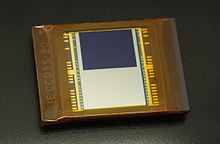

A specially developed CCD in a wire-bonded package used for ultraviolet imaging

A charge-coupled device (CCD) is a device for the movement of electrical charge,

usually from within the device to an area where the charge can be

manipulated, such as conversion into a digital value. This is achieved

by "shifting" the signals between stages within the device one at a

time. CCDs move charge between capacitive bins in the device, with the shift allowing for the transfer of charge between bins.

CCD is a major technology for digital imaging. In a CCD image sensor, pixels are represented by p-doped metal–oxide–semiconductor (MOS) capacitors. These MOS capacitors, the basic building blocks of a CCD, are biased above the threshold for inversion when image acquisition begins, allowing the conversion of incoming photons

into electron charges at the semiconductor-oxide interface; the CCD is

then used to read out these charges. Although CCDs are not the only

technology to allow for light detection, CCD image sensors are widely

used in professional, medical, and scientific applications where

high-quality image data are required. In applications with less exacting

quality demands, such as consumer and professional digital cameras, active pixel sensors, also known as CMOS sensors

(complementary MOS sensors), are generally used. However, the large

quality advantage CCDs enjoyed early on has narrowed over time.

History

George E. Smith and Willard Boyle, 2009.

The basis for the CCD is the metal–oxide–semiconductor (MOS) structure, with MOS capacitors being the basic building blocks of a CCD, and a depleted MOS structure used as the photodetector in early CCD devices. MOS technology was originally invented by Mohamed M. Atalla and Dawon Kahng at Bell Labs in 1959.

In the late 1960s, Willard Boyle and George E. Smith at Bell Labs were researching MOS technology while working on semiconductor bubble memory.

They realized that an electric charge was the analogy of the magnetic

bubble and that it could be stored on a tiny MOS capacitor. As it was

fairly straightforward to fabricate

a series of MOS capacitors in a row, they connected a suitable voltage

to them so that the charge could be stepped along from one to the next.

This led to the invention of the charge-coupled device by Boyle and

Smith in 1969. They conceived of the design of what they termed, in

their notebook, "Charge 'Bubble' Devices".

The initial paper describing the concept in April 1970 listed possible uses as memory, a delay line, and an imaging device. The device could also be used as a shift register.

The essence of the design was the ability to transfer charge along the

surface of a semiconductor from one storage capacitor to the next. The

concept was similar in principle to the bucket-brigade device (BBD), which was developed at Philips Research Labs during the late 1960s.

The first experimental device demonstrating the principle was a row of closely spaced metal squares on an oxidized silicon surface electrically accessed by wire bonds. It was demonstrated by Gil Amelio, Michael Francis Tompsett and George Smith in April 1970. This was the first experimental application of the CCD in image sensor technology, and used a depleted MOS structure as the photodetector. The first patent (U.S. Patent 4,085,456) on the application of CCDs to imaging was assigned to Tompsett, who filed the application in 1971.

The first working CCD made with integrated circuit technology was a simple 8-bit shift register, reported by Tompsett, Amelio and Smith in August 1970. This device had input and output circuits and was used to demonstrate its use as a shift register and as a crude eight pixel

linear imaging device.

Development of the device progressed at a rapid rate. By 1971, Bell

researchers led by Michael Tompsett were able to capture images with

simple linear devices.

Several companies, including Fairchild Semiconductor, RCA and Texas Instruments,

picked up on the invention and began development programs. Fairchild's

effort, led by ex-Bell researcher Gil Amelio, was the first with

commercial devices, and by 1974 had a linear 500-element device and a

2-D 100 x 100 pixel device. Steven Sasson, an electrical engineer working for Kodak, invented the first digital still camera using a Fairchild 100 x 100 CCD in 1975.

The interline transfer (ILT) CCD device was proposed by L. Walsh

and R. Dyck at Fairchild in 1973 to reduce smear and eliminate a

mechanical shutter.

To further reduce smear from bright light sources, the

frame-interline-transfer (FIT) CCD architecture was developed by K.

Horii, T. Kuroda and T. Kunii at Matsushita (now Panasonic) in 1981.

The first KH-11 KENNEN reconnaissance satellite equipped with charge-coupled device array (800 x 800 pixels) technology for imaging was launched in December 1976. Under the leadership of Kazuo Iwama, Sony

started a large development effort on CCDs involving a significant

investment. Eventually, Sony managed to mass-produce CCDs for their camcorders.

Before this happened, Iwama died in August 1982; subsequently, a CCD

chip was placed on his tombstone to acknowledge his contribution.

Early CCD sensors suffered from shutter lag. This was largely resolved with the invention of the pinned photodiode (PPD). It was invented by Nobukazu Teranishi, Hiromitsu Shiraki and Yasuo Ishihara at NEC in 1980. They recognized that lag can be eliminated if the signal carriers could be transferred from the photodiode to the CCD. This led to their invention of the pinned photodiode, a photodetector structure with low lag, low noise, high quantum efficiency and low dark current.

It was first publicly reported by Teranishi and Ishihara with A.

Kohono, E. Oda and K. Arai in 1982, with the addition of an

anti-blooming structure.

The new photodetector structure invented at NEC was given the name

"pinned photodiode" (PPD) by B.C. Burkey at Kodak in 1984. In 1987, the

PPD began to be incorporated into most CCD devices, becoming a fixture

in consumer electronic video cameras and then digital still cameras. Since then, the PPD has been used in nearly all CCD sensors and then CMOS sensors.

In January 2006, Boyle and Smith were awarded the National Academy of Engineering Charles Stark Draper Prize, and in 2009 they were awarded the Nobel Prize for Physics, for their invention of the CCD concept. Michael Tompsett was awarded the 2010 National Medal of Technology and Innovation,

for pioneering work and electronic technologies including the design

and development of the first CCD imagers. He was also awarded the 2012 IEEE Edison Medal for "pioneering contributions to imaging devices including CCD Imagers, cameras and thermal imagers".

Basics of operation

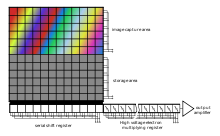

The charge packets (electrons, blue) are collected in potential wells

(yellow) created by applying positive voltage at the gate electrodes

(G). Applying positive voltage to the gate electrode in the correct

sequence transfers the charge packets.

In a CCD for capturing images, there is a photoactive region (an epitaxial layer of silicon), and a transmission region made out of a shift register (the CCD, properly speaking).

An image is projected through a lens onto the capacitor array (the photoactive region), causing each capacitor to accumulate an electric charge proportional to the light

intensity at that location. A one-dimensional array, used in line-scan

cameras, captures a single slice of the image, whereas a two-dimensional

array, used in video and still cameras, captures a two-dimensional

picture corresponding to the scene projected onto the focal plane of the

sensor. Once the array has been exposed to the image, a control circuit

causes each capacitor to transfer its contents to its neighbor

(operating as a shift register). The last capacitor in the array dumps

its charge into a charge amplifier, which converts the charge into a voltage.

By repeating this process, the controlling circuit converts the entire

contents of the array in the semiconductor to a sequence of voltages. In

a digital device, these voltages are then sampled, digitized, and

usually stored in memory; in an analog device (such as an analog video

camera), they are processed into a continuous analog signal (e.g. by

feeding the output of the charge amplifier into a low-pass filter),

which is then processed and fed out to other circuits for transmission,

recording, or other processing.

"One-dimensional" CCD image sensor from a fax machine

Detailed physics of operation

Charge generation

Before the MOS capacitors are exposed to light, they are biased into the depletion region; in n-channel CCDs, the silicon under the bias gate is slightly p-doped

or intrinsic. The gate is then biased at a positive potential, above

the threshold for strong inversion, which will eventually result in the

creation of a n channel below the gate as in a MOSFET.

However, it takes time to reach this thermal equilibrium: up to hours

in high-end scientific cameras cooled at low temperature.

Initially after biasing, the holes are pushed far into the substrate,

and no mobile electrons are at or near the surface; the CCD thus

operates in a non-equilibrium state called deep depletion.

Then, when electron–hole pairs

are generated in the depletion region, they are separated by the

electric field, the electrons move toward the surface, and the holes

move toward the substrate. Four pair-generation processes can be

identified:

- photo-generation (up to 95% of quantum efficiency),

- generation in the depletion region,

- generation at the surface, and

- generation in the neutral bulk.

The last three processes are known as dark-current generation, and

add noise to the image; they can limit the total usable integration

time. The accumulation of electrons at or near the surface can proceed

either until image integration is over and charge begins to be

transferred, or thermal equilibrium is reached. In this case, the well

is said to be full. The maximum capacity of each well is known as the

well depth, typically about 105 electrons per pixel.

Design and manufacturing

The photoactive region of a CCD is, generally, an epitaxial layer of silicon. It is lightly p doped (usually with boron) and is grown upon a substrate

material, often p++. In buried-channel devices, the type of design

utilized in most modern CCDs, certain areas of the surface of the

silicon are ion implanted with phosphorus, giving them an n-doped designation. This region defines the channel in which the photogenerated charge packets will travel. Simon Sze details the advantages of a buried-channel device:

This thin layer (= 0.2–0.3 micron) is fully depleted and the accumulated photogenerated charge is kept away from the surface. This structure has the advantages of higher transfer efficiency and lower dark current, from reduced surface recombination. The penalty is smaller charge capacity, by a factor of 2–3 compared to the surface-channel CCD.

The gate oxide, i.e. the capacitor dielectric, is grown on top of the epitaxial layer and substrate.

Later in the process, polysilicon gates are deposited by chemical vapor deposition, patterned with photolithography,

and etched in such a way that the separately phased gates lie

perpendicular to the channels. The channels are further defined by

utilization of the LOCOS process to produce the channel stop region.

Channel stops are thermally grown oxides

that serve to isolate the charge packets in one column from those in

another. These channel stops are produced before the polysilicon gates

are, as the LOCOS process utilizes a high-temperature step that would

destroy the gate material. The channel stops are parallel to, and

exclusive of, the channel, or "charge carrying", regions.

Channel stops often have a p+ doped region underlying them,

providing a further barrier to the electrons in the charge packets (this

discussion of the physics of CCD devices assumes an electron transfer device, though hole transfer is possible).

The clocking of the gates, alternately high and low, will forward

and reverse bias the diode that is provided by the buried channel

(n-doped) and the epitaxial layer (p-doped). This will cause the CCD to

deplete, near the p–n junction and will collect and move the charge packets beneath the gates—and within the channels—of the device.

CCD manufacturing and operation can be optimized for different

uses. The above process describes a frame transfer CCD. While CCDs may

be manufactured on a heavily doped p++ wafer it is also possible to

manufacture a device inside p-wells that have been placed on an n-wafer.

This second method, reportedly, reduces smear, dark current, and infrared and red response. This method of manufacture is used in the construction of interline-transfer devices.

Another version of CCD is called a peristaltic CCD. In a

peristaltic charge-coupled device, the charge-packet transfer operation

is analogous to the peristaltic contraction and dilation of the digestive system. The peristaltic CCD has an additional implant that keeps the charge away from the silicon/silicon dioxide

interface and generates a large lateral electric field from one gate to

the next. This provides an additional driving force to aid in transfer

of the charge packets.

Architecture

The

CCD image sensors can be implemented in several different

architectures. The most common are full-frame, frame-transfer, and

interline. The distinguishing characteristic of each of these

architectures is their approach to the problem of shuttering.

In a full-frame device, all of the image area is active, and

there is no electronic shutter. A mechanical shutter must be added to

this type of sensor or the image smears as the device is clocked or read

out.

With a frame-transfer CCD, half of the silicon area is covered by

an opaque mask (typically aluminum). The image can be quickly

transferred from the image area to the opaque area or storage region

with acceptable smear of a few percent. That image can then be read out

slowly from the storage region while a new image is integrating or

exposing in the active area. Frame-transfer devices typically do not

require a mechanical shutter and were a common architecture for early

solid-state broadcast cameras. The downside to the frame-transfer

architecture is that it requires twice the silicon real estate of an

equivalent full-frame device; hence, it costs roughly twice as much.

The interline architecture extends this concept one step further

and masks every other column of the image sensor for storage. In this

device, only one pixel shift has to occur to transfer from image area to

storage area; thus, shutter times can be less than a microsecond and

smear is essentially eliminated. The advantage is not free, however, as

the imaging area is now covered by opaque strips dropping the fill factor to approximately 50 percent and the effective quantum efficiency

by an equivalent amount. Modern designs have addressed this deleterious

characteristic by adding microlenses on the surface of the device to

direct light away from the opaque regions and on the active area.

Microlenses can bring the fill factor back up to 90 percent or more

depending on pixel size and the overall system's optical design.

The choice of architecture comes down to one of utility. If the

application cannot tolerate an expensive, failure-prone, power-intensive

mechanical shutter, an interline device is the right choice. Consumer

snap-shot cameras have used interline devices. On the other hand, for

those applications that require the best possible light collection and

issues of money, power and time are less important, the full-frame

device is the right choice. Astronomers tend to prefer full-frame

devices. The frame-transfer falls in between and was a common choice

before the fill-factor issue of interline devices was addressed. Today,

frame-transfer is usually chosen when an interline architecture is not

available, such as in a back-illuminated device.

CCDs containing grids of pixels are used in digital cameras, optical scanners, and video cameras as light-sensing devices. They commonly respond to 70 percent of the incident light (meaning a quantum efficiency of about 70 percent) making them far more efficient than photographic film, which captures only about 2 percent of the incident light.

CCD from a 2.1 megapixel Hewlett-Packard digital camera

Most common types of CCDs are sensitive to near-infrared light, which allows infrared photography, night-vision devices, and zero lux

(or near zero lux) video-recording/photography. For normal

silicon-based detectors, the sensitivity is limited to 1.1 μm. One other

consequence of their sensitivity to infrared is that infrared from remote controls often appears on CCD-based digital cameras or camcorders if they do not have infrared blockers.

Cooling reduces the array's dark current,

improving the sensitivity of the CCD to low light intensities, even for

ultraviolet and visible wavelengths. Professional observatories often

cool their detectors with liquid nitrogen to reduce the dark current, and therefore the thermal noise, to negligible levels.

Frame transfer CCD

A frame transfer CCD sensor

The frame transfer CCD imager was the first imaging structure

proposed for CCD Imaging by Michael Tompsett at Bell Laboratories. A frame transfer CCD is a specialized CCD, often used in astronomy and some professional video cameras, designed for high exposure efficiency and correctness.

The normal functioning of a CCD, astronomical or otherwise, can

be divided into two phases: exposure and readout. During the first

phase, the CCD passively collects incoming photons, storing electrons

in its cells. After the exposure time is passed, the cells are read out

one line at a time. During the readout phase, cells are shifted down

the entire area of the CCD. While they are shifted, they continue to

collect light. Thus, if the shifting is not fast enough, errors can

result from light that falls on a cell holding charge during the

transfer. These errors are referred to as "vertical smear" and cause a

strong light source to create a vertical line above and below its exact

location. In addition, the CCD cannot be used to collect light while it

is being read out. Unfortunately, a faster shifting requires a faster

readout, and a faster readout can introduce errors in the cell charge

measurement, leading to a higher noise level.

A frame transfer CCD solves both problems: it has a shielded, not

light sensitive, area containing as many cells as the area exposed to

light. Typically, this area is covered by a reflective material such as

aluminium. When the exposure time is up, the cells are transferred very

rapidly to the hidden area. Here, safe from any incoming light, cells

can be read out at any speed one deems necessary to correctly measure

the cells' charge. At the same time, the exposed part of the CCD is

collecting light again, so no delay occurs between successive exposures.

The disadvantage of such a CCD is the higher cost: the cell area

is basically doubled, and more complex control electronics are needed.

Intensified charge-coupled device

An intensified charge-coupled device (ICCD) is a CCD that is

optically connected to an image intensifier that is mounted in front of

the CCD.

An image intensifier includes three functional elements: a photocathode, a micro-channel plate (MCP) and a phosphor

screen. These three elements are mounted one close behind the other in

the mentioned sequence. The photons which are coming from the light

source fall onto the photocathode, thereby generating photoelectrons.

The photoelectrons are accelerated towards the MCP by an electrical

control voltage, applied between photocathode and MCP. The electrons are

multiplied inside of the MCP and thereafter accelerated towards the

phosphor screen. The phosphor screen finally converts the multiplied

electrons back to photons which are guided to the CCD by a fiber optic

or a lens.

An image intensifier inherently includes a shutter

functionality: If the control voltage between the photocathode and the

MCP is reversed, the emitted photoelectrons are not accelerated towards

the MCP but return to the photocathode. Thus, no electrons are

multiplied and emitted by the MCP, no electrons are going to the

phosphor screen and no light is emitted from the image intensifier. In

this case no light falls onto the CCD, which means that the shutter is

closed. The process of reversing the control voltage at the photocathode

is called gating and therefore ICCDs are also called gateable CCD cameras.

Besides the extremely high sensitivity of ICCD cameras, which

enable single photon detection, the gateability is one of the major

advantages of the ICCD over the EMCCD cameras. The highest performing ICCD cameras enable shutter times as short as 200 picoseconds.

ICCD cameras are in general somewhat higher in price than EMCCD

cameras because they need the expensive image intensifier. On the other

hand, EMCCD cameras need a cooling system to cool the EMCCD chip down to

temperatures around 170 K. This cooling system adds additional costs to the EMCCD camera and often yields heavy condensation problems in the application.

ICCDs are used in night vision devices and in various scientific applications.

Electron-multiplying CCD

Electrons are transferred serially through the gain stages making up the multiplication register of an EMCCD. The high voltages used in these serial transfers induce the creation of additional charge carriers through impact ionisation.

In an EMCCD

there is a dispersion (variation) in the number of electrons output by

the multiplication register for a given (fixed) number of input

electrons (shown in the legend on the right). The probability

distribution for the number of output electrons is plotted logarithmically on the vertical axis for a simulation of a multiplication register. Also shown are results from the empirical fit equation shown on this page.

An electron-multiplying CCD (EMCCD, also known as an L3Vision

CCD, a product commercialized by e2v Ltd., GB, L3CCD or Impactron CCD, a

now-discontinued product offered in the past by Texas Instruments) is a

charge-coupled device in which a gain register is placed between the

shift register and the output amplifier. The gain register is split up

into a large number of stages. In each stage, the electrons are

multiplied by impact ionization in a similar way to an avalanche diode. The gain probability at every stage of the register is small (P < 2%), but as the number of elements is large (N > 500), the overall gain can be very high (),

with single input electrons giving many thousands of output electrons.

Reading a signal from a CCD gives a noise background, typically a few

electrons. In an EMCCD, this noise is superimposed on many thousands of

electrons rather than a single electron; the devices' primary advantage

is thus their negligible readout noise. It is to be noted that the use

of avalanche breakdown for amplification of photo charges had already been described in the U.S. Patent 3,761,744 in 1973 by George E. Smith/Bell Telephone Laboratories.

EMCCDs show a similar sensitivity to intensified CCDs (ICCDs). However, as with ICCDs, the gain that is applied in the gain register is stochastic and the exact

gain that has been applied to a pixel's charge is impossible to know.

At high gains (> 30), this uncertainty has the same effect on the signal-to-noise ratio (SNR) as halving the quantum efficiency

(QE) with respect to operation with a gain of unity. However, at very

low light levels (where the quantum efficiency is most important), it

can be assumed that a pixel either contains an electron — or not. This

removes the noise associated with the stochastic multiplication at the

risk of counting multiple electrons in the same pixel as a single

electron. To avoid multiple counts in one pixel due to coincident

photons in this mode of operation, high frame rates are essential. The

dispersion in the gain is shown in the graph on the right. For

multiplication registers with many elements and large gains it is well

modelled by the equation:

if

where P is the probability of getting n output electrons given m input electrons and a total mean multiplication register gain of g.

Because of the lower costs and better resolution, EMCCDs are

capable of replacing ICCDs in many applications. ICCDs still have the

advantage that they can be gated very fast and thus are useful in

applications like range-gated imaging. EMCCD cameras indispensably need a cooling system — using either thermoelectric cooling

or liquid nitrogen — to cool the chip down to temperatures in the range

of −65 to −95 °C (−85 to −139 °F). This cooling system unfortunately

adds additional costs to the EMCCD imaging system and may yield

condensation problems in the application. However, high-end EMCCD

cameras are equipped with a permanent hermetic vacuum system confining

the chip to avoid condensation issues.

The low-light capabilities of EMCCDs find use in astronomy and

biomedical research, among other fields. In particular, their low noise

at high readout speeds makes them very useful for a variety of

astronomical applications involving low light sources and transient

events such as lucky imaging of faint stars, high speed photon counting photometry, Fabry-Pérot spectroscopy

and high-resolution spectroscopy. More recently, these types of CCDs

have broken into the field of biomedical research in low-light

applications including small animal imaging, single-molecule imaging, Raman spectroscopy, super resolution microscopy as well as a wide variety of modern fluorescence microscopy techniques thanks to greater SNR in low-light conditions in comparison with traditional CCDs and ICCDs.

In terms of noise, commercial EMCCD cameras typically have

clock-induced charge (CIC) and dark current (dependent on the extent of

cooling) that together lead to an effective readout noise ranging from

0.01 to 1 electrons per pixel read. However, recent improvements in

EMCCD technology have led to a new generation of cameras capable of

producing significantly less CIC, higher charge transfer efficiency and

an EM gain 5 times higher than what was previously available. These

advances in low-light detection lead to an effective total background

noise of 0.001 electrons per pixel read, a noise floor unmatched by any

other low-light imaging device.

Use in astronomy

Due to the high quantum efficiencies of CCDs (for a quantum efficiency

of 100%, one count equals one photon), linearity of their outputs, ease

of use compared to photographic plates, and a variety of other reasons,

CCDs were very rapidly adopted by astronomers for nearly all

UV-to-infrared applications.

Thermal noise and cosmic rays

may alter the pixels in the CCD array. To counter such effects,

astronomers take several exposures with the CCD shutter closed and

opened. The average of images taken with the shutter closed is necessary

to lower the random noise. Once developed, the dark frame average image is then subtracted from the open-shutter image to remove the dark current and other systematic defects (dead pixels, hot pixels, etc.) in the CCD.

The Hubble Space Telescope,

in particular, has a highly developed series of steps (“data reduction

pipeline”) to convert the raw CCD data to useful images.

CCD cameras used in astrophotography

often require sturdy mounts to cope with vibrations from wind and other

sources, along with the tremendous weight of most imaging platforms. To

take long exposures of galaxies and nebulae, many astronomers use a

technique known as auto-guiding.

Most autoguiders use a second CCD chip to monitor deviations during

imaging. This chip can rapidly detect errors in tracking and command the

mount motors to correct for them.

Array of 30 CCDs used on the Sloan Digital Sky Survey telescope imaging camera, an example of "drift-scanning".

An unusual astronomical application of CCDs, called drift-scanning,

uses a CCD to make a fixed telescope behave like a tracking telescope

and follow the motion of the sky. The charges in the CCD are transferred

and read in a direction parallel to the motion of the sky, and at the

same speed. In this way, the telescope can image a larger region of the

sky than its normal field of view. The Sloan Digital Sky Survey is the most famous example of this, using the technique to a survey of over a quarter of the sky.

In addition to imagers, CCDs are also used in an array of analytical instrumentation including spectrometers and interferometers.

Color cameras

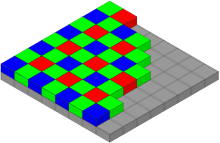

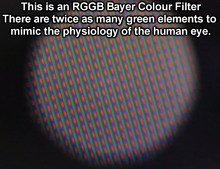

A Bayer filter on a CCD

CCD color sensor

x80 microscope view of an RGGB Bayer filter on a 240 line Sony CCD PAL Camcorder CCD sensor

Digital color cameras generally use a Bayer mask over the CCD. Each square of four pixels has one filtered red, one blue, and two green (the human eye is more sensitive to green than either red or blue). The result of this is that luminance information is collected at every pixel, but the color resolution is lower than the luminance resolution.

Better color separation can be reached by three-CCD devices (3CCD) and a dichroic beam splitter prism, that splits the image into red, green and blue components. Each of the three CCDs is arranged to respond to a particular color. Many professional video

camcorders, and some semi-professional camcorders, use this technique,

although developments in competing CMOS technology have made CMOS

sensors, both with beam-splitters and bayer filters, increasingly

popular in high-end video and digital cinema cameras. Another advantage

of 3CCD over a Bayer mask device is higher quantum efficiency

(and therefore higher light sensitivity for a given aperture size).

This is because in a 3CCD device most of the light entering the aperture

is captured by a sensor, while a Bayer mask absorbs a high proportion

(about 2/3) of the light falling on each CCD pixel.

For still scenes, for instance in microscopy, the resolution of a Bayer mask device can be enhanced by microscanning technology. During the process of color co-site sampling,

several frames of the scene are produced. Between acquisitions, the

sensor is moved in pixel dimensions, so that each point in the visual

field is acquired consecutively by elements of the mask that are

sensitive to the red, green and blue components of its color. Eventually

every pixel in the image has been scanned at least once in each color

and the resolution of the three channels become equivalent (the

resolutions of red and blue channels are quadrupled while the green

channel is doubled).

Sensor sizes

Sensors (CCD / CMOS) come in various sizes, or image sensor formats.

These sizes are often referred to with an inch fraction designation such

as 1/1.8″ or 2/3″ called the optical format. This measurement actually originates back in the 1950s and the time of Vidicon tubes.

Blooming

Vertical smear

When a CCD exposure is long enough, eventually the electrons that

collect in the "bins" in the brightest part of the image will overflow

the bin, resulting in blooming. The structure of the CCD allows the

electrons to flow more easily in one direction than another, resulting

in vertical streaking.

Some anti-blooming features that can be built into a CCD reduce

its sensitivity to light by using some of the pixel area for a drain

structure.

James M. Early

developed a vertical anti-blooming drain that would not detract from

the light collection area, and so did not reduce light sensitivity.