Direct air capture (DAC) is the use of chemical or physical processes to extract carbon dioxide directly from the ambient air. If the extracted CO2 is then sequestered in safe long-term storage (called direct air carbon capture and sequestration (DACCS)), the overall process will achieve carbon dioxide removal and be a "negative emissions technology" (NET). As of 2022, DAC has yet to become profitable because the cost of using DAC to sequester carbon dioxide is several times the carbon price.

The carbon dioxide (CO2) is captured directly from the ambient air; this is contrast to carbon capture and storage (CCS) which captures CO2) from point sources, such as a cement factory or a bioenergy plant. After the capture, DAC generates a concentrated stream of CO2 for sequestration or utilization or production of carbon-neutral fuel and windgas. Carbon dioxide removal is achieved when ambient air makes contact with chemical media, typically an aqueous alkaline solvent or sorbents. These chemical media are subsequently stripped of CO2 through the application of energy (namely heat), resulting in a CO2 stream that can undergo dehydration and compression, while simultaneously regenerating the chemical media for reuse.

When combined with long-term storage of CO2, DAC is known as direct air carbon capture and storage (DACCS or DACS). It would require renewable energies to power since approximately 400kJ of energy is needed per mole of CO2 capture. DACCS can act as a carbon dioxide removal mechanism (or a carbon negative technology), although as of 2022 it has yet to be profitable because the cost per tonne of carbon dioxide is several times the carbon price.

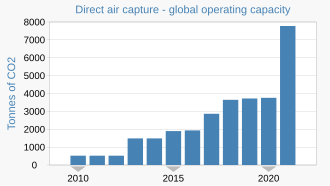

DAC was suggested in 1999 and is still in development. Several commercial plants are planned or in operation in Europe and the US. Large-scale DAC deployment may be accelerated when connected with economical applications or policy incentives.

In contrast to carbon capture and storage (CCS) which captures emissions from a point source such as a factory, DAC reduces the carbon dioxide concentration in the atmosphere as a whole. Typically, CCS is recommended for large and stationary sources of CO2 rather than distributed and movable ones. On the contrary, DAC has no limitation on sources.

Methods of capture

Most commercial techniques require large fans to push ambient air through a filter. More recently, Ireland-based company Carbon Collect Limited has developed the MechanicalTree™ which simply stands in the wind to capture CO2. The company claims this 'passive capture' of CO2 significantly reduces the energy cost of Direct Air Capture, and that its geometry lends itself to scaling for gigaton CO2 capture.

Most commercial techniques use a liquid solvent—usually amine-based or caustic—to absorb CO2 from a gas. For example, a common caustic solvent: sodium hydroxide reacts with CO2 and precipitates a stable sodium carbonate. This carbonate is heated to produce a highly pure gaseous CO2 stream. Sodium hydroxide can be recycled from sodium carbonate in a process of causticizing. Alternatively, the CO2 binds to solid sorbent in the process of chemisorption. Through heat and vacuum, the CO2 is then desorbed from the solid.

Among the specific chemical processes that are being explored, three stand out: causticization with alkali and alkali-earth hydroxides, carbonation, and organic−inorganic hybrid sorbents consisting of amines supported in porous adsorbents.

Other explored methods

The idea of using many small dispersed DAC scrubbers—analogous to live plants—to create environmentally significant reduction in CO2 levels, has earned the technology a name of artificial trees in popular media.

Moisture swing sorbent

In a cyclical process designed in 2012 by professor Klaus Lackner, the director of the Center for Negative Carbon Emissions (CNCE), dilute CO2 can be efficiently separated using an anionic exchange polymer resin called Marathon MSA, which absorbs air CO2 when dry, and releases it when exposed to moisture. A large part of the energy for the process is supplied by the latent heat of phase change of water.[19] The technology requires further research to determine its cost-effectiveness.

Metal-organic frameworks

Other substances which can be used are Metal-organic frameworks (or MOF's).

Membranes

Membrane separation of CO2 rely on semi-permeable membranes. This method requires little water and has a smaller footprint. Typically polymeric membranes, either glassy or rubbery, are used for direct air capture. Glassy membranes typically exhibit high selectivity with respect to Carbon Dioxide; however, they also have low permeabilities. Membrane capture of carbon dioxide is still in development and needs further research before it can be implemented on a larger scale.

Environmental impact

Proponents of DAC argue that it is an essential component of climate change mitigation. Researchers posit that DAC could help contribute to the goals of the Paris Agreement (namely limiting the increase in global average temperature to well below 2 °C above pre-industrial levels). However, others claim that relying on this technology is risky and might postpone emission reduction under the notion that it will be possible to fix the problem later, and suggest that reducing emissions may be a better solution.

DAC relying on amine-based absorption demands significant water input. It was estimated, that to capture 3.3 gigatonnes of CO2 a year would require 300 km3 of water, or 4% of the water used for irrigation. On the other hand, using sodium hydroxide needs far less water, but the substance itself is highly caustic and dangerous.

DAC also requires much greater energy input in comparison to traditional capture from point sources, like flue gas, due to the low concentration of CO2. The theoretical minimum energy required to extract CO2 from ambient air is about 250 kWh per tonne of CO2, while capture from natural gas and coal power plants requires, respectively, about 100 and 65 kWh per tonne of CO2. Because of this implied demand for energy, some geoengineering promoters have proposed using "small nuclear power plants" connected to DAC installations.

When DAC is combined with a carbon capture and storage (CCS) system, it can produce a negative emissions plant, but it would require a carbon-free electricity source. The use of any fossil-fuel-generated electricity would end up releasing more CO2 to the atmosphere than it would capture. Moreover, using DAC for enhanced oil recovery would cancel any supposed climate mitigation benefits.

Applications

Practical applications of DAC include:

- enhanced oil recovery,

- production of carbon-neutral synthetic fuel and plastics,

- beverage carbonation,

- carbon sequestration,

- improving concrete strength,

- creating carbon-neutral concrete alternative,

- enhancing productivity of algae farms,

- enrichment of air in greenhouses

These applications require different concentrations of CO2 product formed from the captured gas. Forms of carbon sequestration such as geological storage require pure CO2 products (concentration > 99%), while other applications such as agriculture can function with more dilute products (~ 5%). Since the air that is processed through DAC originally contains 0.04% CO2 (or 400 ppm), creating a pure product requires more energy than a dilute product and is thus typically more expensive.

DAC is not an alternative to traditional, point-source carbon capture and storage (CCS), rather it is a complementary technology that could be utilized to manage carbon emissions from distributed sources, fugitive emissions from the CCS network, and leakage from geological formations. Because DAC can be deployed far from the source of pollution, synthetic fuel produced with this method can use already existing fuel transport infrastructure.

Cost

One of the largest hurdles to implementing DAC is a cost required to separate CO2 and air. A study from 2011 estimated that a plant designed to capture 1 megatonne of CO2 a year would cost $2.2 billion. Other studies from the same period put the cost of DAC at $200–1000 per tonne of CO2 and $600 per tonne.

It is estimated that the total system cost is $1,000 per tonne of CO2, according to an economic and energetic analysis from 2011.

An economic study of a pilot plant in British Columbia, Canada, conducted from 2015 to 2018, estimated the cost at $94–232 per tonne of atmospheric CO2 removed. It is worth noting that the study was done by Carbon Engineering, which has financial interest in commercializing DAC technology.

Large-scale DAC deployment can be accelerated by policy incentives.

Development

Carbon Engineering

Carbon Engineering is a commercial DAC company founded in 2009 and backed, among others, by Bill Gates and Murray Edwards. As of 2018, it runs a pilot plant in British Columbia, Canada, that has been in use since 2015 and is able to extract about a tonne of CO2 a day. An economic study of its pilot plant conducted from 2015 to 2018 estimated the cost at $94–232 per tonne of atmospheric CO2 removed.

Partnering with California energy company Greyrock, Carbon Engineering converts a portion of its concentrated CO2 into synthetic fuel, including gasoline, diesel, and jet fuel.

The company uses a potassium hydroxide solution. It reacts with CO2 to form potassium carbonate, which removes a certain amount of CO2 from the air.

Climeworks

Climeworks's first industrial-scale DAC plant, which started operation in May 2017 in Hinwil, in the canton of Zurich, Switzerland, can capture 900 tonnes of CO2 per year. To lower its energy requirements, the plant uses heat from a local waste incineration plant. The CO2 is used to increase vegetable yields in a nearby greenhouse.

The company stated that it costs around $600 to capture one tonne of CO2 from the air.

Climeworks partnered with Reykjavik Energy in Carbfix, a project launched in 2007. In 2017, the CarbFix2 project was started and received funding from European Union's Horizon 2020 research program. The CarbFix2 pilot plant project runs alongside a geothermal power plant in Hellisheidi, Iceland. In this approach, CO2 is injected 700 meters under the ground and mineralizes into basaltic bedrock forming carbonate minerals. The DAC plant uses low-grade waste heat from the plant, effectively eliminating more CO2 than they both produce.

Global Thermostat

Global Thermostat is private company founded in 2010, located in Manhattan, New York, with a plant in Huntsville, Alabama. Global Thermostat uses amine-based sorbents bound to carbon sponges to remove CO2 from the atmosphere. The company has projects ranging from 40 to 50,000 tonnes per year.

The company claims to remove CO2 for $120 per tonne at its facility in Huntsville.

Global Thermostat has closed deals with Coca-Cola (which aims to use DAC to source CO2 for its carbonated beverages) and ExxonMobil which intends to start a DAC‑to‑fuel business using Global Thermostat's technology.

Soletair Power

Soletair Power is a startup founded in 2016, located in Lappeenranta, Finland, operating in the fields of DAC and Power-to-X. The startup is primarily backed by the Finnish technology group Wärtsilä. According to Soletair Power, its technology is the first to combine DAC with building integration. It absorbs CO2 from ventilation units inside buildings and captures it to improve air quality. Soletair focuses on the fact that DAC can improve employees' cognitive function by 20% per 400 ppm indoor CO2 removed, according to one study.

The company uses the captured CO2 in creating synthetic renewable fuel and as raw material for industrial applications. In 2020, Wärtsilä, together with Soletair Power and Q Power, created their first demonstration unit of Power-to-X for Dubai Expo 2020, that can produce synthetic methane from captured CO2 from buildings.

Prometheus Fuels

Is a start-up company based in Santa Cruz which launched out of Y Combinator in 2019 to remove CO2 from the air and turn it into zero-net-carbon gasoline and jet fuel. The company uses a DAC technology, adsorbing CO2 from the air directly into process electrolytes, where it is converted into alcohols by electrocatalysis. The alcohols are then separated from the electrolytes using carbon nanotube membranes, and upgraded to gasoline and jet fuels. Since the process uses only electricity from renewable sources, the fuels are carbon neutral when used, emitting no net CO2 to the atmosphere.

Other companies

- Infinitree – earlier known as Kilimanjaro Energy and Global Research Technology. Part of US-based Carbon Sink. Demonstrated a pre-prototype of economically viable DAC technology in 2007

- Skytree – a company from Netherlands

- UK Carbon Capture and Storage Research Centre

- Center for Negative Carbon Emissions of Arizona State University

- Carbyon – a startup company in Eindhoven, the Netherlands

- TerraFixing – a startup in Ottawa, Canada

- Carbfix – a subsidiary of Reykjavik Energy, Iceland

- Energy Impact Center – a research institute that advocates for the use nuclear energy to power direct air capture technologies.

- Mission Zero Technologies — a startup in London, UK.