Reliability engineering is a sub-discipline of systems engineering that emphasizes dependability in the lifecycle management of a product. Dependability, or reliability, describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

Reliability is theoretically defined as the probability of success as the frequency of failures; or in terms of availability, as a probability derived from reliability, testability and maintainability. Testability, maintainability and maintenance are often defined as a part of "reliability engineering" in reliability programs. Reliability plays a key role in the cost-effectiveness of systems.

Reliability engineering deals with the estimation, prevention and management of high levels of "lifetime" engineering uncertainty and risks of failure. Although stochastic parameters define and affect reliability, reliability is not (solely) achieved by mathematics and statistics. One cannot really find a root cause (needed to effectively prevent failures) by only looking at statistics. "Nearly all teaching and literature on the subject emphasize these aspects, and ignore the reality that the ranges of uncertainty involved largely invalidate quantitative methods for prediction and measurement." For example, it is easy to represent "probability of failure" as a symbol or value in an equation, but it is almost impossible to predict its true magnitude in practice, which is massively multivariate, so having the equation for reliability does not begin to equal having an accurate predictive measurement of reliability.

Reliability engineering relates closely to safety engineering and to system safety, in that they use common methods for their analysis and may require input from each other. Reliability engineering focuses on costs of failure caused by system downtime, cost of spares, repair equipment, personnel, and cost of warranty claims. Safety engineering normally focuses more on preserving life and nature than on cost, and therefore deals only with particularly dangerous system-failure modes. High reliability (safety factor) levels also result from good engineering and from attention to detail, and almost never from only reactive failure management (using reliability accounting and statistics).

History

The word reliability can be traced back to 1816, and is first attested to the poet Samuel Taylor Coleridge. Before World War II the term was linked mostly to repeatability;

a test (in any type of science) was considered "reliable" if the same

results would be obtained repeatedly. In the 1920s, product improvement

through the use of statistical process control was promoted by Dr. Walter A. Shewhart at Bell Labs, around the time that Waloddi Weibull

was working on statistical models for fatigue. The development of

reliability engineering was here on a parallel path with quality. The

modern use of the word reliability was defined by the U.S. military in

the 1940s, characterizing a product that would operate when expected and

for a specified period of time.

In World War II, many reliability issues were due to the inherent

unreliability of electronic equipment available at the time, and to

fatigue issues. In 1945, M.A. Miner published the seminal paper titled

"Cumulative Damage in Fatigue" in an ASME journal. A main application

for reliability engineering in the military was for the vacuum tube as

used in radar systems and other electronics, for which reliability

proved to be very problematic and costly. The IEEE formed the Reliability Society in 1948. In 1950, the United States Department of Defense

formed group called the "Advisory Group on the Reliability of

Electronic Equipment" (AGREE) to investigate reliability methods for

military equipment. This group recommended three main ways of working:

- Improve component reliability.

- Establish quality and reliability requirements for suppliers.

- Collect field data and find root causes of failures.

In the 1960s, more emphasis was given to reliability testing on

component and system level. The famous military standard 781 was created

at that time. Around this period also the much-used (and also much-debated) military handbook 217 was published by RCA

and was used for the prediction of failure rates of components. The

emphasis on component reliability and empirical research (e.g. Mil Std

217) alone slowly decreased. More pragmatic approaches, as used in the

consumer industries, were being used. In the 1980s, televisions were

increasingly made up of solid-state semiconductors. Automobiles rapidly

increased their use of semiconductors with a variety of microcomputers

under the hood and in the dash. Large air conditioning systems developed

electronic controllers, as had microwave ovens and a variety of other

appliances. Communications systems began to adopt

electronics to replace older mechanical switching systems. Bellcore issued the first consumer prediction methodology for telecommunications, and SAE

developed a similar document SAE870050 for automotive applications. The

nature of predictions evolved during the decade, and it became apparent

that die complexity wasn't the only factor that determined failure

rates for integrated circuits (ICs).

Kam Wong published a paper questioning the bathtub curve—see also reliability-centered maintenance.

During this decade, the failure rate of many components dropped by a

factor of 10. Software became important to the reliability of systems.

By the 1990s, the pace of IC development was picking up. Wider use of

stand-alone microcomputers was common, and the PC market helped keep IC

densities following Moore's law and doubling about every 18 months.

Reliability engineering was now changing as it moved towards

understanding the physics of failure. Failure rates for components kept dropping, but system-level issues became more prominent. Systems thinking became more and more important. For software, the CMM model (Capability Maturity Model)

was developed, which gave a more qualitative approach to reliability.

ISO 9000 added reliability measures as part of the design and

development portion of certification. The expansion of the World-Wide

Web created new challenges of security and trust. The older problem of

too little reliability information available had now been replaced by

too much information of questionable value. Consumer reliability

problems could now be discussed online in real time using data. New

technologies such as micro-electromechanical systems (MEMS), handheld GPS,

and hand-held devices that combined cell phones and computers all

represent challenges to maintain reliability. Product development time

continued to shorten through this

decade and what had been done in three years was being done in 18

months. This meant that reliability tools and tasks had to be more

closely tied to the development process itself. In many ways,

reliability became part of everyday life and consumer expectations.

Overview

Objective

The objectives of reliability engineering, in decreasing order of priority, are:

- To apply engineering knowledge and specialist techniques to prevent or to reduce the likelihood or frequency of failures.

- To identify and correct the causes of failures that do occur despite the efforts to prevent them.

- To determine ways of coping with failures that do occur, if their causes have not been corrected.

- To apply methods for estimating the likely reliability of new designs, and for analysing reliability data.

The reason for the priority emphasis is that it is by far the most

effective way of working, in terms of minimizing costs and generating

reliable products. The primary skills that are required, therefore, are

the ability to understand and anticipate the possible causes of

failures, and knowledge of how to prevent them. It is also necessary to

have knowledge of the methods that can be used for analysing designs and

data.

Scope and techniques

Reliability engineering for "complex systems"

requires a different, more elaborate systems approach than for

non-complex systems. Reliability engineering may in that case involve:

- System availability and mission readiness analysis and related reliability and maintenance requirement allocation

- Functional system failure analysis and derived requirements specification

- Inherent (system) design reliability analysis and derived requirements specification for both hardware and software design

- System diagnostics design

- Fault tolerant systems (e.g. by redundancy)

- Predictive and preventive maintenance (e.g. reliability-centered maintenance)

- Human factors / human interaction / human errors

- Manufacturing- and assembly-induced failures (effect on the detected "0-hour quality" and reliability)

- Maintenance-induced failures

- Transport-induced failures

- Storage-induced failures

- Use (load) studies, component stress analysis, and derived requirements specification

- Software (systematic) failures

- Failure / reliability testing (and derived requirements)

- Field failure monitoring and corrective actions

- Spare parts stocking (availability control)

- Technical documentation, caution and warning analysis

- Data and information acquisition/organisation (creation of a general reliability development hazard log and FRACAS system)

- Chaos engineering

Effective reliability engineering requires understanding of the basics of failure mechanisms

for which experience, broad engineering skills and good knowledge from

many different special fields of engineering are required, for example:

- Tribology

- Stress (mechanics)

- Fracture mechanics / fatigue

- Thermal engineering

- Fluid mechanics / shock-loading engineering

- Electrical engineering

- Chemical engineering (e.g. corrosion)

- Material science

Definitions

Reliability may be defined in the following ways:

- The idea that an item is fit for a purpose with respect to time

- The capacity of a designed, produced, or maintained item to perform as required over time

- The capacity of a population of designed, produced or maintained items to perform as required over specified time

- The resistance to failure of an item over time

- The probability of an item to perform a required function under stated conditions for a specified period of time

- The durability of an object

Basics of a reliability assessment

Many engineering techniques are used in reliability risk assessments, such as reliability hazard analysis, failure mode and effects analysis (FMEA), fault tree analysis (FTA), Reliability Centered Maintenance,

(probabilistic) load and material stress and wear calculations,

(probabilistic) fatigue and creep analysis, human error analysis,

manufacturing defect analysis, reliability testing, etc. It is crucial

that these analyses are done properly and with much attention to detail

to be effective. Because of the large number of reliability techniques,

their expense, and the varying degrees of reliability required for

different situations, most projects develop a reliability program plan

to specify the reliability tasks (statement of work (SoW) requirements) that will be performed for that specific system.

Consistent with the creation of a safety cases, for example ARP4761,

the goal of reliability assessments is to provide a robust set of

qualitative and quantitative evidence that use of a component or system

will not be associated with unacceptable risk. The basic steps to take are to:

- Thoroughly identify relevant unreliability "hazards", e.g. potential conditions, events, human errors, failure modes, interactions, failure mechanisms and root causes, by specific analysis or tests.

- Assess the associated system risk, by specific analysis or testing.

- Propose mitigation, e.g. requirements, design changes, detection logic, maintenance, training, by which the risks may be lowered and controlled for at an acceptable level.

- Determine the best mitigation and get agreement on final, acceptable risk levels, possibly based on cost/benefit analysis.

Risk here is the combination of probability and severity of the failure incident (scenario) occurring.

In a de minimis definition, severity of failures includes

the cost of spare parts, man-hours, logistics, damage (secondary

failures), and downtime of machines which may cause production loss. A

more complete definition of failure also can mean injury, dismemberment,

and death of people within the system (witness mine accidents,

industrial accidents, space shuttle failures) and the same to innocent

bystanders (witness the citizenry of cities like Bhopal, Love Canal,

Chernobyl, or Sendai, and other victims of the 2011 Tōhoku earthquake

and tsunami)—in this case, reliability engineering becomes system

safety. What is acceptable is determined by the managing authority or

customers or the affected communities. Residual risk is the risk that is

left over after all reliability activities have finished, and includes

the unidentified risk—and is therefore not completely quantifiable.

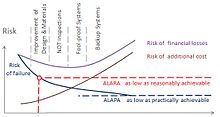

Risk vs cost/complexity

The complexity of the technical systems such as improvements of

design and materials, planned inspections, fool-proof design, and backup

redundancy decreases risk and increases the cost. The risk can be

decreased to ALARA (as low as reasonably achievable) or ALAPA (as low as

practically achievable) levels.

Reliability and availability program plan

Implementing

a reliability program is not simply a software purchase; it is not just

a checklist of items that must be completed that will ensure one has

reliable products and processes. A reliability program is a complex

learning and knowledge-based system unique to one's products and

processes. It is supported by leadership, built on the skills that one

develops within a team, integrated into business processes and executed

by following proven standard work practices.

A reliability program plan is used to document exactly what "best

practices" (tasks, methods, tools, analysis, and tests) are required

for a particular (sub)system, as well as clarify customer requirements

for reliability assessment. For large-scale complex systems, the

reliability program plan should be a separate document.

Resource determination for manpower and budgets for testing and other

tasks is critical for a successful program. In general, the amount of

work required for an effective program for complex systems is large.

A reliability program plan is essential for achieving high levels of reliability, testability, maintainability, and the resulting system availability,

and is developed early during system development and refined over the

system's life-cycle. It specifies not only what the reliability engineer

does, but also the tasks performed by other stakeholders.

A reliability program plan is approved by top program management, which

is responsible for allocation of sufficient resources for its

implementation.

A reliability program plan may also be used to evaluate and

improve the availability of a system by the strategy of focusing on

increasing testability & maintainability and not on reliability.

Improving maintainability is generally easier than improving

reliability. Maintainability estimates (repair rates) are also generally

more accurate. However, because the uncertainties in the reliability

estimates are in most cases very large, they are likely to dominate the

availability calculation (prediction uncertainty problem), even when

maintainability levels are very high. When reliability is not under

control, more complicated issues may arise, like manpower (maintainers /

customer service capability) shortages, spare part availability,

logistic delays, lack of repair facilities, extensive retro-fit and

complex configuration management costs, and others. The problem of

unreliability may be increased also due to the "domino effect" of

maintenance-induced failures after repairs. Focusing only on

maintainability is therefore not enough. If failures are prevented, none

of the other issues are of any importance, and therefore reliability is

generally regarded as the most important part of availability. Reliability needs to be evaluated and improved related to both

availability and the total cost of ownership

(TCO) due to cost of spare parts, maintenance man-hours, transport

costs, storage cost, part obsolete risks, etc. But, as GM and Toyota

have belatedly discovered, TCO also includes the downstream liability

costs when reliability calculations have not sufficiently or accurately

addressed customers' personal bodily risks. Often a trade-off is needed

between the two. There might be a maximum ratio between availability

and cost of ownership. Testability of a system should also be addressed

in the plan, as this is the link between reliability and

maintainability. The maintenance strategy can influence the reliability

of a system (e.g., by preventive and/or predictive maintenance),

although it can never bring it above the inherent reliability.

The reliability plan should clearly provide a strategy for

availability control. Whether only availability or also cost of

ownership is more important depends on the use of the system. For

example, a system that is a critical link in a production system—e.g., a

big oil platform—is normally allowed to have a very high cost of

ownership if that cost translates to even a minor increase in

availability, as the unavailability of the platform results in a massive

loss of revenue which can easily exceed the high cost of ownership. A

proper reliability plan should always address RAMT analysis in its total

context. RAMT stands for reliability, availability,

maintainability/maintenance, and testability in the context of the

customer's needs.

Reliability requirements

For

any system, one of the first tasks of reliability engineering is to

adequately specify the reliability and maintainability requirements

allocated from the overall availability

needs and, more importantly, derived from proper design failure

analysis or preliminary prototype test results. Clear requirements (able

to designed to) should constrain the designers from designing

particular unreliable items / constructions / interfaces / systems.

Setting only availability, reliability, testability, or maintainability

targets (e.g., max. failure rates) is not appropriate. This is a broad

misunderstanding about Reliability Requirements Engineering.

Reliability requirements address the system itself, including test and

assessment requirements, and associated tasks and documentation.

Reliability requirements are included in the appropriate system or

subsystem requirements specifications, test plans, and contract

statements. Creation of proper lower-level requirements is critical.

Provision of only quantitative minimum targets (e.g., MTBF values or

failure rates) is not sufficient for different reasons. One reason is

that a full validation (related to correctness and verifiability in

time) of a quantitative reliability allocation (requirement spec) on

lower levels for complex systems can (often) not be made as a

consequence of (1) the fact that the requirements are probabilistic, (2)

the extremely high level of uncertainties involved for showing

compliance with all these probabilistic requirements, and because (3)

reliability is a function of time, and accurate estimates of a

(probabilistic) reliability number per item are available only very late

in the project, sometimes even after many years of in-service use.

Compare this problem with the continuous (re-)balancing of, for example,

lower-level-system mass requirements in the development of an aircraft,

which is already often a big undertaking. Notice that in this case,

masses do only differ in terms of only some %, are not a function of

time, the data is non-probabilistic and available already in CAD models.

In case of reliability, the levels of unreliability (failure rates) may

change with factors of decades (multiples of 10) as result of very

minor deviations in design, process, or anything else.

The information is often not available without huge uncertainties

within the development phase. This makes this allocation problem almost

impossible to do in a useful, practical, valid manner that does not

result in massive over- or under-specification. A pragmatic approach is

therefore needed—for example: the use of general levels / classes of

quantitative requirements depending only on severity of failure effects.

Also, the validation of results is a far more subjective task than for

any other type of requirement. (Quantitative) reliability parameters—in

terms of MTBF—are by far the most uncertain design parameters in any

design.

Furthermore, reliability design requirements should drive a

(system or part) design to incorporate features that prevent failures

from occurring, or limit consequences from failure in the first place.

Not only would it aid in some predictions, this effort would keep from

distracting the engineering effort into a kind of accounting work. A

design requirement should be precise enough so that a designer can

"design to" it and can also prove—through analysis or testing—that the

requirement has been achieved, and, if possible, within some a stated

confidence. Any type of reliability requirement should be detailed and

could be derived from failure analysis (Finite-Element Stress and

Fatigue analysis, Reliability Hazard Analysis, FTA, FMEA, Human Factor

Analysis, Functional Hazard Analysis, etc.) or any type of reliability

testing. Also, requirements are needed for verification tests (e.g.,

required overload stresses) and test time needed. To derive these

requirements in an effective manner, a systems engineering-based

risk assessment and mitigation logic should be used. Robust hazard log

systems must be created that contain detailed information on why and

how systems could or have failed. Requirements are to be derived and

tracked in this way. These practical design requirements shall drive

the design and not be used only for verification purposes. These

requirements (often design constraints) are in this way derived from

failure analysis or preliminary tests. Understanding of this difference

compared to only purely quantitative (logistic) requirement

specification (e.g., Failure Rate / MTBF target) is paramount in the

development of successful (complex) systems.

The maintainability requirements address the costs of repairs as

well as repair time. Testability (not to be confused with test

requirements) requirements provide the link between reliability and

maintainability and should address detectability of failure modes (on a

particular system level), isolation levels, and the creation of

diagnostics (procedures).

As indicated above, reliability engineers should also address

requirements for various reliability tasks and documentation during

system development, testing, production, and operation. These

requirements are generally specified in the contract statement of work

and depend on how much leeway the customer wishes to provide to the

contractor. Reliability tasks include various analyses, planning, and

failure reporting. Task selection depends on the criticality of the

system as well as cost. A safety-critical system may require a formal

failure reporting and review process throughout development, whereas a

non-critical system may rely on final test reports. The most common

reliability program tasks are documented in reliability program

standards, such as MIL-STD-785 and IEEE 1332. Failure reporting analysis

and corrective action systems are a common approach for product/process

reliability monitoring.

Reliability culture / human errors / human factors

In practice, most failures can be traced back to some type of human error, for example in:

- Management decisions (e.g. in budgeting, timing, and required tasks)

- Systems Engineering: Use studies (load cases)

- Systems Engineering: Requirement analysis / setting

- Systems Engineering: Configuration control

- Assumptions

- Calculations / simulations / FEM analysis

- Design

- Design drawings

- Testing (e.g. incorrect load settings or failure measurement)

- Statistical analysis

- Manufacturing

- Quality control

- Maintenance

- Maintenance manuals

- Training

- Classifying and ordering of information

- Feedback of field information (e.g. incorrect or too vague)

- etc.

However, humans are also very good at detecting such failures,

correcting for them, and improvising when abnormal situations occur.

Therefore, policies that completely rule out human actions in design and

production processes to improve reliability may not be effective. Some

tasks are better performed by humans and some are better performed by

machines.

Furthermore, human errors in management; the organization of data

and information; or the misuse or abuse of items, may also contribute

to unreliability. This is the core reason why high levels of reliability

for complex systems can only be achieved by following a robust systems engineering

process with proper planning and execution of the validation and

verification tasks. This also includes careful organization of data and

information sharing and creating a "reliability culture", in the same

way that having a "safety culture" is paramount in the development of

safety critical systems.

Reliability prediction and improvement

Reliability prediction combines:

- creation of a proper reliability model (see further on this page)

- estimation (and justification) of input parameters for this model (e.g. failure rates for a particular failure mode or event and the mean time to repair the system for a particular failure)

- estimation of output reliability parameters at system or part level (i.e. system availability or frequency of a particular functional failure) The emphasis on quantification and target setting (e.g. MTBF) might imply there is a limit to achievable reliability, however, there is no inherent limit and development of higher reliability does not need to be more costly. In addition, they argue that prediction of reliability from historic data can be very misleading, with comparisons only valid for identical designs, products, manufacturing processes, and maintenance with identical operating loads and usage environments. Even minor changes in any of these could have major effects on reliability. Furthermore, the most unreliable and important items (i.e. the most interesting candidates for a reliability investigation) are most likely to be modified and re-engineered since historical data was gathered, making the standard (re-active or pro-active) statistical methods and processes used in e.g. medical or insurance industries less effective. Another surprising — but logical — argument is that to be able to accurately predict reliability by testing, the exact mechanisms of failure must be known and therefore — in most cases — could be prevented! Following the incorrect route of trying to quantify and solve a complex reliability engineering problem in terms of MTBF or probability using an-incorrect – for example, the re-active – approach is referred to by Barnard as "Playing the Numbers Game" and is regarded as bad practice.

For existing systems, it is arguable that any attempt by a

responsible program to correct the root cause of discovered failures may

render the initial MTBF estimate invalid, as new assumptions

(themselves subject to high error levels) of the effect of this

correction must be made. Another practical issue is the general

unavailability of detailed failure data, with those available often

featuring inconsistent filtering of failure (feedback) data, and

ignoring statistical errors (which are very high for rare events like

reliability related failures). Very clear guidelines must be present to

count and compare failures related to different type of root-causes

(e.g. manufacturing-, maintenance-, transport-, system-induced or

inherent design failures). Comparing different types of causes may lead

to incorrect estimations and incorrect business decisions about the

focus of improvement.

To perform a proper quantitative reliability prediction for

systems may be difficult and very expensive if done by testing. At the

individual part-level, reliability results can often be obtained with

comparatively high confidence, as testing of many sample parts might be

possible using the available testing budget. However, unfortunately

these tests may lack validity at a system-level due to assumptions made

at part-level testing. These authors emphasized the importance of

initial part- or system-level testing until failure, and to learn from

such failures to improve the system or part. The general conclusion is

drawn that an accurate and absolute prediction — by either field-data

comparison or testing — of reliability is in most cases not possible. An

exception might be failures due to wear-out problems such as fatigue

failures. In the introduction of MIL-STD-785 it is written that

reliability prediction should be used with great caution, if not used

solely for comparison in trade-off studies.

Design for reliability

Design

for Reliability (DfR) is a process that encompasses tools and

procedures to ensure that a product meets its reliability requirements,

under its use environment, for the duration of its lifetime. DfR is

implemented in the design stage of a product to proactively improve

product reliability. DfR is often used as part of an overall Design for Excellence (DfX) strategy.

Statistics-based approach (i.e. MTBF)

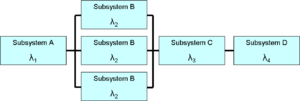

Reliability design begins with the development of a (system) model. Reliability and availability models use block diagrams and Fault Tree Analysis

to provide a graphical means of evaluating the relationships between

different parts of the system. These models may incorporate predictions

based on failure rates taken from historical data. While the (input

data) predictions are often not accurate in an absolute sense, they are

valuable to assess relative differences in design alternatives.

Maintainability parameters, for example Mean time to repair (MTTR), can also be used as inputs for such models.

The most important fundamental initiating causes and failure

mechanisms are to be identified and analyzed with engineering tools. A

diverse set of practical guidance as to performance and reliability

should be provided to designers so that they can generate low-stressed

designs and products that protect, or are protected against, damage and

excessive wear. Proper validation of input loads (requirements) may be

needed, in addition to verification for reliability "performance" by

testing.

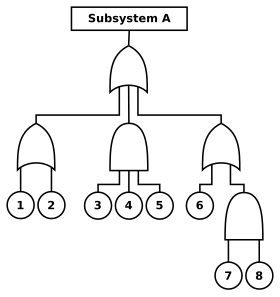

A fault tree diagram

One of the most important design techniques is redundancy.

This means that if one part of the system fails, there is an alternate

success path, such as a backup system. The reason why this is the

ultimate design choice is related to the fact that high-confidence

reliability evidence for new parts or systems is often not available, or

is extremely expensive to obtain. By combining redundancy, together

with a high level of failure monitoring, and the avoidance of common

cause failures; even a system with relatively poor single-channel (part)

reliability, can be made highly reliable at a system level (up to

mission critical reliability). No testing of reliability has to be

required for this. In conjunction with redundancy, the use of dissimilar

designs or manufacturing processes (e.g. via different suppliers of

similar parts) for single independent channels, can provide less

sensitivity to quality issues (e.g. early childhood failures at a single

supplier), allowing very-high levels of reliability to be achieved at

all moments of the development cycle (from early life to long-term).

Redundancy can also be applied in systems engineering by double checking

requirements, data, designs, calculations, software, and tests to

overcome systematic failures.

Another effective way to deal with reliability issues is to

perform analysis that predicts degradation, enabling the prevention of

unscheduled downtime events / failures. RCM (Reliability Centered Maintenance) programs can be used for this.

Physics-of-failure-based approach

For electronic assemblies, there has been an increasing shift towards a different approach called physics of failure.

This technique relies on understanding the physical static and dynamic

failure mechanisms. It accounts for variation in load, strength, and

stress that lead to failure with a high level of detail, made possible

with the use of modern finite element method

(FEM) software programs that can handle complex geometries and

mechanisms such as creep, stress relaxation, fatigue, and probabilistic

design (Monte Carlo Methods/DOE).

The material or component can be re-designed to reduce the probability

of failure and to make it more robust against such variations. Another

common design technique is component derating:

i.e. selecting components whose specifications significantly exceed the

expected stress levels, such as using heavier gauge electrical wire

than might normally be specified for the expected electric current.

Common tools and techniques

Many

of the tasks, techniques, and analyses used in Reliability Engineering

are specific to particular industries and applications, but can commonly

include:

- Physics of failure (PoF)

- Built-in self-test (BIT) (testability analysis)

- Failure mode and effects analysis (FMEA)

- Reliability hazard analysis

- Reliability block-diagram analysis

- Dynamic reliability block-diagram analysis

- Fault tree analysis

- Root cause analysis

- Statistical engineering, design of experiments – e.g. on simulations / FEM models or with testing

- Sneak circuit analysis

- Accelerated testing

- Reliability growth analysis (re-active reliability)

- Weibull analysis (for testing or mainly "re-active" reliability)

- Thermal analysis by finite element analysis (FEA) and / or measurement

- Thermal induced, shock and vibration fatigue analysis by FEA and / or measurement

- Electromagnetic analysis

- Avoidance of single point of failure (SPOF)

- Functional analysis and functional failure analysis (e.g., function FMEA, FHA or FFA)

- Predictive and preventive maintenance: reliability centered maintenance (RCM) analysis

- Testability analysis

- Failure diagnostics analysis (normally also incorporated in FMEA)

- Human error analysis

- Operational hazard analysis

- Preventative/Planned Maintenance Optimization (PMO)

- Manual screening

- Integrated logistics support

Results from these methods are presented during reviews of part or

system design, and logistics. Reliability is just one requirement among

many for a complex part or system. Engineering trade-off studies are

used to determine the optimum balance between reliability requirements and other constraints.

The importance of language

Reliability

engineers, whether using quantitative or qualitative methods to

describe a failure or hazard, rely on language to pinpoint the risks and

enable issues to be solved. The language used must help create an

orderly description of the function/item/system and its complex

surrounding as it relates to the failure of these

functions/items/systems. Systems engineering is very much about finding

the correct words to describe the problem (and related risks), so that

they can be readily solved via engineering solutions. Jack Ring said

that a systems engineer's job is to "language the project." (Ring et al.

2000)

For part/system failures, reliability engineers should concentrate more

on the "why and how", rather that predicting "when". Understanding

"why" a failure has occurred (e.g. due to over-stressed components or

manufacturing issues) is far more likely to lead to improvement in the

designs and processes used

than quantifying "when" a failure is likely to occur (e.g. via

determining MTBF). To do this, first the reliability hazards relating to

the part/system need to be classified and ordered (based on some form

of qualitative and quantitative logic if possible) to allow for more

efficient assessment and eventual improvement. This is partly done in

pure language and proposition logic, but also based on experience with similar items. This can for example be seen in descriptions of events in fault tree analysis, FMEA

analysis, and hazard (tracking) logs. In this sense language and proper

grammar (part of qualitative analysis) plays an important role in

reliability engineering, just like it does in safety engineering or in-general within systems engineering.

Correct use of language can also be key to identifying or reducing the risks of human error,

which are often the root cause of many failures. This can include

proper instructions in maintenance manuals, operation manuals, emergency

procedures, and others to prevent systematic human errors that may

result in system failures. These should be written by trained or

experienced technical authors using so-called simplified English or Simplified Technical English,

where words and structure are specifically chosen and created so as to

reduce ambiguity or risk of confusion (e.g. an "replace the old part"

could ambiguously refer to a swapping a worn-out part with a non

worn-out part, or replacing a part with one using a more recent and

hopefully improved design).

Reliability modeling

Reliability

modeling is the process of predicting or understanding the reliability

of a component or system prior to its implementation. Two types of

analysis that are often used to model a complete system's availability

behavior (including effects from logistics issues like spare part

provisioning, transport and manpower) are Fault Tree Analysis and

reliability block diagrams. At a component level, the same types of

analyses can be used together with others. The input for the models can

come from many sources including testing; prior operational experience;

field data; as well as data handbooks from similar or related

industries. Regardless of source, all model input data must be used with

great caution, as predictions are only valid in cases where the same

product was used in the same context. As such, predictions are often

only used to help compare alternatives.

A reliability block diagram showing a "1oo3" (1 out of 3) redundant designed subsystem

For part level predictions, two separate fields of investigation are common:

- The physics of failure approach uses an understanding of physical failure mechanisms involved, such as mechanical crack propagation or chemical corrosion degradation or failure;

- The parts stress modeling approach is an empirical method for prediction based on counting the number and type of components of the system, and the stress they undergo during operation.

Software reliability

is a more challenging area that must be considered when computer code

provides a considerable component of a system's functionality.

Reliability theory

Reliability is defined as the probability

that a device will perform its intended function during a specified

period of time under stated conditions. Mathematically, this may be

expressed as,

- ,

where is the failure probability density function and is the length of the period of time (which is assumed to start from time zero).

There are a few key elements of this definition:

- Reliability is predicated on "intended function:" Generally, this is taken to mean operation without failure. However, even if no individual part of the system fails, but the system as a whole does not do what was intended, then it is still charged against the system reliability. The system requirements specification is the criterion against which reliability is measured.

- Reliability applies to a specified period of time. In practical terms, this means that a system has a specified chance that it will operate without failure before time . Reliability engineering ensures that components and materials will meet the requirements during the specified time. Note that units other than time may sometimes be used (e.g. "a mission", "operation cycles").

- Reliability is restricted to operation under stated (or explicitly defined) conditions. This constraint is necessary because it is impossible to design a system for unlimited conditions. A Mars Rover will have different specified conditions than a family car. The operating environment must be addressed during design and testing. That same rover may be required to operate in varying conditions requiring additional scrutiny.

- Two notable references on reliability theory and its mathematical and statistical foundations are Barlow, R. E. and Proschan, F. (1982) and Samaniego, F. J. (2007).

Quantitative system reliability parameters—theory

Quantitative requirements are specified using reliability parameters. The most common reliability parameter is the mean time to failure (MTTF), which can also be specified as the failure rate

(this is expressed as a frequency or conditional probability density

function (PDF)) or the number of failures during a given period. These

parameters may be useful for higher system levels and systems that are

operated frequently (i.e. vehicles, machinery, and electronic

equipment). Reliability increases as the MTTF increases. The MTTF is

usually specified in hours, but can also be used with other units of

measurement, such as miles or cycles. Using MTTF values on lower system

levels can be very misleading, especially if they do not specify the

associated Failures Modes and Mechanisms (The F in MTTF).

In other cases, reliability is specified as the probability of

mission success. For example, reliability of a scheduled aircraft flight

can be specified as a dimensionless probability or a percentage, as

often used in system safety engineering.

A special case of mission success is the single-shot device or

system. These are devices or systems that remain relatively dormant and

only operate once. Examples include automobile airbags, thermal batteries and missiles.

Single-shot reliability is specified as a probability of one-time

success or is subsumed into a related parameter. Single-shot missile

reliability may be specified as a requirement for the probability of a

hit. For such systems, the probability of failure on demand

(PFD) is the reliability measure — this is actually an "unavailability"

number. The PFD is derived from failure rate (a frequency of

occurrence) and mission time for non-repairable systems.

For repairable systems, it is obtained from failure rate,

mean-time-to-repair (MTTR), and test interval. This measure may not be

unique for a given system as this measure depends on the kind of demand.

In addition to system level requirements, reliability requirements may

be specified for critical subsystems. In most cases, reliability

parameters are specified with appropriate statistical confidence intervals.

Reliability testing

The

purpose of reliability testing is to discover potential problems with

the design as early as possible and, ultimately, provide confidence that

the system meets its reliability requirements.

Reliability testing may be performed at several levels and there

are different types of testing. Complex systems may be tested at

component, circuit board, unit, assembly, subsystem and system levels.

(The test level nomenclature varies among applications.) For example,

performing environmental stress screening tests at lower levels, such as

piece parts or small assemblies, catches problems before they cause

failures at higher levels. Testing proceeds during each level of

integration through full-up system testing, developmental testing, and

operational testing, thereby reducing program risk. However, testing

does not mitigate unreliability risk.

With each test both a statistical type 1 and type 2 error could

be made and depends on sample size, test time, assumptions and the

needed discrimination ratio. There is risk of incorrectly accepting a

bad design (type 1 error) and the risk of incorrectly rejecting a good

design (type 2 error).

It is not always feasible to test all system requirements. Some systems are prohibitively expensive to test; some failure modes

may take years to observe; some complex interactions result in a huge

number of possible test cases; and some tests require the use of limited

test ranges or other resources. In such cases, different approaches to

testing can be used, such as (highly) accelerated life testing, design of experiments, and simulations.

The desired level of statistical confidence also plays a role in

reliability testing. Statistical confidence is increased by increasing

either the test time or the number of items tested. Reliability test

plans are designed to achieve the specified reliability at the specified

confidence level

with the minimum number of test units and test time. Different test

plans result in different levels of risk to the producer and consumer.

The desired reliability, statistical confidence, and risk levels for

each side influence the ultimate test plan. The customer and developer

should agree in advance on how reliability requirements will be tested.

A key aspect of reliability testing is to define "failure".

Although this may seem obvious, there are many situations where it is

not clear whether a failure is really the fault of the system.

Variations in test conditions, operator differences, weather and

unexpected situations create differences between the customer and the

system developer. One strategy to address this issue is to use a scoring

conference process. A scoring conference includes representatives from

the customer, the developer, the test organization, the reliability

organization, and sometimes independent observers. The scoring

conference process is defined in the statement of work. Each test case

is considered by the group and "scored" as a success or failure. This

scoring is the official result used by the reliability engineer.

As part of the requirements phase, the reliability engineer

develops a test strategy with the customer. The test strategy makes

trade-offs between the needs of the reliability organization, which

wants as much data as possible, and constraints such as cost, schedule

and available resources. Test plans and procedures are developed for

each reliability test, and results are documented.

Reliability testing is common in the Photonics industry. Examples of reliability tests of lasers are life test and burn-in.

These tests consist of the highly accelerated aging, under controlled

conditions, of a group of lasers. The data collected from these life

tests are used to predict laser life expectancy under the intended

operating characteristics.

Reliability test requirements

Reliability

test requirements can follow from any analysis for which the first

estimate of failure probability, failure mode or effect needs to be

justified. Evidence can be generated with some level of confidence by

testing. With software-based systems, the probability is a mix of

software and hardware-based failures. Testing reliability requirements

is problematic for several reasons. A single test is in most cases

insufficient to generate enough statistical data. Multiple tests or

long-duration tests are usually very expensive. Some tests are simply

impractical, and environmental conditions can be hard to predict over a

systems life-cycle.

Reliability engineering is used to design a realistic and

affordable test program that provides empirical evidence that the system

meets its reliability requirements. Statistical confidence levels

are used to address some of these concerns. A certain parameter is

expressed along with a corresponding confidence level: for example, an MTBF

of 1000 hours at 90% confidence level. From this specification, the

reliability engineer can, for example, design a test with explicit

criteria for the number of hours and number of failures until the

requirement is met or failed. Different sorts of tests are possible.

The combination of required reliability level and required

confidence level greatly affects the development cost and the risk to

both the customer and producer. Care is needed to select the best

combination of requirements—e.g. cost-effectiveness. Reliability testing

may be performed at various levels, such as component, subsystem and system.

Also, many factors must be addressed during testing and operation, such

as extreme temperature and humidity, shock, vibration, or other

environmental factors (like loss of signal, cooling or power; or other

catastrophes such as fire, floods, excessive heat, physical or security

violations or other myriad forms of damage or degradation). For systems

that must last many years, accelerated life tests may be needed.

Accelerated testing

The purpose of accelerated life testing (ALT test)

is to induce field failure in the laboratory at a much faster rate by

providing a harsher, but nonetheless representative, environment. In

such a test, the product is expected to fail in the lab just as it would

have failed in the field—but in much less time.

The main objective of an accelerated test is either of the following:

- To discover failure modes

- To predict the normal field life from the high stress lab life

An Accelerated testing program can be broken down into the following steps:

- Define objective and scope of the test

- Collect required information about the product

- Identify the stress(es)

- Determine level of stress(es)

- Conduct the accelerated test and analyze the collected data.

Common ways to determine a life stress relationship are:

- Arrhenius model

- Eyring model

- Inverse power law model

- Temperature–humidity model

- Temperature non-thermal model

Software reliability

Software reliability is a special aspect of reliability engineering.

System reliability, by definition, includes all parts of the system,

including hardware, software, supporting infrastructure (including

critical external interfaces), operators and procedures. Traditionally,

reliability engineering focuses on critical hardware parts of the

system. Since the widespread use of digital integrated circuit technology, software has become an increasingly critical part of most electronics and, hence, nearly all present day systems.

There are significant differences, however, in how software and

hardware behave.

Most hardware unreliability is the result of a component or material

failure that results in the system not performing its intended function.

Repairing or replacing the hardware component restores the system to

its original operating state.

However, software does not fail in the same sense that hardware fails.

Instead, software unreliability is the result of unanticipated results

of software operations. Even relatively small software programs can have

astronomically large combinations

of inputs and states that are infeasible to exhaustively test.

Restoring software to its original state only works until the same

combination of inputs and states results in the same unintended result.

Software reliability engineering must take this into account.

Despite this difference in the source of failure between software and hardware, several software reliability models

based on statistics have been proposed to quantify what we experience

with software: the longer software is run, the higher the probability

that it will eventually be used in an untested manner and exhibit a

latent defect that results in a failure (Shooman 1987), (Musa 2005), (Denney 2005).

As with hardware, software reliability depends on good

requirements, design and implementation. Software reliability

engineering relies heavily on a disciplined software engineering process to anticipate and design against unintended consequences. There is more overlap between software quality engineering

and software reliability engineering than between hardware quality and

reliability. A good software development plan is a key aspect of the

software reliability program. The software development plan describes

the design and coding standards, peer reviews, unit tests, configuration management, software metrics and software models to be used during software development.

A common reliability metric is the number of software faults,

usually expressed as faults per thousand lines of code. This metric,

along with software execution time, is key to most software reliability

models and estimates. The theory is that the software reliability

increases as the number of faults (or fault density) decreases or goes

down. Establishing a direct connection between fault density and

mean-time-between-failure is difficult, however, because of the way

software faults are distributed in the code, their severity, and the

probability of the combination of inputs necessary to encounter the

fault. Nevertheless, fault density serves as a useful indicator for the

reliability engineer. Other software metrics, such as complexity, are

also used. This metric remains controversial, since changes in software

development and verification practices can have dramatic impact on

overall defect rates.

Testing is even more important for software than hardware. Even

the best software development process results in some software faults

that are nearly undetectable until tested. As with hardware, software is

tested at several levels, starting with individual units, through

integration and full-up system testing. Unlike hardware, it is

inadvisable to skip levels of software testing. During all phases of

testing, software faults are discovered, corrected, and re-tested.

Reliability estimates are updated based on the fault density and other

metrics. At a system level, mean-time-between-failure data can be

collected and used to estimate reliability. Unlike hardware, performing

exactly the same test on exactly the same software configuration does

not provide increased statistical confidence. Instead, software

reliability uses different metrics, such as code coverage.

Eventually, the software is integrated with the hardware in the

top-level system, and software reliability is subsumed by system

reliability. The Software Engineering Institute's capability maturity model is a common means of assessing the overall software development process for reliability and quality purposes.

Structural reliability

Structural reliability or the reliability of structures is the application of reliability theory to the behavior of structures. It is used in both the design and maintenance of different types of structures including concrete and steel structures.

In structural reliability studies both loads and resistances are

modeled as probabilistic variables. Using this approach the probability

of failure of a structure is calculated.

Comparison to safety engineering

Reliability

engineering is concerned with overall minimisation of failures that

could lead to financial losses for the responsible entity, whereas safety engineering

focuses on minimising a specific set of failure types that in general

could lead to large scale, widespread issues beyond the responsible

entity.

Reliability hazards could transform into incidents leading to a

loss of revenue for the company or the customer, for example due to

direct and indirect costs associated with: loss of production due to

system unavailability; unexpected high or low demands for spares; repair

costs; man-hours; (multiple) re-designs; interruptions to normal

production etc.

Safety engineering is often highly specific, relating only to

certain tightly regulated industries, applications, or areas. It

primarily focuses on system safety hazards that could lead to severe

accidents including: loss of life; destruction of equipment; or

environmental damage. As such, the related system functional reliability

requirements are often extremely high. Although it deals with unwanted

failures in the same sense as reliability engineering, it, however, has

less of a focus on direct costs, and is not concerned with post-failure

repair actions. Another difference is the level of impact of failures on

society, leading to a tendency for strict control by governments or

regulatory bodies (e.g. nuclear, aerospace, defense, rail and oil

industries).

This can occasionally lead to safety engineering and reliability

engineering having contradictory requirements or conflicting choices at a

system architecture level.

For example, in train signal control systems it is common practice to

use a "fail-safe" system design concept. In this example, a wrong-side failure

needs an extremely low failure rate as such failures can lead to such

severe effects, like frontal collisions of two trains where a signalling

failure leads to two oncoming trains on the same track being given

GREEN lights. Such systems should be (and thankfully are) designed in a

way that the vast majority of failures (e.g. temporary or total loss of

signals or open contacts of relays) will generate RED lights for all

trains. This is the safe state. This means in the event of a failure,

all trains are stopped immediately. This fail-safe logic might,

unfortunately, lower the reliability of the system. The reason for this

is the higher risk of false tripping, as any failure whether temporary

or not may be trigger such a safe – but costly – shut-down state.

Different solutions can be applied for similar issues. See the section

on fault tolerance below.

Fault tolerance

Reliability can be increased by using "1oo2" (1 out of 2) redundancy

at a part or system level. However, if both redundant elements disagree

it can be difficult to know which is to be relied upon. In the previous

train signalling example this could lead to lower safety levels as there

are more possibilities for allowing "wrong side" or other undetected

dangerous failures. Fault-tolerant systems often rely on additional

redundancy (e.g. 2003 voting logic)

where multiple redundant elements must agree on a potentially unsage

action before it is performed. This increases both reliability and

safety at a system level and is often used for so-called "operational"

or "mission" systems. This is common practice in Aerospace systems that

need continued availability and do not have a fail-safe mode. For example, aircraft may use triple modular redundancy for flight computers

and control surfaces (including occasionally different modes of

operation e.g. electrical/mechanical/hydraulic) as these need to always

be operational, due to the fact that there are no "safe" default

positions for control surfaces such as rudders or ailerons when the

aircraft is flying.

Basic reliability and mission (operational) reliability

The

above example of a 2oo3 fault tolerant system increases both mission

reliability as well as safety. However, the "basic" reliability of the

system will in this case still be lower than a non-redundant (1oo1) or

2oo2 system. Basic reliability engineering covers all failures,

including those that might not result in system failure, but do result

in additional cost due to: maintenance repair actions; logistics; spare

parts etc. For example, replacement or repair of 1 faulty channel in a

2oo3 voting system, (the system is still operating, although with one

failed channel it has actually become a 2oo2 system) is contributing to

basic unreliability but not mission unreliability. As an example, the

failure of the tail-light of an aircraft will not prevent the plane from

flying (and so is not considered a mission failure), but it does need

to be remedied (with a related cost, and so does contribute to the basic

unreliability levels).

Detectability and common cause failures

When

using fault tolerant (redundant architectures) systems or systems that

are equipped with protection functions, detectability of failures and

avoidance of common cause failures becomes paramount for safe

functioning and/or mission reliability.

Reliability versus quality (Six Sigma)

Six Sigma

has its roots in manufacturing. Reliability engineering is a specialty

engineering part of systems engineering. The systems engineering process

is a discovery process that is quite unlike a manufacturing process. A

manufacturing process is focused on repetitive activities that achieve

high quality outputs with minimum cost and time. The systems engineering

process must begin by discovering a real (potential) problem that needs

to be solved; the biggest failure that can be made in systems

engineering is finding an elegant solution to the wrong problem (or in terms of reliability: "providing elegant solutions to the wrong root causes of system failures").

The everyday usage term "quality of a product" is loosely taken

to mean its inherent degree of excellence. In industry, a more precise

definition of quality as "conformance to requirements or specifications

at the start of use" is used. Assuming the final product specification

adequately captures the original requirements and customer/system needs,

the quality level can be measured as the fraction of product units

shipped that meet specifications.

Variation of this static output may affect quality and

reliability, but this is not the total picture. More inherent aspects

may play a role, and in some cases, these may not be readily measured or

controlled by any means. At a part level microscopic material

variations such as unavoidable micro-cracks and chemical impurities may

over time (due to physical or chemical "loading") become macroscopic

defects. At a system level, systematic failures may play a dominant role

(e.g. requirement errors or software or software compiler or design

flaws).

Furthermore, for more complex systems it should be questioned if

derived or lower-level requirements and related product specifications

are truly valid and correct? Will these result in premature failure due

to excessive wear, fatigue, corrosion, and debris accumulation, or other

issues such as maintenance induced failures? Are there any interactions

at a system level (as investigated by for example Fault Tree Analysis)?

How many of these systems still meet function and fulfill the needs

after a week of operation? What performance losses occurred? Did full

system failure occur? What happens after the end of a one-year warranty

period? And what happens after 50 years (a common lifetime for aircraft,

trains, nuclear systems, etc.)? That is where "reliability" comes in.

These issues are far more complex and can not be controlled only by a

standard "quality" (six sigma) way of working. They need a systems engineering approach.

Quality is a snapshot at the start of life and mainly related to control of lower-level product specifications. This includes time-zero defects i.e. where manufacturing mistakes escaped final Quality Control. In theory the quality level might be described by a single fraction of defective products. Reliability (as a part of systems engineering) acts as more of an ongoing account of operational capabilities, often over many years. Theoretically, all items will fail over an infinite period of time. Defects that appear over time are referred to as reliability fallout. To describe reliability fallout a probability model that describes the fraction fallout over time is needed. This is known as the life distribution model. Some of these reliability issues may be due to inherent design issues, which may exist even though the product conforms to specifications. Even items that are produced perfectly may fail over time due to one or more failure mechanisms (e.g. due to human error or mechanical, electrical, and chemical factors). These reliability issues can also be influenced by acceptable levels of variation during initial production.

Quality is therefore related to manufacturing, and reliability is

more related to the validation of sub-system or lower item

requirements, (system or part) inherent design and life cycle solutions.

Items that do not conform to (any) product specification will generally

do worse in terms of reliability (having a lower MTTF), but this does

not always have to be the case. The full mathematical quantification (in

statistical models) of this combined relation is in general very

difficult or even practically impossible. In cases where manufacturing

variances can be effectively reduced, six sigma tools may be useful to

find optimal process solutions which can increase reliability. Six Sigma

may also help to design products that are more robust to manufacturing

induced failures.

In contrast with Six Sigma, reliability engineering solutions are

generally found by focusing on a (system) design and not on the

manufacturing process. Solutions are found in different ways, such as by

simplifying a system to allow more of the mechanisms of failure

involved to be understood; performing detailed calculations of material

stress levels allowing suitable safety factors to be determined; finding

possible abnormal system load conditions and using this to increase

robustness of a design to manufacturing variance related failure

mechanisms. Furthermore, reliability engineering uses system-level

solutions, like designing redundant and fault-tolerant systems for

situations with high availability needs.

Six-Sigma is also more quantified (measurement-based). The core

of Six-Sigma is built on empirical research and statistical analysis

(e.g. to find transfer functions) of directly measurable parameters.

This can not be translated practically to most reliability issues, as

reliability is not (easily) measurable due to being very much a function

of time (large times may be involved), especially during the

requirements-specification and design phases, where reliability

engineering is the most efficient. Full quantification of reliability is

in this phase extremely difficult or costly (due to the amount of

testing required). It also may foster re-active management (waiting for

system failures to be measured before a decision can be taken).

Furthermore, as explained on this page, Reliability problems are likely

to come from many different causes (e.g. inherent failures, human error,

systematic failures) besides manufacturing induced defects.

Note: A "defect" in six-sigma/quality literature is not the same

as a "failure" (Field failure | e.g. fractured item) in reliability. A

six-sigma/quality defect refers generally to non-conformance with a

requirement (e.g. basic functionality or a key dimension). Items can,

however, fail over time, even if these requirements are all fulfilled.

Quality is generally not concerned with asking the crucial question "are

the requirements actually correct?", whereas reliability is.

Within an entity, departments related to Quality (i.e. concerning

manufacturing), Six Sigma (i.e. concerning process control), and

Reliability (product design) should provide input to each other to cover

the complete risks more efficiently.

Reliability operational assessment

Once

systems or parts are being produced, reliability engineering attempts

to monitor, assess, and correct deficiencies. Monitoring includes

electronic and visual surveillance of critical parameters identified

during the fault tree analysis design stage. Data collection is highly

dependent on the nature of the system. Most large organizations have quality control

groups that collect failure data on vehicles, equipment and machinery.

Consumer product failures are often tracked by the number of returns.

For systems in dormant storage or on standby, it is necessary to

establish a formal surveillance program to inspect and test random

samples. Any changes to the system, such as field upgrades or recall

repairs, require additional reliability testing to ensure the

reliability of the modification. Since it is not possible to anticipate

all the failure modes of a given system, especially ones with a human

element, failures will occur. The reliability program also includes a

systematic root cause analysis

that identifies the causal relationships involved in the failure such

that effective corrective actions may be implemented. When possible,

system failures and corrective actions are reported to the reliability

engineering organization.

Some of the most common methods to apply to a reliability operational assessment are failure reporting, analysis, and corrective action systems

(FRACAS). This systematic approach develops a reliability, safety, and

logistics assessment based on failure/incident reporting, management,

analysis, and corrective/preventive actions. Organizations today are

adopting this method and utilizing commercial systems (such as Web-based

FRACAS applications) that enable them to create a failure/incident data

repository from which statistics can be derived to view accurate and

genuine reliability, safety, and quality metrics.

It is extremely important for an organization to adopt a common

FRACAS system for all end items. Also, it should allow test results to

be captured in a practical way. Failure to adopt one easy-to-use (in

terms of ease of data-entry for field engineers and repair shop

engineers) and easy-to-maintain integrated system is likely to result in

a failure of the FRACAS program itself.

Some of the common outputs from a FRACAS system include Field

MTBF, MTTR, spares consumption, reliability growth, failure/incidents

distribution by type, location, part no., serial no., and symptom.

The use of past data to predict the reliability of new comparable

systems/items can be misleading as reliability is a function of the

context of use and can be affected by small changes in

design/manufacturing.

Reliability organizations

Systems of any significant complexity are developed by organizations of people, such as a commercial company or a government agency. The reliability engineering organization must be consistent with the company's organizational structure.

For small, non-critical systems, reliability engineering may be

informal. As complexity grows, the need arises for a formal reliability

function. Because reliability is important to the customer, the customer

may even specify certain aspects of the reliability organization.

There are several common types of reliability organizations. The

project manager or chief engineer may employ one or more reliability

engineers directly. In larger organizations, there is usually a product

assurance or specialty engineering organization, which may include reliability, maintainability, quality, safety, human factors, logistics, etc. In such case, the reliability engineer reports to the product assurance manager or specialty engineering manager.

In some cases, a company may wish to establish an independent

reliability organization. This is desirable to ensure that the system

reliability, which is often expensive and time-consuming, is not unduly

slighted due to budget and schedule pressures. In such cases, the

reliability engineer works for the project day-to-day, but is actually

employed and paid by a separate organization within the company.

Because reliability engineering is critical to early system

design, it has become common for reliability engineers, however, the

organization is structured, to work as part of an integrated product team.

Education

Some

universities offer graduate degrees in reliability engineering. Other

reliability engineers typically have an engineering degree, which can be

in any field of engineering, from an accredited university or college

program. Many engineering programs offer reliability courses, and some

universities have entire reliability engineering programs. A reliability

engineer may be registered as a professional engineer

by the state, but this is not required by most employers. There are

many professional conferences and industry training programs available

for reliability engineers. Several professional organizations exist for

reliability engineers, including the American Society for Quality

Reliability Division (ASQ-RD), the IEEE Reliability Society, the American Society for Quality (ASQ), and the Society of Reliability Engineers (SRE).

A group of engineers have provided a list of useful tools for

reliability engineering. These include: RelCalc software, Military

Handbook 217 (Mil-HDBK-217), and the NAVMAT P-4855-1A manual. Analyzing

failures and successes coupled with a quality standards process also

provides systemized information to making informed engineering designs.