|

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

2-Chlorobuta-1,3-diene

| |||

| Other names

Chloroprene, 2-chloro-1,3-butadiene, Chlorobutadiene, β-Chloroprene

| |||

| Identifiers | |||

3D model (JSmol)

|

|||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

| ECHA InfoCard | 100.004.381 | ||

| KEGG | |||

PubChem CID

|

|||

| RTECS number |

| ||

CompTox Dashboard (EPA)

|

|||

| Properties | |||

| C4H5Cl | |||

| Molar mass | 88.5365 g/mol | ||

| Appearance | Colorless liquid | ||

| Odor | pungent, ether-like | ||

| Density | 0.9598 g/cm3 | ||

| Melting point | −130 °C (−202 °F; 143 K) | ||

| Boiling point | 59.4 °C (138.9 °F; 332.5 K) | ||

| 0.026 g/100 mL | |||

| Solubility | soluble in alcohol, diethyl ether miscible in ethyl ether, acetone, benzene | ||

| Vapor pressure | 188 mmHg (20 °C) | ||

Refractive index (nD)

|

1.4583 | ||

| Hazards | |||

| Main hazards | Highly flammable, irritant, toxic. | ||

| R-phrases (outdated) | R45, R11, R20/22, R36/37/38, R48/20 | ||

| S-phrases (outdated) | S53, S45 | ||

| NFPA 704 (fire diamond) | |||

| Flash point | −15.6 °C (3.9 °F; 257.5 K) | ||

| Explosive limits | 1.9%–11.3% | ||

| Lethal dose or concentration (LD, LC): | |||

LD50 (median dose)

|

450 mg/kg (rat, oral) | ||

LC50 (median concentration)

|

3207 ppm (rat, 4 hr) | ||

LCLo (lowest published)

|

1052 ppm (rabbit, 8 hr) 350 ppm (cat, 8 hr) | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible)

|

TWA 25 ppm (90 mg/m3) [skin] | ||

REL (Recommended)

|

Ca C 1 ppm (3.6 mg/m3) [15-minute] | ||

IDLH (Immediate danger)

|

300 ppm | ||

| Related compounds | |||

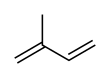

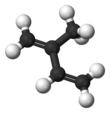

Related Dienes

|

Butadiene Isoprene | ||

Related compounds

|

Vinyl chloride | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

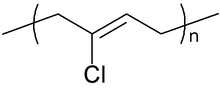

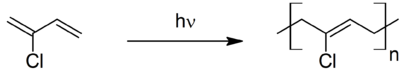

Chloroprene is the common name for 2-chlorobuta-1,3-diene (IUPAC name) with the chemical formula CH2=CCl−CH=CH2. Chloroprene is a colorless volatile liquid, almost exclusively used as a monomer for the production of the polymer polychloroprene, a type of synthetic rubber. Polychloroprene is better known as Neoprene, the trade name given by DuPont.

History

Although

it may have been discovered earlier, the chemistry of chloroprene was

largely developed by DuPont during the early 1930s, specifically with

the formation of neoprene in mind. The chemists Elmer K. Bolton, Wallace Carothers, Arnold Collins and Ira Williams are generally accredited with its development and commercialisation although the work was based upon that of Julius Arthur Nieuwland, with whom they collaborated.

Production

Chloroprene is produced in three steps from 1,3-butadiene: (i) chlorination, (ii) isomerization of part of the product stream, and (iii) dehydrochlorination of 3,4-dichlorobut-1-ene.

Chlorine

adds to 1,3-butadiene to afford a mixture of 3,4-dichlorobut-1-ene and

1,4-dichlorobut-2-ene. The 1,4-dichloro isomer is subsequently

isomerized to 3,4 isomer, which in turn is treated with base to induce

dehydrochlorination to 2-chlorobuta-1,3-diene. This dehydrohalogenation

entails loss of a hydrogen atom

in the 3 position and the chlorine atom in the 4 position thereby

forming a double bond between carbons 3 and 4. In 1983, approximately

2,000,000 kg was produced in this manner. The chief impurity in chloroprene prepared in this way is

1-chlorobuta-1,3-diene, which is usually separated by distillation.

Acetylene process

Until

the 1960s, chloroprene production was dominated by the "acetylene

process," which was modeled after the original synthesis of vinylacetylene. In this process, acetylene is dimerized to give vinyl acetylene, which is then combined with hydrogen chloride to afford 4-chloro-1,2-butadiene (an allene derivative), which in the presence of copper(I) chloride, rearranges to the targeted 2-chlorobuta-1,3-diene.

This process is energy-intensive and has high investment costs.

Furthermore, the intermediate vinyl acetylene is unstable. This

"acetylene process" has been replaced by a process, which adds Cl2 to one of the double bonds in 1,3-butadiene, and subsequent elimination produces HCl instead, as well as chloroprene.

Regulations

Transportation

Transportation of uninhibited chloroprene has been banned in the United States by the US Department of Transportation. Stabilized chloroprene is in hazard class 3 (flammable liquid). Its UN number is 1991 and is in packing group 1.

Occupational health and safety

Hazards

GHS hazard pictograms

that apply to chloroprene. From left: flammability; carcinogenicity,

mutagenicity, reproductive toxicity, respiratory sensitization, target

organ toxicity, or aspiration toxicity; irritant (skin and eye), skin

sensitizer, respiratory tract irritant, hazardous to ozone layer, may

have narcotic effects; aquatic toxicity; and acute toxicity (fatal or

toxic).

As a way to visually communicate hazards associated with chloroprene exposure, the United Nations Globally Harmonized System of Classification and Labeling of Chemicals

(GHS) has designated the following hazards for exposure to chloroprene:

flammable, toxic, dangerous to the environment, health hazard and

irritant. Chloroprene poses fire hazard (flash point -4 °F).

OSHA identifies chloroprene as a category 2 flammable liquid and

emphasizes that at least one portable fire extinguisher should be within

10 and no more than 25 feet away from the flammable liquid storage

area.

OSHA provides resources on addressing flammable liquids at industrial

plants which is where the likely exposure to chloroprene exists (see

external resources). As a vapor, chloroprene is heavier than air.

According to the National Fire Protection Association's

rating system, chloroprene is designated with a category 2 health

hazard (temporary incapacitation or residual injury), a category 3 fire

hazard (ignition under the presence of moderate heat), and a category 1

reactivity (unstable at high temperatures and pressures).

Chronic exposure to chloroprene may have the following symptoms:

liver function abnormalities, disorders of the cardiovascular system,

and depression of the immune system.

The Environmental Protection Agency(EPA)

designated chloroprene as likely to be carcinogenic to humans based on

evidence from studies that showed a statistically significant

association between occupational chloroprene exposure and the risk of

lung cancer.

As early as 1975, NIOSH had identified the potential health hazards of

chloroprene in their bulletin primarily citing two Russian cohort

studies from those working with chloroprene in an occupational setting.

Hazard determination

OSHA

defines hazard determination as "the process of evaluating available

scientific evidence in order to determine if a chemical is hazardous

pursuant to the HCS." While chemical manufacturers and importers are

required to conduct a hazard determination, other companies may

voluntarily conduct a hazard determination to ensure worker health and

safety. Under the hazard determination framework, any chemical that has a

physical or health hazard is considered a hazardous chemical. Physical

hazards include fire hazards, reactive hazards, and explosion hazards.

Heath hazards include systemic effects and target organ effects.

Chloroprene is on OSHA's list for substances that are regulated as toxic

and hazardous.

In the European Union, the hazard-determination-equivalent is the

Registration, Evaluation, Authorization, and Restriction of Chemicals

(REACH) regulation enacted on June 1, 2007 by the European Chemicals

Agency (ECHA). The goal of REACH is to "improve the protection of human

health and the environment from the risks that can be posed by

chemicals, while enhancing the competitiveness of the EU chemicals

industry." If risks of chemicals are unmanageable, ECHA may ban its use.

Hazard controls

Several epidemiological studies and toxicological reports provide

evidence of chloroprene's capability to inflict occupational health and

safety concerns. However, varying reviews of the degree to which

chloroprene should be held responsible for health concerns highlight the

criticality of sound scientific research.

Nonetheless, health and safety practices should always be implemented

in the workplace. Some of these occupational concerns include: cleaning

equipment or unclogging pipes coated with chloroprene, inhaling

chloroprene off-gas, chloroprene spontaneously reacting with other

chemicals and chloroprene inducing a workplace fire. Upon the clogging

of equipment associated with occupational chloroprene use, employers

should ensure that their employees are wearing the proper PPE and set up

administrative controls so that skin exposure to and inhalation of

chloroprene is avoided.

Only one fatality as a result of chloroprene intoxication has been

recorded which was a result of cleaning a container used for

chloroprene.

NIOSH Hierarchy of Controls

The primary occupational concern for chloroprene is limited to the

facilities producing chloroprene and using chloroprene to produce the

synthetic rubber, polychloroprene.

NIOSH developed a list of actions to address specific workplace

hazards. These actions are represented in their diagram of the "Hierarchy of Controls" shown below with the most effective steps at the top and the least effective at the bottom.

The high vaporization potential and flammability of chloroprene

has significant implications for handling and storage operations in the

occupational setting. Chloroprene should be stored in closed containers

in a cool, well-ventilated area with the temperature no higher than 50

degrees Fahrenheit. In addition, chloroprene has a high reactivity and

should be stored away from oxidizing agents such as perchlorate,

peroxides, permanganates, chlorates, nitrates, chlorine, bromine, and

fluorine. All activities inducing a potential fire hazard should be

avoided. For instance, smoking, having open flames or using sparking

tools to open or close storage containers should be prohibited. It is

also advised that grounded and bonded metal containers are used for the

transport of chloroprene.

Occupational exposure limits

The

official legal body that develops and enforces occupational exposure

limits (OEL) in order to ensure workplace safety and health regulations

is the Occupational Health and Safety Administration (OSHA) that works

under the U.S. Department of Labor.

OSHA's permissible exposure limits (PELs), a guideline for occupational

exposures, were adopted from the 1968 threshold limit values (TLVs) of

the American Conference of Governmental Industrial Hygienists (ACGIH). Each year, the ACGIH publish their TLV and BEI booklet

that provides updated information on "occupational exposure guidelines

for more than 700 chemical substances and physical agents."

The scientific literature on certain chemical and physical exposures

has evolved since 1968, therefore OSHA recognizes that their PELs may

not guarantee worker health and safety. The National Institute for Occupational Health and Safety (NIOSH) under the U.S. Department of Health and Human Services

compensates for the rigidity of the PEL by researching "all medical,

biological, engineering, chemical, and trade information relevant to the

hazard" and publishing recommended exposure limits (RELs) based on

their research.

Therefore, as a way to ensure worker safety and health, the following

sections on safety guidelines and hazard control will consider the most

recent occupational exposure limits from ACGIH's 2018 TLV and BEI booklet and NIOSH's REL.

A table of occupational exposure limits (OELs) from various jurisdictions follows. In general, the OELs range from 0.55 ppm to 25 ppm.

| Occupational Exposure Limits for Chloroprene |

|---|

In the ACGIH's 2018 TLV and BEI booklet, chloroprene was

designated with a skin and an A2 notation. The skin notation designation

is based on animal and human research that have shown chloroprene's

ability to be absorbed by the skin. An A2 designation by the ACGIH means that the substance is a suspected human carcinogen

with support from human data that are accepted as adequate in quality

but may not be enough to declare an A1 (known human carcinogen)

designation. Additionally, the TLV basis for these designations are due

to scientific studies that show an association between chloroprene

exposure and lung cancer, upper respiratory tract (URT) and eye

irritation.

Public health implications

Since

chloroprene usage is limited to those facilities producing Neoprene,

the occupational health risks are isolated to those facilities. However,

insufficient control of chloroprene emissions may extend the health and

safety concerns of chloroprene beyond the facility and into the

surrounding areas. Chloroprene release is predominately as an air

pollutant, but other feasible fates and transport of chloroprene in the

environment are discussed below.

In the fourteenth edition of the National Institute of Health

report on carcinogens, the half-life time differences between

chloroprene in air, water and soil were highlighted. In the air,

chloroprene “reacts with photo-chemically generated hydroxyl radicals”

and has a half-life of 18 hours. The smaller amounts that are removed by

reaction with ozone have a half-life of 10 days. In streams,

chloroprene is stated to volatilize quickly with a half-life of 3 hours.

However, in bigger bodies of water such as a lake, the half-life of

chloroprene is 4 days. Similar to its reaction with water, chloroprene

on soil was cited to volatilize from the surface. However, the report

remarked that chloroprene holds the potential to leach into groundwater

supplies.

Due to its volatility and extreme reactivity, the threat of chloroprene

exists predominantly as an air pollutant and is not expected to

bioaccumulate or persist in the environment according to the U.S EPA

Toxicological Review of Chloroprene.

However, the Centers for Disease Control and Prevention (CDC) states

that chloroprene does, in fact, have the potential to persist in the

environment. Nonetheless, the primary route of exposure for animals and

humans is inhalation, but can be absorbed through the skin or

indigestion.

In December 2015, the EPA released its 2011 National Air Toxic

Assessment to help state and local agencies prioritize the required

steps in identifying and mitigating sources of air pollution.

In this report, it was measured that chloroprene was being released

from Denka Performance Elastomer's Pontchartrain facility located in LaPlace, Louisiana.

EPA worked with the Louisiana Department of Environmental Quality,

DuPont and the nonprofit organization Louisiana Environmental Action

Network to institute monitoring of chloroprene pollution near the

facility and in the surrounding neighborhood. Air monitoring is ongoing.