A superhard material is a material with a hardness value exceeding 40 gigapascals (GPa) when measured by the Vickers hardness test. They are highly incompressible solids with high electron density and high bond covalency. As a result of their unique properties, these materials are of great interest in many industrial areas including, but not limited to, abrasives, polishing and cutting tools and wear-resistant and protective coatings.

Diamond is the hardest known material to date, with a Vickers hardness in the range of 70–150 GPa. Diamond demonstrates both high thermal conductivity and electrically insulating properties and much attention has been put into finding practical applications of this material. However, diamond has several limitations for mass industrial application, including its high cost and oxidation at temperatures above 800 °C. In addition, diamond dissolves in iron and forms iron carbides at high temperatures and therefore is inefficient in cutting ferrous materials including steel. Therefore, recent research of superhard materials has been focusing on compounds which would be thermally and chemically more stable than pure diamond.

Superhard materials can be generally classified into two categories: intrinsic compounds and extrinsic compounds. The intrinsic group includes diamond, cubic boron nitride (c-BN), carbon nitrides and ternary compounds such as B-N-C, which possess an innate hardness. Conversely, extrinsic materials are those that have superhardness and other mechanical properties that are determined by their microstructure rather than composition. An example of extrinsic superhard material is nanocrystalline diamond known as aggregated diamond nanorods.

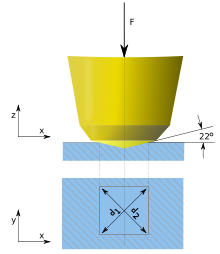

A nanoindenter, used to measure the hardness and related properties of materials

Definition and mechanics of hardness

Vickers test scheme

An indentation left in case-hardened steel after a Vickers hardness test.

The hardness of a material is directly related to its

incompressibility, elasticity and resistance to change in shape. A

superhard material has high shear modulus, high bulk modulus and does not deform plastically.

Ideally superhard materials should have a defect-free, isotropic

lattice. This greatly reduces structural deformations that can lower the

strength of the material. However, defects can actually strengthen some

covalent structures. Traditionally, high-pressure and high-temperature

(HPHT) conditions have been used to synthesize superhard materials, but

recent superhard material syntheses aim at using less energy and lower

cost materials.

Historically, hardness was first defined as the ability of one

material to scratch another and quantified by an integer (sometimes

half-integer) from 0 to 10 on the Mohs scale.

This scale was however quickly found too discrete and non-linear.

Measuring the mechanical hardness of materials changed to using a nanoindenter (usually made of diamond) and evaluating bulk moduli, and the Brinell, Rockwell, Knoop and Vickers scales have been developed. Whereas the Vickers scale is widely accepted as a most common test,

there remain controversies on the weight load to be applied during the

test. Bulk moduli, shear moduli, and elasticity are the key factors in

the superhard classification process.

| Material | Vickers hardness (GPa) |

|---|---|

| Diamond | 115 |

| c-BC2N | 76 |

| c-BN | 48 |

| OsB2 | 37 |

| B4C | 30 |

| WB4 | ~30 |

| AlMgB14 | 26.7 |

| ReB2 | ~20 |

The incompressibility of a material is quantified by the bulk modulus

B, which measures the resistance of a solid to volume compression under

hydrostatic stress

as B = −Vdp/dV. Here V is the volume, p is pressure, and dp/dV is the

partial derivative of pressure with respect to the volume. The bulk

modulus test uses an indenter tool to form a permanent deformation in a

material. The size of the deformation depends on the material’s

resistance to the volume compression made by the tool. Elements with

small molar volumes and strong interatomic forces usually have high bulk

moduli. Bulk moduli was the first major test of hardness and originally

shown to be correlated with the molar volume (Vm) and cohesive energy (Ec) as B ~ Ec/Vm

Bulk modulus was believed to be a direct measure of a material’s

hardness but this no longer remains the dominant school of thought. For

example, some alkali and noble metals

(Pd, Ag) have anomalously high ratio of the bulk modulus to the Vickers

of Brinell hardness. In the early 2000s, a direct relationship between

bulk modulus and valence electron density was found as the more

electrons were present the greater the repulsions within the structure

were.

Bulk modulus is still used as a preliminary measure of a material as

superhard but it is now known that other properties must be taken into

account.

In contrast to bulk modulus, shear modulus measures the

resistance to shape change at a constant volume, taking into account the

crystalline plane and direction of shear. The shear modulus G is

defined as ratio of shear stress to shear strain: G = stress/strain =

F·L/(A·dx), where F is the applied force, A is the area upon which the

force acts, dx is the resulting displacement and L is the initial

length. The larger the shear modulus, the greater the ability for a

material to resist shearing forces. Therefore, the shear modulus is a

measure of rigidity. Shear modulus is related to bulk modulus as 3/G = 2B(1 − 2v)(1 + v),

where v is the Poisson’s ratio, which is typically ~0.1 in covalent

materials. If a material contains highly directional bonds, the shear

modulus will increase and give a low Poisson ratio.

A material is also considered hard if it resists plastic

deformation. If a material has short covalent bonds, atomic dislocations

that lead to plastic deformation are less likely to occur than in

materials with longer, delocalized bonds. If a material contains many

delocalized bonds it is likely to be soft. Somewhat related to hardness is another mechanical property fracture toughness, which is a material's ability to resist breakage from forceful impact (note that this concept is distinct from the notion of toughness). A superhard material is not necessarily "supertough". For example, the fracture toughness of diamond is about 7–10 MPa·m1/2,

which is high compared to other gemstones and ceramic materials, but

poor compared to many metals and alloys – common steels and aluminium

alloys have the toughness values at least 5 times higher.

Several properties must be taken into account when evaluating a

material as (super)hard. While hard materials have high bulk moduli, a

high bulk modulus does not mean a material is hard. Inelastic

characteristics must be considered as well, and shear modulus might even

provide a better correlation with hardness than bulk modulus. Covalent

materials generally have high bond-bending force constants and high

shear moduli and are more likely to give superhard structures than, for

example, ionic solids.

Diamond

Diamond and graphite materials and structure

Diamond is an allotrope of carbon where the atoms are arranged in a modified version of face-centered cubic (fcc) structure known as "diamond cubic".

It is known for its hardness (see table above) and incompressibility

and is targeted for some potential optical and electrical applications.

The properties of individual natural diamonds or carbonado vary too widely for industrial purposes, and therefore synthetic diamond became a major research focus.

Synthetic diamond

The high-pressure synthesis of diamond in 1953 in Sweden and in 1954 in the US,

made possible by the development of new apparatus and techniques,

became a milestone in synthesis of artificial superhard materials. The

synthesis clearly showed the potential of high-pressure applications for

industrial purposes and stimulated growing interest in the field. Four

years after the first synthesis of artificial diamond, cubic boron nitride c-BN was obtained and found to be the second hardest solid.

Synthetic diamond

can exist as a single, continuous crystal or as small polycrystals

interconnected through the grain boundaries. The inherent spatial

separation of these subunits causes the formation of grains, which are

visible by the unaided eye due to the light absorption and scattering

properties of the material.

The hardness of synthetic diamond (70–150 GPa) is very dependent

on the relative purity of the crystal itself. The more perfect the

crystal structure, the harder the diamond becomes. It has recently been

reported that HPHT single crystals and nanocrystalline diamond

aggregates (aggregated diamond nanorods) can be harder than natural diamond.

Historically, it was thought that synthetic diamond should be

structurally perfect to be useful. This is because diamond was mainly

preferred for its aesthetic qualities, and small flaws in structure and

composition were visible by naked eye. Although this is true, the

properties associated with these small changes has led to interesting

new potential applications of synthetic diamond. For example, nitrogen

doping can enhance mechanical strength of diamond, and heavy doping with boron (several atomic percent) makes it a superconductor.

Cubic boron nitride

History

Cubic boron nitride or c-BN was first synthesized in 1957 by Robert H. Wentorf at General Electric, shortly after the synthesis of diamond.

The general process for c-BN synthesis is the dissolution of hexagonal

boron nitride (h-BN) in a solvent-catalyst, usually alkali or alkaline earth metals or their nitrides, followed by spontaneous nucleation of c-BN under high pressure, high temperature (HPHT) conditions.

The yield of c-BN is lower and substantially slower compared to

diamond's synthetic route due to the complicated intermediate steps. Its

insolubility in iron and other metal alloys makes it more useful for

some industrial applications than diamond.

Sphalerite BN structure

Pure cubic boron nitride is transparent or slightly amber. Different

colors can be produced depending on defects or an excess of boron (less

than 1%).

Defects can be produced by doping solvent-catalysts (i.e. Li, Ca, or Mg

nitrides) with Al, B, Ti, or Si. This induces a change in the

morphology and color of c-BN crystals.

The result is darker and larger (500 μm) crystals with better shapes and a higher yield.

Structure and properties

Cubic boron nitride adopts a sphalerite crystal structure,

which can be constructed by replacing every two carbon atoms in diamond

with one boron atom and one nitrogen atom. The short B-N (1.57 Å) bond

is close to the diamond C-C bond length (1.54 Å), that results in strong

covalent bonding between atoms in the same fashion as in diamond. The

slight decrease in covalency for B-N bonds compared to C-C bonds reduces

the hardness from ~100 GPa for diamond down to 48 GPa in c-BN. As

diamond is less stable than graphite, c-BN is less stable than h-BN, but

the conversion rate between those forms is negligible at room

temperature.

Cubic boron nitride is insoluble in iron, nickel, and related

alloys at high temperatures, but it binds well with metals due to

formation of interlayers of metal borides and nitrides. It is also

insoluble in most acids, but is soluble in alkaline molten salts and

nitrides, such as LiOH, KOH, NaOH/Na2CO3, NaNO3 which are used to etch c-BN.

Because of its stability with heat and metals, c-BN surpasses diamond

in mechanical applications. The thermal conductivity of BN is among the

highest of all electric insulators. In addition, c-BN consists of only

light elements and has low X-ray absorptivity, capable of reducing the

X-ray absorption background.

Research and development

Due

to its great chemical and mechanical robustness, c-BN has widespread

application as an abrasive, such as on cutting tools and scratch

resistant surfaces. Cubic boron nitride is also highly transparent to

X-rays. This, along with its high strength, makes it possible to have

very thin coatings of c-BN on structures that can be inspected using

X-rays. Several hundred tonnes of c-BN are produced worldwide each year.

By modification, Borazon, a US brand name of c-BN, is used in

industrial applications to shape tools, as it can withstand temperatures

greater than 2,000 °C. Cubic boron nitride-coated grinding wheels,

referred to as Borazon wheels, are routinely used in the machining of

hard ferrous metals, cast irons, and nickel-base and cobalt-base superalloys. Other brand names, such as Elbor and Cubonite, are marketed by Russian vendors.

New approaches in research focus on improving c-BN pressure capabilities of the devices used for c-BN synthesis.

At present, the capabilities for the production of c-BN are restricted

to pressures of about 6 GPa. Increasing the pressure limit will permit

synthesis of larger single crystals than from the present catalytic

synthesis. However, the use of solvents under supercritical conditions

for c-BN synthesis has been shown to reduce pressure requirements. The high cost of c-BN still limits its application, which motivates the search for other superhard materials.

Carbon nitride

The structure of beta carbon nitride (β-C3N4) was first proposed by Marvin Cohen and Amy Liu in 1989. It is isostructural with Si3N4 and was predicted to be harder than diamond.

The calculated bond length was 1.47 Å, 5% shorter than the C-C bond

length in diamond. Later calculations indicated that the shear modulus

is 60% of that of diamond, and carbon nitride is less hard than c-BN.

Despite two decades of pursuit of this compound, no synthetic sample of C3N4 has validated the hardness predictions; this has been attributed to the difficulty in synthesis and the instability of C3N4.

Carbon nitride is only stable at a pressure that is higher than that of

the graphite-to-diamond transformation. The synthesis conditions would

require extremely high pressures because carbon is four- and sixfold

coordinated. In addition, C3N4

would pose problems of carbide formation if they were to be used to

machine ferrous metals. Although publications have reported preparation

of C3N4 at lower pressures than stated, synthetic C3N4 was not proved superhard.

Boron carbon nitride

The

similar atomic sizes of boron, carbon and nitrogen, as well as the

similar structures of carbon and boron nitride polymorphs, suggest that

it might be possible to synthesize diamond-like phase containing all

three elements. It is also possible to make compounds containing B-C-O,

B-O-N, or B-C-O-N under high pressure, but their synthesis would expect

to require a complex chemistry and in addition, their elastic properties

would be inferior to that of diamond.

Beginning in 1990, a great interest has been put in studying the

possibility to synthesize dense B-C-N phases. They are expected to be

thermally and chemically more stable than diamond, and harder than c-BN,

and would therefore be excellent materials for high speed cutting and

polishing of ferrous alloys. These characteristic properties are

attributed to the diamond-like structure combined with the sp3 σ-bonds

among carbon and the heteroatoms. BCxNy thin films were synthesized by chemical vapor deposition in 1972.

However, data on the attempted synthesis of B-C-N dense phases reported

by different authors have been contradictory. It is unclear whether the

synthesis products are diamond-like solid solutions between carbon and

boron nitride or just mechanical mixtures of highly dispersed diamond

and c-BN. In 2001, a diamond-like-structured c-BC2N was

synthesized at pressures >18 GPa and temperatures >2,200 K by a

direct solid-state phase transition of graphite-like (BN)0.48C0.52.

The reported Vickers and Knoop hardnesses were intermediate between

diamond and c-BN, making the new phase the second hardest known

material.

Ternary B–C–N phases can also be made using shock-compression

synthesis. It was further suggested to extend the B–C–N system to

quaternary compounds with silicon included.

Metal borides

Unlike

carbon-based systems, metal borides can be easily synthesized in large

quantities under ambient conditions, an important technological

advantage. Most metal borides are hard; however, a few stand out among them for their particularly high hardnesses (for example, WB4, RuB2, OsB2 and ReB2).

These metal borides are still metals and not semiconductors or insulators (as indicated by their high electronic density of states at the Fermi Level); however, the additional covalent B-B and M-B bonding (M = metal) lead to high hardness. Dense heavy metals, such as osmium, rhenium, tungsten

etc., are particularly apt at forming hard borides because of their

high electron densities, small atomic radii, high bulk moduli, and

ability to bond strongly with boron.

Osmium diboride

Crystal structure of OsB2

Osmium diboride (OsB2)

has a high bulk modulus of 395 GPa and therefore is considered as a

candidate superhard material, but the maximum achieved Vickers hardness

is 37 GPa, slightly below the 40 GPa limit of superhardness. A common

way to synthesize OsB2 is by a solid-state metathesis reaction containing a 2:3 mixture of OsCl3:MgB2. After the MgCl2 product is washed away, X-ray diffraction indicates products of OsB2, OsB and Os. Heating this product at 1,000 °C for three days produces pure OsB2 crystalline product. OsB2 has an orthorhombic structure (space group Pmmn)

with two planes of osmium atoms separated by a non-planar layer of

hexagonally coordinated boron atoms; the lattice parameters are a = 4.684 Å, b = 2.872 Å and c = 4.096 Å. The b direction of the crystal is the most compressible and the c direction is the least compressible. This can be explained by the orthorhombic structure. When looking at the boron and osmium atoms in the a and b

directions, they are arranged in a way that is offset from one another.

Therefore, when they are compressed they are not pushed right up

against one another. Electrostatic repulsion is the force that maximizes

the materials incompressibility and so in this case the electrostatic

repulsion is not taken full advantage of. When compressed in the c

direction, the osmium and boron atoms are almost directly in line with

one another and the electrostatic repulsion is therefore high, causing

direction c to be the least compressible. This model implies that

if boron is more evenly distributed throughout the lattice then

incompressibility could be higher. Electron backscatter diffraction coupled with hardness measurements reveals that in the (010) plane, the crystal is 54% harder in the <100>

than <001> direction. This is seen by looking at how long the

indentation is along a certain direction (related to the indentations

made with a Vickers hardness test). Along with the alignment of the

atoms, this is also due to the short covalent B-B (1.80 Å) bonds in the

<100> direction, which are absent in the <001> direction

(B-B = 4.10 Å).

Rhenium borides

Rhenium

was targeted as a candidate for superhard metal borides because of its

desirable physical and chemical characteristics. It has a high electron

density, a small atomic radius and a high bulk modulus. When combined

with boron, it makes a crystal with highly covalent bonding allowing it

to be incompressible and potentially very hard. A wide array of rhenium borides have been investigated including Re3B, Re7B3, Re2B, ReB, Re2B3, Re3B7, Re2B5, ReB3 and ReB2.

Each of these materials has their own set of properties and

characteristics. Some show promise as superconductors and some have

unique elastic and electronic properties, but the most relevant to

superhard materials is ReB2.

Rhenium diboride (ReB2) is a refractory compound which was first synthesized in the 1960s, using arc melting, zone melting,

or optical floating zone furnaces. An example synthesis of this

material is the flux method, which is conducted by placing rhenium metal

and amorphous boron in an alumina

crucible with excess aluminium. This can be run with a ratio of 1:2:50

for Re:B:Al, with the excess aluminum as a growth medium. The crucible

is placed in an alumina tube, inserted into a resistively heated furnace

with flowing argon gas and sintered at 1,400 °C for several hours. After cooling, the aluminium is dissolved in NaOH. Each ReB2 synthesis route has its own drawbacks, and this one gives small inclusions of aluminum incorporated into the crystal lattice.

Rhenium diboride has a very high melting point approaching 2,400 °C and a highly anisotropic, layered crystal structure. Its symmetry is either hexagonal (space group P63mc) or orthorhombic (Cmcm)

depending on the phase. There, close-packed Re layers alternate with

puckered triangular boron layers along the (001) plane. This can be seen

above on the example of osmium diboride. The density of states for ReB2 has one of the lowest values among the metal borides, indicating strong covalent bonding and high hardness.

Owing to the anisotropic nature of this material, the hardness

depends on the crystal orientation. The (002) plane contains the most

covalent character and exhibits a maximum Vickers hardness value of 40.5

GPa, while the perpendicular planes were 6% lower at 38.1 GPa. These

values decrease with increased load, settling at around 28 GPa each. The

nanoindentation

values were found to be 36.4 GPa and 34.0 GPa for the (002) and

perpendicular planes respectively. The hardness values depend on the

material purity and composition – the more boron the harder the boride –

and the above values are for a Re:B ratio of approximately 1.00:1.85.

Rhenium diboride also has a reported bulk modulus of 383 GPa and a shear

modulus of 273 GPa.

The hardness of rhenium diboride, and most other materials also depends

on the load during the test. The above values of about 40 GPa were all

measured with an effective load of 0.5–1 N. At such low load, the

hardness values are also overestimated for other materials, for example

it exceeds 100 GPa for c-BN. Other researchers, while having reproduced the high ReB2 hardness at low load, reported much lower values of 19–17 GPa at a more conventional load of 3–49 N, that makes ReB2 a hard, but not a superhard material.

Rhenium diboride exhibits metallic conductivity which increases

as temperature decreases and can be explained by a nonzero density of

states due to the d and p overlap of rhenium and boron respectively. At

this point, it is the only superhard material with metallic behavior.

The material also exhibits relatively high thermal stability. Depending

on the heating method, it will maintain its mass up to temperatures of

600–800 °C, with any drop being due to loss of absorbed water. A small

loss of mass can then be seen at temperatures approaching 1,000 °C. It

performs better when a slower heat ramp is utilized. Part of this small

drop at around 1,000 °C was explained by the formation of a dull B2O3

coating on the surface as boron is leached out of the solid, which

serves as a protective coating, thereby reducing additional boron loss.

This can be easily dissolved by methanol to restore the material to it

native shiny state.

Aluminum Magnesium Boride

Aluminum magnesium boride or BAM is a chemical compound of aluminium, magnesium and boron. Whereas its nominal formula is AlMgB14, the chemical composition is closer to Al0.75Mg0.75B14. It is a ceramic alloy that is highly resistive to wear and has a low coefficient of sliding friction.

Other boron-rich superhard materials

Boron carbide

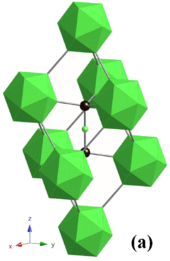

Crystal structure of B6O

Other hard boron-rich compounds include B4C and B6O. Amorphous a-B4C has a hardness of about 50 GPa, which is in the range of superhardness.

It can be looked at as consisting of boron icosahedra-like crystals

embedded in an amorphous medium. However, when studying the crystalline

form of B4C, the hardness is only about 30 GPa. This crystalline form has the same stoichiometry as B13C3, which consists of boron icosahedra connected by boron and carbon atoms. Boron suboxide (B6O) has a hardness of about 35 GPa. Its structure contains eight B12

icosahedra units, which are sitting at the vertices of a rhombohedral

unit cell. There are two oxygen atoms located along the (111)

rhombohedral direction.

Nanostructured superhard materials

Nanosuperhard

materials fall into the extrinsic category of superhard materials.

Because molecular defects affect the superhard properties of bulk

materials it is obvious that the microstructure of superhard materials

give the materials their unique properties. Focus on synthesizing nano

superhard materials is around minimizing microcracks occurring within

the structure through grain boundary hardening. The elimination of

microcracks can strengthen the material by 3 to 7 times its original

strength. Grain boundary strengthening is described by the Hall-Petch equation

Here σc is the critical fracture stress, d the crystallite size and σ0 and kgb are constants.

If a material is brittle its strength depends mainly on the

resistance to forming microcracks. The critical stress which causes the

growth of a microcrack of size a0 is given by a general formula

Here E is the Young's modulus, kcrack is a constant dependent on the nature and shape of the microcrack and the stress applied and γs the surface cohesive energy.

The average hardness of a material decreases with d (crystallite

size) decreasing below 10 nm. There have been many mechanisms proposed

for grain boundary sliding

and hence material softening, but the details are still not understood.

Besides grain boundary strengthening, much attention has been put into

building microheterostructures,

or nanostructures of two materials with very large differences in

elastic moduli. Heterostructures were first proposed in 1970 and

contained such highly ordered thin layers that they could not

theoretically be separated by mechanical means. These highly ordered

heterostructures were believed to be stronger than simple mixtures. This

theory was confirmed with Al/Cu and Al/Ag structures. After the

formation of Al/Cu and Al/Ag, the research was extended to multilayer

systems including Cu/Ni, TiN/VN, W/WN, Hf/HfN and more. In all cases,

decreasing the lattice period increased the hardness. One common form of a nanostructured material is aggregated diamond nanorods, which is harder than bulk diamond and is currently the hardest (~150 GPa) material known.