The launch of Apollo 10 on Saturn V AS-505, May 18, 1969

| |

| Function | |

|---|---|

| Manufacturer | |

| Country of origin | United States |

| Project cost | $6.417 billion in 1964–1973 dollars (~$42 billion in 2018 dollars) |

| Cost per launch | $185 million in 1969–1971 dollars ($1.16 billion in 2016 value), of which $110 million was for vehicle. |

| Size | |

| Height | 363.0 ft (110.6 m) |

| Diameter | 33.0 ft (10.1 m) |

| Mass | 6,540,000 lb (2,970,000 kg) |

| Stages | 3 |

| Capacity | |

| Payload to LEO (90 nmi (170 km), 30° inclination) | 310,000 lb (140,000 kg) |

| Payload to TLI | 107,100 lb (48,600 kg) |

| Associated rockets | |

| Family | Saturn |

| Derivatives | Saturn INT-21 |

| Comparable |

|

| Launch history | |

| Status | Retired |

| Launch sites | LC-39, Kennedy Space Center |

| Total launches | 13 |

| Successes | 12 |

| Failures | 0 |

| Partial failures | 1 (Apollo 6) |

| First flight | November 9, 1967 (AS-501 Apollo 4) |

| Last flight | May 14, 1973 (AS-513 Skylab 1) |

| First stage – S-IC | |

| Length | 138.0 ft (42.1 m) |

| Diameter | 33.0 ft (10.1 m) |

| Empty mass | 287,000 lb (130,000 kg) |

| Gross mass | 5,040,000 lb (2,290,000 kg) |

| Engines | 5 Rocketdyne F-1 |

| Thrust | 7,891,000 lbf (35,100 kN) sea level |

| Specific impulse | 263 seconds (2.58 km/s) sea level |

| Burn time | 168 seconds |

| Fuel | RP-1/LOX |

| Second stage – S-II | |

| Length | 81.5 ft (24.8 m) |

| Diameter | 33.0 ft (10.1 m) |

| Empty mass | 88,400 lb (40,100 kg) |

| Gross mass | 1,093,900 lb (496,200 kg) |

| Engines | 5 Rocketdyne J-2 |

| Thrust | 1,155,800 lbf (5,141 kN) vacuum |

| Specific impulse | 421 seconds (4.13 km/s) vacuum |

| Burn time | 360 seconds |

| Fuel | LH2/LOX |

| Third stage – S-IVB | |

| Length | 61.6 ft (18.8 m) |

| Diameter | 21.7 ft (6.6 m) |

| Empty mass | 29,700 lb (13,500 kg) |

| Gross mass | 271,000 lb (123,000 kg) |

| Engines | 1 Rocketdyne J-2 |

| Thrust | 225,000 lbf (1,000 kN) vacuum |

| Specific impulse | 421 seconds (4.13 km/s) vacuum |

| Burn time | 165 + 335 seconds (2 burns) |

| Fuel | LH2/LOX |

The Saturn V (pronounced "Saturn five") was an American human-rated expendable rocket used by NASA between 1967 and 1973. The three-stage liquid-propellant super heavy-lift launch vehicle was developed to support the Apollo program for human exploration of the Moon and was later used to launch Skylab, the first American space station.

The Saturn V was launched 13 times from the Kennedy Space Center in Florida with no loss of crew or payload. As of 2018, the Saturn V remains the tallest, heaviest, and most powerful (highest total impulse) rocket ever brought to operational status, and holds records for the heaviest payload launched and largest payload capacity to low Earth orbit (LEO) of 140,000 kg (310,000 lb), which included the third stage and unburned propellant needed to send the Apollo Command/Service Module and Lunar Module to the Moon.

The largest production model of the Saturn family of rockets, the Saturn V was designed under the direction of Wernher von Braun and Arthur Rudolph at the Marshall Space Flight Center in Huntsville, Alabama, with Boeing, North American Aviation, Douglas Aircraft Company, and IBM as the lead contractors.

To date, the Saturn V remains the only launch vehicle to carry humans beyond low Earth orbit. A total of 15 flight-capable vehicles were built, but only 13 were flown. An additional three vehicles were built for ground testing purposes. A total of 24 astronauts were launched to the Moon, three of them twice, in the four years spanning December 1968 through December 1972.

Historical background

The origins of the Saturn V rocket begin with the US government bringing Wernher von Braun along with about seven hundred German rocket engineers and technicians to the United States in Operation Paperclip,

a program authorized by President Truman in August 1946 with the

purpose of harvesting Germany's rocket expertise, to give the US an edge

in the Cold War through development of intermediate-range (IRBM) and intercontinental ballistic missiles (ICBM). It was known that America's rival, the Soviet Union, would also try to secure some of the Germans.

Von Braun was put into the rocket design division of the Army due to his prior direct involvement in the creation of the V-2 rocket. Between 1945 and 1958, his work was restricted to conveying the ideas and methods behind the V-2 to the American engineers.

Despite Von Braun's many articles on the future of space rocketry, the

US Government continued funding Air Force and Navy rocket programs to

test their Vanguard missiles in spite of numerous costly failures.

It was not until the 1957 Soviet launch of Sputnik 1 atop an R-7 ICBM, capable of carrying a thermonuclear warhead to the US, that the Army and the government started taking serious steps towards putting Americans in space. Finally, they turned to von Braun and his team, who during these years created and experimented with the Jupiter series of rockets.

The Juno I was the rocket that launched the first American satellite in January 1958, and part of the last-ditch plan for NACA (the predecessor of NASA) to get its foot in the Space Race. The Jupiter series was one more step in von Braun's journey to the Saturn V, later calling that first series "an infant Saturn".

Saturn development

The Saturn V's design stemmed from the designs of the Jupiter series

rockets. As the success of the Jupiter series became evident, the Saturn

series emerged.

C-1 to C-4

Between 1960 and 1962, the Marshall Space Flight Center (MSFC) designed a series of Saturn rockets that could be used for various Earth orbit or lunar missions.

The C-1 was developed into the Saturn I, and the C-2 rocket was dropped early in the design process in favor of the C-3, which was intended to use two F-1 engines on its first stage, four J-2 engines for its second stage, and an S-IV stage, using six RL10 engines.

NASA planned to use the C-3 as part of the Earth Orbit Rendezvous (EOR) concept, with at least four or five launches needed for a single lunar mission.

But MSFC was already planning an even bigger rocket, the C-4, which

would use four F-1 engines on its first stage, an enlarged C-3 second

stage, and the S-IVB, a stage with a single J-2 engine, as its third stage. The C-4 would need only two launches to carry out an EOR lunar mission.

C-5

On January 10,

1962, NASA announced plans to build the C-5. The three-stage rocket

would consist of: the S-IC first stage, with five F-1 engines; the S-II second stage, with five J-2 engines; and the S-IVB third stage, with a single J-2 engine. The C-5 was designed for a 90,000-pound (41,000 kg) payload capacity to the Moon.

The C-5 would undergo component testing even before the first

model was constructed. The S-IVB third stage would be used as the second

stage for the C-IB, which would serve both to demonstrate proof of

concept and feasibility for the C-5, but would also provide flight data

critical to development of the C-5.

Rather than undergoing testing for each major component, the C-5 would

be tested in an "all-up" fashion, meaning that the first test flight of

the rocket would include complete versions of all three stages. By

testing all components at once, far fewer test flights would be required

before a manned launch.

The C-5 was confirmed as NASA's choice for the Apollo program in early 1963, and was named the Saturn V. The C-1 became the Saturn I, and C-1B became Saturn IB. Von Braun headed a team at the Marshall Space Flight Center in building a vehicle capable of launching a manned spacecraft on a trajectory to the Moon.

Before they moved under NASA's jurisdiction, von Braun's team had

already begun work on improving the thrust, creating a less complex

operating system, and designing better mechanical systems.

It was during these revisions that the decision to reject the single

engine of the V-2's design came about, and the team moved to a

multiple-engine design. The Saturn I and IB reflected these changes, but

were not large enough to send a manned spacecraft to the Moon. These designs, however, provided a basis for which NASA could determine its best method towards landing a man on the Moon.

The Saturn V's final design had several key features. Engineers

determined that the best engines were the F-1s coupled with the new

liquid hydrogen propulsion system called J-2, which made the Saturn C-5

configuration optimal. By 1962, NASA had finalized its plans to proceed with von Braun's Saturn designs, and the Apollo space program gained speed.

With the configuration finalized, NASA turned its attention to mission profiles. Despite some controversy, a lunar orbit rendezvous for the lunar module was chosen over an Earth orbital rendezvous.

Issues such as type of fuel injections, the needed amount of fuel for

such a trip, and rocket manufacturing processes were ironed out, and the

designs for the Saturn V were selected. The stages were designed by von

Braun's Marshall Space Flight Center in Huntsville, and outside contractors were chosen for the construction: Boeing (S-IC), North American Aviation (S-II), Douglas Aircraft (S-IVB), and IBM (Instrument Unit).

Selection for Apollo lunar landing

Early in the planning process, NASA considered three leading ideas for the Moon mission: Earth Orbit Rendezvous, Direct Ascent, and Lunar Orbit Rendezvous

(LOR). A direct ascent configuration would require an extremely large

rocket to send a three-man spacecraft to land directly on the lunar

surface. Earth orbit rendezvous would launch the direct-landing

spacecraft in two smaller parts which would combine in Earth orbit. A

LOR mission would involve a single rocket launching two spacecraft: a

mother ship, and a smaller, two-man landing module which would

rendezvous back with the main spacecraft in lunar orbit. The lander

would be discarded and the mother ship would return home.

NASA at first dismissed LOR as a riskier option, given that a space rendezvous

had yet to be performed in Earth orbit, much less in lunar orbit.

Several NASA officials, including Langley Research Center engineer John Houbolt and NASA Administrator George Low,

argued that a Lunar Orbit Rendezvous provided the simplest landing on

the Moon with the most cost–efficient launch vehicle, and the best

chance to accomplish the lunar landing within the decade.

Other NASA officials were convinced, and LOR was officially selected as

the mission configuration for the Apollo program on November 7, 1962.

Technology

Saturn V diagram

The Saturn V's size and payload capacity dwarfed all other previous

rockets which had successfully flown at that time. With the Apollo

spacecraft on top, it stood 363 feet (111 m) tall, and without fins, it

was 33 feet (10 m) in diameter. Fully fueled, the Saturn V weighed 6.5

million pounds (2,950,000 kg) and had a low Earth orbit payload capacity originally estimated at 261,000 pounds (118,000 kg), but was designed to send at least 90,000 pounds (41,000 kg) to the Moon.

Later upgrades increased that capacity; during the final three

Apollo lunar missions it deployed about 310,000 pounds (140,000 kg) to LEO and sent up to 107,100 lb (48,600 kg) spacecraft to the Moon. At a height of 363 feet (111 m), the Saturn V was 58 feet (18 m) taller than the Statue of Liberty from the ground to the torch, and 48 feet (15 m) taller than the Big Ben clock tower.

In contrast, the Mercury-Redstone Launch Vehicle used on Freedom 7, the first manned American spaceflight, was just under 11 feet (3.4 m) longer than the S-IVB stage, and delivered less sea level thrust (78,000 pounds-force (350 kN)) than the Launch Escape System rocket (150,000 pounds-force (667 kN) sea level thrust) mounted atop the Apollo Command Module.

The Saturn V was principally designed by the Marshall Space Flight Center in Huntsville, Alabama, although numerous major systems, including propulsion, were designed by subcontractors. It used the powerful new F-1 and J-2 rocket engines for propulsion. When tested at Stennis Space Center, these engines shattered the windows of nearby houses. Designers decided early on to attempt to use as much technology from the Saturn I program as possible. Consequently, the S-IVB-500 third stage of the Saturn V was based on the S-IVB-200 second stage of the Saturn IB. The Instrument Unit that controlled the Saturn V shared characteristics with that carried by the Saturn IB.

Blueprints and other Saturn V plans are available on microfilm at the Marshall Space Flight Center.

Stages

The

Saturn V consisted of three stages—the S-IC first stage, S-II second

stage and the S-IVB third stage—and the instrument unit. All three

stages used liquid oxygen (LOX) as the oxidizer. The first stage used RP-1 for fuel, while the second and third stages used liquid hydrogen (LH2). The upper stages also used small solid-propellant ullage motors

that helped to separate the stages during the launch, and to ensure

that the liquid propellants were in a proper position to be drawn into

the pumps.

S-IC first stage

The S-IC was built by the Boeing Company at the Michoud Assembly Facility, New Orleans, where the Space Shuttle External Tanks would later be built by Lockheed Martin. Most of its mass at launch was propellant, RP-1 fuel with liquid oxygen as the oxidizer.

It was 138 feet (42 m) tall and 33 feet (10 m) in diameter, and

provided over 7,600,000 pounds-force (34,000 kN) of thrust. The S-IC

stage had a dry weight of about 289,000 pounds (131 metric tons) and

fully fueled at launch had a total weight of 5,100,000 pounds (2,300

metric tons). It was powered by five Rocketdyne F-1 engines arrayed in a quincunx

(five units, with four arranged in a square, and the fifth in the

center) The center engine was held in a fixed position, while the four

outer engines could be hydraulically turned (gimballed) to steer the rocket.

In flight, the center engine was turned off about 26 seconds earlier

than the outboard engines to limit acceleration. During launch, the S-IC

fired its engines for 168 seconds (ignition occurred about 8.9 seconds

before liftoff) and at engine cutoff, the vehicle was at an altitude of

about 36 nautical miles (67 km), was downrange about 50 nautical miles

(93 km), and was moving about 7,500 feet per second (2,300 m/s).

S-II second stage

An S-II stage hoisted onto the A-2 test stand at the Mississippi Test Facility

The S-II was built by North American Aviation at Seal Beach, California. Using liquid hydrogen and liquid oxygen, it had five Rocketdyne J-2

engines in a similar arrangement to the S-IC, also using the outer

engines for control. The S-II was 81.6 feet (24.87 m) tall with a

diameter of 33 feet (10 m), identical to the S-IC, and thus was the

largest cryogenic stage until the launch of the Space Shuttle

in 1981. The S-II had a dry weight of about 80,000 pounds (36,000 kg)

and fully fueled, weighed 1,060,000 pounds (480,000 kg). The second

stage accelerated the Saturn V through the upper atmosphere with

1,100,000 pounds-force (4,900 kN) of thrust in vacuum.

When loaded, significantly more than 90 percent of the mass of

the stage was propellant; however, the ultra-lightweight design had led

to two failures in structural testing. Instead of having an intertank

structure to separate the two fuel tanks as was done in the S-IC, the

S-II used a common bulkhead that was constructed from both the top of

the LOX tank and bottom of the LH2 tank. It consisted of two aluminum sheets separated by a honeycomb structure made of phenolic resin.

This bulkhead had to insulate against the 126 °F (70 °C) temperature

difference between the two tanks. The use of a common bulkhead saved

7,900 pounds (3.6 t). Like the S-IC, the S-II was transported from its

manufacturing plant to the Cape by sea.

S-IVB third stage

Cutaway drawing of the Saturn V S-IVB

The S-IVB was built by the Douglas Aircraft Company at Huntington Beach, California.

It had one J-2 engine and used the same fuel as the S-II. The S-IVB

used a common bulkhead to separate the two tanks. It was 58.6 feet

(17.86 m) tall with a diameter of 21.7 feet (6.604 m) and was also

designed with high mass efficiency, though not quite as aggressively as

the S-II. The S-IVB had a dry weight of about 23,000 pounds (10,000 kg)

and, fully fueled, weighed about 262,000 pounds (119,000 kg).

The S-IVB-500 model used on the Saturn V differed from the

S-IVB-200 used as the second stage of the Saturn IB, in that the engine

was restartable once per mission. This was necessary as the stage would

be used twice during a lunar mission: first in a 2.5 min burn for the

orbit insertion after second stage cutoff, and later for the trans-lunar injection

(TLI) burn, lasting about 6 min. Two liquid-fueled Auxiliary Propulsion

System (APS) units mounted at the aft end of the stage were used for

attitude control during the parking orbit and the trans-lunar phases of the mission. The two APSs were also used as ullage engines to settle the propellants in the aft tank engine feed lines prior to the trans-lunar injection burn.

The S-IVB was the only rocket stage of the Saturn V small enough to be transported by plane, in this case the Pregnant Guppy.

Instrument Unit

The Instrument Unit for the Apollo 4 Saturn V

The Instrument Unit was built by IBM

and rode atop the third stage. It was constructed at the Space Systems

Center in Huntsville, Alabama. This computer controlled the operations

of the rocket from just before liftoff until the S-IVB was discarded. It

included guidance and telemetry systems for the rocket. By measuring the acceleration and vehicle attitude, it could calculate the position and velocity of the rocket and correct for any deviations.

Range safety

In

the event of an abort requiring the destruction of the rocket, the

range safety officer would remotely shut down the engines and after

several seconds send another command for the shaped explosive charges

attached to the outer surfaces of the rocket to detonate. These would

make cuts in fuel and oxidizer tanks to disperse the fuel quickly and to

minimize mixing. The pause between these actions would give time for

the crew to escape using the Launch Escape Tower

or (in the later stages of the flight) the propulsion system of the

Service module. A third command, "safe", was used after the S-IVB stage

reached orbit to irreversibly deactivate the self-destruct system. The

system was also inactive as long as the rocket was still on the launch

pad.

Comparisons

Titan II

The Saturn V had a much lower thrust-to-weight ratio than Project Gemini's Titan II GLV. Richard F. Gordon, Jr. described Saturn as "an old man's ride", with "a lot more shake-rattle-and-roll" but milder thrust. Buzz Aldrin

and other Apollo 11 astronauts agreed that they could not tell when

Saturn liftoff occurred except from instruments, unlike on Titan.

Soviet N1-L3

A comparison of the U.S. Saturn V rocket with the Soviet N1-L3

The Soviet space program's counterpart to the Saturn V was Sergei Korolev's N1-L3. The Saturn V was taller, heavier, and had greater payload capacity, both to low Earth orbit and to translunar injection. The N-1 was a three-stage launch vehicle with more liftoff thrust and a larger first stage diameter than the Saturn V. It was to carry the 209,000 lb (95,000 kg) L3 vehicle into orbit.

The L3 contained an Earth departure stage, which would send to

the Moon a 51,800 lb (23,500 kg) package which contained another stage

for lunar orbit insertion and powered descent initiation, a single-cosmonaut lander, and a two-cosmonaut lunar orbiter for the return to Earth. The N1/L3 would have produced more total impulse

(product of thrust and time) in its first four stages than the

three-stage Saturn V, but it was not able to convert as much of this

into payload momentum (product of mass and velocity).

The N1 never became operational; four test launches each resulted

in catastrophic vehicle failure early in flight, and the program was

canceled. Korolev elected to cluster 30 relatively small engines for the

first stage, rather than develop a large engine like the Rocketdyne F-1.

The three-stage Saturn V grew over its lifetime to a peak thrust of at least 7,650,000 lbf (34,020 kN) (AS-510 and subsequent) and a lift capacity of 310,000 lb (140,000 kg) to LEO. The AS-510 mission (Apollo 15) had a liftoff thrust of 7,823,000 lbf (34,800 kN). The AS-513 mission (Skylab 1)

had slightly greater liftoff thrust of 7,891,000 lbf (35,100 kN). By

comparison, the N-1 had a sea-level liftoff thrust of about

10,200,000 lbf (45,400 kN). No other operational launch vehicle has ever surpassed the Saturn V in height, weight, total impulse, or payload capability. The closest contenders were the US Space Shuttle and the Soviet Energia.

|

|

Saturn V (Apollo 11) | N1-L3 |

|---|---|---|

| Diameter, maximum | 33 ft (10 m) | 56 ft (17 m) |

| Height w/ payload | 363 ft (111 m) | 344 ft (105 m) |

| Gross weight | 6,478,000 lb (2,938 t) | 6,030,000 lb (2,735 t) |

| First stage | S-IC | Block A |

| Thrust, SL | 7,500,000 lbf (33,000 kN) | 10,200,000 lbf (45,400 kN) |

| Burn time, s | 168 | 125 |

| Second stage | S-II | Block B |

| Thrust, vac | 1,155,800 lbf (5,141 kN) | 3,160,000 lbf (14,040 kN) |

| Burn time, s | 384 | 120 |

| Orbital insertion stage | S-IVB (burn 1) | Block V |

| Thrust, vac | 202,600 lbf (901 kN) | 360,000 lbf (1,610 kN) |

| Burn time, s | 147 | 370 |

| Total impulse | 1.7336×109 lbf (7.711×106 kN)·s | 1.789×109 lbf (7.956×106 kN)·s |

| Orbital payload | 264,900 lb (120.2 t) | 209,000 lb (95 t) |

| Injection velocity | 25,568 ft/s (7,793 m/s) | 25,570 ft/s (7,793 m/s) |

| Payload momentum | 2.105×108 slug-ft/s (9.363×108 kg·m/s) | 1.6644×108 slug-ft/s (7.403×108 kg·m/s) |

| Propulsive efficiency | 12.14% | 9.31% |

| Earth departure stage | S-IVB (burn 2) | Block G |

| Thrust, vac | 201,100 lbf (895 kN) | 100,000 lbf (446 kN) |

| Burn time, s | 347 | 443 |

| Total impulse | 1.8034×109 lbf (8.022×106 kN)·s | 1.833×109 lbf (8.153×106 kN)·s |

| Translunar payload | 100,740 lb (45.69 t) | 52,000 lb (23.5 t) |

| Injection velocity | 35,545 ft/s (10,834 m/s) | 35,540 ft/s (10,834 m/s) |

| Payload momentum | 1.1129×108 slug-ft/s (4.95×108 kg·m/s) | 5.724×107 slug-ft/s (2.546×108 kg·m/s) |

| Propulsive efficiency | 6.17% | 3.12% |

U.S. Space Shuttle

The Space Shuttle generated a peak thrust of 6,800,000 lb. (30,100 kN),

and payload capacity to LEO (excluding the Orbiter itself) was 63,500

pounds (28,800 kg), which was about 25 percent of the Saturn V's

payload. Total mass in orbit, including the Orbiter, was about

247,000 lb (112,000 kg), compared to the Apollo 15 total orbital mass of

the S-IVB third stage and Apollo spacecraft, of 309,771 lb

(140,510 kg), some 62,800 lb (28,500 kg) heavier than the Shuttle was rated to carry to LEO.

Soviet Energia/Buran

Energia had a liftoff thrust of 7,826,000 lbf (34,810 kN), and flew twice in 1987 and 1988, the second time as the launcher for the Buran shuttle.

However, both the Energia and Buran programs were cancelled in 1993.

Hypothetical future versions of Energia might have been significantly

more powerful than the Saturn V, delivering 10,000,000 lbf (46,000 kN)

of thrust and able to deliver up to 386,000 lb (175 t) to LEO in the

"Vulkan" configuration. Planned uprated versions of the Saturn V using F-1A engines would have had about 18 percent more thrust and 302,580 pounds (137,250 kg) payload. NASA contemplated building larger members of the Saturn family, such as the Saturn C-8, and also unrelated rockets, such as Nova, but these were never produced.

Other vehicles

Some other recent US launch vehicles have significantly lower launch capacity to LEO than Saturn V: the US Delta 4 Heavy capacity is 63,470 lb (28,790 kg), the Atlas V 551 has a capacity of 41,478 lb (18,814 kg), and the SpaceX Falcon Heavy has a capacity of 140,700 lb (63,800 kg). The European Ariane 5 ES delivers up to 46,000 lb (21,000 kg) and the Russian Proton-M can launch 49,000 lb (22,000 kg).

Space Launch System

NASA's Space Launch System,

planned for its first flight in 2020, in its final configuration is

planned to be 400 feet (120 m) tall with payload, and lift up to 290,000

pounds (130,000 kg) into low Earth orbit.

S-IC thrust comparisons

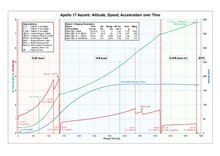

Apollo 17 ascent flight parameters

Because of its large size, attention is often focused on the S-IC

thrust and how this compares to other large rockets. However, several

factors make such comparisons more complex than first appears:

- Commonly referenced thrust numbers are a specification, not an actual measurement. Individual stages and engines may fall short or exceed the specification, sometimes significantly.

- The F-1 thrust specification was uprated beginning with Apollo 15 (SA-510) from 1,500,000 lbf (6,670 kN) to 1,520,000 lbf (6,770 kN), yielding 7,610,000 lbf (33,850 kN) for the S-IC stage. The higher thrust was achieved via a redesign of the injector orifices and a slightly higher propellant mass flow rate. However, comparing the specified number to the actual measured thrust of 7,800,000 lbf (34,800 kN) on Apollo 15 shows a significant difference.

- There is no way to directly measure thrust of a rocket in flight; Rather, a mathematical calculation is made from combustion chamber pressure, turbopump speed, calculated propellant density and flow rate, nozzle design, and atmospheric pressure.

- Thrust varies greatly with external pressure and thus with altitude, even for a non-throttled engine. For example, on Apollo 15, the calculated total liftoff thrust (based on actual measurements) was about 7,830,000 lbf (34,810 kN), which increased to 9,200,000 lbf (40,800 kN) at T+135 seconds, just before center engine cutoff (CECO), at which time the jet was heavily underexpanded.

- Thrust specifications are often given as vacuum thrust (for upper stages) or sea level thrust (for lower stages or boosters), sometimes without qualifying which one. This can lead to incorrect comparisons.

- Thrust specifications are often given as average thrust or peak thrust, sometimes without qualifying which one. Even for a non-throttled engine at a fixed altitude, thrust can often vary somewhat over the firing period due to several factors. These include intentional or unintentional mixture ratio changes, slight propellant density changes over the firing period, and variations in turbopump, nozzle and injector performance over the firing period.

Without knowing the exact measurement technique and mathematical

method used to determine thrust for each different rocket, comparisons

are often inexact. As the above shows, the specified thrust often

differs significantly from actual flight thrust calculated from direct

measurements. The thrust stated in various references is often not

adequately qualified as to vacuum vs sea level, or peak vs average

thrust.

Similarly, payload increases are often achieved in later missions

independent of engine thrust. This is by weight reduction or trajectory

reshaping.

The result is there is no single absolute figure for engine

thrust, stage thrust or vehicle payload. There are specified values and

actual flight values, and various ways of measuring and deriving those

actual flight values.

The performance of each Saturn V launch was extensively analyzed

and a Launch Evaluation Report produced for each mission, including a

thrust/time graph for each vehicle stage on each mission.

Assembly

The Apollo 10 Saturn V during rollout

After the construction and ground testing of a stage was completed,

it was then shipped to the Kennedy Space Center. The first two stages

were so large that the only way to transport them was by barge. The

S-IC, constructed in New Orleans, was transported down the Mississippi River to the Gulf of Mexico.

After rounding Florida, it was then transported up the Intra-Coastal Waterway to the Vehicle Assembly Building

(originally called the Vertical Assembly Building). This was

essentially the same route which would be used later by NASA to ship

Space Shuttle External Tanks. The S-II was constructed in California and thus traveled to Florida via the Panama Canal. The third stage and Instrument Unit could be carried by the Aero Spacelines Pregnant Guppy and Super Guppy, but could also have been carried by barge if warranted.

On arrival at the Vertical Assembly Building, each stage was

inspected in a horizontal position before being moved to a vertical

position. NASA also constructed large spool-shaped structures that could

be used in place of stages if a particular stage was late. These spools

had the same height and mass and contained the same electrical

connections as the actual stages.

NASA stacked or assembled the Saturn V on a Mobile Launcher Platform

(MLP), which consisted of a Launch Umbilical Tower (LUT) with nine

swing arms (including the crew access arm), a "hammerhead" crane, and a

water suppression system which was activated prior to launch. After

assembly was completed, the entire stack was moved from the VAB to the

launch pad using the Crawler Transporter (CT). Built by the Marion Power Shovel

company (and later used for transporting the smaller and lighter Space

Shuttle), the CT ran on four double-tracked treads, each with 57

'shoes'. Each shoe weighed 2,000 pounds (910 kg). This transporter was

also required to keep the rocket level as it traveled the 3 miles

(4.8 km) to the launch site, especially at the 3 percent grade encountered at the launch pad. The CT also carried the Mobile Service Structure

(MSS), which allowed technicians access to the rocket until eight hours

before launch, when it was moved to the "halfway" point on the

Crawlerway (the junction between the VAB and the two launch pads).

Lunar mission launch sequence

Liftoff of Apollo 11, the first mission to land humans on the Moon, July 16, 1969

Apollo 11 launch pad filmed at 500 fps.

The Saturn V carried all Apollo lunar missions. All Saturn V missions were launched from Launch Complex 39 at the John F. Kennedy Space Center in Florida. After the rocket cleared the launch tower, flight control transferred to Johnson Space Center's Mission Control in Houston, Texas.

An average mission used the rocket for a total of just 20 minutes. Although Apollo 6 experienced three engine failures, and Apollo 13 one engine shutdown,

the onboard computers were able to compensate by burning the remaining

engines longer to achieve parking orbit. None of the Saturn V launches

resulted in a payload loss.

S-IC sequence

A condensation cloud surrounds the Apollo 11 Saturn V as it works its way through the dense lower atmosphere.

The first stage burned for about 2 minutes and 41 seconds, lifting

the rocket to an altitude of 42 miles (68 km) and a speed of 6,164 miles

per hour (2,756 m/s) and burning 4,700,000 pounds (2,100,000 kg) of

propellant.

At 8.9 seconds before launch, the first stage ignition sequence

started. The center engine ignited first, followed by opposing outboard

pairs at 300-millisecond intervals to reduce the structural loads on the

rocket. When thrust had been confirmed by the onboard computers, the

rocket was "soft-released" in two stages: first, the hold-down arms

released the rocket, and second, as the rocket began to accelerate

upwards, it was slowed by tapered metal pins pulled through dies for

half a second.

Once the rocket had lifted off, it could not safely settle back

down onto the pad if the engines failed. The astronauts considered this

one of the tensest moments in riding the Saturn V, for if the

rocket did fail to lift off after release they had a low chance of

survival given the large amounts of propellant. A fully fueled Saturn V

exploding on the pad would have released the energy equivalent of two

kilotons of TNT. To improve safety, the Saturn Emergency Detection

System (EDS) inhibited engine shutdown for the first 30 seconds of

flight.

It took about 12 seconds for the rocket to clear the tower. During this time, it yawed

1.25 degrees away from the tower to ensure adequate clearance despite

adverse winds. (This yaw, although small, can be seen in launch photos

taken from the east or west.) At an altitude of 430 feet (130 m) the

rocket rolled to the correct flight azimuth and then gradually pitched

down until 38 seconds after second stage ignition. This pitch program

was set according to the prevailing winds during the launch month.

The four outboard engines also tilted toward the outside so that

in the event of a premature outboard engine shutdown the remaining

engines would thrust through the rocket's center of mass.

The Saturn V reached 400 feet per second (120 m/s) at over 1 mile

(1,600 m) in altitude. Much of the early portion of the flight was spent

gaining altitude, with the required velocity coming later. The Saturn V

broke the sound barrier at just over 1 minute at an altitude of between

3 and 4 nautical miles (5.5 to 7.4 kilometers). At this point, shock

collars, or condensation clouds, could be seen forming around the bottom

of the command module and around the top of the second stage.

Apollo 11 S-IC separation

At about 80 seconds, the rocket experienced maximum dynamic pressure (max Q). The dynamic pressure on a rocket varies with air density

and the square of relative velocity. Although velocity continues to

increase, air density decreases so quickly with altitude that dynamic

pressure falls below max Q.

Acceleration increased during S-IC flight for three reasons. One,

increased acceleration increased the propellant pressure at the

engines, increasing the flow rate somewhat. This was the least important

factor, though this feedback effect often led to an undesirable thrust

oscillation called pogo.

Two, as it climbed into thinner air F-1 engine efficiency increased

significantly, a property of all rockets. The combined thrust of five

engines on the pad was about 7.5 million pounds, reaching nearly 9

million pounds at altitude. But the biggest contribution by far was the

rocket's rapidly decreasing mass.

The propellant in just the S-IC made up about three-quarters of

Saturn V's entire launch mass, and it was furiously consumed at over 13

metric tonnes per second. Newton's second law states that force is equal

to mass multiplied by acceleration, or equivalently that acceleration

is equal to force divided by mass, so as the mass decreased (and the

force increased somewhat), acceleration rose. Including gravity, launch

acceleration was only 1¼ g,

i.e., the astronauts felt 1¼ g while the rocket accelerated vertically

at ¼ g. As the rocket rapidly lost mass, total acceleration including

gravity increased to nearly 4 g at T+135 seconds. At this point, the

inboard (center) engine was shut down to prevent acceleration from

increasing beyond 4 g.

When oxidizer or fuel depletion was sensed in the suction

assemblies, the remaining four outboard engines were shut down. First

stage separation occurred a little less than one second after this to

allow for F-1 thrust tail-off. Eight small solid fuel separation motors

backed the S-IC from the rest of the vehicle at an altitude of about 36

nautical miles (67 km). The first stage continued ballistically to an

altitude of about 59 nautical miles (109 km) and then fell in the

Atlantic Ocean about 300 nautical miles (560 km) downrange.

The engine shutdown procedure was changed for the launch of Skylab to avoid damage to the Apollo Telescope Mount.

Rather than shutting down all four outboard engines at once, they were

shut down two at a time with a delay to reduce peak acceleration

further.

S-II sequence

Still from film footage of Apollo 6's interstage falling away

After S-IC separation, the S-II second stage burned for 6 minutes and

propelled the craft to 109 miles (175 km) and 15,647 mph (6,995 m/s),

close to orbital velocity.

For the first two unmanned launches, eight solid-fuel ullage motors

ignited for four seconds to give positive acceleration to the S-II

stage, followed by start of the five J-2 engines. For the first seven

manned Apollo missions only four ullage motors were used on the S-II,

and they were eliminated completely for the final four launches. About

30 seconds after first stage separation, the interstage ring dropped

from the second stage. This was done with an inertially fixed attitude

so that the interstage, only 1 meter from the outboard J-2 engines,

would fall cleanly without hitting them, as the interstage could have

potentially damaged two of the J-2 engines if it was attached to the

S-IC. Shortly after interstage separation the Launch Escape System was also jettisoned. See Apollo abort modes for more information about the various abort modes that could have been used during a launch.

Apollo 6 interstage falling away. The engine exhaust from the S-II stage glows as it impacts the interstage.

About 38 seconds after the second stage ignition the Saturn V

switched from a preprogrammed trajectory to a "closed loop" or Iterative

Guidance Mode. The Instrument Unit now computed in real time the most

fuel-efficient trajectory toward its target orbit. If the Instrument

Unit failed, the crew could switch control of the Saturn to the Command

Module's computer, take manual control, or abort the flight.

About 90 seconds before the second stage cutoff, the center engine shut down to reduce longitudinal pogo oscillations.

At around this time, the LOX flow rate decreased, changing the mix

ratio of the two propellants, ensuring that there would be as little

propellant as possible left in the tanks at the end of second stage

flight. This was done at a predetermined delta-v.

Five level sensors in the bottom of each S-II propellant tank

were armed during S-II flight, allowing any two to trigger S-II cutoff

and staging when they were uncovered. One second after the second stage

cut off it separated and several seconds later the third stage ignited.

Solid fuel retro-rockets mounted on the interstage at the top of the

S-II fired to back it away from the S-IVB. The S-II impacted about 2,300 nautical miles (4,200 km) from the launch site.

On the Apollo 13

mission, the inboard engine suffered from major pogo oscillation,

resulting in an early automatic cutoff. To ensure sufficient velocity

was reached, the remaining four engines were kept active for longer than

planned. A pogo suppressor was fitted to later Apollo missions to avoid

this, though the early engine 5 cutoff remained to reduce g-forces.

S-IVB sequence

Unlike

the two-plane separation of the S-IC and S-II, the S-II and S-IVB

stages separated with a single step. Although it was constructed as part

of the third stage, the interstage remained attached to the second

stage.

During Apollo 11,

a typical lunar mission, the third stage burned for about 2.5 minutes

until first cutoff at 11 minutes 40 seconds. At this point it was 1,430

nautical miles (2,650 km) downrange and in a parking orbit at an

altitude of 103.2 nautical miles (191.1 km) and velocity of 17,432 mph

(7,793 m/s). The third stage remained attached to the spacecraft while

it orbited the Earth one and a half times while astronauts and mission controllers prepared for translunar injection (TLI).

Apollo 17 S-IVB rocket stage, shortly after transposition and docking with the Lunar Module

This parking orbit was quite low by Earth orbit standards, and it

would have been short-lived due to aerodynamic drag. This was not a

problem on a lunar mission because of the short stay in the parking

orbit. The S-IVB also continued to thrust at a low level by venting

gaseous hydrogen, to keep propellants settled in their tanks and prevent

gaseous cavities from forming in propellant feed lines. This venting

also maintained safe pressures as liquid hydrogen boiled off in the fuel

tank. This venting thrust easily exceeded aerodynamic drag.

For the final three Apollo flights, the temporary parking orbit

was even lower (approximately 93 nautical miles (172 km)), to increase

payload for these missions. The Apollo 9

Earth orbit mission was launched into the nominal orbit consistent with

Apollo 11, but the spacecraft were able to use their own engines to

raise the perigee high enough to sustain the 10-day mission. The Skylab

was launched into a quite different orbit, with a 234-nautical-mile

(434 km) perigee which sustained it for six years, and also a higher

inclination to the equator (50 degrees versus 32.5 degrees for Apollo).

On Apollo 11, TLI came at 2 hours and 44 minutes after launch.

The S-IVB burned for almost six minutes giving the spacecraft a velocity

close to the Earth's escape velocity of 25,053 mph (11,200 m/s). This

gave an energy-efficient transfer to lunar orbit, with the Moon helping

to capture the spacecraft with a minimum of CSM fuel consumption.

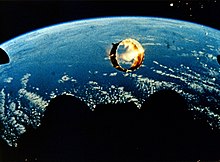

About 40 minutes after TLI the Apollo Command Service Module (CSM) separated from the third stage, turned 180 degrees and docked with the Lunar Module

(LM) that rode below the CSM during launch. The CSM and LM separated

from the spent third stage 50 minutes later. This process is known as Transposition, docking, and extraction.

If it were to remain on the same trajectory as the spacecraft,

the S-IVB could have presented a collision hazard so its remaining

propellants were vented and the auxiliary propulsion system fired to

move it away. For lunar missions before Apollo 13, the S-IVB was directed toward the Moon's trailing edge in its orbit so that the moon would slingshot it beyond earth escape velocity and into solar orbit. From Apollo 13 onwards, controllers directed the S-IVB to hit the Moon. Seismometers left behind by previous missions detected the impacts, and the information helped map the interior structure of the Moon.

On September 3, 2002, astronomer Bill Yeung discovered a suspected asteroid, which was given the discovery designation J002E3. It appeared to be in orbit around the Earth, and was soon discovered from spectral analysis to be covered in white titanium dioxide,

which was a major constituent of the paint used on the Saturn V.

Calculation of orbital parameters led to tentative identification as

being the Apollo 12 S-IVB stage.

Mission controllers had planned to send Apollo 12's S-IVB into solar

orbit after separating from the Apollo spacecraft, but it is believed

the burn lasted too long, and hence did not send it close enough to the

Moon, remaining in a barely stable orbit around the Earth and Moon. In

1971, through a series of gravitational perturbations, it is believed to

have entered in a solar orbit and then returned into weakly captured

Earth orbit 31 years later. It left Earth orbit again in June 2003.

Skylab

The last Saturn V launch carried the Skylab space station to low Earth orbit in place of the third stage

In 1965, the Apollo Applications Program

(AAP) was created to look into science missions that could be performed

using Apollo hardware. Much of the planning centered on the idea of a

space station. Wernher von Braun's earlier (1964) plans employed a "wet workshop" concept, with a spent S-II Saturn V second stage being launched into orbit and outfitted in space. The next year AAP studied a smaller station using an S-IVB Saturn 1B

second stage. By 1969, Apollo funding cuts eliminated the possibility

of procuring more Apollo hardware, and in fact forced the cancellation

of some later Moon landing flights. This freed up at least one Saturn V,

allowing the wet workshop to be replaced with the "dry workshop"

concept: the station (now known as Skylab) would be built on the ground from a surplus Saturn IB second stage and launched atop the first two live stages of a Saturn V. A backup station, constructed from a Saturn V third stage, was built and is now on display at the National Air and Space Museum.

Skylab was the only launch not directly related to the Apollo

lunar landing program. The only significant changes to the Saturn V from

the Apollo configurations involved some modification to the S-II

to act as the terminal stage for inserting the Skylab payload into

Earth orbit, and to vent excess propellant after engine cutoff so the

spent stage would not rupture in orbit. The S-II remained in orbit for

almost two years, and made an uncontrolled re-entry on January 11, 1975.

Three crews lived aboard Skylab from May 25, 1973 to February 8, 1974, with Skylab remaining in orbit until July 11, 1979.

Proposed post-Apollo developments

The Saturn-Shuttle concept

After Apollo, the Saturn V was planned to be the prime launch vehicle for Prospector intended to land a 330-kilogram (730 lb) robotic rover on the Moon, similar to the Soviet Lunokhod, and the Voyager Mars probes, as well a scaled-up version of the Voyager interplanetary probes. It was also to have been the launch vehicle for the nuclear rocket stage RIFT test program and the later NERVA.[52] All of these planned uses of the Saturn V were cancelled, with cost being a major factor. Edgar Cortright, who had been director of NASA Langley,

stated decades later that "JPL never liked the big approach. They

always argued against it. I probably was the leading proponent in using

the Saturn V, and I lost. Probably very wise that I lost."

The canceled second production run of Saturn Vs would very likely have used the F-1A engine in its first stage, providing a substantial performance boost.

Other likely changes would have been the removal of the fins (which

turned out to provide little benefit when compared to their weight); a

stretched S-IC first stage to support the more powerful F-1As; and uprated J-2s or an M-1 for the upper stages.

A number of alternate Saturn vehicles were proposed based on the Saturn V, ranging from the Saturn INT-20 with an S-IVB stage and interstage mounted directly onto an S-IC stage, through to the Saturn V-23(L) which would not only have five F-1 engines in the first stage, but also four strap-on boosters with two F-1 engines each: giving a total of thirteen F-1 engines firing at launch.

The Space Shuttle was initially conceived as a cargo transport to be used in concert with the Saturn V, even to the point that a Saturn-Shuttle was proposed, using the winged shuttle orbiter and external tank,

but with the tank mounted on a modified, fly-back version of the S-IC.

The first S-IC stage would be used to power the Shuttle during the first

two minutes of flight, after which the S-IC would be jettisoned (which

would then fly back to KSC for refurbishment) and the Space Shuttle Main Engines would then fire and place the orbiter into orbit. The Shuttle would handle space station logistics, while Saturn V would launch components.

Lack of a second Saturn V production run killed this plan and left the United States without a heavy-lift launch vehicle. Some in the U.S. space community came to lament this situation, as continued production would have allowed the International Space Station, using a Skylab or Mir configuration with both U.S. and Russian docking ports, to have been lifted with just a handful of launches. The Saturn-Shuttle concept also would have eliminated the Space Shuttle Solid Rocket Boosters that ultimately precipitated the Challenger accident in 1986.

Cost

From 1964 until 1973, $6.417 billion (equivalent to $33 billion in 2016) in total was appropriated for the R&D and flights of the Saturn V, with the maximum being in 1966 with $1.2 billion (equivalent to $6.95 billion in 2016). That same year, NASA received its biggest budget of $4.5 billion, about 0.5 percent of the gross domestic product (GDP) of the United States at that time.

One of the main reasons for the cancellation of the last three

Apollo flights was the cost. In the time frame from 1969 to 1971 the

cost of launching a Saturn V Apollo mission was

$185,000,000–$189,000,000, of which $110 million was for the production of the vehicle (equivalent to $566 million in 2016).

Saturn V vehicles and launches

All Saturn V launches, 1967–1973

| Serial number |

Mission | Launch date |

Pad | Notes |

|---|---|---|---|---|

| SA-500F | Facilities integration | Used to check precise fits and test facilities operation on Pad 39A before a flight model was ready. First stage scrapped, second stage converted to S-II-F/D, third stage on display at Kennedy Space Center. | ||

| SA-500D | Dynamic testing | Used to evaluate the vehicle's response to vibrations. On display at the U.S. Space & Rocket Center, Huntsville, Alabama | ||

| S-IC-T | All Systems Test | First stage used for static test firing at Marshall Space Flight Center. On display at Kennedy Space Center. | ||

| SA-501 | Apollo 4 | November 9, 1967 | 39A | First unmanned, all-up test flight; complete success. |

| SA-502 | Apollo 6 | April 4, 1968 | 39A | Second unmanned test flight; J-2 engine problems caused early shutdown of two engines in second stage, and prevented third stage restart. |

| SA-503 | Apollo 8 | December 21, 1968 | 39A | First manned flight; first translunar injection of Apollo Command/Service Module |

| SA-504 | Apollo 9 | March 3, 1969 | 39A | Manned low Earth orbit test of complete Apollo spacecraft with LM |

| SA-505 | Apollo 10 | May 18, 1969 | 39B | Second manned translunar injection of complete Apollo spacecraft with LM |

| SA-506 | Apollo 11 | July 16, 1969 | 39A | First manned lunar landing, at Sea of Tranquility |

| SA-507 | Apollo 12 | November 14, 1969 | 39A | Vehicle was struck twice by lightning shortly after liftoff, no serious damage. Precision manned lunar landing, near Surveyor 3 at Ocean of Storms. |

| SA-508 | Apollo 13 | April 11, 1970 | 39A | Severe pogo oscillations in second stage caused early center engine shutdown; guidance compensated by burning remaining engines longer. Third manned lunar landing mission was aborted by Service Module failure. |

| SA-509 | Apollo 14 | January 31, 1971 | 39A | Third manned lunar landing, near Fra Mauro, Apollo 13's intended landing site. |

| SA-510 | Apollo 15 | July 26, 1971 | 39A | Fourth manned lunar landing, at Hadley–Apennine. First extended Apollo mission, carrying lunar orbital Scientific Instrument Module and Lunar Roving Vehicle. |

| SA-511 | Apollo 16 | April 16, 1972 | 39A | Fifth manned lunar landing, at Descartes Highlands. |

| SA-512 | Apollo 17 | December 7, 1972 | 39A | Only night launch. Sixth and final manned lunar landing, at Taurus–Littrow. |

| SA-513 | Skylab 1 | May 14, 1973 | 39A | Unmanned launch of the Skylab orbital workshop, which replaced the third stage, S-IVB-513, on display at Johnson Space Center. Originally designated for canceled Apollo 18. |

| SA-514 | Unused | Originally designated for canceled Apollo 19; never used. First stage (S-IC-14) on display at Johnson Space Center, second and third stage (S-II-14, S-IV-14) on display at Kennedy Space Center. | ||

| SA-515 | Unused | Originally designated for Apollo 20, later as a backup Skylab launch vehicle; never used. The first stage was on display at Michoud Assembly Facility, until June 2016 then was moved to the INFINITY Science Center in Mississippi. The second stage (S-II-15) is on display at Johnson Space Center. The third stage was converted to a backup Skylab orbital workshop and is on display at the National Air and Space Museum. | ||

Proposed successors

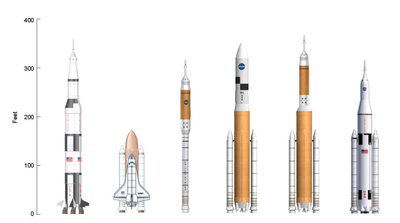

Comparison of maximum payload to low Earth orbit (LEO) (Left to right). Space Shuttle payload includes 7 crew and cargo. Ares I payload includes 4 crew and inherent craft. Saturn V payload includes 3 crew, inherent craft and cargo. Ares V payload includes only cargo and inherent craft. The Saturn V was capable of lifting approximately 140 metric tons of payload to LEO. The Ares V was being designed to lift 188 metric tons to LEO.

U.S. proposals for a rocket larger than the Saturn V from the late 1950s through the early 1980s were generally called Nova. Over thirty different large rocket proposals carried the Nova name, but none was developed.

Wernher von Braun and others also had plans for a rocket that would have featured eight F-1 engines in its first stage, like the Saturn C-8, allowing a direct ascent flight to the Moon. Other plans for the Saturn V called for using a Centaur as an upper stage or adding strap-on boosters. These enhancements would have enabled the launch of large robotic spacecraft to the outer planets or send astronauts to Mars. Other Saturn-V derivatives analyzed included the Saturn MLV

family of "Modified Launch Vehicles", which would have almost doubled

the payload lift capability of the standard Saturn V and were intended

for use in a proposed mission to Mars by 1980.

In 1968, Boeing studied another Saturn-V derivative, the Saturn C-5N, which included a nuclear thermal rocket engine for the third stage of the vehicle. The Saturn C-5N would carry a considerably greater payload to interplanetary destinations. Work on the nuclear engines, along with all Saturn V ELVs, was ended in 1973.

The 2009 test flight of the prototype Ares I-X launch vehicle, a component of the Constellation Program that was cancelled in 2010

In 2006, as part of the proposed Constellation Program, NASA unveiled plans to construct two Shuttle Derived Launch Vehicles, the Ares I and Ares V,

which would use some existing Space Shuttle and Saturn V hardware and

infrastructure. The two rockets were intended to increase safety by specializing each vehicle for different tasks, Ares I for crew launches and Ares V for cargo launches.

The original design of the heavy-lift Ares V, named in homage to the

Saturn V, was 360 ft (110 m) in height and featured a core stage based

on the Space Shuttle External Tank, with a diameter of 28 ft (8.4 m). It

was to be powered by five Space Shuttle Main Engines (SSMEs) and two five-segment Space Shuttle Solid Rocket Boosters (SRBs). As the design evolved, the SSMEs were replaced with five RS-68 engines, the same engines used on the Delta IV.

The switch from the SSME to the RS-68 was intended to reduce cost, the

RS-68 being cheaper, simpler to manufacture, and more powerful than the

SSME, though the lower efficiency

of the RS-68 required an increase in core stage diameter to 33 ft

(10 m), the same diameter as the Saturn V's S-IC and S-II stages.

Comparison of Saturn V, Shuttle, Ares I, Ares V, Ares IV, and SLS Block I

In 2008, NASA again redesigned the Ares V, lengthening the core

stage, adding a sixth RS-68 engine, and increasing the SRBs to 5.5

segments each. This vehicle would have been 381 ft (116 m) tall and would have produced a total thrust of approximately 8,900,000 lbf (40 MN) at liftoff, more than the Saturn V or the Soviet Energia, but less than the Soviet N-1. Projected to place approximately 180 metric tons into orbit, the Ares V would have surpassed the Saturn V in payload capability. An upper stage, the Earth Departure Stage, would have utilized a more advanced version of the J-2 engine, the J-2X. Ares V would have placed the Altair lunar landing vehicle into low Earth orbit. An Orion

crew vehicle launched on Ares I would have docked with Altair, and the

Earth Departure Stage would then send the combined stack to the Moon.

After the cancellation of the Constellation Program – and hence Ares I and Ares V – NASA announced the Space Launch System (SLS) heavy-lift launch vehicle for deep-space exploration.[64]

The SLS, similar to the original Ares V concept, will be powered by

four SSMEs and two five-segment SRBs. Its Block I configuration will

lift approximately 70 metric tons to low Earth orbit. Block IB will add a second stage, the Exploration Upper Stage, powered by four RL10

engines, to increase payload to LEO and deep space. An eventual Block

II variant will upgrade to advanced boosters, increasing LEO payload to

at least 130 metric tons.

One proposal for advanced boosters would use a derivative of the Saturn V's F-1, the F-1B, and increase SLS payload to around 150 metric tons to LEO. The F-1B is to have better specific impulse

and be cheaper than the F-1, with a simplified combustion chamber and

fewer engine parts, while producing 1,800,000 lbf (8.0 MN) of thrust at

sea level, an increase over the approximate 1,550,000 lbf (6.9 MN)

achieved by the mature Apollo 15 F-1 engine.

NASA SLS deputy project manager Jody Singer of the Marshall Space

Flight Center in Huntsville, in 2012 stated that the vehicle will have a

launch cost of approximately $500 million per launch, with a relatively

minor dependence of costs on launch capability.

Saturn V displays

- Two at the U.S. Space & Rocket Center in Huntsville:

- SA-500D is on horizontal display made up of S-IC-D, S-II-F/D and S-IVB-D. These were all test stages not meant for flight. This vehicle was displayed outdoors from 1969 to 2007, was restored, and is now displayed in the Davidson Center for Space Exploration.

- Vertical display (replica) built in 1999 located in an adjacent area.

- One at the Johnson Space Center made up of first stage from SA-514, the second stage from SA-515 and the third stage from SA-513 (replaced for flight by the Skylab workshop). With stages arriving between 1977 and 1979, this was displayed in the open until its 2005 restoration when a structure was built around it for protection. This is the only display Saturn consisting entirely of stages intended to be launched.

- One at the Kennedy Space Center Visitor Complex, made up of S-IC-T (test stage) and the second and third stages from SA-514. It was displayed outdoors for decades, then in 1996 was enclosed for protection from the elements in the Apollo/Saturn V Center.

- The S-IC stage from SA-515 is on display at the Infinity Science Center in Mississippi.

- The S-IVB stage from SA-515 was converted for use as a backup for Skylab, and is on display at the National Air and Space Museum in Washington, D.C..

Media

Launch of Apollo 15: T-30s through T+40s.

Saturn V in fiction

Film footage of the Saturn V appears in the Star Trek TV episode "Assignment: Earth",

originally broadcast on March 29, 1968. Saturn V and the Apollo program

are not mentioned by name, but the rocket was used as a stand-in for

the launching of a fictional "orbital nuclear warhead platform by the United States, countering a similar launch by other powers." Pre-launch footage comes from the unflown SA-500F Facilities Integration Vehicle (the only Saturn V with "USA" markings on the third stage) and Apollo 6 (the only Saturn V launched with a white service module), while launch footage comes from Apollo 4 (as the episode aired six days prior to the launch of Apollo 6, the second Saturn V launch.)