Commutator in a universal motor from a vacuum cleaner. Parts: (A) commutator, (B) brush, (C) rotor (armature) windings, (D) stator (F) (field) windings, (E) brush guides

A commutator is a rotary electrical switch in certain types of electric motors and electrical generators that periodically reverses the current

direction between the rotor and the external circuit. It consists of a

cylinder composed of multiple metal contact segments on the rotating armature of the machine. Two or more electrical contacts called "brushes" made of a soft conductive material like carbon

press against the commutator, making sliding contact with successive

segments of the commutator as it rotates. The windings (coils of wire)

on the armature are connected to the commutator segments.

Commutators are used in direct current (DC) machines: dynamos (DC generators) and many DC motors as well as universal motors. In a motor the commutator applies electric current to the windings. By reversing the current direction in the rotating windings each half turn, a steady rotating force (torque)

is produced. In a generator the commutator picks off the current

generated in the windings, reversing the direction of the current with

each half turn, serving as a mechanical rectifier to convert the alternating current from the windings to unidirectional direct current in the external load circuit. The first direct current commutator-type machine, the dynamo, was built by Hippolyte Pixii in 1832, based on a suggestion by André-Marie Ampère.

Commutators are relatively inefficient, and also require periodic

maintenance such as brush replacement. Therefore, commutated machines

are declining in use, being replaced by alternating current (AC) machines, and in recent years by brushless DC motors which use semiconductor switches.

Principle of operation

A

commutator consists of a set of contact bars fixed to the rotating

shaft of a machine, and connected to the armature windings. As the shaft

rotates, the commutator reverses the flow of current in a winding. For a

single armature winding, when the shaft has made one-half complete

turn, the winding is now connected so that current flows through it in

the opposite of the initial direction. In a motor, the armature current

causes the fixed magnetic field to exert a rotational force, or a torque,

on the winding to make it turn. In a generator, the mechanical torque

applied to the shaft maintains the motion of the armature winding

through the stationary magnetic field, inducing a current in the

winding. In both the motor and generator case, the commutator

periodically reverses the direction of current flow through the winding

so that current flow in the circuit external to the machine continues in

only one direction.

Simplest practical commutator

|

|

|

Practical commutators have at least three contact segments, to

prevent a "dead" spot where two brushes simultaneously bridge only two

commutator segments. Brushes are made wider than the insulated gap, to

ensure that brushes are always in contact with an armature coil. For

commutators with at least three segments, although the rotor can

potentially stop in a position where two commutator segments touch one

brush, this only de-energizes one of the rotor arms while the others

will still function correctly. With the remaining rotor arms, a motor

can produce sufficient torque to begin spinning the rotor, and a

generator can provide useful power to an external circuit.

Ring/segment construction

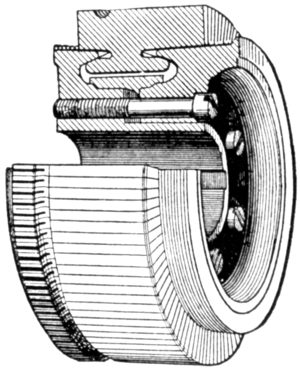

Cross-section of a commutator that can be disassembled for repair.

A commutator consists of a set of copper segments, fixed around the part of the circumference of the rotating machine, or the rotor, and a set of spring-loaded brushes

fixed to the stationary frame of the machine. Two or more fixed brushes

connect to the external circuit, either a source of current for a motor

or a load for a generator.

Commutator segments are connected to the coils of the armature,

with the number of coils (and commutator segments) depending on the

speed and voltage of the machine. Large motors may have hundreds of

segments.

Each conducting segment of the commutator is insulated from adjacent

segments. Mica

was used on early machines and is still used on large machines. Many

other insulating materials are used to insulate smaller machines;

plastics allow quick manufacture of an insulator, for example. The

segments are held onto the shaft using a dovetail

shape on the edges or underside of each segment. Insulating wedges

around the perimeter of each segment are pressed so that the commutator

maintains its mechanical stability throughout its normal operating

range.

In small appliance and tool motors the segments are typically

crimped permanently in place and cannot be removed. When the motor fails

it is discarded and replaced. On large industrial machines (say, from

several kilowatts to thousands of kilowatts in rating) it is economical

to replace individual damaged segments, and so the end-wedge can be

unscrewed and individual segments removed and replaced. Replacing the

copper and mica segments is commonly referred to as "refilling".

Refillable dovetailed commutators are the most common construction of

larger industrial type commutators, but refillable commutators may also

be constructed using external bands made of fiberglass (glass banded

construction) or forged steel rings (external steel shrink ring type

construction and internal steel shrink ring type construction).

Disposable, molded type commutators commonly found in smaller DC motors

are becoming increasingly more common in larger electric motors. Molded

type commutators are not repairable and must be replaced if damaged. In

addition to the commonly used heat, torque, and tonnage methods of

seasoning commutators, some high performance commutator applications

require a more expensive, specific "spin seasoning" process or

over-speed spin-testing to guarantee stability of the individual

segments and prevent premature wear of the carbon brushes. Such

requirements are common with traction, military, aerospace, nuclear,

mining, and high speed applications where premature failure can lead to

serious negative consequences.

Friction between the segments and the brushes eventually causes

wear to both surfaces. Carbon brushes, being made of a softer material,

wear faster and may be designed to be replaced easily without

dismantling the machine. Older copper brushes caused more wear to the

commutator, causing deep grooving and notching of the surface over time.

The commutator on small motors (say, less than a kilowatt rating) is

not designed to be repaired through the life of the device. On large

industrial equipment, the commutator may be re-surfaced with abrasives,

or the rotor may be removed from the frame, mounted in a large metal lathe,

and the commutator resurfaced by cutting it down to a smaller diameter.

The largest of equipment can include a lathe turning attachment

directly over the commutator.

A tiny 5-segment commutator less than 2 mm in diameter, on a direct-current motor in a toy radio control ZipZaps car.

Brush construction

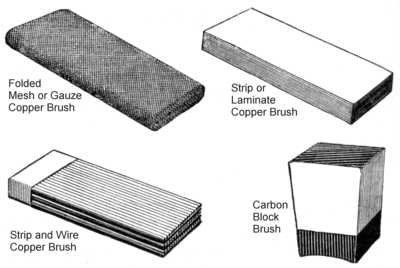

Various types of copper and carbon brushes.

Early machines used brushes made from strands of copper wire to

contact the surface of the commutator. However, these hard metal brushes

tended to scratch and groove the smooth commutator segments, eventually

requiring resurfacing of the commutator. As the copper brushes wore

away, the dust and pieces of the brush could wedge between commutator

segments, shorting them and reducing the efficiency of the device. Fine

copper wire mesh or gauze provided better surface contact with less

segment wear, but gauze brushes were more expensive than strip or wire

copper brushes.

Modern rotating machines with commutators almost exclusively use

carbon brushes, which may have copper powder mixed in to improve

conductivity. Metallic copper brushes can be found in toy or very small

motors, such as the one illustrated above, and some motors which only

operate very intermittently, such as automotive starter motors.

Motors and generators suffer from a phenomenon known as 'armature

reaction', one of the effects of which is to change the position at

which the current reversal through the windings should ideally take

place as the loading varies. Early machines had the brushes mounted on a

ring that was provided with a handle. During operation, it was

necessary to adjust the position of the brush ring to adjust the

commutation to minimise the sparking at the brushes. This process was

known as 'rocking the brushes'.

Various developments took place to automate the process of

adjusting the commutation and minimizing the sparking at the brushes.

One of these was the development of 'high resistance brushes', or

brushes made from a mixture of copper powder and carbon.

Although described as high resistance brushes, the resistance of such a

brush was of the order of milliohms, the exact value dependent on the

size and function of the machine. Also, the high resistance brush was

not constructed like a brush but in the form of a carbon block with a

curved face to match the shape of the commutator.

The high resistance or carbon brush is made large enough that it

is significantly wider than the insulating segment that it spans (and on

large machines may often span two insulating segments). The result of

this is that as the commutator segment passes from under the brush, the

current passing to it ramps down more smoothly than had been the case

with pure copper brushes where the contact broke suddenly. Similarly

the segment coming into contact with the brush has a similar ramping up

of the current. Thus, although the current passing through the brush

was more or less constant, the instantaneous current passing to the two

commutator segments was proportional to the relative area in contact

with the brush.

The introduction of the carbon brush had convenient side effects.

Carbon brushes tend to wear more evenly than copper brushes, and the

soft carbon causes far less damage to the commutator segments. There is

less sparking with carbon as compared to copper, and as the carbon

wears away, the higher resistance of carbon results in fewer problems

from the dust collecting on the commutator segments.

The ratio of copper to carbon can be changed for a particular

purpose. Brushes with higher copper content perform better with very low

voltages and high current, while brushes with a higher carbon content

are better for high voltage and low current. High copper content brushes

typically carry 150 to 200 amperes per square inch of contact surface,

while higher carbon content only carries 40 to 70 amperes per square

inch. The higher resistance of carbon also results in a greater voltage

drop of 0.8 to 1.0 volts per contact, or 1.6 to 2.0 volts across the

commutator.

Brush holders

Compound carbon brush holder, with individual clamps and tension adjustments for each block of carbon.

A spring is typically used with the brush, to maintain constant

contact with the commutator. As the brush and commutator wear down, the

spring steadily pushes the brush downwards towards the commutator.

Eventually the brush wears small and thin enough that steady contact is

no longer possible or it is no longer securely held in the brush holder,

and so the brush must be replaced.

It is common for a flexible power cable to be directly attached

to the brush, because current flowing through the support spring would

cause heating, which may lead to a loss of metal temper and a loss of

the spring tension.

When a commutated motor or generator uses more power than a

single brush is capable of conducting, an assembly of several brush

holders is mounted in parallel across the surface of the very large

commutator. This parallel holder distributes current evenly across all

the brushes, and permits a careful operator to remove a bad brush and

replace it with a new one, even as the machine continues to spin fully

powered and under load.

High power, high current commutated equipment is now uncommon,

due to the less complex design of alternating current generators that

permits a low current, high voltage spinning field coil to energize high

current fixed-position stator coils. This permits the use of very small

singular brushes in the alternator design. In this instance, the rotating contacts are continuous rings, called slip rings, and no switching happens.

Modern devices using carbon brushes usually have a

maintenance-free design that requires no adjustment throughout the life

of the device, using a fixed-position brush holder slot and a combined

brush-spring-cable assembly that fits into the slot. The worn brush is

pulled out and a new brush inserted.

Brush contact angle

Different types of brushes have different brush contact angles

Commutator and brush assembly of a traction motor;

the copper bars can be seen with lighter insulation strips between the

bars. Each dark grey carbon brush has a short flexible copper jumper

lead attached. Parts of the motor field winding, in red, can be seen to

the right of the commutator.

The different brush types make contact with the commutator in

different ways. Because copper brushes have the same hardness as the

commutator segments, the rotor cannot be spun backwards against the ends

of copper brushes without the copper digging into the segments and

causing severe damage. Consequently, strip/laminate copper brushes only

make tangential contact with the commutator, while copper mesh and wire

brushes use an inclined contact angle touching their edge across the

segments of a commutator that can spin in only one direction.

The softness of carbon brushes permits direct radial end-contact

with the commutator without damage to the segments, permitting easy

reversal of rotor direction, without the need to reorient the brush

holders for operation in the opposite direction. Although never

reversed, common appliance motors that use wound rotors, commutators and

brushes have radial-contact brushes. In the case of a reaction-type

carbon brush holder, carbon brushes may be reversely inclined with the

commutator so that the commutator tends to push against the carbon for

firm contact.

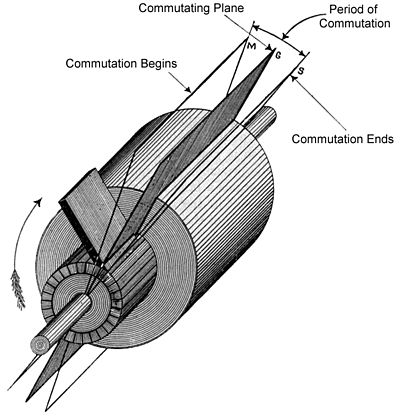

The commutating plane

Commutating plane definitions.

The contact point where a brush touches the commutator is referred to as the commutating plane.

To conduct sufficient current to or from the commutator, the brush

contact area is not a thin line but instead a rectangular patch across

the segments. Typically the brush is wide enough to span 2.5 commutator

segments. This means that two adjacent segments are electrically

connected by the brush when it contacts both.

Compensation for stator field distortion

Centered position of the commutating plane if there were no field distortion effects.

Most introductions to motor and generator design start with a simple

two-pole device with the brushes arranged at a perfect 90-degree angle

from the field. This ideal is useful as a starting point for

understanding how the fields interact but it is not how a motor or

generator functions in actual practice.

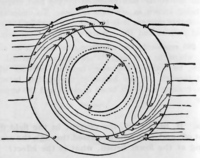

| On the left is an exaggerated example of how the field is distorted by the rotor. On the right, iron filings show the distorted field across the rotor. |

In a real motor or generator, the field around the rotor is never

perfectly uniform. Instead, the rotation of the rotor induces field

effects which drag and distort the magnetic lines of the outer

non-rotating stator.

Actual position of the commutating plane to compensate for field distortion.

The faster the rotor spins, the further this degree of field

distortion. Because a motor or generator operates most efficiently with

the rotor field at right angles to the stator field, it is necessary to

either retard or advance the brush position to put the rotor's field

into the correct position to be at a right angle to the distorted field.

These field effects are reversed when the direction of spin is

reversed. It is therefore difficult to build an efficient reversible

commutated dynamo, since for highest field strength it is necessary to

move the brushes to the opposite side of the normal neutral plane.

These effects can be mitigated by a Compensation winding in the face of the field pole that carries armature current.

The effect can be considered to be analogous to timing advance in

an internal combustion engine. Generally a dynamo that has been

designed to run at a certain fixed speed will have its brushes

permanently fixed to align the field for highest efficiency at that

speed.

Further compensation for self-induction

Brush advance for Self-Induction.

Self-induction – The magnetic fields in each coil of wire join and

compound together to create a magnetic field that resists changes in the

current, which can be likened to the current having inertia.

In the coils of the rotor, even after the brush has been reached,

currents tend to continue to flow for a brief moment, resulting in a

wasted energy as heat due to the brush spanning across several

commutator segments and the current short-circuiting across the

segments.

Spurious resistance is an apparent increase in the

resistance in the armature winding, which is proportional to the speed

of the armature, and is due to the lagging of the current.

To minimize sparking at the brushes due to this short-circuiting,

the brushes are advanced a few degrees further yet, beyond the advance

for field distortions. This moves the rotor winding undergoing

commutation slightly forward into the stator field which has magnetic

lines in the opposite direction and which oppose the field in the

stator. This opposing field helps to reverse the lagging self-inducting

current in the stator.

So even for a rotor which is at rest and initially requires no

compensation for spinning field distortions, the brushes should still be

advanced beyond the perfect 90-degree angle as taught in so many

beginners textbooks, to compensate for self-induction.

Limitations and alternatives

Low

voltage dynamo from late 1800s for electroplating. The resistance of

the commutator contacts causes inefficiency in low voltage, high current

machines like this, requiring a huge elaborate commutator. This

machine generated 7 volts at 310 amps.

Although direct current motors and dynamos once dominated industry,

the disadvantages of the commutator have caused a decline in the use of

commutated machines in the last century. These disadvantages are:

- The sliding friction between the brushes and commutator consumes power, which can be significant in a low power machine.

- Due to friction, the brushes and copper commutator segments wear down, creating dust. In small consumer products such as power tools and appliances the brushes may last as long as the product, but larger machines require regular replacement of brushes and occasional resurfacing of the commutator. So commutated machines are not used in low particulate or sealed applications or in equipment that must operate for long periods without maintenance.

- The resistance of the sliding contact between brush and commutator causes a voltage drop called the "brush drop". This may be several volts, so it can cause large power losses in low voltage, high current machines. Alternating current motors, which do not use commutators, are much more efficient.

- There is a limit to the maximum current density and voltage which can be switched with a commutator. Very large direct current machines, say, more than several megawatts rating, cannot be built with commutators. The largest motors and generators are all alternating-current machines.

- The switching action of the commutator causes sparking at the contacts, posing a fire hazard in explosive atmospheres, and generating electromagnetic interference.

With the wide availability of alternating current, DC motors have been replaced by more efficient AC synchronous or induction motors. In recent years, with the widespread availability of power semiconductors, in many remaining applications commutated DC motors have been replaced with "brushless direct current motors".

These don't have a commutator; instead the direction of the current is

switched electronically. A sensor keeps track of the rotor position

and semiconductor switches such as transistors reverse the current. Operating life of these machines is much longer, limited mainly by bearing wear.

Repulsion induction motors

These are single-phase AC-only motors with higher starting torque

than could be obtained with split-phase starting windings, before

high-capacitance (non-polar, relatively high-current electrolytic)

starting capacitors became practical. They have a conventional wound

stator as with any induction motor, but the wire-wound rotor is much

like that with a conventional commutator. Brushes opposite each other

are connected to each other (not to an external circuit), and

transformer action induces currents into the rotor that develop torque

by repulsion.

One variety, notable for having an adjustable speed, runs

continuously with brushes in contact, while another uses repulsion only

for high starting torque and in some cases lifts the brushes once the

motor is running fast enough. In the latter case, all commutator

segments are connected together as well, before the motor attains

running speed.

Once at speed, the rotor windings become functionally equivalent

to the squirrel-cage structure of a conventional induction motor, and

the motor runs as such.

Laboratory commutators

Commutators

were used as simple forward-off-reverse switches for electrical

experiments in physics laboratories. There are two well-known historical

types:

Ruhmkorff commutator

This is similar in design to the commutators used in motors and dynamos. It was usually constructed of brass and ivory (later ebonite).

Pohl commutator

This consisted of a block of wood or ebonite with four wells, containing mercury, which were cross-connected by copper wires. The output was taken from a pair of curved copper wires which were moved to dip into one or other pair of mercury wells.

Instead of mercury, ionic liquids or other liquid metals could be used.