Schematic of plastic solar cells. PET – polyethylene terephthalate, ITO – indium tin oxide, PEDOT:PSS – poly(3,4-ethylenedioxythiophene), active layer (usually a polymer:fullerene blend), Al – aluminium.

An organic solar cell or plastic solar cell is a type of photovoltaic that uses organic electronics, a branch of electronics that deals with conductive organic polymers or small organic molecules, for light absorption and charge transport to produce electricity from sunlight by the photovoltaic effect. Most organic photovoltaic cells are polymer solar cells.

The molecules used in organic solar cells are

solution-processable at high throughput and are cheap, resulting in low

production costs to fabricate a large volume. Combined with the flexibility of organic molecules,

organic solar cells are potentially cost-effective for photovoltaic

applications. Molecular engineering (e.g. changing the length and functional group of polymers) can change the band gap, allowing for electronic tunability. The optical absorption coefficient

of organic molecules is high, so a large amount of light can be

absorbed with a small amount of materials, usually on the order of

hundreds of nanometers. The main disadvantages associated with organic

photovoltaic cells are low efficiency, low stability and low strength compared to inorganic photovoltaic cells such as silicon solar cells.

Compared to silicon-based

devices, polymer solar cells are lightweight (which is important for

small autonomous sensors), potentially disposable and inexpensive to

fabricate (sometimes using printed electronics),

flexible, customizable on the molecular level and potentially have less

adverse environmental impact. Polymer solar cells also have the

potential to exhibit transparency, suggesting applications in windows,

walls, flexible electronics, etc. An example device is shown in the figure above.

The disadvantages of polymer solar cells are also serious: they offer

about 1/3 of the efficiency of hard materials, and experience

substantial photochemical degradation.

Polymer solar cells inefficiency and stability problems, combined with their promise of low costs and increased efficiency

made them a popular field in solar cell research. As of 2015, polymer

solar cells were able to achieve over 10% efficiency via a tandem

structure.

Physics

Examples of organic photovoltaic materials

A photovoltaic cell is a specialized semiconductor diode that converts light into direct current (DC) electricity. Depending on the band gap of the light-absorbing material, photovoltaic cells can also convert low-energy, infrared (IR) or high-energy, ultraviolet (UV) photons into DC electricity . A common characteristic of both the small molecules and polymers (Fig 1) used as the light-absorbing material in photovoltaics is that they all have large conjugated systems. A conjugated system is formed where carbon atoms covalently bond with alternating single and double bonds. These hydrocarbons' electrons pz orbitals delocalize and form a delocalized bonding π orbital with a π* antibonding orbital. The delocalized π orbital is the highest occupied molecular orbital (HOMO), and the π* orbital is the lowest unoccupied molecular orbital (LUMO). In organic semiconductor physics, the HOMO takes the role of the valence band while the LUMO serves as the conduction band.

The energy separation between the HOMO and LUMO energy levels is

considered the band gap of organic electronic materials and is typically

in the range of 1–4 eV.

All light with energy greater than the band gap of the material

can be absorbed, though there is a trade-off to reducing the band gap as

photons absorbed with energies higher than the band gap will thermally

give off its excess energy, resulting in lower voltages and power

conversion efficiencies. When these materials absorb a photon, an excited state is created and confined to a molecule or a region of a polymer chain. The excited state can be regarded as an exciton, or an electron-hole pair bound together by electrostatic

interactions. In photovoltaic cells, excitons are broken up into free

electron-hole pairs by effective fields. The effective fields are set up

by creating a heterojunction between two dissimilar materials. In

organic photovoltaics, effective fields break up excitons by causing the

electron to fall from the conduction band of the absorber to the

conduction band of the acceptor molecule. It is necessary that the

acceptor material has a conduction band edge that is lower than that of

the absorber material.

Polymer solar cells usually consist of an electron- or hole-blocking layer on top of an indium tin oxide (ITO) conductive glass followed by electron donor and an electron acceptor (in the case of bulk heterojunction solar cells), a hole or electron blocking layer, and metal electrode

on top. The nature and order of the blocking layers – as well as the

nature of the metal electrode – depends on whether the cell follows a

regular or an inverted device architecture. In an inverted cell, the

electric charges exit the device in the opposite direction as in a

normal device because the positive and negative electrodes are reversed.

Inverted cells can utilize cathodes out of a more suitable material;

inverted OPVs enjoy longer lifetimes than regularly structured OPVs, but

they typically don’t reach efficiencies as high as regular OPVs.

In bulk heterojunction polymer solar cells, light generates

excitons. Subsequent charge separation in the interface between an

electron donor and acceptor blend within the device’s active layer.

These charges then transport to the device’s electrodes where the

charges flow outside the cell, perform work and then re-enter the device

on the opposite side. The cell's efficiency is limited by several

factors, especially non-geminate recombination. Hole mobility leads to

faster conduction across the active layer.

Organic photovoltaics are made of electron donor and electron acceptor materials rather than semiconductor p-n junctions. The molecules forming the electron donor region of organic PV cells, where exciton electron-hole pairs are generated, are generally conjugated polymers possessing delocalized π electrons

that result from carbon p orbital hybridization. These π electrons can

be excited by light in or near the visible part of the spectrum from the

molecule's highest occupied molecular orbital (HOMO) to the lowest unoccupied molecular orbital (LUMO), denoted by a π -π* transition. The energy bandgap between these orbitals determines which wavelength(s) of light can be absorbed.

Unlike in an inorganic crystalline PV cell

material, with its band structure and delocalized electrons, excitons

in organic photovoltaics are strongly bound with an energy between 0.1

and 1.4 eV.

This strong binding occurs because electronic wave functions in organic

molecules are more localized, and electrostatic attraction can thus

keep the electron and hole together as an exciton. The electron and hole

can be dissociated by providing an interface across which the chemical

potential of electrons decreases. The material that absorbs the photon

is the donor, and the material acquiring the electron is called the

acceptor. Even after dissociation, the electron and hole may still be joined as a "geminate pair", and an electric field is then required to separate them. The electron and hole must be collected at contacts. If charge carrier

mobility is insufficient, the carriers will not reach the contacts, and

instead recombine at trap sites or remain in the device as undesirable

space charges that oppose the flow of new carriers. The latter problem

can occur if electron and hole mobilities are not matched. In that case,

space-charge limited photocurrent (SCLP) hampers device performance.

Organic photovoltaics can be fabricated with an active polymer

and a fullerene-based electron acceptor. Illumination of this system by

visible light leads to electron transfer from the polymer to a fullerene

molecule. As a result, the formation of a photoinduced quasiparticle, or polaron (P+), occurs on the polymer chain and the fullerene becomes a radical anion (C−

60). Polarons are highly mobile and can diffuse away.

60). Polarons are highly mobile and can diffuse away.

Junction types

The simplest organic PV device features a planar heterojunction. A film of organic active material (polymer or small

molecule), of electron donor or electron acceptor type is sandwiched

between contacts. Excitons created in the active material may diffuse

before recombining and separate, hole and electron diffusing to its

specific collecting electrode. Because charge carriers have diffusion

lengths of just 3–10 nm in typical amorphous organic semiconductors,

planar cells must be thin, but the thin cells absorb light less well.

Bulk heterojunctions (BHJs) address this shortcoming. In a BHJ, a blend

of electron donor and acceptor materials is cast as a mixture, which

then phase-separates. Regions of each material in the device are

separated by only several nanometers, a distance suited for carrier

diffusion. BHJs require sensitive control over materials morphology on

the nanoscale. Important variables include materials, solvents and the

donor-acceptor weight ratio.

The next logical step beyond BHJs are ordered nanomaterials for

solar cells, or ordered heterojunctions (OHJs). OHJs minimize the

variability associated with BHJs. OHJs are generally hybrids of ordered

inorganic materials and organic active regions. For example, a

photovoltaic polymer can be deposited into pores in a ceramic such as TiO2.

Since holes still must diffuse the length of the pore through the

polymer to a contact, OHJs suffer similar thickness limitations.

Mitigating the hole mobility bottleneck is key to further enhancing

device performance of OHJ's.

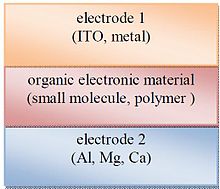

Single layer

Sketch of a single layer organic photovoltaic cell

Single layer organic photovoltaic cells are the simplest form. These

cells are made by sandwiching a layer of organic electronic materials

between two metallic conductors, typically a layer of indium tin oxide (ITO) with high work function

and a layer of low work function metal such as Aluminum, Magnesium or

Calcium. The basic structure of such a cell is illustrated above.

The difference of work function between the two conductors sets

up an electric field in the organic layer. When the organic layer

absorbs light, electrons will be excited to the LUMO and leave holes in

the HOMO, thereby forming excitons. The potential created by the different work functions helps to split the exciton pairs, pulling electrons to the positive electrode (an electrical conductor used to make contact with a non-metallic part of a circuit) and holes to the negative electrode.

Examples

In 1958 the photovoltaic effect or the creation of voltage of a cell based on magnesium phthalocyanine

(MgPc)—a macrocyclic compound having an alternating nitrogen

atom-carbon atom ring structure—was discovered to have a photovoltage of

200 mV. An Al/MgPc/Ag cell obtained photovoltaic efficiency of 0.01% under illumination at 690 nm.

Conjugated polymers were also used in this type of photovoltaic

cell. One device used polyacetylene (Fig 1) as the organic layer, with

Al and graphite, producing an open circuit voltage of 0.3 V and a charge collection efficiency of 0.3%. An Al/poly(3-nethyl-thiophene)/Pt cell had an external quantum yield of 0.17%, an open circuit voltage of 0.4 V and a fill factor of 0.3.

An ITO/PPV/Al cell showed an open circuit voltage of 1 V and a power

conversion efficiency of 0.1% under white-light illumination.

Issues

Single

layer organic solar cells do not work well. They have low quantum

efficiencies (<1 a="" and="" between="" conductive="" conversion="" difference="" efficiencies="" electric="" electrode.="" electrodes="" electrons="" excitons.="" field="" from="" holes="" is="" low="" major="" often="" p="" power="" problem="" reaching="" recombine="" resulting="" seldom="" split="" sufficient="" that="" the="" them="" to="" two="" with="" without="">

Bilayer

Sketch of a multilayer organic photovoltaic cell.

Bilayer cells contain two layers in between the conductive electrodes. The two layers have different electron affinity and ionization energies,

therefore electrostatic forces are generated at the interface between

the two layers. Light must create excitons in this small charged region

for an efficient charge separation and collecting. The materials are

chosen to make the differences large enough that these local electric

fields are strong, which splits excitons much more efficiently than

single layer photovoltaic cells. The layer with higher electron affinity

and ionization potential is the electron acceptor, and the other layer

is the electron donor. This structure is also called a planar

donor-acceptor heterojunction.

Examples

C60 has high electron affinity, making it a good acceptor. A C60/MEH-PPV

double layer cell had a relatively high fill factor of 0.48 and a power

conversion efficiency of 0.04% under monochromatic illumination. PPV/C60

cells displayed a monochromatic external quantum efficiency of 9%, a

power conversion efficiency of 1% and a fill factor of 0.48.

Perylene derivatives display high electron affinity and chemical stability. A layer of copper phthalocyanine

(CuPc) as electron donor and perylene tetracarboxylic derivative as

electron acceptor, fabricating a cell with a fill factor as high as 0.65

and a power conversion efficiency of 1% under simulated AM2

illumination.

Halls et al. fabricated a cell with a layer of bis(phenethylimido)

perylene over a layer of PPV as the electron donor. This cell had peak

external quantum efficiency of 6% and power conversion efficiency of 1%

under monochromatic illumination, and a fill factor of up to 0.6.

Issues

The

diffusion length of excitons in organic electronic materials is

typically on the order of 10 nm. In order for most excitons to diffuse

to the interface of layers and split into carriers, the layer thickness

should be in the same range as the diffusion length. However, a polymer

layer typically needs a thickness of at least 100 nm to absorb enough

light. At such a large thickness, only a small fraction of the excitons

can reach the heterojunction interface.

Discrete heterojunction

A three-layer (two acceptor and one donor) fullerene-free

stack achieved a conversion efficiency of 8.4%. The implementation

produced high open-circuit voltages and absorption in the visible

spectra and high short-circuit currents. Quantum efficiency was above

75% between 400 nm and 720 nm wavelengths, with an open-circuit voltage

around 1 V.

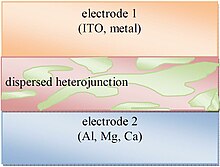

Bulk heterojunction

Sketch of a dispersed junction photovoltaic cell

Bulk heterojunctions have an absorption layer consisting of a

nanoscale blend of donor and acceptor materials. The domain sizes of

this blend are on the order of nanometers, allowing for excitons with

short lifetimes to reach an interface and dissociate due to the large

donor-acceptor interfacial area.

However, efficient bulk heterojunctions need to maintain large enough

domain sizes to form a percolating network that allows the donor

materials to reach the hole transporting electrode and the acceptor materials to reach the electron transporting

electrode. Without this percolating network, charges might

be trapped in a donor or acceptor rich domain and undergo

recombination. Bulk heterojunctions have an advantage over layered

photoactive structures because they can be made thick enough for

effective photon absorption without the difficult processing involved in

orienting a layered structure while retaining similar level of

performances.

Bulk heterojunctions are most commonly created by forming a

solution containing the two components, casting (e.g. drop casting and spin coating)

and then allowing the two phases to separate, usually with the

assistance of an annealing step. The two components will self-assemble

into an interpenetrating network connecting the two electrodes. They are normally composed of a conjugated molecule based donor and fullerene

based acceptor. The nanostructural morphology of bulk heterojunctions

tends to be difficult to control, but is critical to photovoltaic

performance.

After the capture of a photon, electrons move to the acceptor

domains, then are carried through the device and collected by one

electrode, and holes move in the opposite direction and collected at the

other side. If the dispersion of the two materials is too fine, it will

result in poor charge transfer through the layer.

Most bulk heterojunction cells use two components, although

three-component cells have been explored. The third component, a

secondary p-type donor polymer, acts to absorb light in a different

region of the solar spectrum. This in theory increases the amount of

absorbed light. These ternary cells operate through one of three

distinct mechanisms: charge transfer, energy transfer or

parallel-linkage.

In charge transfer, both donors contribute directly to the

generation of free charge carriers. Holes pass through only one donor

domain before collection at the anode. In energy transfer, only one

donor contributes to the production of holes. The second donor acts

solely to absorb light, transferring extra energy to the first donor

material. In parallel linkage, both donors produce excitons

independently, which then migrate to their respective donor/acceptor

interfaces and dissociate.

Examples

Fullerenes such as C60

and its derivatives are used as electron acceptor materials in bulk

heterojunction photovoltaic cells. A cell with the blend of MEH-PPV and a

methano-functionalized C60 derivative as the heterojunction, ITO and Ca as the electrodes

showed a quantum efficiency of 29% and a power conversion efficiency of

2.9% under monochromatic illumination. Replacing MEH-PPV with P3HT produced a quantum yield of 45% under a 10 V reverse bias.

Further advances in modifying the electron acceptor has resulted in a

device with a power conversion efficiency of 10.61% with a blend of PC71BM as the electron acceptor and PTB7-Th as the electron donor.

Polymer/polymer blends are also used in dispersed heterojunction

photovoltaic cells. A blend of CN-PPV and MEH-PPV with Al and ITO as the

electrodes, yielded peak monochromatic power conversion efficiency of

1% and fill factor of 0.38.

Dye sensitized photovoltaic cells can also be considered important examples of this type.

Issues

Fullerenes such as PC71BM are often the electron

acceptor materials found in high performing bulk heterojunction solar

cells. However, these electron acceptor materials very weakly absorb

visible light, decreasing the volume fraction occupied by the strongly

absorbing electron donor material. Furthermore, fullerenes have poor

electronic tunability, resulting in restrictions placed on the

development of conjugated systems with more appealing electronic

structures for higher voltages. Recent research has been done on trying

to replace these fullerenes with organic molecules that can be

electronically tuned and contribute to light absorption.

Graded heterojunction

The

electron donor and acceptor are mixed in such a way that the gradient

is gradual. This architecture combines the short electron travel

distance in the dispersed heterojunction with the advantage of the

charge gradient of the bilayer technology.

Examples

A cell with a blend of CuPc and C60 showed a quantum efficiency of 50% and a power conversion efficiency of 2.1% using 100 mW/cm2 simulated AM1.5G solar illumination for a graded heterojunction.

Continuous junction

Similar

to the graded heterojunction the continuous junction concept aims at

realizing a gradual transition from an electron donor to an electron

acceptor. However, the acceptor material is prepared directly from the

donor polymer in a post-polymerization modification step.

Production

Since its active layer largely determines device efficiency, this component's morphology received much attention.

If one material is more soluble in the solvent than the other, it will deposit first on top of the substrate, causing a concentration gradient through the film. This has been demonstrated for poly-3-hexyl thiophene (P3HT), phenyl-C61-butyric acid methyl ester (PCBM) devices where the PCBM tends to accumulate towards the device's bottom upon spin coating from ODCB solutions.

This effect is seen because the more soluble component tends to migrate

towards the “solvent rich” phase during the coating procedure,

accumulating the more soluble component towards the film's bottom, where

the solvent remains longer. The thickness of the generated film affects

the phases segregation because the dynamics of crystallization and

precipitation are different for more concentrated solutions or faster

evaporation rates (needed to build thicker devices). Crystalline P3HT enrichment closer to the hole-collecting electrode can only be achieved for relatively thin (100 nm) P3HT/PCBM layers.

The gradients in the initial morphology are then mainly generated

by the solvent evaporation rate and the differences in solubility

between the donor and acceptor inside the blend. This dependence on

solubility has been clearly demonstrated using fullerene derivatives and

P3HT. When using solvents which evaporate at a slower rate (as chlorobenzene (CB) or dichlorobenzene

(DCB)) you can get larger degrees of vertical separation or aggregation

while solvents that evaporate quicker produce a much less effective

vertical separation. Larger solubility gradients should lead to more

effective vertical separation while smaller gradients should lead to

more homogeneous films. These two effects were verified on P3HT:PCBM

solar cells.

The solvent evaporation speed as well as posterior solvent vapor or thermal annealing procedures were also studied.

Blends such as P3HT:PCBM seem to benefit from thermal annealing

procedures, while others, such as PTB7:PCBM, seem to show no benefit.

In P3HT the benefit seems to come from an increase of crystallinity of

the P3HT phase which is generated through an expulsion of PCBM molecules

from within these domains. This has been demonstrated through studies

of PCBM miscibility in P3HT as well as domain composition changes as a function of annealing times.

The above hypothesis based on miscibility does not fully explain

the efficiency of the devices as solely pure amorphous phases of either

donor or acceptor materials never exist within bulk heterojunction

devices. A 2010 paper

suggested that current models that assume pure phases and discrete

interfaces might fail given the absence of pure amorphous regions. Since

current models assume phase separation at interfaces without any

consideration for phase purity, the models might need to be changed.

The thermal annealing procedure varies depending on precisely

when it is applied. Since vertical species migration is partly

determined by the surface tension

between the active layer and either air or another layer, annealing

before or after the deposition of additional layers (most often the

metal cathode) affects the result. In the case of P3HT:PCBM solar cells

vertical migration is improved when cells are annealed after the

deposition of the metal cathode.

Donor or acceptor accumulation next to the adjacent layers might

be beneficial as these accumulations can lead to hole or electron

blocking effects which might benefit device performance. In 2009 the

difference in vertical distribution on P3HT:PCBM solar cells was shown

to cause problems with electron mobility which ends up with the yielding

of very poor device efficiencies.

Simple changes to device architecture – spin coating a thin layer of

PCBM on top of the P3HT – greatly enhance cell reproducibility, by

providing reproducible vertical separation between device components.

Since higher contact between the PCBM and the cathode is required for

better efficiencies, this largely increases device reproducibility.

According to neutron scattering analysis, P3HT:PCBM blends have

been described as “rivers" (P3HT regions) interrupted by “streams” (PCBM

regions).

Solvent effects

Conditions for spin coating and evaporation affect device efficiency. Solvent and additives influence donor-acceptor morphology.

Additives slow down evaporation, leading to more crystalline polymers

and thus improved hole conductivities and efficiencies. Typical

additives include 1,8-octanedithiol, ortho-dichlorobenzene, 1,8-diiodooctane (DIO), and nitrobenzene.

The DIO effect was attributed to the selective solubilization of PCBM

components, modifies fundamentally the average hopping distance of

electrons, and thus improves electron mobility. Additives can also lead to big increases in efficiency for polymers. For HXS-1/PCBM solar cells, the effect was correlated with charge generation, transport and shelf-stability.

Other polymers such as PTTBO also benefit significantly from DIO,

achieving PCE values of more than 5% from around 3.7% without the

additive.

Polymer Solar Cells fabricated from chloronaphthalene (CN) as a

co-solvent enjoy a higher efficiency than those fabricated from the more

conventional pure chlorobenzene solution. This is because the

donor-acceptor morphology changes, which reduces the phase separation

between donor polymer and fullerene. As a result, this translates into

high hole mobilities. Without co-solvents, large domains of fullerene

form, decreasing photovoltaic performance of the cell due to polymer

aggregation in solution. This morphology originates from the

liquid-liquid phase separation during drying; solve evaporation causes

the mixture to enter into the spinodal region, in which there are

significant thermal fluctuations. Large domains prevent electrons from

being collected efficiently (decreasing PCE).

Small differences in polymer structure can also lead to

significant changes in crystal packing that inevitably affect device

morphology. PCPDTBT differs from PSBTBT caused by the difference in

bridging atom between the two polymers (C vs. Si), which implies that

better morphologies are achievable with PCPDTBT:PCBM solar cells

containing additives as opposed to the Si system which achieves good

morphologies without help from additional substances.

Self-assembled cells

Supramolecular chemistry

was investigated, using donor and acceptor molecules that assemble upon

spin casting and heating. Most supramolecular assemblies employ small

molecules. Donor and acceptor domains in a tubular structure appear ideal for organic solar cells.

Diblock polymers containing fullerene yield stable organic solar cells upon thermal annealing. Solar cells with pre-designed morphologies resulted when appropriate supramolecular interactions are introduced.

Progress on BCPs containing polythiophene derivatives yield solar cells that assemble into well defined networks. This system exhibits a PCE of 2.04%. Hydrogen bonding guides the morphology.

Device efficiency based on co-polymer approaches have yet to

cross the 2% barrier, whereas bulk-heterojunction devices exhibit

efficiencies greater than 7% in single junction configurations.

Fullerene-grafted rod-coil block copolymers have been used to study domain organization.

Supramolecular approaches to organic solar cells provide

understanding about the macromolecular forces that drive domain

separation.

Infrared polymer cells

Infrared cells preferentially absorb light in the infrared

range rather than visible wavelengths. As of 2012, such cells can be

made nearly 70% transparent to visible light. The cells allegedly can be

made in high volume at low cost using solution processing. Infrared

polymer cells can be used as add-on components of portable electronics,

smart windows, and building-integrated photovoltaics.The cells employ

silver nanowire/titanium dioxide composite films as the top electrode, replacing conventional opaque metal electrodes. With this combination, 4% power-conversion efficiency was achieved.

Near-infrared Polymer solar cells based on a copolymer of

naphthodithiophene diimide and bithiophene (PNDTI-BT-DT) are also being

fabricated in combination with PTB7 as an electron donor. Both

PNDTI-BT-DT and PTB7 formed a crystalline structure in the blend films

similar to in the pristine films, leading to the efficient charge

generation contributed from both polymers.

Power Conversion Efficiency

One of the major issues surrounding polymer solar cells is the low Power Conversion Efficiency

(PCE) of fabricated cells. In order to be considered commercially

viable, PSCs must be able to achieve at least 10–15% efficiency—this

is already much lower than inorganic PVs. However, due to the low cost

of polymer solar cells, a 10–15% efficiency is commercially viable.

PCE (η) is proportional to the product of the short-circuit current (JSC), the open circuit voltage (VOC), and the fill factor (FF).

Where Pin is the incident solar power. Recent advances

in polymer solar cell performance have resulted from compressing the

bandgap to enhance short-circuit current while lowering the Highest

Occupied Molecular Orbital (HOMO) to increase open-circuit voltage.

However, PSCs still suffer from low fill factors (typically below 70%).

However, as of 2013, researchers have been able to fabricate PSCs with

fill factors of over 75%. Scientists have been able to accomplish via an

inverted BHJ and by using nonconventional donor / acceptor

combinations.

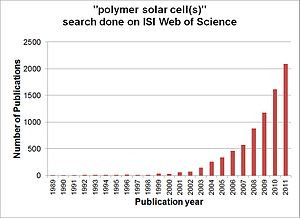

Commercialization

Number of scientific publications contributing to the subject “polymer solar cell(s)” by year. Search done through ISI, Web of Science.

Polymer solar cells have yet to commercially compete with silicon solar cells and other thin-film cells.

The present efficiency of polymer solar cells lies near 10%, well below

silicon cells. Polymer solar cells also suffer from environmental

degradation, lacking effective protective coatings.

Further improvements in performance are needed to promote charge

carrier diffusion; transport must be enhanced through control of order

and morphology; and interface engineering must be applied to the problem

of charge transfer across interfaces.

Research is being conducted into using tandem architecture in

order to increase efficiency of polymer solar cells. Similar to

inorganic tandem architecture, organic tandem architecture is expected

to increase efficiency. Compared with a single-junction device using

low-bandgap materials, the tandem structure can reduce heat loss during

photon-to-electron conversion.

Polymer solar cells are not widely produced commercially. Starting in 2008, Konarka Technologies started production of polymer-fullerene solar cells.

The initial modules were 3–5% efficient, and only last for a few years.

Konarka has since filed for bankruptcy, as those polymer solar cells

were unable to penetrate the PV market.

PSCs also still suffer from low fill factors (typically below

70%). However, as of 2013, researchers have been able to fabricate PSCs

with fill factors of over 75%. Scientists have been able to accomplish

via an inverted BHJ and by using nonconventional donor / acceptor

combinations.

However, efforts are being made to upscale manufacturing of

polymer solar cells, in order to decrease costs and also advocate for a

practical approach for PSC production. Such efforts include full

roll-to-roll solution processing. However, roll-to-roll solution

processing is ill-suited for on-grid electricity production due to the

short lifetime of polymer solar cells. Therefore, commercial

applications for polymer solar cells still include primarily consumer

electronics and home appliances.

Modeling organic solar cells

As

discussed above, organic semiconductors are highly disordered materials

with no long range order. This means that the conduction band and

valance band edges are not well defined. Furthermore, this physical and

energetic disorder generates trap states in which photogenerated

electrons and holes can become trapped and then eventually recombine.

Key to accurately describing organic solar cells in a device

model is to include carrier trapping and recombination via trap states.

A commonly used approach is to use an effective medium model, where by

standard drift diffusion equations are used to describe transport

across the device. Then, an exponential tail of trap states is

introduced which decays into the band gap from the mobility edges. To describe capture/escape from these trap states the Shockley–Read–Hall (SRH)

can be used. The Shockley-Read-Hall mechanism has been shown able to

reproduce polymer:fullerene device behavior in both time domain and

steady state.

Current challenges and recent progress

Difficulties associated with organic photovoltaic cells include their low external quantum efficiency (up to 70%)

compared to inorganic photovoltaic devices, despite having good

internal quantum efficiency; this is due to insufficient absorption with

active layers on the order of 100 nanometers. Instabilities against

oxidation and reduction, recrystallization and temperature variations

can also lead to device degradation and decreased performance over time.

This occurs to different extents for devices with different

compositions, and is an area into which active research is taking place.

Other important factors include the exciton diffusion length,

charge separation and charge collection which are affected by the

presence of impurities.

Charge carrier mobility and transport

Especially

for bulk heterojunction solar cells, understanding charge carrier

transport is vital in improving the efficiencies of organic

photovoltaics. Currently, bulk heterojunction devices have imbalanced

charge-carrier mobility, with the hole mobility being at least an order

of magnitude lower than that of the electron mobility; this results in space charge build-up and a decrease in the fill factor and power conversation efficiency of a device.

Due to having low mobility, efficient bulk heterojunction photovoltaics

have to be designed with thin active layers to avoid recombination of

the charge carriers, which is detrimental to absorption and scalability

in processing. Simulations have demonstrated that in order to have an

bulk heterojunction solar cell with a fill factor above 0.8 and external

quantum efficiency above 90%, there needs to be balanced charge carrier

mobility to reduce a space charge effect, as well as an increase in

charge carrier mobility and/or a decrease in the bimolecular recombination rate constant.

Effect of film morphology

Highly folded heterojunction (a); heterojunction with controlled growth (b)

As described above, dispersed heterojunctions

of donor-acceptor organic materials have high quantum efficiencies

compared to the planar hetero-junction, because in dispersed

heterojunctions it is more likely for an exciton to find an interface

within its diffusion length. Film morphology can also have a drastic

effect on the quantum efficiency of the device. Rough surfaces and the

presence of voids can increase the series resistance and also the chance

of short-circuiting. Film morphology and, as a result, quantum

efficiency can be improved by annealing of a device after covering it by

a ~1000 Å thick metal cathode. Metal film on top of the organic film

applies stresses on the organic film, which helps to prevent the

morphological relaxation in the organic film. This gives more densely

packed films and at the same time allows the formation of

phase-separated interpenetrating donor-acceptor interface inside the

bulk of organic thin film.

Controlled growth heterojunction

Charge

separation occurs at the donor-acceptor interface. Whilst traveling to

the electrode, a charge can become trapped and/or recombine in a

disordered interpenetrating organic material, resulting in decreased

device efficiency. Controlled growth of the heterojunction provides

better control over positions of the donor-acceptor materials, resulting

in much greater power efficiency (ratio of output power to input power)

than that of planar and highly disoriented hetero-junctions (as shown above). Thus, the choice of suitable processing parameters in order

to better control the structure and film morphology is highly desirable.

Progress in growth techniques

Mostly organic films for photovoltaic applications are deposited by spin coating

and vapor-phase deposition. However each method has certain draw backs,

spin coating technique can coat larger surface areas with high speed

but the use of solvent for one layer can degrade the already existing

polymer layer. Another problem is related with the patterning of the

substrate for device as spin-coating results in coating the entire

substrate with a single material.

Vacuum thermal evaporation

Vacuum thermal evaporation (a) and organic phase vapor deposition (b)

Another deposition technique is vacuum thermal evaporation

(VTE) which involves the heating of an organic material in vacuum. The

substrate is placed several centimeters away from the source so that

evaporated material may be directly deposited onto the substrate, as

shown above. This method is useful for depositing many layers of

different materials without chemical interaction between different

layers. However, there are sometimes problems with film-thickness

uniformity and uniform doping over large-area substrates. In addition,

the materials that deposit on the wall of the chamber can contaminate

later depositions. This "line of sight" technique also can create holes

in the film due to shadowing, which causes an increase in the device

series-resistance and short circuit.

Organic vapor phase deposition

Organic

vapor phase deposition (OVPD, figure above) allows better control of the

structure and morphology of the film than vacuum thermal evaporation.

The process involves evaporation of the organic material over a

substrate in the presence of an inert carrier gas. The resulting film

morphology can be tuned by changing the gas flow rate and the source

temperature. Uniform films can be grown by reducing the carrier gas

pressure, which will increase the velocity and mean free path of the

gas, and as a result boundary layer thickness decreases. Cells produced

by OVPD do not have issues related with contaminations from the flakes

coming out of the walls of the chamber, as the walls are warm and do not

allow molecules to stick to and produce a film upon them.

Another advantage over VTE is the uniformity in evaporation rate.

This occurs because the carrier gas becomes saturated with the vapors

of the organic material coming out of the source and then moves towards

the cooled substrate. Depending on the growth parameters

(temperature of the source, base pressure and flux of the carrier gas)

the deposited film can be crystalline or amorphous in nature. Devices

fabricated using OVPD show a higher short-circuit current density than

that of devices made using VTE. An extra layer of donor-acceptor

hetero-junction at the top of the cell may block excitons, whilst

allowing conduction of electron; resulting in improved cell efficiency.

Organic solar ink

Organic solar ink is able to deliver higher performance in fluorescent lighting conditions in comparison to amorphous silicon

solar cells, and said to have a 30% to 40% increase in indoor power

density in comparison to the standard organic solar technology.

Light trapping

Various type of components are applied to increase light trapping (Light in-coupling) effects in thin organic solar cells. In addition to the flexibility of organic solar cells, by using flexible electrodes and substrates

instead of ITO and glass respectively, fully flexible organic solar

cells can be produced. By these use of flexible substrates and

substrates, easier methods to provide light trapping effects to OPVs are

introduced such as polymer electrodes with embedded scattering

particles, nano imprinted polymer electrodes, patterned PET substrates and even optical display film commercialized for liquid crystal displays (LCD) as substrates. Much research will be taken for enhancing the performance of OPVs with the merit of easy light trapping structures processing.

Use in tandem photovoltaics

Recent research and study has been done in utilizing an organic solar cell as the top cell in a hybrid tandem solar cell stack. Because organic solar cells have a higher band gap than traditional inorganic photovoltaics like silicon or CIGS,

they can absorb higher energy photons without losing much of the energy

due to thermalization, and thus operate at a higher voltage. The lower

energy photons and higher energy photons that are unabsorbed pass

through the top organic solar cell and are then absorbed by the bottom

inorganic cell. Organic solar cells are also solution processible at low

temperatures with a low cost of 10 dollars per square meter, resulting

in a printable top cell that improves the overall efficiencies of

existing, inorganic solar cell technologies.

Much research has been done to enable the formation of such a hybrid

tandem solar cell stack, including research in the deposition of

semi-transparent electrodes that maintain low contact resistance while

having high transparency.