Currently, bioprinting can be used to print tissues and organs to help research drugs and pills. However, emerging innovations span from bioprinting of cells or

extracellular matrix deposited into a 3D gel layer by layer to produce

the desired tissue or organ. In addition, 3D bioprinting has begun to

incorporate the printing of scaffolds. These scaffolds can be used to regenerate joints and ligaments.

Process

Bioprinting of 3D Convoluted Renal Proximal Tubules on Perfusable Chips

3D bioprinting generally follows three steps, pre-bioprinting, bioprinting, and post-bioprinting.

Pre-bioprinting

Pre-bioprinting

is the process of creating a model that the printer will later create

and choosing the materials that will be used. One of the first steps is

to obtain a biopsy of the organ. Common technologies used for

bioprinting are computed tomography (CT) and magnetic resonance imaging

(MRI). To print with a layer-by-layer approach, tomographic

reconstruction is done on the images. The now-2D images are then sent to

the printer to be made. Once the image is created, certain cells are

isolated and multiplied.

These cells are then mixed with a special liquefied material that

provides oxygen and other nutrients to keep them alive. In some

processes, the cells are encapsulated in cellular spheroids 500μm in

diameter. This aggregation of cells does not require a scaffold, and are

required for placing in the tubular-like tissue fusion for processes

such as extrusion.

Bioprinting

In the second step, the liquid mixture of cells, matrix, and nutrients known as bioinks are placed in a printer cartridge and deposited using the patients' medical scans. When a bioprinted pre-tissue is transferred to an incubator, this cell-based pre-tissue matures into a tissue.

3D bioprinting for fabricating biological constructs typically

involves dispensing cells onto a biocompatible scaffold using a

successive layer-by-layer approach to generate tissue-like

three-dimensional structures.

Artificial organs such as livers and kidneys made by 3D bioprinting

have been shown to lack crucial elements that affect the body such as

working blood vessels, tubules for collecting urine, and the growth of

billions of cells required for these organs. Without these components

the body has no way to get the essential nutrients and oxygen deep

within their interiors.

Given that every tissue in the body is naturally composed of different

cell types, many technologies for printing these cells vary in their

ability to ensure stability and viability of the cells during the

manufacturing process. Some of the methods that are used for 3D

bioprinting of cells are photolithography, magnetic bioprinting, stereolithography, and direct cell extrusion.

Post-bioprinting

The

post-bioprinting process is necessary to create a stable structure from

the biological material. If this process is not well-maintained, the

mechanical integrity and function of the 3D printed object is at risk.

To maintain the object, both mechanical and chemical stimulations are

needed. These stimulations send signals to the cells to control the

remodeling and growth of tissues. In addition, in recent development,

bioreactor technologies have allowed the rapid maturation of tissues, vascularization of tissues and the ability to survive transplants.

Bioreactors work in either providing convective nutrient

transport, creating microgravity environments, changing the pressure

causing solution to flow through the cells, or add compression for

dynamic or static loading. Each type of bioreactor is ideal for

different types of tissue, for example compression bioreactors are ideal

for cartilage tissue.

Bioprinting approach

Researchers

in the field have developed approaches to produce living organs that

are constructed with the appropriate biological and mechanical

properties. 3D bioprinting is based on three main approaches:

Biomimicry, autonomous self-assembly and mini-tissue building blocks.

Biomimicry

The

first approach of bioprinting is called biomimicry. The main goal of

this approach is to create fabricated structures that are identical to

the natural structure that are found in the tissues and organs in the

human body. Biomimicry requires duplication of the shape, framework, and

the microenvironment of the organs and tissues.

The application of biomimicry in bioprinting involves creating both

identical cellular and extracellular parts of organs. For this approach

to be successful, the tissues must be replicated on a micro scale.

Therefore, it is necessary to understand the microenvironment, the

nature of the biological forces in this microenvironment, the precise

organization of functional and supporting cell types, solubility

factors, and the composition of extracellular matrix.

Autonomous self-assembly

The

second approach of bioprinting is autonomous self-assembly. This

approach relies on the physical process of embryonic organ development

as a model to replicate the tissues of interest.

When cells are in their early development, they create their own

extracellular matrix building block, the proper cell signaling, and

independent arrangement and patterning to provide the required

biological functions and micro-architecture.

Autonomous self-assembly demands specific information about the

developmental techniques of the tissues and organs of the embryo.

There is a "scaffold-free" model that uses self-assembling spheroids

that subjects to fusion and cell arrangement to resemble evolving

tissues. Autonomous self-assembly depends on the cell as the fundamental

driver of histogenesis, guiding the building blocks, structural and

functional properties of these tissues. It demands a deeper

understanding of how embryonic tissues mechanisms develop as well as the

microenvironment surrounded to create the bioprinted tissues.

Mini-tissue

The

third approach of bioprinting is a combination of both the biomimicry

and self-assembly approaches, which is called mini tissues.

Organs and tissues are built from very small functional components.

Mini-tissue approach takes these small pieces and manufacture and

arrange them into larger framework.

Printers

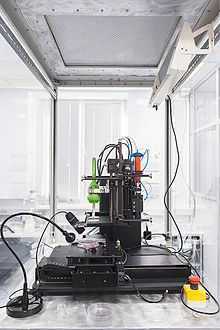

Printer from 3D Bioprinting Solutions

Akin to ordinary ink printers, bioprinters have three major

components to them. These are the hardware used, the type of bio-ink,

and the material it is printed on (biomaterials).

"Bio-ink is a material made from living cells that behaves much like a

liquid, allowing people to "print" it in order to create a desired

shape. To make bio-ink, scientists create a slurry of cells that can be

loaded into a cartridge and inserted into a specially designed printer,

along with another cartridge containing a gel known as bio-paper."

In bioprinting, there are three major types of printers that have

been used. These are inkjet, laser-assisted, and extrusion printers.

Inkjet printers are mainly used in bioprinting for fast and large-scale

products. One type of inkjet printer, called drop-on-demand inkjet

printer, prints materials in exact amounts, minimizing cost and waste.

Printers that utilize lasers provide high-resolution printing; however,

these printers are often expensive. Extrusion printers print cells

layer-by-layer, just like 3D printing to create 3D constructs. In addition to just cells, extrusion printers may also use hydrogels infused with cells.

Impact

3D bioprinting contributes to significant advances in the medical field of tissue engineering by allowing for research to be done on innovative materials called biomaterials.

Biomaterials are the materials adapted and used for printing

three-dimensional objects. Some of the most notable bioengineered

substances are usually stronger than the average bodily materials,

including soft tissue and bone. These constituents can act as future

substitutes, even improvements, for the original body materials. Alginate,

for example, is an anionic polymer with many biomedical implications

including feasibility, strong biocompatibility, low toxicity, and

stronger structural ability in comparison to some of the body's

structural material.

Synthetic hydrogels are also commonplace, including PV-based gels. The

combination of acid with a UV-initiated PV-based cross-linker has been

evaluated by the Wake Forest Institute of Medicine and determined to be a

suitable biomaterial.

Engineers are also exploring other options such as printing

micro-channels that can maximize the diffusion of nutrients and oxygen

from neighboring tissues In addition, the Defense Threat Reduction Agency

aims to print mini organs such as hearts, livers, and lungs as the

potential to test new drugs more accurately and perhaps eliminate the

need for testing in animals.