Latex being collected from a tapped rubber tree, Cameroon

Rubber tree plantation in Thailand

Natural rubber, also called India rubber or caoutchouc, as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds, plus water. Malaysia and Indonesia are two of the leading rubber producers. Forms of polyisoprene that are used as natural rubbers are classified as elastomers.

Currently, rubber is harvested mainly in the form of the latex from the rubber tree or others. The latex is a sticky, milky colloid

drawn off by making incisions in the bark and collecting the fluid in

vessels in a process called "tapping". The latex then is refined into

rubber ready for commercial processing. In major areas, latex is

allowed to coagulate in the collection cup. The coagulated lumps are

collected and processed into dry forms for marketing.

Natural rubber is used extensively in many applications and

products, either alone or in combination with other materials. In most

of its useful forms, it has a large stretch ratio and high resilience, and is extremely waterproof.

Varieties

Hevea brasiliensis

The major commercial source of natural rubber latex is the Pará rubber tree (Hevea brasiliensis), a member of the spurge family, Euphorbiaceae.

This species is preferred because it grows well under cultivation. A

properly managed tree responds to wounding by producing more latex for

several years.

Congo rubber

Congo rubber, formerly a major source of rubber, came from vines in the genus Landolphia (L. kirkii, L. heudelotis, and L. owariensis).

Dandelion

Dandelion milk contains latex. The latex exhibits the same quality as the natural rubber from rubber trees. In the wild types of dandelion, latex content is low and varies greatly. In Nazi Germany, research projects tried to use dandelions as a base for rubber production, but failed. In 2013, by inhibiting one key enzyme and using modern cultivation methods and optimization techniques, scientists in the Fraunhofer Institute for Molecular Biology and Applied Ecology (IME) in Germany developed a cultivar that is suitable for commercial production of natural rubber. In collaboration with Continental Tires, IME began a pilot facility.

Other

Many other

plants produce forms of latex rich in isoprene polymers, though not all

produce usable forms of polymer as easily as the Pará. Some of them

require more elaborate processing to produce anything like usable

rubber, and most are more difficult to tap. Some produce other desirable

materials, for example gutta-percha (Palaquium gutta) and chicle from Manilkara species. Others that have been commercially exploited, or at least showed promise as rubber sources, include the rubber fig (Ficus elastica), Panama rubber tree (Castilla elastica), various spurges (Euphorbia spp.), lettuce (Lactuca species), the related Scorzonera tau-saghyz, various Taraxacum species, including common dandelion (Taraxacum officinale) and Russian dandelion (Taraxacum kok-saghyz), and perhaps most importantly for its hypoallergenic properties, guayule (Parthenium argentatum). The term gum rubber is sometimes applied to the tree-obtained version of natural rubber in order to distinguish it from the synthetic version.

History

The first use of rubber was by the indigenous cultures of Mesoamerica. The earliest archeological evidence of the use of natural latex from the Hevea tree comes from the Olmec culture, in which rubber was first used for making balls for the Mesoamerican ballgame. Rubber was later used by the Maya and Aztec

cultures – in addition to making balls Aztecs used rubber for other

purposes such as making containers and to make textiles waterproof by

impregnating them with the latex sap.

The Pará rubber tree is indigenous to South America. Charles Marie de La Condamine is credited with introducing samples of rubber to the Académie Royale des Sciences of France in 1736. In 1751, he presented a paper by François Fresneau

to the Académie (published in 1755) that described many of rubber's

properties. This has been referred to as the first scientific paper on

rubber. In England, Joseph Priestley, in 1770, observed that a piece of the material was extremely good for rubbing off pencil marks on paper, hence the name "rubber". It slowly made its way around England. In 1764 François Fresnau discovered that turpentine was a rubber solvent. Giovanni Fabbroni is credited with the discovery of naphtha as a rubber solvent in 1779.

South America remained the main source of the limited amounts of

latex rubber used during much of the 19th century. The trade was heavily

protected and exporting seeds from Brazil was a capital offense, although no law prohibited it. Nevertheless, in 1876, Henry Wickham smuggled 70,000 Pará rubber tree seeds from Brazil and delivered them to Kew Gardens, England. Only 2,400 of these germinated. Seedlings were then sent to India, British Ceylon (Sri Lanka), Dutch East Indies (Indonesia), Singapore, and British Malaya. Malaya (now Peninsular Malaysia) was later to become the biggest producer of rubber.

In the early 1900s, the Congo Free State in Africa was also a significant source of natural rubber latex, mostly gathered by forced labor.

King Leopold II's colonial state brutally enforced production quotas.

Tactics to enforce the rubber quotas included removing the hands of

victims to prove they had been killed. Soldiers often came back from

raids with baskets full of chopped-off hands. Villages that resisted

were razed to encourage better compliance locally. Liberia and Nigeria started production.

In India,

commercial cultivation was introduced by British planters, although the

experimental efforts to grow rubber on a commercial scale were

initiated as early as 1873 at the Calcutta Botanical Gardens. The first commercial Hevea plantations were established at Thattekadu in Kerala in 1902. In later years the plantation expanded to Karnataka, Tamil Nadu and the Andaman and Nicobar Islands of India. India today is the world's 3rd largest producer and 4th largest consumer.

In Singapore and Malaya, commercial production was heavily promoted by Sir Henry Nicholas Ridley, who served as the first Scientific Director of the Singapore Botanic Gardens

from 1888 to 1911. He distributed rubber seeds to many planters and

developed the first technique for tapping trees for latex without

causing serious harm to the tree. Because of his fervent promotion of this crop, he is popularly remembered by the nickname "Mad Ridley".

Pre-World War II

Charles Goodyear developed vulcanization in 1839, although Mesoamericans used stabilized rubber for balls and other objects as early as 1600 BC.

Before World War II significant uses included door and window profiles, hoses, belts, gaskets, matting, flooring and dampeners (antivibration mounts) for the automotive industry. The use of rubber in car tires (initially solid rather than pneumatic) in particular consumed a significant amount of rubber. Gloves (medical, household and industrial) and toy balloons

were large consumers of rubber, although the type of rubber used is

concentrated latex. Significant tonnage of rubber was used as adhesives

in many manufacturing industries and products, although the two most

noticeable were the paper and the carpet industries. Rubber was commonly

used to make rubber bands and pencil erasers.

Rubber produced as a fiber, sometimes called 'elastic', had

significant value to the textile industry because of its excellent

elongation and recovery properties. For these purposes, manufactured

rubber fiber was made as either an extruded round fiber or rectangular

fibers cut into strips from extruded film. Because of its low dye

acceptance, feel and appearance, the rubber fiber was either covered by

yarn of another fiber or directly woven with other yarns into the

fabric. Rubber yarns were used in foundation garments. While rubber is

still used in textile manufacturing, its low tenacity limits its use in

lightweight garments because latex lacks resistance to oxidizing agents

and is damaged by aging, sunlight, oil and perspiration. The textile

industry turned to neoprene (polymer of chloroprene), a type of synthetic rubber, as well as another more commonly used elastomer fiber, spandex (also known as elastane), because of their superiority to rubber in both strength and durability.

Properties

Rubber latex

Rubber exhibits unique physical and chemical properties. Rubber's stress–strain behavior exhibits the Mullins effect and the Payne effect and is often modeled as hyperelastic. Rubber strain crystallizes.

Due to the presence of weakened allylic C-H bonds in each repeat unit, natural rubber is susceptible to vulcanisation as well as being sensitive to ozone cracking.

The two main solvents for rubber are turpentine and naphtha (petroleum). Because rubber does not dissolve easily, the material is finely divided by shredding prior to its immersion.

An ammonia solution can be used to prevent the coagulation of raw latex.

Rubber begins to melt at approximately 180 °C (356 °F).

Elasticity

On a microscopic scale, relaxed rubber is a disorganized cluster of

erratically changing wrinkled chains. In stretched rubber, the chains

are almost linear. The restoring force is due to the preponderance of

wrinkled conformations over more linear ones. For the quantitative

treatment see ideal chain, for more examples see entropic force.

Cooling below the glass transition temperature

permits local conformational changes but a reordering is practically

impossible because of the larger energy barrier for the concerted

movement of longer chains. "Frozen" rubber's elasticity is low and strain results from small changes of bond lengths and angles: this caused the Challenger disaster, when the American Space Shuttle's flattened o-rings failed to relax to fill a widening gap. The glass transition is fast and reversible: the force resumes on heating.

The parallel chains of stretched rubber are susceptible to

crystallization. This takes some time because turns of twisted chains

have to move out of the way of the growing crystallites. Crystallization

has occurred, for example, when, after days, an inflated toy balloon is

found withered at a relatively large remaining volume. Where it is

touched, it shrinks because the temperature of the hand is enough to

melt the crystals.

Vulcanization of rubber creates di- and polysulfide bonds between chains, which limits the degrees of freedom

and results in chains that tighten more quickly for a given strain,

thereby increasing the elastic force constant and making the rubber

harder and less extensible.

Malodour

Raw

rubber storage depots and rubber processing can produce malodour that is

serious enough to become a source of complaints and protest to those

living in the vicinity.

Microbial impurities originate during the processing of block

rubber. These impurities break down during storage or thermal

degradation and produce volatile organic compounds. Examination of these

compounds using gas chromatography/mass spectrometry (GC/MS) and gas chromatography (GC) indicates that they contain sulphur, ammonia, alkenes, ketones, esters, hydrogen sulphite, nitrogen, and low molecular weight fatty acids (C2-C5).

When latex concentrate is produced from rubber, sulphuric acid is

used for coagulation. This produces malodourous hydrogen sulphide.

The industry can mitigate these bad odours with scrubber systems.

Chemical makeup

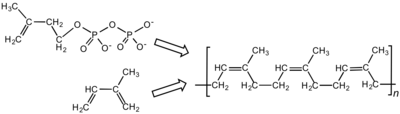

Chemical

structure of cis-polyisoprene, the main constituent of natural rubber.

Synthetic cis-polyisoprene and natural cis-polyisoprene are derived from

different precursors, isopentenyl pyrophosphate and isoprene.

Latex is the polymer cis-1,4-polyisoprene – with a molecular weight of 100,000 to 1,000,000 daltons. Typically, a small percentage (up to 5% of dry mass) of other materials, such as proteins, fatty acids, resins,

and inorganic materials (salts) are found in natural rubber.

Polyisoprene can also be created synthetically, producing what is

sometimes referred to as "synthetic natural rubber", but the synthetic

and natural routes are different. Some natural rubber sources, such as gutta-percha, are composed of trans-1,4-polyisoprene, a structural isomer that has similar properties.

Natural rubber is an elastomer and a thermoplastic. Once the rubber is vulcanized, it is a thermoset.

Most rubber in everyday use is vulcanized to a point where it shares

properties of both; i.e., if it is heated and cooled, it is degraded but

not destroyed.

The final properties of a rubber item depend not just on the polymer, but also on modifiers and fillers, such as carbon black, factice, whiting and others.

Biosynthesis

Rubber particles are formed in the cytoplasm of specialized latex-producing cells called laticifers within rubber plants. Rubber particles are surrounded by a single phospholipid membrane with hydrophobic

tails pointed inward. The membrane allows biosynthetic proteins to be

sequestered at the surface of the growing rubber particle, which allows

new monomeric units to be added from outside the biomembrane, but within

the lacticifer. The rubber particle is an enzymatically active entity

that contains three layers of material, the rubber particle, a

biomembrane and free monomeric units. The biomembrane is held tightly to

the rubber core due to the high negative charge along the double bonds

of the rubber polymer backbone. Free monomeric units and conjugated proteins make up the outer layer. The rubber precursor is isopentenyl pyrophosphate (an allylic compound), which elongates by Mg2+-dependent condensation by the action of rubber transferase. The monomer adds to the pyrophosphate end of the growing polymer.

The process displaces the terminal high-energy pyrophosphate. The

reaction produces a cis polymer. The initiation step is catalyzed by prenyltransferase, which converts three monomers of isopentenyl pyrophosphate into farnesyl pyrophosphate. The farnesyl pyrophosphate can bind to rubber transferase to elongate a new rubber polymer.

The required isopentenyl pyrophosphate is obtained from the mevalonate pathway, which derives from acetyl-CoA in the cytosol.

In plants, isoprene pyrophosphate can also be obtained from the

1-deox-D-xyulose-5-phosphate/2-C-methyl-D-erythritol-4-phosphate pathway

within plasmids.

The relative ratio of the farnesyl pyrophosphate initiator unit and

isoprenyl pyrophosphate elongation monomer determines the rate of new

particle synthesis versus elongation of existing particles. Though

rubber is known to be produced by only one enzyme, extracts of latex

host numerous small molecular weight proteins with unknown function. The

proteins possibly serve as cofactors, as the synthetic rate decreases

with complete removal.

Production

Rubber

is generally cultivated in large plantations. The image shows a coconut

shell used in collecting latex, in plantations in Kerala, India.

Close to 28 million tons of rubber were produced in 2013, of which

approximately 44% was natural. Since the bulk is synthetic, which is

derived from petroleum, the price of natural rubber is determined, to a

large extent, by the prevailing global price of crude oil. Asia was the main source of natural rubber, accounting for about 94% of output in 2005. The three largest producers, Thailand, Indonesia (2.4 million tons)

and Malaysia, together account for around 72% of all natural rubber

production. Natural rubber is not cultivated widely in its native

continent of South America due to the existence of South American leaf blight, and other natural predators.

Cultivation

Rubber

latex is extracted from rubber trees. The economic life period of

rubber trees in plantations is around 32 years — up to 7 years of

immature phase and about 25 years of productive phase.

The soil requirement is well-drained, weathered soil consisting of laterite, lateritic types, sedimentary types, nonlateritic red or alluvial soils.

The climatic conditions for optimum growth of rubber trees are:

- Rainfall of around 250 centimeters (98 in) evenly distributed without any marked dry season and with at least 100 rainy days per year

- Temperature range of about 20 to 34 °C, with a monthly mean of 25 to 28 °C

- Atmospheric humidity of around 80%

- About 2000 hours sunshine per year at the rate of six hours per day throughout the year

- Absence of strong winds

Many high-yielding clones have been developed for commercial

planting. These clones yield more than 2,000 kg of dry rubber per

hectare per year, under ideal conditions.

Collection

A woman in Sri Lanka harvesting rubber, circa 1920

In places such as Kerala and Sri Lanka where coconuts are in

abundance, the half shell of coconut was used as the latex collection

container. Glazed pottery or aluminium or plastic cups became more

common in Kerala and other countries. The cups are supported by a wire

that encircles the tree. This wire incorporates a spring so it can

stretch as the tree grows. The latex is led into the cup by a galvanised

"spout" knocked into the bark. Tapping normally takes place early in

the morning, when the internal pressure of the tree is highest. A good

tapper can tap a tree every 20 seconds on a standard half-spiral system,

and a common daily "task" size is between 450 and 650 trees. Trees are

usually tapped on alternate or third days, although many variations in

timing, length and number of cuts are used. "Tappers would make a slash

in the bark with a small hatchet. These slanting cuts allowed latex to

flow from ducts located on the exterior or the inner layer of bark

(cambium) of the tree. Since the cambium controls the growth of the

tree, growth stops if it is cut. Thus, rubber tapping demanded accuracy,

so that the incisions would not be too many given the size of the tree,

or too deep, which could stunt its growth or kill it."

It is usual to tap a pannel at least twice, sometimes three

times, during the tree's life. The economic life of the tree depends on

how well the tapping is carried out, as the critical factor is bark

consumption. A standard in Malaysia for alternate daily tapping is 25 cm

(vertical) bark consumption per year. The latex-containing tubes in the

bark ascend in a spiral to the right. For this reason, tapping cuts

usually ascend to the left to cut more tubes.

The trees drip latex for about four hours, stopping as latex

coagulates naturally on the tapping cut, thus blocking the latex tubes

in the bark. Tappers usually rest and have a meal after finishing their

tapping work, then start collecting the liquid "field latex" at about

midday.

Field coagula

Mixed field coagula.

Smallholder's lump at a remilling factory

The four types of field coagula are "cuplump", "treelace",

"smallholders' lump" and "earth scrap". Each has significantly different

properties.

Some trees continue to drip after the collection leading to a small

amount of "cup lump" that is collected at the next tapping. The latex

that coagulates on the cut is also collected as "tree lace". Tree lace

and cup lump together account for 10–20% of the dry rubber produced.

Latex that drips onto the ground, "earth scrap", is also collected

periodically for processing of low-grade product.

Cup lump

Cup

lump is the coagulated material found in the collection cup when the

tapper next visits the tree to tap it again. It arises from latex

clinging to the walls of the cup after the latex was last poured into

the bucket, and from late-dripping latex exuded before the

latex-carrying vessels of the tree become blocked. It is of higher

purity and of greater value than the other three types.

Tree lace

Tree

lace is the coagulum strip that the tapper peels off the previous cut

before making a new cut. It usually has higher copper and manganese

contents than cup lump. Both copper and manganese are pro-oxidants and

can damage the physical properties of the dry rubber.

Smallholders' lump

Smallholders'

lump is produced by smallholders who collect rubber from trees far from

the nearest factory. Many Indonesian smallholders, who farm paddies in

remote areas, tap dispersed trees on their way to work in the paddy

fields and collect the latex (or the coagulated latex) on their way

home. As it is often impossible to preserve the latex sufficiently to

get it to a factory that processes latex in time for it to be used to

make high quality products, and as the latex would anyway have

coagulated by the time it reached the factory, the smallholder will

coagulate it by any means available, in any container available. Some

smallholders use small containers, buckets etc., but often the latex is

coagulated in holes in the ground, which are usually lined with plastic

sheeting. Acidic materials and fermented fruit juices are used to

coagulate the latex — a form of assisted biological coagulation. Little

care is taken to exclude twigs, leaves, and even bark from the lumps

that are formed, which may also include tree lace.

Earth scrap

Earth

scrap is material that gathers around the base of the tree. It arises

from latex overflowing from the cut and running down the bark, from rain

flooding a collection cup containing latex, and from spillage from

tappers' buckets during collection. It contains soil and other

contaminants, and has variable rubber content, depending on the amount

of contaminants. Earth scrap is collected by field workers two or three

times a year and may be cleaned in a scrap-washer to recover the rubber,

or sold to a contractor who cleans it and recovers the rubber. It is of

low quality.

Processing

Removing coagulum from coagulating troughs.

Latex coagulates in the cups if kept for long and must be collected

before this happens. The collected latex, "field latex", is transferred

into coagulation tanks for the preparation of dry rubber or transferred

into air-tight containers with sieving for ammoniation. Ammoniation

preserves the latex in a colloidal state for longer periods of time.

Latex is generally processed into either latex concentrate for

manufacture of dipped goods or coagulated under controlled, clean

conditions using formic acid. The coagulated latex can then be processed

into the higher-grade, technically specified block rubbers such as SVR

3L or SVR CV or used to produce Ribbed Smoke Sheet grades.

Naturally coagulated rubber (cup lump) is used in the manufacture

of TSR10 and TSR20 grade rubbers. Processing for these grades is a size

reduction and cleaning process to remove contamination and prepare the

material for the final stage of drying.

The dried material is then baled and palletized for storage and shipment.

Vulcanized rubber

Torn latex rubber dry suit wrist seal

Natural rubber is often vulcanized, a process by which the rubber is heated and sulfur, peroxide or bisphenol are added to improve resistance and elasticity and to prevent it from perishing. Carbon black

is often used as an additive to rubber to improve its strength,

especially in vehicle tires, which account for about 70% (~9 million

tons) of carbon black production.

Transportation

Natural

rubber latex is shipped from factories in south-west Asia, South

America, and West and Center Africa to destinations around the world. As

the cost of natural rubber has risen significantly and rubber products

are dense, the shipping methods offering the lowest cost per unit weight

are preferred. Depending on destination, warehouse availability, and

transportation conditions, some methods are preferred by certain buyers.

In international trade, latex rubber is mostly shipped in 20-foot ocean

containers. Inside the container, smaller containers are used to store

the latex.

Uses

Compression molded (cured) rubber boots before the flashes are removed

Uncured rubber is used for cements; for adhesive, insulating, and friction tapes; and for crepe rubber used in insulating blankets and footwear. Vulcanized rubber

has many more applications. Resistance to abrasion makes softer kinds

of rubber valuable for the treads of vehicle tires and conveyor belts,

and makes hard rubber valuable for pump housings and piping used in the

handling of abrasive sludge.

The flexibility of rubber is appealing in hoses, tires and

rollers for devices ranging from domestic clothes wringers to printing

presses; its elasticity makes it suitable for various kinds of shock

absorbers and for specialized machinery mountings designed to reduce

vibration. Its relative gas impermeability makes it useful in the

manufacture of articles such as air hoses, balloons, balls and cushions.

The resistance of rubber to water and to the action of most fluid

chemicals has led to its use in rainwear, diving gear, and chemical and

medicinal tubing, and as a lining for storage tanks, processing

equipment and railroad tank cars. Because of their electrical

resistance, soft rubber goods are used as insulation and for protective

gloves, shoes and blankets; hard rubber is used for articles such as

telephone housings, parts for radio sets, meters and other electrical

instruments. The coefficient of friction of rubber, which is high on dry

surfaces and low on wet surfaces, leads to its use for

power-transmission belting and for water-lubricated bearings in

deep-well pumps. Indian rubber balls or lacrosse balls are made of rubber.

Around 25 million tonnes of rubber are produced each year, of which 30 percent is natural.

The remainder is synthetic rubber derived from petrochemical sources.

The top end of latex production results in latex products such as

surgeons' gloves, condoms, balloons and other relatively high-value

products. The mid-range which comes from the technically specified

natural rubber materials ends up largely in tires but also in conveyor

belts, marine products, windshield wipers and miscellaneous goods.

Natural rubber offers good elasticity, while synthetic materials tend to

offer better resistance to environmental factors such as oils,

temperature, chemicals and ultraviolet light. "Cured rubber" is rubber

that has been compounded and subjected to the vulcanisation process to

create cross-links within the rubber matrix.

Allergic reactions

Some people have a serious latex allergy, and exposure to natural latex rubber products such as latex gloves can cause anaphylactic shock. The antigenic proteins found in Hevea latex may be deliberately reduced (though not eliminated) through processing.

Latex from non-Hevea sources, such as Guayule, can be used without allergic reaction by persons with an allergy to Hevea latex.

Some allergic reactions are not to the latex itself, but from

residues of chemicals used to accelerate the cross-linking process.

Although this may be confused with an allergy to latex, it is distinct

from it, typically taking the form of Type IV hypersensitivity in the presence of traces of specific processing chemicals.

Microbial degradation

Natural rubber is susceptible to degradation by a wide range of bacteria.

The bacteria Streptomyces coelicolor, Pseudomonas citronellolis, and Nocardia spp. are capable of degrading vulcanized natural rubber.