A molecularly imprinted polymer (MIP) is a polymer that has been processed using the molecular imprinting

technique which leaves cavities in the polymer matrix with an affinity

for a chosen "template" molecule. The process usually involves

initiating the polymerization of monomers in the presence of a template

molecule that is extracted afterwards, leaving behind complementary

cavities. These polymers have affinity for the original molecule and

have been used in applications such as chemical separations, catalysis,

or molecular sensors. Published works on the topic date to the 1930s.

Molecular imprinting techniques (state of the art and perspectives)

Molecular

imprinting is the process of generating an impression within a solid or

a gel, the size, shape and charge distribution of which corresponds to a

template molecule (typically present during polymerisation). The result

is a synthetic receptor capable of binding to a target molecule, which

fits into the binding site with high affinity and specificity. The

interactions between the polymer and the template are similar to those

between antibodies and antigens, consisting of electrostatic interactions, hydrogen bonds, Van der Waals forces, and hydrophobic interactions.

One of the greatest advantages of artificial receptors over

naturally occurring receptors is freedom of molecular design. Their

frameworks are not restricted to proteins, and a variety of skeletons

(e.g., carbon chains and fused aromatic rings) can be used. Thus, the

stability, flexibility, and other properties are freely modulated

according to need. Even functional groups that are not found in nature

can be employed in these synthetic compounds. Furthermore, when

necessary, the activity in response towards outer stimuli

(photo-irradiation, pH change, electric or magnetic field, and others)

can be provided by using appropriate functional groups.

In a molecular imprinting processes, one needs a 1) template, 2) functional monomer(s) 3) cross-linker, 4) radical or other polymerization initiator,

5) porogenic solvent and 6) extraction solvent. According to

polymerization method and final polymer format one or some of the

reagent can be avoided.

There are two main methods for creating these specialized polymers. The

first is known as self-assembly, which involves the formation of

polymer by combining all elements of the MIP and allowing the molecular

interactions to form the cross-linked polymer with the template molecule

bound. The second method of formation of MIPs involves covalently

linking the imprint molecule to the monomer. After polymerization, the

monomer is cleaved from the template molecule.

The selectivity is greatly influenced by the kind and amount of

cross-linking agent used in the synthesis of the imprinted polymer. The

selectivity is also determined by the covalent and non-covalent

interactions between the target molecule and monomer functional groups.

The careful choice of functional monomer is another important choice to

provide complementary interactions with the template and substrates.

In an imprinted polymer, the cross-linker fulfills three major

functions: First of all, the cross-linker is important in controlling

the morphology of the polymer matrix, whether it is gel-type,

macroporous or a microgel powder. Secondly, it serves to stabilize the

imprinted binding site. Finally, it imparts mechanical stability to the

polymer matrix. From a polymerization point of view, high cross-link

ratios are generally preferred in order to access permanently porous

materials and in order to be able to generate materials with adequate

mechanical stability.

The self-assembly method has advantages in the fact that it forms

a more natural binding site, and also offers additional flexibility in

the types of monomers that can be polymerized. The covalent method has

its advantages in generally offering a high yield of homogeneous binding

sites, but first requires the synthesis of a derivatized imprint

molecule and may not imitate the "natural" conditions that could be

present elsewhere.

Over the recent years, interest in the technique of molecular imprinting

has increased rapidly, both in the academic community and in the

industry. Consequently, significant progress has been made in developing

polymerization methods that produce adequate MIP formats with rather

good binding properties expecting an enhancement in the performance or

in order to suit the desirable final application, such as beads, films

or nanoparticles. One of the key issues that have limited the

performance of MIPs in practical applications so far is the lack of

simple and robust methods to synthesize MIPs in the optimum formats

required by the application. Chronologically, the first polymerization

method encountered for MIP was based on "bulk" or solution

polymerization. This method is the most common technique used by groups

working on imprinting especially due to its simplicity and versatility.

It is used exclusively with organic solvents mainly with low dielectric

constant and consists basically of mixing all the components (template,

monomer, solvent and initiator) and subsequently polymerizing them. The

resultant polymeric block is then pulverized, freed from the template,

crushed and sieved to obtain particles of irregular shape and size

between 20 and 50 µm.

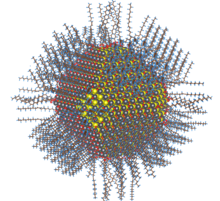

Depending on the target (template) type and the final application of the

MIP, MIPs are appeared in different formats such as nano/micro

spherical particles, nanowires and thin film or membranes. They are

produced with different polymerization techniques like bulk, precipitation, emulsion, suspension, dispersion, gelation,

and multi-step swelling polymerization. Most of investigators in the

field of MIP are making MIP with heuristic techniques such as

hierarchical imprinting method. The technique for the first time was

used for making MIP by Sellergren et al. for imprinting small target molecules. With the same concept, Nematollahzadeh et al.

developed a general technique, so-called polymerization packed bed, to

obtain hierarchically-structured, high capacity protein imprinted porous

polymer beads by using silica porous particles for protein recognition

and capture.

Solid-phase synthesis

Solid-phase

molecular imprinting has been recently developed as an alternative to

traditional bulk imprinting, generating water-soluble nanoparticles.

As the name implies, this technique requires the immobilisation of the

target molecule on a solid support prior to performing polymerisation.

This is analogous to solid-phase synthesis of peptides.

The solid phase doubles as an affinity separation matrix, allowing the

removal of low-affinity MIPs and overcoming many of the previously

described limitations of MIPs:

- Separation of MIPs from the immobilised template molecule is greatly simplified.

- Binding sites are more uniform, and template molecules cannot become trapped within the polymer matrix.

- MIPs can be functionalised post-synthesis (whilst attached to the solid phase) without significantly influencing binding sites.

- The immobilised template can be reused, reducing the cost of MIP synthesis.

MIP nanoparticles synthesised via this approach have found applications in various diagnostic assay and sensors.

Molecular modelling

Molecular modelling

has become a convenient choice in MIP design and analysis, allowing

rapid selection of monomers and optimisation of polymer composition,

with a range of different techniques being applied.

The application of molecular modelling in this capacity is commonly

attributed to Sergey A. Piletsky, who developed a method of automated

screening of a large database of monomers against a given target or

template with a molecular mechanics approach. In recent years technological advances have permitted more efficient analysis of monomer-template interactions by quantum mechanical molecular modelling, providing more precise calculations of binding energies. Molecular dynamics has also been applied for more detailed analysis of systems before polymerisation, and of the resulting polymer,

which by including more system components (cross-linkers, solvents)

provide greater accuracy in predicting successful MIP synthesis than

monomer-template interactions alone. Molecular modelling, particular molecular dynamics and the less common coarse-grained techniques,

can often also be integrated into greater theoretical models permitting

thermodynamic analysis and kinetic data for mesoscopic analysis of

imprinted polymer bulk monoliths and MIP nanoparticles.

Applications

Niche

areas for application of MIPs are in sensors and separation. Despite

the current good health of molecular imprinting in general, one

difficulty which appears to remain to this day is the commercialization

of molecularly imprinted polymers. Despite this, many patents (1035

patents, up to October 2018, according to the Scifinder

data base) on molecular imprinting were held by different groups.

Commercial interest is also confirmed by the fact that MIP Technologies, offers a range of commercially available MIP products and Sigma-Aldrich produces SupelMIP for beta-agonists, beta-blockers, pesticides and some drugs of abuse such as amphetamine. Additionally, POLYINTELL designs, manufactures and markets AFFINIMIPSPE products for instance for mycotoxins such as patulin, zearalenone, fumonisins, ochratoxin A, for endocrine disruptors (bisphenol A, estrogen derivatives etc...) or for the purification of radiotracers before their use in positron emission tomography (PET).

Fast and cost-effective molecularly imprinted polymer technique

has applications in many fields of chemistry, biology and engineering,

particularly as an affinity material for sensors, detection of chemical, antimicrobial, and dye, residues in food, adsorbents for solid phase extraction,

binding assays, artificial antibodies, chromatographic stationary

phase, catalysis, drug development and screening, and byproduct removal

in chemical reaction.

Molecular imprinted polymers pose this wide range of capabilities in

extraction through highly specific micro-cavity binding sites.

Due to the specific binding site created in a MIP this technique is

showing promise in analytical chemistry as a useful method for solid

phase extraction.

The capability for MIPs to be a cheaper easier production of

antibody/enzyme like binding sites doubles the use of this technique as a

valuable breakthrough in medical research and application.

Such possible medical applications include "controlled release drugs,

drug monitoring devices, and biological receptor mimetics". Beyond this MIPs show a promising future in the developing knowledge and application in food sciences.

"Plastic antibodies"

The binding activity of MIPs can be two magnitudes of activity lower than that of specific antibodies. These binding sites, though not as strong as antibodies, are still highly specific

that can be made easily and relatively cheaply. This yields a wide

variety of applications for MIPs from efficient extraction to

pharmaceutical/medical uses.

MIPs offer many advantages over protein binding sites. Proteins are

difficult and expensive to purify, denature (pH, heat, proteolysis), and

are difficult to immobilize for reuse. Synthetic polymers are cheap,

easy to synthesize, and allow for elaborate, synthetic side chains to be

incorporated. Unique side chains allow for higher affinity,

selectivity, and specificity.

Molecularly imprinted assays

Molecularly imprinted polymers arguably demonstrate their greatest

potential as alternative affinity reagents for use in diagnostic

applications, due to their comparable (and in some regards superior)

performance to antibodies. Many studies have therefore focused on the

development of molecularly imprinted assays (MIAs) since the seminal

work by Vlatakis et al. in 1993, where the term “molecularly imprinted

[sorbet] assay” was first introduced. Initial work on ligand binding

assays utilising MIPs in place of antibodies consisted of radio-labelled

MIAs, however the field has now evolved to include numerous assay

formats such as fluorescence MIAs, enzyme-linked MIAs, and molecularly

imprinted nanoparticle assay (MINA).

Molecularly imprinted polymers have also been used to enrich low abundant phosphopeptides from a cell lysate, outperforming titanium dioxide (TiO2) enrichment- a gold standard to enrich phosphopeptides.

History

In a paper published in 1931,

Polyakov reported the effects of presence of different solvents

(benzene, toluene and xylene) on the silica pore structure during drying

a newly prepared silica. When H2SO4 was used as

the polymerization initiator (acidifying agent), a positive correlation

was found between surface areas, e.g. load capacities, and the molecular

weights of the respective solvents. Later on, in 1949 Dickey reported

the polymerization of sodium silicate in the presence of four different

dyes (namely methyl, ethyl, n-propyl and n-butyl orange). The dyes were

subsequently removed, and in rebinding experiments it was found that

silica prepared in the presence of any of these "pattern molecules"

would bind the pattern molecule in preference to the other three dyes.

Shortly after this work had appeared, several research groups pursued

the preparation of specific adsorbents using Dickey's method. Some

commercial interest was also shown by the fact that Merck patented a

nicotine filter,

consisting of nicotine imprinted silica, able to adsorb 10.7% more

nicotine than non-imprinted silica. The material was intended for use in

cigarettes, cigars and pipes filters.

Shortly after this work had appeared, molecular imprinting attracted

wide interest from the scientific community as reflected in the 4000

original papers published in the field during for the period 1931–2009

(from Scifinder). However, although interest in the technique is new,

commonly the molecularly imprinted technique has been shown to be

effective when targeting small molecules of molecular weight less than 1000.

Therefore, in following subsection molecularly imprinted polymers are

reviewed into two categories, for small and big templates.

Production limitations

Production

of novel MIPs has implicit challenges unique to this field. These

challenges arise chiefly from the fact that all substrates are different

and thus require different monomer and cross-linker combinations to

adequately form imprinted polymers for that substrate. The first, and

lesser, challenge arises from choosing those monomers which will yield

adequate binding sites complementary to the functional groups of the

substrate molecule. For example, it would be unwise to choose completely

hydrophobic monomers to be imprinted with a highly hydrophilic

substrate. These considerations need to be taken into account before any

new MIP is created. Molecular modelling can be used to predict favourable interactions between templates and monomers, allowing intelligent monomer selection.

Secondly, and more troublesome, the yield of properly created

MIPs is limited by the capacity to effectively wash the substrate from

the MIP once the polymer has been formed around it.

In creating new MIPs, a compromise must be created between full removal

of the original template and damaging of the substrate binding cavity.

Such damage is generally caused by strong removal methods and includes

collapsing of the cavity, distorting the binding points, incomplete

removal of the template and rupture of the cavity.

Challenges of Template Removal for Molecular Imprinted Polymers

Template removal

Most

of the developments in MIP production during the last decade have come

in the form of new polymerization techniques in an attempt to control

the arrangement of monomers and therefore the polymers structure.

However, there have been very few advances in the efficient removal of

the template from the MIP once it has been polymerized. Due to this

neglect, the process of template removal is now the least cost efficient

and most time consuming process in MIP production.

Furthermore, in order of MIPs to reach their full potential in

analytical and biotechnological applications, an efficient removal

process must be demonstrated.

There are several different methods of extraction which are

currently being used for template removal. These have been grouped into 3

main categories: Solvent extraction, physically assisted extraction,

and subcritical or supercritical solvent extraction.

Solvent extraction

- Soxhlet extraction This has been a standard extraction method with organic solvents since its creation over a century ago. This technique consists of placing the MIP particles into a cartridge inside the extraction chamber, and the extraction solvent in poured into a flask connected to the extractor chamber. The solvent is then heated and condenses inside the cartridge thereby contacting the MIP particles and extracting the template. The main advantages to this technique are the repeated washing of MIP particles with fresh extracting solvent, favors solubilization because it uses hot solvent, no filtration is required upon completion to collect the MIP particles, the equipment is affordable, and it is very versatile and can be applied to nearly any polymer matrix. The main disadvantages are the long extraction time, the large amount of organic solvent used, the possibility or degradation for temperature sensitive polymers, the static nature of the technique does not facilitate solvent flow through MIP, and the automation is difficult.

- Incubation This involves the immersion of the MIPs into solvents that can induce swelling of the polymer network and simultaneously favor the dissociation of the template from the polymer. Generally this method is carried out under mild conditions and the stability of the polymer is not affected. However, much like the Soxhlet extraction technique, this method also is very time consuming.

- Solid-phase template As described above, one benefit of immobilising the template molecule on a solid support such as glass beads is the easy removal of the MIPs from the template. Following a cold wash to remove unreacted monomers and low-affinity polymers, hot solvent can be added to disrupt binding and allow the collection of high affinity MIPs.

Physically-assisted extraction

- Ultrasound-assisted extraction (UAE) This method uses Ultrasound which is a cyclic sound pressure with a frequency greater than 20 kHz. This method works through the process known as cavitation which forms small bubbles in liquids and the mechanical erosion of solid particles. This causes a local increase in temperature and pressure which favor solubility, diffusivity, penetration and transport of solvent and template molecules.

- Microwave-assisted extraction (MAE) This method uses microwaves which directly interact with the molecules causing Ionic conduction and dipole rotation. The use of microwaves for extraction make the extraction of the template occur rapidly, however, one must be careful to avoid excessively high temperatures if the polymers are heat sensitive. This has the best results when the technique is used in concert with strong organic acids, however, this poses another problem because it may cause partial MIP degradation as well. This method does have some benefits in that it significantly reduces the time required to extract the template, decreases the solvent costs, and is considered to be a clean technique.

- Mechanical method A study has shown that the microcontact molecular imprinting method allows mechanical removal of the target (large biomolecules, proteins etc.) from the template. This technology combined with biosensor applications is promising for biotechnological, environmental and medical applications.

Subcritical or supercritical solvent extraction

- Subcritical water (PHWE) This method employs the use of water, which is the cheapest and greenest solvent, under high temperatures (100–374 C) and pressures ( 10–60 bar). This method is based upon the high reduction in polarity that liquid water undergoes when heated to high temperatures. This allows water to solubilize a wide variety of polar, ionic and non-polar compounds. The decreased surface tension and viscosity under these conditions also favor diffusivity. Furthermore, the high thermal energy helps break intermolecular forces such as dipole-dipole interactions, vander Waals forces, and hydrogen bonding between the template and the matrix.

- Supercritical CO2 (SFE)