Technology computer-aided design (technology CAD or TCAD) is a branch of electronic design automation that models semiconductor fabrication

and semiconductor device operation. The modeling of the fabrication

is termed Process TCAD, while the modeling of the device operation is

termed Device TCAD. Included are the modelling of process steps (such as diffusion and ion implantation), and modelling of the behavior of the electrical devices based on fundamental physics, such as the doping profiles of the devices. TCAD may also include the creation of compact models (such as the well known SPICE transistor

models), which try to capture the electrical behavior of such devices

but do not generally derive them from the underlying physics. (However,

the SPICE simulator itself is usually considered as part of ECAD rather than TCAD.)

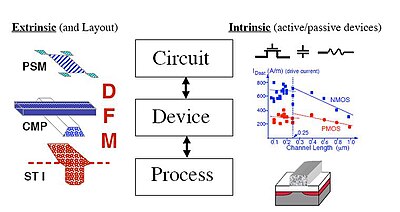

Hierarchy

of technology CAD tools building from the process level to circuits.

Left side icons show typical manufacturing issues; right side icons

reflect MOS scaling results based on TCAD (CRC Electronic Design

Automation for IC Handbook, Chapter 25)

From the diagram on the right:

- See SPICE for an example of a circuit simulator

- See semiconductor device modeling for a description of modeling devices from dopant profiles.

- See semiconductor process simulation for the generation of these profiles

- See BACPAC for an analysis tool that tries to take all of these into account to estimate system performance

Introduction

Technology files and design rules are essential building blocks of the integrated circuit design

process. Their accuracy and robustness over process technology, its

variability and the operating conditions of the IC — environmental,

parasitic interactions and testing, including adverse conditions such as

electro-static discharge — are critical in determining performance,

yield and reliability. Development of these technology and design rule

files involves an iterative process that crosses boundaries of

technology and device development, product design and quality assurance.

Modeling and simulation play a critical role in support of many

aspects of this evolution process.

The goals of TCAD start from the physical description of

integrated circuit devices, considering both the physical configuration

and related device properties, and build the links between the broad

range of physics and electrical behavior models that support circuit

design. Physics-based modeling of devices, in distributed and lumped

forms, is an essential part of the IC process development. It seeks to

quantify the underlying understanding of the technology and abstract

that knowledge to the device design level, including extraction of the

key parameters that support circuit design and statistical metrology.

Although the emphasis here is on Metal Oxide Semiconductor

(MOS) transistors — the workhorse of the IC industry — it is useful to

briefly overview the development history of the modeling tools and

methodology that has set the stage for the present state-of-the-art.

History

The

evolution of technology computer-aided design (TCAD) — the synergistic

combination of process, device and circuit simulation and modeling tools

— finds its roots in bipolar

technology, starting in the late 1960s, and the challenges of junction

isolated, double-and triple-diffused transistors. These devices and

technology were the basis of the first integrated circuits; nonetheless,

many of the scaling issues and underlying physical effects are integral

to IC design, even after four decades of IC development. With these

early generations of IC, process variability and parametric yield were

an issue — a theme that will reemerge as a controlling factor in future

IC technology as well.

Process control issues — both for the intrinsic devices and all

the associated parasitics — presented formidable challenges and mandated

the development of a range of advanced physical models for process and

device simulation. Starting in the late 1960s and into the 1970s, the

modeling approaches exploited were dominantly one- and two-dimensional

simulators. While TCAD in these early generations showed exciting

promise in addressing the physics-oriented challenges of bipolar

technology, the superior scalability and power consumption of MOS

technology revolutionized the IC industry. By the mid-1980s, CMOS

became the dominant driver for integrated electronics. Nonetheless,

these early TCAD developments set the stage for their growth and broad deployment as an essential

toolset that has leveraged technology development through the VLSI and

ULSI eras which are now the mainstream.

IC development for more than a quarter-century has been dominated by the MOS technology. In the 1970s and 1980s NMOS

was favored owing to speed and area advantages, coupled with technology

limitations and concerns related to isolation, parasitic effects and

process complexity. During that era of NMOS-dominated LSI and the

emergence of VLSI, the fundamental scaling laws of MOS technology were

codified and broadly applied.

It was also during this period that TCAD reached maturity in terms of

realizing robust process modeling (primarily one-dimensional) which then

became an integral technology design tool, used universally across the

industry.

At the same time device simulation, dominantly two-dimensional owing

to the nature of MOS devices, became the work-horse of technologists in

the design and scaling of devices. The transition from NMOS to CMOS

technology resulted in the necessity of tightly coupled and fully 2D

simulators for process and device simulations. This third generation of

TCAD tools became critical to address the full complexity of twin-well

CMOS technology (see Figure 3a), including issues of design rules and

parasitic effects such as latchup. An abbreviated but prospective view of this period, through the mid-1980s, is given in; and from the point of view of how TCAD tools were used in the design process.

Modern TCAD

Today

the requirements for and use of TCAD cross-cut a very broad landscape

of design automation issues, including many fundamental physical limits.

At the core are still a host of process and device modeling challenges

that support intrinsic device scaling and parasitic extraction. These

applications include technology and design rule development, extraction

of compact models and more generally design for manufacturability (DFM).

The dominance of interconnects for giga-scale integration (transistor

counts in O(billion)) and clocking frequencies in O (10 gigahertz)) have

mandated the development of tools and methodologies that embrace

patterning by electro-magnetic simulations—both for optical patterns and

electronic and optical interconnect performance modeling—as well as

circuit-level modeling. This broad range of issues at the device and

interconnect levels, including links to underlying patterning and

processing technologies, is summarized in Figure 1 and provides a

conceptual framework for the discussion that now follows.

Figure

1: Hierarchy of technology CAD tools building from the process level to

circuits. Left side icons show typical manufacturing issues; right side

icons reflect MOS scaling results based on TCAD (CRC Electronic Design

Automation for IC Handbook, Chapter 25)

Figure 1 depicts a hierarchy of process, device and circuit levels of

simulation tools. On each side of the boxes indicating modeling level

are icons that schematically depict representative applications for

TCAD. The left side gives emphasis to Design For Manufacturing (DFM) issues such as: shallow-trench isolation (STI), extra features required for phase-shift masking (PSM) and challenges for multi-level interconnects that include processing issues of chemical-mechanical planarization (CMP), and the need to consider electro-magnetic effects using electromagnetic field solvers.

The right side icons show the more traditional hierarchy of expected

TCAD results and applications: complete process simulations of the

intrinsic devices, predictions of drive current scaling and extraction

of technology files for the complete set of devices and parasitics.

Figure 2 again looks at TCAD capabilities but this time more in

the context of design flow information and how this relates to the

physical layers and modeling of the electronic design automation (EDA)

world. Here the simulation levels of process and device modeling are

considered as integral capabilities (within TCAD) that together provide

the "mapping" from mask-level information to the functional capabilities

needed at the EDA level such as compact models ("technology files") and

even higher-level behavioral models. Also shown is the extraction and

electrical rule checking (ERC); this indicates that many of the details

that to date have been embedded in analytical formulations, may in fact

also be linked to the deeper TCAD level in order to support the growing

complexity of technology scaling.

Providers

Current major suppliers of TCAD tools include Synopsys, Silvaco, Crosslight, Cogenda Software, Global TCAD Solutions and Tiberlab. The open source GSS, Archimedes, Aeneas, NanoTCAD ViDES, DEVSIM, and GENIUS have some of the capabilities of the commercial products.