XRS-2200 linear aerospike engine for the X-33 program being tested at the Stennis Space Center

The aerospike engine is a type of rocket engine that maintains its aerodynamic efficiency across a wide range of altitudes. It belongs to the class of altitude compensating nozzle engines. A vehicle with an aerospike engine uses 25–30% less fuel at low altitudes, where most missions have the greatest need for thrust. Aerospike engines have been studied for a number of years and are the baseline engines for many single-stage-to-orbit (SSTO) designs and were also a strong contender for the Space Shuttle main engine. However, no such engine is in commercial production, although some large-scale aerospikes are in testing phases.

The terminology in the literature surrounding this subject is somewhat confused—the term aerospike was originally used for a truncated plug nozzle

with a very rough conical taper and some gas injection, forming an "air

spike" to help make up for the absence of the plug tail. However,

frequently, a full-length plug nozzle is now called an aerospike.

Principles

The

purpose of any engine bell is to direct the exhaust of a rocket engine

in one direction, generating thrust in the opposite direction. The

exhaust, a high-temperature mix of gases, has an effectively random

momentum distribution (i.e., the exhaust pushes in any direction it

can). If the exhaust is allowed to escape in this form, only a small

part of the flow will be moving in the correct direction and thus

contribute to forward thrust. The bell redirects exhaust moving in the

wrong direction so that it generates thrust in the correct direction.

Ambient air pressure also imparts a small pressure against the exhaust,

helping to keep it moving in the "right" direction as it exits the

engine. As the vehicle travels upwards through the atmosphere, ambient

air pressure is reduced. This causes the thrust-generating exhaust to

begin to expand outside the edge of the bell. Since this exhaust begins

traveling in the "wrong" direction (i.e., outward from the main exhaust

plume), the efficiency of the engine is reduced as the rocket travels

because this escaping exhaust is no longer contributing to the thrust of

the engine. An aerospike rocket engine seeks to eliminate this loss of

efficiency.

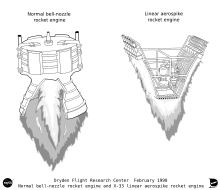

Comparison between the design of a bell-nozzle rocket (left) and an aerospike rocket (right)

Instead of firing the exhaust out of a small hole in the middle of a

bell, an aerospike engine avoids this random distribution by firing

along the outside edge of a wedge-shaped protrusion, the "spike", which

serves the same function as a traditional engine bell. The spike forms

one side of a "virtual" bell, with the other side being formed by the

outside air—thus the "aerospike".

The idea behind the aerospike design is that at low altitude the

ambient pressure compresses the exhaust against the spike. Exhaust

recirculation in the base zone of the spike can raise the pressure in

that zone to nearly ambient. Since the pressure in front of the vehicle

is ambient, this means that the exhaust at the base of the spike nearly

balances out with the drag experienced by the vehicle. It gives no

overall thrust, but this part of the nozzle also doesn't lose thrust by forming a partial vacuum. The thrust at the base part of the nozzle can be ignored at low altitude.

As the vehicle climbs to higher altitudes, the air pressure

holding the exhaust against the spike decreases, as does the drag in

front of the vehicle. The recirculation zone at the base of the spike

maintains the pressure in that zone to a fraction of 1 bar,

higher than the near-vacuum in front of the vehicle, thus giving extra

thrust as altitude increases. This effectively behaves like an

"altitude compensator" in that the size of the bell automatically

compensates as air pressure falls.

The disadvantages of aerospikes seem to be extra weight for the

spike, and increased cooling requirements to the extra heated area, the

spike.

Furthermore, the larger cooled area can reduce performance below

theoretical levels by reducing the pressure against the nozzle.

Aerospikes work relatively poorly between Mach 1–3, where the airflow around the vehicle has reduced the pressure, thus reducing the thrust.

Variations

Several versions of the design exist, differentiated by their shapes. In the toroidal aerospike

the spike is bowl-shaped with the exhaust exiting in a ring around the

outer rim. In theory this requires an infinitely long spike for best

efficiency, but by blowing a small amount of gas out of the center of a

shorter truncated spike (like base bleed in an artillery shell), something similar can be achieved.

In the linear aerospike the spike consists of a tapered

wedge-shaped plate, with exhaust exiting on either side at the "thick"

end. This design has the advantage of being stackable, allowing several

smaller engines to be placed in a row to make one larger engine while

augmenting steering performance with the use of individual engine

throttle control.

Performance

Rocketdyne's J-2T-250k annular aerospike test firing.

Rocketdyne

conducted a lengthy series of tests in the 1960s on various designs.

Later models of these engines were based on their highly reliable J-2 engine machinery and provided the same sort of thrust levels as the conventional engines they were based on; 200,000 lbf (890 kN) in the J-2T-200k, and 250,000 lbf (1.1 MN) in the J-2T-250k (the T refers to the toroidal combustion chamber). Thirty years later their work was dusted off again for use in NASA's X-33 project. In this case the slightly upgraded J-2S engine machinery was used with a linear spike, creating the XRS-2200.

After more development and considerable testing, this project was

cancelled when the X-33's composite fuel tanks repeatedly failed.

CSULB aerospike engine

Three XRS-2200 engines were built during the X-33 program and underwent testing at NASA's Stennis Space Center.

The single-engine tests were a success, but the program was halted

before the testing for the two-engine setup could be completed. The

XRS-2200 produces 204,420 lbf (909,300 N) thrust with an Isp of 339 seconds at sea level, and 266,230 lbf (1,184,300 N) thrust with an Isp of 436.5 seconds in a vacuum.

The RS-2200 Linear Aerospike Engine was derived from the XRS-2200. The RS-2200 was to power the VentureStar single-stage-to-orbit

vehicle. In the latest design, seven RS-2200s producing 542,000

pounds-force (2,410 kN) each would boost the VentureStar into low earth

orbit. The development on the RS-2200 was formally halted in early 2001

when the X-33 program did not receive Space Launch Initiative funding. Lockheed Martin

chose to not continue the VentureStar program without any funding

support from NASA. An engine of this type is on outdoor display on the

grounds of the NASA Marshall Space Flight Center in Huntsville Alabama.

NASA's Toroidal aerospike nozzle

The cancellation of the Lockheed Martin X-33 by the federal government in 2001

decreased funding availability, but aerospike engines remain an area of

active research. For example, a milestone was achieved when a joint

academic/industry team from California State University, Long Beach (CSULB) and Garvey Spacecraft Corporation successfully conducted a flight test of a liquid-propellant powered aerospike engine in the Mojave Desert on September 20, 2003. CSULB students had developed their Prospector 2 (P-2) rocket using a 1,000 lbf

(4.4 kN) LOX/ethanol aerospike engine. This work on aerospike engines

continues; Prospector-10, a ten-chamber aerospike engine, was test-fired

June 25, 2008.

Nozzle performance comparison of bell and aerospike nozzle

Further progress came in March 2004 when two successful tests

sponsored by the NASA Dryden Flight Research Centre using high-power

rockets manufactured by Blacksky Corporation, based in Carlsbad, California. The aerospike nozzles and solid rocket motors were developed and built by the rocket motor division of Cesaroni Technology Incorporated,

north of Toronto, Ontario. The two rockets were solid-fuel powered and

fitted with non-truncated toroidal aerospike nozzles. Flown at the Pecos

County Aerospace Development Center, Fort Stockton, Texas, the rockets

achieved apogees of 26,000 ft (7,900 m) and speeds of about Mach 1.5.

Small-scale aerospike engine development using a hybrid rocket propellant configuration has been ongoing by members of the Reaction Research Society.

Implementations

Firefly Aerospace

In July 2014 Firefly Space Systems

announced its planned Alpha launcher that uses an aerospike engine for

its first stage. Intended for the small satellite launch market, it is

designed to launch satellites into low-Earth orbit (LEO) at a price of

US$8–9 million, much lower than with conventional launchers.

Firefly Alpha

1.0 was designed to carry payloads of up to 400 kilograms (880 lb). It

uses carbon composite materials and uses the same basic design for both

stages. The plug-cluster aerospike engine puts out 90,000 pounds-force

(400 kN) of thrust. The engine has a bell-shaped nozzle that has been

cut in half, then stretched to form a ring with the half-nozzle now

forming the profile of a plug.

But this rocket design was never launched. The design was abandoned after Firefly Space Systems went bankrupt. A new company, Firefly Aerospace, has replaced the aerospike engine with a conventional engine in the Alpha 2.0 design.

ARCA Space

In March 2017 ARCA Space Corporation

announced their intention to build a single-stage-to-orbit rocket,

named Haas 2CA, using a linear aerospike engine. The rocket is designed

to send up to 100kg into low-Earth orbit, at a price of US$ 1 million

per launch.

They later announced that their Executor Aerospike engine would produce

50,500 pounds-force (225 kN) of thrust at sea-level and 73,800

pounds-force (328 kN) of thrust in vacuum.

In June 2017, ARCA announced that they would fly their

Demonstrator3 rocket to space, using a linear aerospike engine. This

rocket was designed to test several components of their Haas 2CA at a

lower cost. They announced a flight for August 2017.

In September 2017, ARCA announced that after being delayed, their

linear aerospike engine was ready to perform ground tests and flight

tests on a Demonstrator3 rocket.

KSF Space and Interstellar Space

Another

spike engine concept model, by KSF Space and Interstellar Space in Los

Angeles, was designed for orbital vehicle named SATORI. Due to lack of

funding, the concept is still undeveloped.

Rocketstar

Rocketstar announced that it would launch its 3D-printed aerospike rocket to an altitude of 50 miles in February 2019.