An old textile factory ("Cvernovka") in Bratislava, Slovakia (1901-2004).

Textile factory (Germany, c. 1975).

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

Industry process

Cotton manufacturing

Cotton

is the world's most important natural fibre. In the year 2007, the

global yield was 25 million tons from 35 million hectares cultivated in

more than 50 countries.

There are five stages:

- Cultivating and Harvesting

- Preparatory Processes

- Spinning — giving yarn

- Weaving — giving fabrics

- Finishing — giving textiles

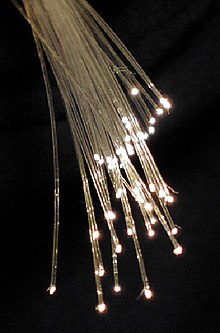

Synthetic fibres

Artificial fibres can be made by extruding a polymer,

through a spinneret into a medium where it hardens. Wet spinning

(rayon) uses a coagulating medium. In dry spinning (acetate and

triacetate), the polymer is contained in a solvent that evaporates in

the heated exit chamber. In melt spinning (nylons and polyesters) the

extruded polymer is cooled in gas or air and then sets. All these fibres will be of great length, often kilometres long.

Artificial fibres can be processed as long fibres or batched and cut so they can be processed like a natural fibre.

Natural fibres

Natural fibres are either from animals (sheep, goat, rabbit, silk-worm) mineral (asbestos) or from plants (cotton, flax, sisal). These vegetable fibres can come from the seed (cotton), the stem (known as bast fibres: flax, hemp, jute) or the leaf (sisal).

Without exception, many processes are needed before a clean even staple

is obtained- each with a specific name. With the exception of silk,

each of these fibres is short, being only centimeters in length, and

each has a rough surface that enables it to bond with similar staples.

History

Cottage stage

There are some indications that weaving was already known in the Palaeolithic. An indistinct textile impression has been found at Pavlov, Moravia. Neolithic textiles were found in pile dwellings excavations in Switzerland and at El Fayum, Egypt at a site which dates to about 5000 BC.

In Roman times, wool, linen and leather clothed the European population, and silk, imported along the Silk Road from China, was an extravagant luxury. The use of flax fiber in the manufacturing of cloth in Northern Europe dates back to Neolithic times.

During the late medieval period, cotton began to be imported into Northern Europe. Without any knowledge of what it came from, other than that it was a plant, noting its similarities to wool, people in the region could only imagine that cotton must be produced by plant-borne sheep. John Mandeville, writing in 1350, stated as fact the now-preposterous belief: "There grew in India

a wonderful tree which bore tiny lambs on the edges of its branches.

These branches were so pliable that they bent down to allow the lambs to

feed when they are hungry." This aspect is retained in the name for

cotton in many European languages, such as German Baumwolle,

which translates as "tree wool". By the end of the 16th century, cotton

was cultivated throughout the warmer regions of Asia and the Americas.

The main steps in the production of cloth are producing the

fibre, preparing it, converting it to yarn, converting yarn to cloth,

and then finishing the cloth. The cloth is then taken to the

manufacturer of garments. The preparation of the fibres differs the

most, depending on the fibre used. Flax requires retting and dressing, while wool requires carding and washing. The spinning and weaving processes are very similar between fibers, however.

Spinning evolved from twisting the fibers by hand, to using a drop spindle, to using a spinning wheel.

Spindles or parts of them have been found in archaeological sites and

may represent one of the first pieces of technology available. The spinning wheel was most likely invented in the Islamic world by the 11th century.

India

A woman in Dhaka clad in fine Bengali muslin, 18th century.

Up until the 18th century, Mughal Empire was the most important center of manufacturing in international trade. Up until 1750, India produced about 25% of the world's industrial output. The largest manufacturing industry in Mughal Empire (16th to 18th centuries) was textile manufacturing, particularly cotton textile manufacturing, which included the production of piece goods, calicos, and muslins,

available unbleached and in a variety of colours. The cotton textile

industry was responsible for a large part of the empire's international

trade. Bengal had a 25% share of the global textile trade in the early 18th century.

Bengal cotton textiles were the most important manufactured goods in

world trade in the 18th century, consumed across the world from the Americas to Japan. The most important center of cotton production was the Bengal Subah province, particularly around its capital city of Dhaka.

Bengal accounted for more than 50% of textiles and around 80% of silks imported by the Dutch from Asia and marketed it to the world, Bengali silk and cotton textiles were exported in large quantities to Europe, Asia, and Japan, and Bengali muslin textiles from Dhaka were sold in Central Asia, where they were known as "daka" textiles. Indian textiles dominated the Indian Ocean trade for centuries, were sold in the Atlantic Ocean trade, and had a 38% share of the West African

trade in the early 18th century, while Bengal calicos were major force

in Europe, and Bengal textiles accounted for 30% of total English trade

with Southern Europe in the early 18th century.

In early modern Europe, there was significant demand for textiles from The Mughal Empire, including cotton textiles and silk products. European fashion,

for example, became increasingly dependent on textiles and silks

imported from The Mughal Empire. In the late 17th and early 18th

centuries, The Mughal Empire accounted for 95% of British imports from Asia.

Britain

The key British industry at the beginning of the 18th century was the

production of textiles made with wool from the large sheep-farming

areas in the Midlands and across the country (created as a result of land-clearance and enclosure). This was a labour-intensive activity providing employment throughout Britain, with major centres being the West Country; Norwich and environs; and the West Riding of Yorkshire.

The export trade in woolen goods accounted for more than a quarter of

British exports during most of the 18th century, doubling between 1701

and 1770.

Exports by the cotton industry – centered in Lancashire

– had grown tenfold during this time, but still accounted for only a

tenth of the value of the woolen trade. Before the 17th century, the

manufacture of goods was performed on a limited scale by individual

workers, usually on their own premises (such as weavers' cottages). Goods were transported around the country by clothiers who visited the village with their trains of packhorses. Some of the cloth was made into clothes for people living in the same area, and a large amount of cloth was exported. River navigations were constructed, and some contour-following canals. In the early 18th century, artisans were inventing ways to become more productive. Silk, wool, fustian, and linen were being eclipsed by cotton, which was becoming the most important textile. This set the foundations for the changes.

Industrial revolution

The woven fabric portion of the textile industry grew out of the industrial revolution in the 18th century as mass production of yarn and cloth became a mainstream industry.

In 1734 in Bury, Lancashire John Kay invented the flying shuttle — one of the first of a series of inventions associated with the cotton woven fabric industry. The flying shuttle increased the width of cotton cloth and speed of production of a single weaver at a loom.

Resistance by workers to the perceived threat to jobs delayed the

widespread introduction of this technology, even though the higher rate

of production generated an increased demand for spun cotton.

Shuttles

In 1761, the Duke of Bridgewater's canal connected Manchester to the coal fields of Worsley and in 1762, Matthew Boulton opened the Soho Foundry engineering works in Handsworth, Birmingham. His partnership with Scottish engineer James Watt resulted, in 1775, in the commercial production of the more efficient Watt steam engine which used a separate condenser.

In 1764, James Hargreaves is credited as inventor of the spinning jenny

which multiplied the spun thread production capacity of a single worker

— initially eightfold and subsequently much further. Others credit the invention to Thomas Highs. Industrial unrest

and a failure to patent the invention until 1770 forced Hargreaves from

Blackburn, but his lack of protection of the idea allowed the concept

to be exploited by others. As a result, there were over 20,000 spinning

jennies in use by the time of his death. Also in 1764, Thorp Mill, the

first water-powered cotton mill in the world was constructed at Royton,

Lancashire, and was used for carding cotton. With the spinning and

weaving process now mechanized, cotton mills cropped up all over the

North West of England.

The stocking frame invented in 1589 for silk became viable when in 1759, Jedediah Strutt introduced an attachment for the frame which produced what became known as the Derby Rib,

that produced a knit and purl stitch. This allowed stockings to be

manufactured in silk and later in cotton. In 1768, Hammond modified the

stocking frame to weave weft-knitted openworks or nets by crossing over

the loops, using a mobile tickler bar- this led in 1781 to Thomas

Frost's square net. Cotton had been too coarse for lace, but by 1805 Houldsworths of Manchester were producing reliable 300 count cotton thread.

19th-century developments

With the Cartwright Loom, the Spinning Mule and the Boulton &

Watt steam engine, the pieces were in place to build a mechanised woven

fabric textile industry. From this point there were no new inventions,

but a continuous improvement in technology as the mill-owner strove to

reduce cost and improve quality. Developments in the transport

infrastructure; that is the canals and after 1831 the railways

facilitated the import of raw materials and export of finished cloth.

Firstly, the use of water power to drive mills was supplemented

by steam driven water pumps, and then superseded completely by the steam engines. For example, Samuel Greg

joined his uncle's firm of textile merchants, and, on taking over the

company in 1782, he sought out a site to establish a mill.Quarry Bank Mill was built on the River Bollin at Styal in Cheshire. It was initially powered by a water wheel, but installed steam engines in 1810. Quarry Bank Mill in Cheshire

still exists as a well-preserved museum, having been in use from its

construction in 1784 until 1959. It also illustrates how the mill

owners exploited child labour, taking orphans from nearby Manchester

to work the cotton. It shows that these children were housed, clothed,

fed and provided with some education. In 1830, the average power of a

mill engine was 48 hp, but Quarry Bank mill installed a new 100 hp water

wheel.

William Fairbairn addressed the problem of line-shafting and was

responsible for improving the efficiency of the mill. In 1815 he

replaced the wooden turning shafts that drove the machines at 50rpm, to

wrought iron shafting working at 250 rpm, these were a third of the

weight of the previous ones and absorbed less power.

A Roberts loom in a weaving shed in 1835. Note the wrought iron shafting, fixed to the cast iron columns

Secondly, in 1830, using an 1822 patent, Richard Roberts manufactured the first loom with a cast iron frame, the Roberts Loom. In 1842 James Bullough and William Kenworthy, made the Lancashire Loom, a semiautomatic power loom: although it is self-acting, it has to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a century, until the Northrop Loom (invented in 1894, with an automatic weft replenishment function) gained ascendancy.

Roberts self-acting mule with quadrant gearing

Thirdly, also in 1830, Richard Roberts patented the first self-acting

mule. Stalybridge mule spinners strike was in 1824; this stimulated

research into the problem of applying power to the winding stroke of the

mule.

The draw while spinning had been assisted by power, but the push of the

wind had been done manually by the spinner, the mule could be operated

by semiskilled labor. Before 1830, the spinner would operate a partially

powered mule with a maximum of 400 spindles; after, self-acting mules

with up to 1300 spindles could be built.

| Year | 1803 | 1820 | 1829 | 1833 | 1857 |

|---|---|---|---|---|---|

| Looms | 2400 | 14650 | 55500 | 100000 | 250000 |

The industrial revolution changed the nature of work and society The three key drivers in these changes were textile manufacturing, iron founding and steam power. The geographical focus of textile manufacture in Britain was Manchester and the small towns of the Pennines and southern Lancashire.

Textile production in England peaked in 1926, and as mills were

decommissioned, many of the scrapped mules and looms were bought up and

reinstated in India.

20th century

Textile factory workers in Poland, 1950s

Major changes came to the textile industry during the 20th century,

with continuing technological innovations in machinery, synthetic fibre,

logistics, and globalization of the business. The business model that

had dominated the industry for centuries was to change radically. Cotton

and wool producers were not the only source for fibres, as chemical

companies created new synthetic fibres that had superior qualities for

many uses, such as rayon, invented in 1910, and DuPont's nylon,

invented in 1935 as in inexpensive silk substitute, and used for

products ranging from women's stockings to tooth brushes and military

parachutes.

The variety of synthetic fibres used in manufacturing fibre grew steadily throughout the 20th century. In the 1920s, the computer was invented; in the 1940s, acetate, modacrylic, metal fibres, and saran were developed; acrylic, polyester, and spandex

were introduced in the 1950s. Polyester became hugely popular in the

apparel market, and by the late 1970s, more polyester was sold in the

United States than cotton.

By the late 1980s, the apparel segment was no longer the largest

market for fibre products, with industrial and home furnishings together

representing a larger proportion of the fibre market.

Industry integration and global manufacturing led to many small firms

closing for good during the 1970s and 1980s in the United States; during

those decades, 95 percent of the looms in North Carolina, South

Carolina and Georgia shut down, and Alabama and Virginia also saw many

factories close.

The largest exporters of textiles in 2013 were China ($274 billion), India ($40 billion), Italy ($36 billion), Germany ($35 billion), Bangladesh ($28 billion) and Pakistan ($27 Billion).

Pakistan

The textile sector accounts for 70% of Pakistan's

exports, but the working conditions of workers are deplorable. Small

manufacturing workshops generally do not sign employment contracts, do

not respect the minimum wage and sometimes employ children. Violations

of labour law also occur among major subcontractors of international

brands, where workers may be beaten, insulted by their superiors or paid

below the minimum wage. Factories do not comply with safety standards,

leading to accidents: in 2012, 255 workers died in a fire at a Karachi

factory. With 547 labour inspectors in Pakistan supervising the

country's 300,000 factories, the textile industry is out of control. Nor

are workers protected by trade unions, which are prohibited in

industrial export zones. Elsewhere, "workers involved in the creation of

trade unions are victims of violence, intimidation, threats or

dismissals".

Bangladesh

Many

Western multinationals use labour in Bangladesh, which is one of the

cheapest in the world: 30 euros per month compared to 150 or 200 in

China. Four days is enough for the CEO of one of the top five global

textile brands to earn what a Bangladeshi garment worker will earn in

her lifetime. In April 2013, at least 1,135 textile workers died in the

collapse of their factory. Other fatal accidents due to unsanitary

factories have affected Bangladesh: in 2005 a factory collapsed and

caused the death of 64 people. In 2006, a series of fires killed 85

people and injured 207 others. In 2010, some 30 people died of

asphyxiation and burns in two serious fires.

In 2006, tens of thousands of workers mobilized in one of the

country's largest strike movements, affecting almost all of the 4,000

factories. The Bangladesh Garment Manufacturers and Exporters

Association (BGMEA) uses police forces to crack down. Three workers were

killed, hundreds more were wounded by bullets, or imprisoned. In 2010,

after a new strike movement, nearly 1,000 people were injured among

workers as a result of the repression.

Ethiopia

Employees of Ethiopian garment factories, who work for brands such as Guess, H&M or Calvin Klein,

receive a monthly salary of 26 dollars per month. These very low wages

have led to low productivity, frequent strikes and high turnover. Some

factories have replaced all their employees on average every 12 months,

according to the 2019 report of the Stern Centre for Business and Human

Rights at New York University.

The report states:" Rather than the docile and cheap labour force

promoted in Ethiopia, foreign-based suppliers have met employees who

are unhappy with their pay and living conditions and who want to protest

more and more by stopping work or even quitting. In their eagerness to

create a "made in Ethiopia" brand, the government, global brands and

foreign manufacturers did not anticipate that the base salary was simply

too low for workers to make a living from.

Commerce and regulation

The Multi Fibre Arrangement (MFA) governed the world trade in textiles and garments from 1974 through 2004, imposing quotas on the amount developing countries could export to developed countries. It expired on 1 January 2005.

The MFA was introduced in 1974 as a short-term measure intended

to allow developed countries to adjust to imports from the developing

world. Developing countries have a natural advantage in textile

production because it is labor-intensive and they have low labor costs.

According to a World Bank/International Monetary Fund (IMF) study, the system has cost the developing world 27 million jobs and $40 billion a year in lost exports.

However, the Arrangement was not negative for all developing countries. For example, the European Union (EU) imposed no restrictions or duties on imports from the very poor countries, such as Bangladesh, leading to a massive expansion of the industry there.

At the General Agreement on Tariffs and Trade (GATT) Uruguay Round, it was decided to bring the textile trade under the jurisdiction of the World Trade Organization

(WTO). The WTO Agreement on Textiles and Clothing provided for the

gradual dismantling of the quotas that existed under the MFA. This

process was completed on 1 January 2005. However, large tariffs remain

in place on many textile products.

Women work in a textile factory outside Dhaka, Bangladesh.

Bangladesh was expected to suffer the most from the ending of the

MFA, as it was expected to face more competition, particularly from China.

However, this was not the case. It turns out that even in the face of

other economic giants, Bangladesh's labor is “cheaper than anywhere else

in the world.” While some smaller factories were documented making pay

cuts and layoffs, most downsizing was essentially speculative – the

orders for goods kept coming even after the MFA expired. In fact,

Bangladesh's exports increased in value by about $500 million in 2006.

Regulatory standards

For

textiles, like for many other products, there are certain national and

international standards and regulations that need to be complied with to

ensure quality, safety and sustainability.

The following standards amongst others apply to textiles:

CPSIA, e.g. Standard for the Flammability of Clothing Textiles

- ASTM Textile Standards

- REACH Regulations for Textiles

- China Product Standard for Textiles