Change in total number of manufacturing jobs in metropolitan areas, 1954–2002 (figures for New England are from 1958).

Three metropolitan areas lost more than four fifths of their manufacturing jobs: Steubenville, Ohio, Johnstown, Pennsylvania, and Augusta, Maine.

>58% loss

43–56% loss

31–43.2% loss

8.7–29.1% loss [United States average: 8.65% loss]

7.5% loss – 54.4% gain

>62% gain

Change in per capita personal income in metropolitan counties, 1980–2002, relative to the average for U.S. metropolitan areas.

income above average, growth faster than average

income above average, growth average or below average

income above average but decreasing

income below average, growth faster than average

income below average, growth average or below average

income below average and further decreasing

"Rust Belt" is a term for an informal region of the United States that experienced industrial decline starting around 1980. It is made up mostly of places in the Midwest and Great Lakes, though definitions vary. Rust refers to the deindustrialization, or economic decline, population loss, and urban decay due to the shrinking of its once-powerful industrial sector. The term gained popularity in the U.S. in the 1980s.

The Rust Belt begins in Central New York and traverses west through Pennsylvania, West Virginia, Ohio, Indiana, and the Lower Peninsula of Michigan, ending in northern Illinois, eastern Iowa, and southeastern Wisconsin.

New England was also hard hit by industrial decline during the same

era. Industry has been declining in the region, which was previously

known as the industrial heartland of America, since the mid-20th century

due to a variety of economic factors, such as the transfer of

manufacturing overseas, increased automation, and the decline of the US steel and coal industries. While some cities and towns have managed to adapt by shifting focus towards services and high-tech industries, others have not fared as well, witnessing rising poverty and declining populations.

Background

In

the 20th century, local economies in these states specialized in

large-scale manufacturing of finished medium to heavy industrial and

consumer products, as well as the transportation and processing of the

raw materials required for heavy industry. The area was referred to as the Manufacturing Belt, Factory Belt, or Steel Belt as distinct from the agricultural Midwestern states forming the so-called Corn Belt and Great Plains states that are often called the "bread-basket of America".

The flourishing of industrial manufacturing in the region was caused in part by the proximity to the Great Lakes

waterways, and abundance of paved roads, water canals and railroads.

After the transportation infrastructure linked the iron ore found in

northern Minnesota, Wisconsin and Upper Michigan with the coal mined from Appalachian Mountains, the Steel Belt was born. Soon it developed into the Factory Belt with its great American manufacturing cities: Chicago, Buffalo, Detroit, Milwaukee, Cincinnati, Toledo, Cleveland, St. Louis, and Pittsburgh

among others. This region for decades served as a magnet for immigrants

from Austria-Hungary, Poland and Russia who provided the industrial

facilities with inexpensive labor.

Following several "boom" periods from the late-19th to the mid-20th century,

cities in this area struggled to adapt to a variety of adverse economic

and social conditions. From 1979 to 1982, the US Federal Reserve

decided to raise the base interest rate in the United States to 19%.

High interest rates attracted wealthy foreign "hot money" into US banks

and caused the US dollar to appreciate. This made US products more

expensive for foreigners to buy and also made imports much cheaper for

Americans to purchase. The misaligned exchange rate was not rectified

until 1986, by which time Japanese imports in particular had made rapid

inroads into US markets.

From 1987 to 1999, the US stock market went into stratospheric rise,

and this continued to pull wealthy foreign money into US banks, which

biased the exchange rate against manufactured goods. Related issues

include the decline of the iron and steel industry, the movement of manufacturing to the southeastern states with their lower labor costs, the layoffs due to the rise of automation in industrial processes, the decreased need for labor in making steel products, new organizational methods such as just-in-time manufacturing which allowed factories to maintain production with fewer workers, the internationalization of American business, and the liberalization of foreign trade policies due to globalization. Cities struggling with these conditions shared several difficulties, including population loss,

lack of education, declining tax revenues, high unemployment and crime,

drugs, swelling welfare rolls, deficit spending, and poor municipal

credit ratings.

Geography

As people migrate, they often coin new names for their destinations.

Since the term "Rust Belt" pertains to a set of economic and social

conditions rather than to an overall geographical region of the United

States, the Rust Belt has no precise boundaries. The extent to which a

community may have been described as a "Rust Belt city" depends at least

as much on how great a role industrial manufacturing played in its

local economy in the past and how it does now, as on perceptions of the

economic viability and living standards of the present day.

News media occasionally refer to a patchwork of defunct centres

of heavy industry and manufacturing across the Great Lakes and

mid-western United States as the snow belt, the manufacturing belt, or the factory belt

- because of their vibrant industrial economies in the past. This

includes most of the cities of the Midwest as far west as the Mississippi River, including St. Louis, and many of those in the Great Lakes and Northern New York. At the center of this expanse lies an area stretching from northern Indiana and southern Michigan in the west to Upstate New York in the east, where local tax revenues as of 2004 relied more heavily on manufacturing than on any other sector.

Before World War II,

the cities in the Rust Belt region were among the largest in the United

States. However, by the twentieth century's end their population had

fallen the most in the country.

History

The linking of the former Northwest Territory with the once-rapidly industrializing East Coast was affected through several large-scale infrastructural projects, most notably the Erie Canal in 1825, the Baltimore and Ohio Railroad in 1830, the Allegheny Portage Railroad in 1834, and the consolidation of the New York Central after the American Civil War. A gate was thereby opened between a variety of burgeoning industries on the interior North American continent and the markets not only of the large Eastern cities, but of Western Europe as well.

Coal, iron ore and other raw materials were shipped in from

surrounding regions which emerged as major ports on the Great Lakes and

served as transportation hubs for the region with a proximity to

railroad lines. Coming in the other direction were millions of European

immigrants, who populated the cities along the Great Lakes shores with

then-unprecedented speed. Chicago, famously, was a rural trading post in

the 1840s but grew to be as big as Paris by the time of the 1893 Columbian Exposition.

Sectors of the US Economy as percent of GDP 1947–2009.

Early signs of the difficulty in the northern states were evident

early in the 20th century, before the "boom years" were even over. Lowell, Massachusetts, once the centre of textile production in the United States, was described in the magazine Harper's as a "depressed industrial desert" as early as 1931, as its textile concerns were being uprooted and sent southward, primarily to the Carolinas. After the Great Depression, American entry into the Second World War

effected a rapid return to economic growth, during which much of the

industrial North reached its peak in population and industrial output.

The northern cities experienced changes that followed the end of

the war, with the onset of the outward migration of residents to newer

suburban communities, and the declining role of manufacturing in the American economy.

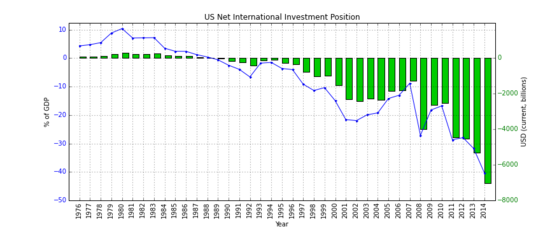

Deteriorating U.S. net international investment position (N.I.I.P.) has caused concern among economists over the effects of outsourcing and high U.S. trade deficits over the long-run.

Outsourcing of manufacturing jobs in tradeable goods has been an important issue in the region. One source has been globalization and the expansion of worldwide free trade

agreements. Anti-globalization groups argue that trade with developing

countries has resulted in stiff competition from countries such as China

which pegs its currency to the dollar and has much lower prevailing

wages, forcing domestic wages to drift downward. Some economists are

concerned that long-run effects of high trade deficits and outsourcing are a cause of economic problems in the U.S. with high external debt (amount owed to foreign lenders) and a serious deterioration in the United States net international investment position (NIIP) (−24% of GDP).

Some economists contend that the U.S. is borrowing to fund

consumption of imports while accumulating unsustainable amounts of debt.

On June 26, 2009, Jeff Immelt, the CEO of General Electric, called for

the United States to increase its manufacturing base employment to 20%

of the workforce, commenting that the U.S. has outsourced too much in

some areas and can no longer rely on the financial sector and consumer

spending to drive demand.

A disused grain elevator in Buffalo, New York

Since the 1960s, the expansion of worldwide free trade agreements have been less favorable to U.S. workers. Imported goods such as steel cost much less to produce in Third World countries with cheap foreign labor (see steel crisis).

Beginning with the recession of 1970–71, a new pattern of

deindustrializing economy emerged. Competitive devaluation combined with

each successive downturn saw traditional U.S. manufacturing

workers experiencing lay-offs. In general, in the Factory Belt

employment in the manufacturing sector declined by 32.9% between 1969

and 1996.

Wealth-producing primary and secondary sector jobs such as those

in manufacturing and computer software were often replaced by

much-lower-paying wealth-consuming jobs such as those in retail and

government in the service sector when the economy recovered.

A gradual expansion of the U.S. trade deficit with China began in

1985. In the ensuing years the U.S. developed a massive trade deficit

with the East Asian nations of China, Japan, Taiwan, and South Korea. As

a result, the traditional manufacturing workers in the region have

experienced economic upheaval. This effect has devastated government

budgets across the U.S. and increased corporate borrowing to fund

retiree benefits. Some economists believe that GDP and employment can be dragged down by large long-run trade deficits.

A March 3, 2008 Wall Street Journal

editorial claimed that, while Ohio lost 10,000 jobs in the past decade,

Texas created 1.6 million new jobs. The editorial stated, "Ohio's most

crippling handicap may be that its politicians—and thus its

employers—are still in the grip of such industrial unions as the United

Auto Workers." A September 13, 2008 opinion column by Phil Gramm

and Mike Solon stated, "Yes, Michigan lost 83,000 auto manufacturing

jobs during the past decade and a half, but more than 91,000 new auto

manufacturing jobs sprung up in Alabama, Tennessee, Kentucky, Georgia,

South Carolina, Virginia and Texas."

Outcomes

Francis Fukuyama

considers the social and cultural consequences of deindustrialization

and manufacturing decline that turned a former thriving Factory Belt

into a Rust Belt as a part of a bigger transitional trend that he called

the Great Disruption:

"People associate the information age with the advent of the Internet

in the 1990s, but the shift from the industrial era started more than a

generation earlier, with the deindustrialization of the Rust Belt in the

United States and comparable movements away from manufacturing in other

industrialized countries. … The decline is readily measurable in

statistics on crime, fatherless children, broken trust, reduced

opportunities for and outcomes from education, and the like".

Problems associated with the Rust Belt persist even today, particularly around the eastern Great Lakes states, and many once-booming manufacturing metropolises dramatically slowed down.

From 1970 to 2006, Cleveland, Detroit, Buffalo, and Pittsburgh lost

about 45% of their population and median household incomes fell: in

Cleveland and Detroit by about 30%, in Buffalo by 20%, and Pittsburgh by

10%.

An abandoned Fisher auto body plant in Detroit

A steel plant in Bethlehem, Pennsylvania. Though the blast furnaces themselves remain intact, part of the property was sold in 2007 and turned into the Sands Casino Resort Bethlehem.

The Huber Breaker (in Ashley, Pennsylvania) was one of the largest anthracite coal breakers in North America. It was built in the 1930s; it closed in the 1970s.

It seemed that during the mid-1990s in several Rust Belt metro areas

the negative growth was suspended as indicated by major statistical

indicators: unemployment, wages, population change.

However, during the first decade of the 21st century, a negative trend

persisted: Detroit lost 25.7% of its population; Gary, Indiana – 22%;

Youngstown, Ohio – 18.9%; Flint, Michigan – 18.7%; and Cleveland, Ohio –

14.5%.

| City | Population change | 2018 population | 2000 population |

|---|---|---|---|

| Detroit, Michigan | −29.3% | 672,662 | 951,270 |

| Gary, Indiana | −26.7% | 75,282 | 102,746 |

| Flint, Michigan | −23.2% | 95,943 | 124,943 |

| Saginaw, Michigan | −21.8% | 48,323 | 61,799 |

| Youngstown, Ohio | −20.8% | 64,958 | 82,026 |

| Cleveland, Ohio | −19.8% | 383,793 | 478,403 |

| Dayton, Ohio | −15.4% | 140,640 | 166,179 |

| Niagara Falls, New York | −13.4% | 48,144 | 55,593 |

| St. Louis, Missouri | −13.0% | 302,838 | 348,189 |

| Decatur, Illinois | −12.9% | 71,290 | 81,860 |

| Canton, Ohio | −12.8% | 70,458 | 80,806 |

| Buffalo, New York | −12.4% | 256,304 | 292,648 |

| Toledo, Ohio | −12.3% | 274,975 | 313,619 |

| Charleston, West Virginia | −11.6% | 47,215 | 53,421 |

| Lakewood, Ohio | −11.6% | 50,100 | 56,646 |

| Pittsburgh, Pennsylvania | −10.0% | 301,048 | 334,563 |

| Pontiac, Michigan | −9.9% | 59,772 | 66,337 |

| Springfield, Ohio | −9.3% | 59,282 | 65,358 |

| Akron, Ohio | −8.8% | 198,006 | 217,074 |

| Hammond, Indiana | −8.7% | 75,795 | 83,048 |

| Cincinnati, Ohio | −8.7% | 302,605 | 331,285 |

| Parma, Ohio | −8.1% | 78,751 | 85,655 |

| Lorain, Ohio | −6.7% | 64,028 | 68,652 |

| Chicago, Illinois | −6.6% | 2,705,994 | 2,896,016 |

| South Bend, Indiana | −5.5% | 101,860 | 107,789 |

In the late-2000s, American manufacturing recovered faster from the Great Recession of 2008 than the other sectors of the economy,

and a number of initiatives, both public and private, are encouraging

the development of alternative fuel, nano and other technologies. Together with the neighboring Golden Horseshoe of Southern Ontario, Canada, the so-called Rust Belt still composes one of the world's major manufacturing regions.

Transformation

Since

the 1980s, presidential candidates have devoted much of their time to

the economic concerns of the Rust Belt region, which contains the

populous swing states of Pennsylvania, Ohio, and Michigan. Those states were also critical and decisive to Donald Trump's victory in the 2016 US Presidential Election.

Different strategies were proposed in order to reverse the

fortunes of the former Factory Belt including building casinos and

convention centers, retaining the so-called "creative class" through

arts and downtown renewal, encouraging the "knowledge" economy type of

entrepreneurship, etc. Lately, analysts suggested that industrial

comeback might be the actual path for the future resurgence of the

region.

That includes growing new industrial base with a pool of skilled

labor, rebuilding the infrastructure and infrasystems, creating R&D

university-business partnerships, and close cooperation between central,

state and local government and business.

New types of R&D-intensive nontraditional manufacturing have emerged recently in Rust Belt, such as biotechnology, the polymer industry, infotech, and nanotech. Infotech in particular creates a promising venue for the Rust Belt's revitalization.

Among the successful recent examples is the Detroit Aircraft

Corporation, which specializes in unmanned aerial systems integration,

testing and aerial cinematography services.

In Pittsburgh, robotics research centres and companies such as National Robotics Engineering Center

and Robotics Institute, Aethon Inc., American Robot Corporation,

Automatika, Quantapoint, Blue Belt Technologies and Seegrid are creating

state-of-the-art robotic technology applications. Akron, a former "Rubber Capital of the World" that lost 35,000 jobs after major tire and rubber manufacturers Goodrich, Firestone and General Tire

closed their production lines, is now again well known around the world

as a centre of polymer research with four hundred polymer-related

manufacturing and distribution companies operating in the area. The

turnaround was accomplished in part due to a partnership between Goodyear Tire & Rubber, which chose to stay, the University of Akron

and the city mayor's office. The Akron Global Business Accelerator that

jump-started a score of successful business ventures in Akron resides

in the refurbished B.F. Goodrich tire factory.

Additive manufacturing, or 3D printing, creates another promising venue for the manufacturing resurgence. Such companies as MakerGear from Beachwood, Ohio, or ExOne Company from North Huntingdon, PA, are designing and manufacturing industrial and consumer products using 3-D imaging systems. Not long ago, the London-based Economist pointed towards a growing trend of reshoring, or inshoring, of manufacture when a growing number of American companies are moving their production facilities from overseas back home. Rust Belt states can ultimately benefit from this process of an international insourcing.

However, automation has led to the types of manufacturing that

requires fewer workers even with advanced skills. That is why job gains

in manufacture in Rust Belt have not been nearly enough to keep pace

with lay-offs. As a result, middle class incomes and savings in the Rust Belt states continue to be negatively impacted.

Delving into the past and musing on the future of Rust Belt states, the Brookings Institution

report suggests that the Great Lakes region has a sizable potential for

transformation, citing already existing global trade networks, clean

energy/low carbon capacity, developed innovation infrastructure and

higher educational network.

International equivalents

The following regions, areas, and cities are known to have some similarities to the rust belt in the United States:

- Bergslagen, Sweden

- Donbass, Ukraine

- Nord-Pas-de-Calais, France

- Ruhr Area, Germany

- Silesian Voivodeship, Poland

- Shikoku, Japan

- Kymenlaakso, Finland

- Mindanao, Philippines

- Southern Ontario, Canada - does not include Toronto and Ottawa

- Northeast China – a former center of heavy industry that declined for other reasons

- Northern England – another former industrial center which began declining in the 1980s.