioplastic is misleading because it suggests that any polymer derived

from the biomass is environmentally friendly.

- Note 3: The use of the term "bioplastic" is discouraged. Use the expression

"biobased polymer".

- Note 4: A biobased polymer similar to a petro-based one does not imply any

superiority with respect to the environment unless the comparison of respective

life cycle assessments is favorable.

Biodegradable plastic utensils

Packaging peanuts made from bioplastics (thermoplastic starch)

Plastics packaging made from bioplastics and other biodegradable plastics

Applications

Bioplastics are used for disposable items, such as packaging, crockery, cutlery, pots, bowls, and straws.

Few commercial applications exist for bioplastics. In principle they

could replace many applications for petroleum-derived plastics, however

cost and performance remain problematic. As a matter of fact, their

usage is favourable only if supported by specific regulations limiting

the usage of conventional plastics.

Typical is the example of Italy, where biodegradable plastic bags and

shoppers are compulsory since 2011 with the introduction of a specific

law. Beyond structural materials, electroactive bioplastics are being developed that promise to be used to carry electric current.

Biopolymers are available as coatings for paper rather than the more common petrochemical coatings.

Types

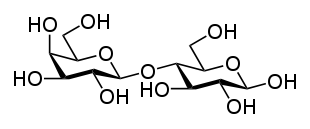

Starch-based plastics

Thermoplastic starch currently represents the most widely used bioplastic, constituting about 50 percent of the bioplastics market. Simple starch bioplastic can be made at home. Pure starch is able to absorb humidity, and is thus a suitable material for the production of drug capsules by the pharmaceutical sector. Flexibiliser and plasticizer such as sorbitol and glycerine

can also be added so the starch can also be processed

thermo-plastically. The characteristics of the resulting bioplastic

(also called "thermo-plastical starch") can be tailored to specific

needs by adjusting the amounts of these additives.

Starch-based bioplastics are often blended with biodegradable polyesters to produce starch/polylactic acid, starch/polycaprolactone or starch/Ecoflex (polybutylene adipate-co-terephthalate produced by BASF). blends. These blends are used for industrial applications and are also compostable. Other producers, such as Roquette, have

developed other starch/polyolefin

blends. These blends are not biodegradable, but have a lower carbon

footprint than petroleum-based plastics used for the same applications.

Due to the origin of its raw material, starch is cheap, abundant, and renewable.

Starch based plastics are complex blends of starch with

compostable plastics such as Polylactic acid, Polybutylene Adipate

Terephthalate, Polybutylene Succinate, Polycaprolactone, and

Polyhydroxyalkanoates. These complex blends improve water resistance as

well as processing and mechanical properties.

Starch-based films (mostly used for packaging purposes) are made

mainly from starch blended with thermoplastic polyesters to form

biodegradable and compostable products. These films are seen

specifically in consumer goods packaging of magazine wrappings and

bubble films. In food packaging, these films are seen as bakery or fruit

and vegetable bags. Composting bags with this films are used in

selective collecting of organic waste.

Further, a new starch-based film was developed by Agricultural Research Service scientists can even be used as a paper.

Cellulose-based plastics

A packaging blister made from cellulose acetate, a bioplastic

Cellulose bioplastics are mainly the cellulose esters, (including cellulose acetate and nitrocellulose) and their derivatives, including celluloid.

Cellulose can become thermoplastic when extensively modified. An

example of this is cellulose acetate, which is expensive and therefore

rarely used for packaging. However, cellulosic fibers added to starches

can improve mechanical properties, permeability to gas, and water

resistance due to being less hydrophilic than starch.

A group at Shanghai University was able to construct a novel

green plastic based on cellulose through a method called hot pressing.

Protein-based plastics

Bioplastics

can be made from proteins from different sources. For example, wheat

gluten and casein show promising properties as a raw material for

different biodegradable polymers.

Additionally, soy protein is being considered as another source

of bioplastic. Soy proteins have been used in plastic production for

over one hundred years. For example, body panels of an original Ford

automobile were made of soy-based plastic.

There are difficulties with using soy protein-based plastics due

to their water sensitivity and relatively high cost. Therefore,

producing blends of soy protein with some already-available

biodegradable polyesters improves the water sensitivity and cost.

Some aliphatic polyesters

The aliphatic biopolyesters are mainly polyhydroxyalkanoates (PHAs) like the poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV) and polyhydroxyhexanoate (PHH).

Polylactic acid (PLA)

Mulch film made of polylactic acid (PLA)-blend bio-flex

Polylactic acid (PLA) is a transparent plastic produced from corn or dextrose. Superficially, it is similar to conventional petrochemical-based mass plastics like PS.

It has the distinct advantage of degrading to nontoxic products.

Unfortunately it exhibits inferior impact strength, thermal robustness,

and barrier properties (blocking air transport across the membrane).

PLA and PLA blends generally come in the form of granulates with

various properties, and are used in the plastic processing industry for

the production of films, fibers, plastic containers, cups and bottles.

PLA is also the most common type of plastic filament used for home fused deposition modeling.

Poly-3-hydroxybutyrate

The biopolymer poly-3-hydroxybutyrate (PHB) is a polyester produced by certain bacteria processing glucose, corn starch or wastewater. Its characteristics are similar to those of the petroplastic polypropylene. PHB production is increasing. The South American sugar

industry, for example, has decided to expand PHB production to an

industrial scale. PHB is distinguished primarily by its physical

characteristics. It can be processed into a transparent film with a

melting point higher than 130 degrees Celsius, and is biodegradable

without residue.

Polyhydroxyalkanoates

Polyhydroxyalkanoates are linear polyesters produced in nature by bacterial fermentation of sugar or lipids.

They are produced by the bacteria to store carbon and energy. In

industrial production, the polyester is extracted and purified from the

bacteria by optimizing the conditions for the fermentation of sugar.

More than 150 different monomers

can be combined within this family to give materials with extremely

different properties. PHA is more ductile and less elastic than other

plastics, and it is also biodegradable. These plastics are being widely

used in the medical industry.

Polyamide 11

PA 11 is a biopolymer derived from natural oil. It is also known under the tradename Rilsan B, commercialized by Arkema. PA 11 belongs to the technical polymers family and is not biodegradable. Its properties are similar to those of PA 12,

although emissions of greenhouse gases and consumption of nonrenewable

resources are reduced during its production. Its thermal resistance is

also superior to that of PA 12. It is used in high-performance

applications like automotive fuel lines, pneumatic airbrake tubing,

electrical cable antitermite sheathing, flexible oil and gas pipes,

control fluid umbilicals, sports shoes, electronic device components,

and catheters.

A similar plastic is Polyamide 410 (PA 410), derived 70% from castor oil, under the trade name EcoPaXX, commercialized by DSM.

PA 410 is a high-performance polyamide that combines the benefits of a

high melting point (approx. 250 °C), low moisture absorption and

excellent resistance to various chemical substances.

Bio-derived polyethylene

The basic building block (monomer) of polyethylene

is ethylene. Ethylene is chemically similar to, and can be derived from

ethanol, which can be produced by fermentation of agricultural

feedstocks such as sugar cane or corn. Bio-derived polyethylene is

chemically and physically identical to traditional polyethylene – it

does not biodegrade but can be recycled. The Brazilian chemicals group Braskem

claims that using its method of producing polyethylene from sugar cane

ethanol captures (removes from the environment) 2.15 tonnes of CO2 per tonne of Green Polyethylene produced.

Genetically modified bioplastics

Genetic modification

(GM) is also a challenge for the bioplastics industry. None of the

currently available bioplastics – which can be considered first

generation products – require the use of GM crops, although GM corn is

the standard feedstock.

Looking further ahead, some of the second generation bioplastics

manufacturing technologies under development employ the "plant factory"

model, using genetically modified crops or genetically modified bacteria to optimize efficiency.

Polyhydroxyurethanes

Recently,

there have been a large emphasis on producing biobased and

isocyanate-free polyurethanes. One such example utilizes a spontaneous

reaction between polyamines and cyclic carbonates to produce

polyhydroxurethanes.

Unlike traditional cross-linked polyurethanes, cross-linked

polyhydroxyurethanes have been shown to be capable of recycling and

reprocessing through dynamic transcarbamoylation reactions.

Lipid derived polymers

A number bioplastic classes have been synthesized from plant and animal derived fats and oils. Polyurethanes, polyesters, epoxy resins, and a number of other types of polymers have been developed with

comparable properties to crude oil based materials. The recent

development of olefin metathesis has opened a wide variety of feedstocks to economical conversion into biomonomers and polymers. With the growing production of traditional vegetable oils as well as low cost microalgae derived oils, there is huge potential for growth in this area.

Environmental impact

Confectionery packaging made of PLA-blend bio-flex

Bottles made from cellulose acetate biograde

Drinking straws made of PLA-blend bio-flex

Jar made of PLA-blend bio-flex, a bioplastic

Materials such as starch, cellulose, wood, sugar and biomass are used

as a substitute for fossil fuel resources to produce bioplastics; this

makes the production of bioplastics a more sustainable activity compared

to conventional plastic production.

The environmental impact of bioplastics is often debated, as there are

many different metrics for "greenness" (e.g., water use, energy use,

deforestation, biodegradation, etc.).

Hence bioplastic environmental impacts are categorized into

nonrenewable energy use, climate change, eutrophication and

acidification. Bioplastic production significantly reduces greenhouse gas emissions and decreases non-renewable energy consumption. Firms worldwide would also be able to increase the environmental sustainability of their products by using bioplastics.

Although bioplastics save more nonrenewable energy than

conventional plastics and emit less GHG compared to conventional

plastics, bioplastics also have negative environmental impacts such as

eutrophication and acidification. Bioplastics induce higher eutrophication potentials than conventional plastics.

Biomass production during industrial farming practices causes nitrate

and phosphate to filtrate into water bodies; this causes eutrophication

which is the richness of the nutrients in body waters.

Eutrophication is a threat to water resources around the world since it

kills aquatic organisms, creates dead zones and causes harmful algal

blooms. Bioplastics also increase acidification.

The high increase in eutrophication and acidification caused by

bioplastics is also caused by using chemical fertilizer in the

cultivation of renewable raw materials to produce bioplastics.

Other environmental impacts of bioplastics include exerting lower

human and terrestrial ecotoxicity and carcinogenic potentials compared

to conventional plastics. However, bioplastics exert higher aquatic ecotoxicity than conventional materials.

Bioplastics and other bio-based materials increase stratospheric ozone

depletion compared to conventional plastics; this is a result of nitrous

oxide emissions during fertilizer application during industrial farming

for biomass production. Artificial fertilizer increase nitrous oxide emissions especially when the crop does not need all the nitrogen. Minor environmental impacts of bioplastics include toxicity through using pesticides on the crops used to make bioplastics. Bioplastics also cause carbon dioxide emissions from harvesting vehicles.

Other minor environmental impacts include high water consumption for

biomass cultivation, soil erosion, soil carbon losses and loss of

biodiversity, and they are mainly are a result of land use associated

with bioplastics.

Land use for bioplastics production leads to lost carbon sequestration

and increases the carbon costs while diverting land from its existing

uses

Although bioplastics are extremely advantageous because they

reduce non-renewable consumption and GHG emissions, they also negatively

affect the environment through land and water consumption, using

pesticide and fertilizer, eutrophication and acidification; hence one's

preference for either bioplastics or conventional plastics depends on

what one considers the most important environmental impact.

Biodegradation of Bioplastics

Packaging air pillow made of PLA-blend bio-flex

Biodegradation of any plastic is a process that happens at

solid/liquid interface whereby the enzymes in the liquid phase

depolymerize the solid phase Both bioplastics and conventional plastics containing additives are able to biodegrade. Bioplastics are able to biodegrade in different environments hence they are more acceptable than conventional plastics. Biodegradability of bioplastics occurs under various environmental conditions including soil, aquatic environments and compost.

Both the structure and composition of biopolymer or bio-composite have

an effect on the biodegradation process, hence changing the composition

and structure might increase biodegradability. Soil and compost as environment conditions are more efficient in biodegradation due to their high microbial diversity. Composting not only biodegrades bioplastics efficiently but it also significantly reduces the emission of greenhouse gases.

Biodegradability of bioplastics in compost environments can be upgraded

by adding more soluble sugar and increasing temperature.

Soil environments on the other hand have high diversity of

microorganisms making it easier for biodegradation of bioplastics to

occur. However, bioplastics in soil environments need higher temperatures and a longer time to biodegrade.

Some bioplastics biodegrade more efficiently in water bodies and marine

systems; however, this causes danger to marine ecosystems and

freshwater.

Hence it is accurate to conclude that biodegradation of bioplastics in

water bodies which leads to the death of aquatic organisms and unhealthy

water can be noted as one of the negative environmental impacts of

bioplastics.

Industry and markets

Tea bags made of polylactide (PLA), (peppermint tea)

While

plastics based on organic materials were manufactured by chemical

companies throughout the 20th century, the first company solely focused

on bioplastics- Marlborough Biopolymers- was founded in 1983. However,

Marlborough and other ventures that followed failed to find commercial

success, with the first such company to secure long-term financial

success being the Italian company Novamont, founded in 1989.

The expense and time requirements of researching and testing new

bio-based and biodegradable polymers have placed bioplastics at a

commercial disadvantage compared to petrochemical-based plastics.

Bioplastics remain less than one percent of all plastics manufactured

worldwide, and until very recently have been an average of 2-4 times more expensive to manufacture than petrochemical plastics. Most bioplastics do not yet save more carbon emissions than are required to manufacture them.

In addition to the cost of research, bioplastics lack the versatility

of application that petrochemical plastics possess, with many

conventional plastics having no bio-based equivalent that can match

their quality.

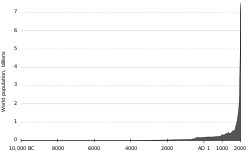

Finally, the industry faces logistical problems with both material

sources and waste disposal infrastructure. As most bioplastics are

produced from plant sugars, starches, or oils, it is estimated that

replacing 250 million tons of the plastic manufactured each year with

bio-based plastics would require 100 million hectares of land, or 7

percent of the arable land on Earth. And when bioplastics reach the end

of their life cycle, those designed to be compostable and marketed as

biodegradable are often sent to landfills due to the lack of proper

composting facilities or waste sorting, where they then release methane

as they break down anaerobically.

Despite this, the bioplastics industry has grown by 20-30% a year. BCC

Research forecast that the global market for biodegradable polymers

would grow at a compound average growth rate of more than 17 percent

through 2012, and this rate of growth has actually been exceeded.

Bio-based plastics are predicted to make up 5% of all manufactured

plastics in 2020, and 40% of all manufactured plastics in 2030.

Ceresana predicts that when bioplastics reach 5% of the plastics market

in 2020, the market for bio-based plastics will be worth 5.8 billion

dollars, three times the size of the bioplastics market in 2014.

The largest demand for bioplastics has been in packaging, driven by

widespread concern over the use of petrochemical plastics in disposable,

one-use products that are then sequestered in landfills or the natural

environment. Packaging continues to provide 60% of the market for

bioplastic, and to account for the largest share of growth in the

industry. There has been a shift in the market for an increased demand of bioplastics, especially for sustainable packaging.

This has been seen specifically in Western Europe, which accounted for

more than 45% of the global biodegradable plastics demand in 2014. This

demand from consumers for more sustainable options was also seen in

recent policies; Italy has banned the use of petroleum-based plastic

bags, and there is a tax on use of petroleum based plastic bags in

Germany.

However, the industry in biobased polymers has not grown as rapidly as

some have predicted. The NNFCC predicted that the industry would exceed

2.1 million tonnes produced each year by 2013,

but by in 2017, only 2.05 million tonnes of bioplastic were produced in

that year. This remains only a small fraction of all plastics

manufacturing, which produced a total 292 million tonnes of

thermoplastics in 2015.

As production expands, there remain no universal standards governing

bioplastics and their manufacture or disposal. This includes a lack of

any regulation on the amount of sustainably sourced material in a

product required for it to be marketed as a bioplastic.

It should also be noted that, according to Market and Market, the

global biodegradable plastics market is just beginning and only accounts

for less than 1% of the overall plastics market.

Prism pencil sharpener made from cellulose acetate biograde

Because of the fragmentation in the market and ambiguous definitions

it is difficult to describe the total market size for bioplastics, but

estimates put global production capacity at 327,000 tonnes. In contrast, global production of polyethylene (PE) and polypropylene (PP), the world's leading petrochemical derived polyolefins, was estimated at over 150 million tonnes in 2015.

COPA (Committee of Agricultural Organisation in the European

Union) and COGEGA (General Committee for the Agricultural Cooperation in

the European Union) have made an assessment of the potential of

bioplastics in different sectors of the European economy:

- Catering products: 450,000 tonnes per year

- Organic waste bags: 100,000 tonnes per year

- Biodegradable mulch foils: 130,000 tonnes per year

- Biodegradable foils for diapers 80,000 tonnes per year

- Diapers, 100% biodegradable: 240,000 tonnes per year

- Foil packaging: 400,000 tonnes per year

- Vegetable packaging: 400,000 tonnes per year

- Tyre components: 200,000 tonnes per year

- Total: 2,000,000 tonnes per year

History and development of bioplastics

- 1862: At the Great London Exhibition, Alexander Parkensine displays Parkenisine, the first plastic. Parkensine is made from nitrocellulose. (White 1998)

- 1897: Still produced today, Galalith is a milk-based bioplastic that was created by German chemists in 1897. Galalith is primarily found in buttons. (Thielen 2014)

- 1907: Leo Baekeland invented Bakelite, which received the National Historic Chemical Landmark for its non-conductivity and heat-resistant properties. It is used in radio and telephone casings, kitchenware, firearms and many more products. (Pathak, Sneha, Mathew 2014)

- 1912: Brandenberger invents Cellophane out of wood, cotton, or hemp cellulose. (Thielen 2014)

- 1920s: Wallace Carothers finds Polylactic Acid (PLA) plastic. PLA is incredibly expensive to produce and is not mass-produced until 1989. (Whiteclouds 2018)

- 1926: Maurice Lemoigne invents polyhydroxybutyrate (PHB) which is the first bioplastic made from bacteria. (Thielen 2014)

- 1930s: The first bioplastic car was made from soy beans by Henry Ford. (Thielen 2014)

- 1940-1945: During World War II, an increase in plastic production is seen as it is used in many wartime materials. Due to government funding and oversight the United States production of plastics (in general, not just bioplastics) tripled during 1940-1945(Rogers 2005).

- 1950s: Amylomaize (>50% amylose content corn) was successfully bred and commercial bioplastics applications started to be explored. (Liu, Moult, Long, 2009) A decline in bioplastic development is seen due to the cheap oil prices, however the development of synthetic plastics continues.

- 1970s: The environmental movement spurred more development in bioplastics. (Rogers 2005)

- 1983: The first bioplastics company, Marlborough Biopolymers, is started which uses a bacteria-based bioplastic called biopal. (Feder 1985)

- 1989: The further development of PLA is made by Dr. Patrick R. Gruber when he figures out how to create PLA from corn. (Whiteclouds 2018). The leading bioplastic company is created called Novamount. Novamount uses matter-bi, a bioplastic, in multiple different applications. (Novamount 2018)

- 1992: It is reported in Science that PHB can be produced by the plant Arabidopsis thaliana. (Poirier, Dennis, Klomparens, Nawrath, Somerville 1992)

- Late 1990s: The development of TP starch and BIOPLAST from research and production of the company BIOTEC lead to the BIOFLEX film. BIOFLEX film can be classified as blown film extrusion, flat film extrusion, and injection moulding lines. These three classifications have applications as follows: Blown films - sacks, bags, trash bags, mulch foils, hygiene products, diaper films, air bubble films, protective clothing, gloves, double rib bags, labels, barrier ribbons; Flat films - trays, flower pots, freezer products and packaging, cups, pharmaceutical packaging; Injection moulding - disposable cutlery, cans, containers, performed pieces, CD trays, cemetery articles, golf tees, toys, writing materials. (Lorcks 1998)

- 2001: Metabolix inc. purchases Monsanto's biopol business (originally Zeneca) which uses plants to produce bioplastics. (Barber and Fisher 2001)

- 2001: Nick Tucker uses elephant grass as a bioplastic base to make plastic car parts. (Tucker 2001)

- 2005: Cargill and Dow Chemicals is rebranded as NatureWorks and becomes the leading PLA producer. (Penisi 2016)

- 2007: Metabolix inc. market tests its first 100% biodegradable plastic called Mirel, made from corn sugar fermenation and genetically engineered bacteria. (Digregorio 2009)

- 2012: A bioplastic is developed from seaweed proving to be one of the most environmentally friendly bioplastics based on research published in the journal of pharmacy research. (Rajendran, Puppala, Sneha, Angeeleena, Rajam 2012)

- 2013: a patent is put on bioplastic derived from blood and a crosslinking agent like sugars, proteins, etc. (iridoid derivatives, diimidates, diones, carbodiimides, acrylamides, dimethylsuberimidates, aldehydes, Factor XIII, dihomo bifunctional NHS esters, carbonyldiimide, glyoxyls, proanthocyanidin, reuterin). This invention can be applied by using the bioplastic as tissue, cartilage, tendons, ligaments, bones, and being used in stem cell delivery. (Campbell, Burgess, Weiss, Smith 2013)

- 2014: It is found in a study published in 2014 that bioplastics can be made from blending vegetable waste (parsley and spinach stems, the husks from cocoa, the hulls of rice, etc.) with TFA solutions of pure cellulose creates a bioplastic. (Bayer, Guzman-Puyol, Heredia-Guerrero, Ceseracciu, Pignatelli, Ruffilli, Cingolani, and Athanassiou 2014)

- 2016: An experiment finds that a car bumper that passes regulation can be made from nano-cellulose based bioplastic biomaterials using banana peels. (Hossain, Ibrahim, Aleissa 2016)

- 2017: A new proposal for bioplastics made from Lignocellulosics resources (dry plant matter). (Brodin, Malin, Vallejos, Opedal, Area, Chinga-Carrasco 2017)

- 2018: Many developments occur including Ikea starting industrial production of bioplastics furniture (Barret 2018), Project Effective focusing on replacing nylon with bio-nylon (Barret 2018), and the first packaging made from fruit (Barret 2018).

*not a comprehensive list; inventions pulled by the author to show

versatility of bioplastics and important breakthroughs; new applications

and inventions of bioplastics happen each year

| Year | Bioplastic Discovery or Development |

|---|---|

| 1862 | Parkesine - Alexander Parkes |

| 1868 | Celluloid - John Wesley Hyatt |

| 1897 | Galalith - German chemists |

| 1907 | Bakelite - Leo Baekeland |

| 1912 | Cellophane - Jacques E. Brandenberger |

| 1920s | Polylactic ACid (PLA) - Wallace Carothers |

| 1926 | Polyhydroxybutyrate (PHB) - Maurice Lemoigne |

| 1930s | Soy bean-based bioplastic car - Henry Ford |

| 1983 | Biopal - Marlborough Biopolymers |

| 1989 | PLA from corn - Dr. Patrick R. Gruber; Matter-bi - Novamount |

| 1992 | PHB can be produced by Arabidopsis thaliana (a small flowering plant) |

| 1998 | Bioflex film (blown, flat, injection molding) leads to many different applications of bioplastic |

| 2001 | PHB can be produced by elephant grass |

| 2007 | Mirel (100% biodegradable plastic) by Metabolic inc. is market tested |

| 2012 | Bioplastic is developed from seaweed |

| 2013 | Bioplastic made from blood and a cross-linking agent which is used in medical procedures |

| 2014 | Bioplastic made from vegetable waste |

| 2016 | Car bumper made from banana peel bioplastic |

| 2017 | Bioplastics made from lignocellulosic resources (dry plant matter) |

| 2018 | Bioplastic furniture, bio-nylon, packaging from fruit |

Bioplastics Development Center - University of Massachusetts Lowell

A pen made with bioplastics (Polylactide, PLA)

Testing procedures

A bioplastic shampoo bottle made of PLA-blend bio-flex

Industrial compostability – EN 13432, ASTM D6400

The EN

13432 industrial standard is arguably the most international in scope.

This standard must be met in order to claim that a plastic product is

compostable in the European marketplace. In summary, it requires

biodegradation of 90% of the materials in a lab within 90 days. The ASTM

6400 standard is the regulatory framework for the United States and

sets a less stringent threshold of 60% biodegradation within 180 days

for non-homopolymers, and 90% biodegradation of homopolymers within

industrial composting conditions (temperatures at or above 140F).

Municipal compost facilities do not see above 130F.

Many starch-based plastics, PLA-based plastics and certain aliphatic-aromatic co-polyester compounds, such as succinates and adipates, have obtained these certificates. Additive-based bioplastics sold as photodegradable or Oxo Biodegradable do not comply with these standards in their current form.

Compostability – ASTM D6002

The ASTM D 6002 method for determining the compostability of a plastic defined the word compostable as follows:

...that which is capable of undergoing biological decomposition in a compost site such that the material is not visually distinguishable and breaks down into carbon dioxide, water, inorganic compounds and biomass at a rate consistent with known compostable materials.

This definition drew much criticism because, contrary to the way the

word is traditionally defined, it completely divorces the process of

"composting" from the necessity of it leading to humus/compost as the end product. The only criterion this standard does describe is that a compostable plastic must look to be going away as fast as something else one has already established to be compostable under the traditional definition.

Withdrawal of ASTM D 6002

In

January 2011, the ASTM withdrew standard ASTM D 6002, which had

provided plastic manufacturers with the legal credibility to label a

plastic as compostable. Its description is as follows:

This guide covered suggested criteria, procedures, and a general approach to establish the compostability of environmentally degradable plastics.

The ASTM has yet to replace this standard.

Biobased – ASTM D6866

The

ASTM D6866 method has been developed to certify the biologically

derived content of bioplastics. Cosmic rays colliding with the

atmosphere mean that some of the carbon is the radioactive isotope carbon-14. CO2 from the atmosphere is used by plants in photosynthesis, so new plant material will contain both carbon-14 and carbon-12. Under the right conditions, and over geological timescales, the remains of living organisms can be transformed into fossil fuels.

After ~100,000 years all the carbon-14 present in the original organic

material will have undergone radioactive decay leaving only carbon-12. A

product made from biomass

will have a relatively high level of carbon-14, while a product made

from petrochemicals will have no carbon-14. The percentage of renewable

carbon in a material (solid or liquid) can be measured with an

accelerator mass spectrometer.

There is an important difference between biodegradability and

biobased content. A bioplastic such as high-density polyethylene (HDPE)

can be 100% biobased (i.e. contain 100% renewable carbon), yet be

non-biodegradable. These bioplastics such as HDPE nonetheless play an

important role in greenhouse gas abatement, particularly when they are

combusted for energy production. The biobased component of these

bioplastics is considered carbon-neutral since their origin is from

biomass.

Anaerobic biodegradability – ASTM D5511-02 and ASTM D5526

The

ASTM D5511-12 and ASTM D5526-12 are testing methods that comply with

international standards such as the ISO DIS 15985 for the

biodegradability of plastic.