This Amonix

system in Las Vegas, USA consists of thousands of small Fresnel lenses,

each focusing sunlight to ~500X higher intensity onto a tiny,

high-efficiency multi-junction solar cell. A Tesla Roadster is parked beneath for scale.

Concentrator photovoltaics (CPV) modules on dual axis solar trackers in Golmud, China

Concentrator photovoltaics (CPV) (also known as Concentration Photovoltaics) is a photovoltaic technology that generates electricity from sunlight. Contrary to conventional photovoltaic systems, it uses lenses and curved mirrors to focus sunlight onto small, but highly efficient, multi-junction (MJ) solar cells. In addition, CPV systems often use solar trackers and sometimes a cooling system to further increase their efficiency. Ongoing research and development is rapidly improving their competitiveness in the utility-scale segment and in areas of high insolation. This sort of solar technology can be thus used in smaller areas.

Systems using high-concentration photovoltaics (HCPV) especially have the potential to become competitive in the near future. They possess the highest efficiency of all existing PV technologies, and a smaller photovoltaic array also reduces the balance of system costs. Currently, CPV is not used in the PV rooftop segment and is far less common than conventional PV systems. For regions with a high annual direct normal irradiance of 2000 kilowatt-hour (kWh) per square meter or more, the levelized cost of electricity is in the range of $0.08–$0.15 per kWh and installation cost for a 10-megawatt CPV power plant was identified to lie between €1.40–€2.20 (~$1.50-$2.30) per watt-peak (Wp).

In 2016, cumulative CPV installations reached 350 megawatts (MW), less than 0.2% of the global installed capacity of 230,000 MW. Commercial HCPV systems reached instantaneous ("spot") efficiencies of up to 42% under standard test conditions (with concentration levels above 400) and the International Energy Agency sees potential to increase the efficiency of this technology to 50% by the mid-2020s. As of December 2014, the best lab cell efficiency for concentrator MJ-cells reached 46% (four or more junctions). Under outdoor, operating conditions, CPV module efficiencies have exceeded 33% ("one third of a sun"). System-level AC efficiencies are in the range of 25-28%. CPV installations are located in China, the United States, South Africa, Italy and Spain.

HCPV directly competes with concentrated solar power (CSP) as both technologies are suited best for areas with high direct normal irradiance, which are also known as the Sun Belt region in the United States and the Golden Banana in Southern Europe. CPV and CSP are often confused with one another, despite being intrinsically different technologies from the start: CPV uses the photovoltaic effect to directly generate electricity from sunlight, while CSP – often called concentrated solar thermal – uses the heat from the sun's radiation in order to make steam to drive a turbine, that then produces electricity using a generator. Currently, CSP is more common than CPV.

History

Research

into concentrator photovoltaics has taken place since the mid 1970s,

initially spurred on by the energy shock from a mideast oil embargo. Sandia National Laboratories

in Albuquerque, New Mexico was the site for most of the early work,

with the first modern-like photovoltaic concentrating system produced

there late in the decade. Their first system was a linear-trough

concentrator system that used a point focus acrylic Fresnel lens

focusing on water-cooled silicon cells and two axis tracking. Cell

cooling with a passive heat sink and use of silicone-on-glass Fresnel

lenses was demonstrated in 1979 by the Ramón Areces Project at the Institute of Solar Energy of the Technical University of Madrid. The 350 kW SOLERAS project in Saudi Arabia—the largest until many years later—was constructed by Sandia/Martin Marietta in 1981.

Research and development continued through the 1980s and 1990s

without significant industry interest. Improvements in cell efficiency

were soon recognized as essential to making the technology economical.

However the improvements to Si-based cell technologies used by both

concentrators and flat PV failed to favor the system-level economics of

CPV. The introduction of III-V Multi-junction solar cells starting in the early 2000s has since provided a clear differentiator. MJ cell efficiencies have improved from 34% (3-junctions) to 46% (4-junctions) at research-scale production levels. A substantial number of multi-MW CPV projects have also been commissioned worldwide since 2010.

Challenges

Modern

CPV systems operate most efficiently in highly concentrated sunlight

(i.e. concentration levels equivalent to hundreds of suns), as long as

the solar cell is kept cool through the use of heat sinks.

Diffuse light, which occurs in cloudy and overcast conditions, cannot

be highly concentrated using conventional optical components only (i.e.

macroscopic lenses and mirrors). Filtered light, which occurs in hazy or

polluted conditions, has spectral variations which produce mismatches

between the electrical currents generated within the series-connected

junctions of spectrally "tuned" multi-junction (MJ) photovoltaic cells. These CPV features lead to rapid decreases in power output when atmospheric conditions are less than ideal.

To produce equal or greater energy per rated watt than

conventional PV systems, CPV systems must be located in areas that

receive plentiful direct sunlight. This is typically specified as average DNI greater than 5.5-6 kWh/m2/day or 2000kWh/m2/yr.

Otherwise, evaluations of annualized DNI vs. GNI/GHI irradiance data

have concluded that conventional PV should still perform better over

time than presently available CPV technology in most regions of the

world.

| CPV Strengths | CPV Weaknesses |

|---|---|

| High efficiencies under direct normal irradiance | HCPV cannot utilize diffuse radiation. LCPV can only utilize a fraction of diffuse radiation. |

| Low cost per watt of manufacturing capital | Power output of MJ solar cells is more sensitive to shifts in radiation spectra caused by changing atmospheric conditions. |

| Low temperature coefficients | Tracking with sufficient accuracy and reliability is required. |

| No cooling water required for passively cooled systems | May require frequent cleaning to mitigate soiling losses, depending on the site |

| Additional use of waste heat possible for systems with active cooling possible (e.g.large mirror systems) | Limited market – can only be used in regions with high DNI, cannot be easily installed on rooftops |

| Modular – kW to GW scale | Strong cost decrease of competing technologies for electricity production |

| Increased and stable energy production throughout the day due to (two-axis) tracking | Bankability and perception issues |

| Low energy payback time | New generation technologies, without a history of production (thus increased risk) |

| Potential double use of land e.g. for agriculture, low environmental impact | Optical losses |

| High potential for cost reduction | Lack of technology standardization |

| Opportunities for local manufacturing | – |

| Smaller cell sizes could prevent large fluctuations in module price due to variations in semiconductor prices | – |

| Greater potential for efficiency increase in the future compared to single-junction flat plate systems could lead to greater improvements in land area use, BOS costs, and BOP costs | – |

Ongoing research and development

International CPV-x Conference - Historical Participation Statistics. Data Source - CPV-x Proceedings

CPV research and development has been pursued in over 20 countries

for more than a decade. The annual CPV-x conference series has served

as a primary networking and exchange forum between university,

government lab, and industry participants. Government agencies have

also continued to encourage a number of specific technology thrusts.

ARPA-E

announced a first round of R&D funding in late 2015 for the MOSAIC

Program (Microscale Optimized Solar-cell Arrays with Integrated

Concentration) to further combat the location and expense challenges of

existing CPV technology. As stated in the program description:

"MOSAIC projects are grouped into three categories: complete systems

that cost effectively integrate micro-CPV for regions such as sunny

areas of the U.S. southwest that have high Direct Normal Incident (DNI)

solar radiation; complete systems that apply to regions, such as areas

of the U.S. Northeast and Midwest, that have low DNI solar radiation or

high diffuse solar radiation; and concepts that seek partial solutions

to technology challenges."

In Europe the CPVMATCH Program (Concentrating PhotoVoltaic

Modules using Advanced Technologies and Cells for Highest efficiencies)

aims "to bring practical performance of HCPV modules closer to

theoretical limits". Efficiency goals achievable by 2019 are identified

as 48% for cells and 40% for modules at greater than 800x concentration.

The Australian Renewable Energy Agency (ARENA) extended its

support in 2017 for further commercialization of the HCPV technology

developed by Raygen.

Their 250kW dense array receivers are the most powerful CPV receivers

thus far created, with demonstrated PV efficiency of 40.4% and include

usable heat co-generation.

Optical design

The

design of macroscopic sunlight concentrators for CPV introduces a very

specific optical design problem, with features that makes it different

from any other optical design. It has to be efficient, suitable for mass

production, capable of high concentration, insensitive to manufacturing

and mounting inaccuracies, and capable of providing uniform

illumination of the cell. All these reasons make nonimaging optics the most suitable for CPV.

For very low concentrations, the wide acceptance angles of nonimaging optics avoid the need for active solar tracking. For medium and high

concentrations, a wide acceptance angle can be seen as a measure of how

tolerant the optic is to imperfections in the whole system. It is vital

to start with a wide acceptance angle since it must be able to

accommodate tracking errors, movements of the system due to wind,

imperfectly manufactured optics, imperfectly assembled components,

finite stiffness of the supporting structure or its deformation due to

aging, among other factors. All of these reduce the initial acceptance

angle and, after they are all factored in, the system must still be able

to capture the finite angular aperture of sunlight.

Efficiency

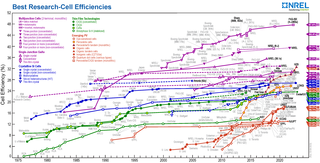

Reported records of solar cell efficiency since 1975. As of December 2014, best lab cell efficiency reached 46% (for multi-junction concentrator, 4+ junctions).

All CPV systems have a concentrating optic and a solar cell. Generally, active solar tracking

is necessary. Low-concentration systems often have a simple booster

reflector, which can increase solar electric output by over 30% from

that of non-concentrator PV systems.

Experimental results from such LCPV systems in Canada resulted in

energy gains over 40% for prismatic glass and 45% for traditional

crystalline silicon PV modules.

Semiconductor properties allow solar cells to operate more efficiently in concentrated light, as long as the cell Junction temperature is kept cool by suitable heat sinks. Efficiency of multi-junction photovoltaic cells developed in research is upward of 44% today, with the potential to approach 50% in the coming years. The theoretical limiting efficiency under concentration approaches 65% for 5 junctions, which is a likely practical maximum.

Types

CPV systems are categorized according to the amount of their solar concentration, measured in "suns" (the square of the magnification).

Low concentration PV (LCPV)

An example of a Low Concentration PV Cell's surface, showing the glass lensing

Low concentration PV are systems with a solar concentration of 2–100 suns. For economic reasons, conventional or modified silicon solar cells are typically used, and, at these concentrations, the heat flux

is low enough that the cells do not need to be actively cooled. There

is now modeling and experimental evidence that standard solar modules do

not need any modification, tracking or cooling if the concentration

level is low and yet still have increased output of 35% or more.

Medium concentration PV

From

concentrations of 100 to 300 suns, the CPV systems require two-axis

solar tracking and cooling (whether passive or active), which makes them

more complex.

A 10×10 mm HCPV solar cell

High concentration photovoltaics (HCPV)

High

concentration photovoltaics (HCPV) systems employ concentrating optics

consisting of dish reflectors or fresnel lenses that concentrate

sunlight to intensities of 1,000 suns or more.

The solar cells require high-capacity heat sinks to prevent thermal

destruction and to manage temperature related electrical performance and

life expectancy losses. To further exacerbate the concentrated cooling

design, the heat sink must be passive, otherwise the power required for

active cooling will reduce the overall conversion efficiency and economy. Multi-junction solar cells

are currently favored over single junction cells, as they are more

efficient and have a lower temperature coefficient (less loss in

efficiency with an increase in temperature). The efficiency of both cell

types rises with increased concentration; multi-junction efficiency

rises faster. Multi-junction solar cells, originally designed for non-concentrating PV on space-based satellites, have been re-designed due to the high-current density encountered with CPV (typically 8 A/cm2

at 500 suns). Though the cost of multi-junction solar cells is roughly

100 times that of conventional silicon cells of the same area, the small

cell area employed makes the relative costs of cells in each system

comparable and the system economics favor the multi-junction cells.

Multi-junction cell efficiency has now reached 44% in production cells.

The 44% value given above is for a specific set of conditions

known as "standard test conditions". These include a specific spectrum,

an incident optical power of 850 W/m², and a cell temperature of 25 °C.

In a concentrating system, the cell will typically operate under

conditions of variable spectrum, lower optical power, and higher

temperature. The optics needed to concentrate the light have limited

efficiency themselves, in the range of 75–90%. Taking these factors into

account, a solar module incorporating a 44% multi-junction cell might

deliver a DC efficiency around 36%. Under similar conditions, a

crystalline silicon module would deliver an efficiency of less than 18%.

When high concentration is needed (500–1000 times), as occurs in

the case of high efficiency multi-junction solar cells, it is likely

that it will be crucial for commercial success at the system level to

achieve such concentration with a sufficient acceptance angle. This

allows tolerance in mass production of all components, relaxes the

module assembling and system installation, and decreasing the cost of

structural elements. Since the main goal of CPV is to make solar energy

inexpensive, there can be used only a few surfaces. Decreasing the

number of elements and achieving high acceptance angle, can be relaxed

optical and mechanical requirements, such as accuracy of the optical

surfaces profiles, the module assembling, the installation, the

supporting structure, etc. To this end, improvements in sunshape

modelling at the system design stage may lead to higher system

efficiencies.

Reliability requirements

The maximum operating temperatures (Tmax cell) of CPV systems are limited to less than approximately 100–125 °C on account of the intrinsic reliability limitation of their multi-junction PV cells. This contrasts to CSP and other CHP

systems which may be designed to function at temperatures in excess of

several hundred degrees. More specifically, the cells are fabricated

from a layering of thin-film III-V semiconductor materials having intrinsic lifetimes during operation that rapidly decrease with an Arrhenius-type

temperature dependence. The system receiver must therefore provide for

highly efficient and uniform cell cooling, where an ideal receiver would

provide Tmax coolant ~ Tmax cell. In addition to material and design limitations in receiver heat-transfer performance, numerous extrinsic factors, such as the frequent system thermal cycling, further reduce the practical Tmax coolant compatible with long system life to below about 80 °C.

The higher capital costs, lesser standardization,

and added engineering & operational complexities (in comparison to

zero and low-concentration PV technologies) make long-life performance a

critical demonstration goal for the first generations of CPV

technologies. Performance certification standards (e.g. IEC 62108, UL 8703, IEC 62789, IEC 62670) include stress testing conditions that may be useful to uncover some predominantly infant and early life (less than 1–2 year) failure modes

at the system, module, and sub-component levels. However, such

standardized tests – as typically performed on only a small sampling of

units – are generally incapable to evaluate comprehensive long-term

lifetimes (10 to 25 or more years) for each unique system design and

application under its broader range of actual operating conditions.

Reliability of these complex systems is therefore assessed in the field,

and is improved through aggressive product development cycles which are guided by the results of accelerated component/system aging, performance monitoring diagnostics, and failure analysis.

Significant growth in the deployment of CPV can be anticipated once

these concerns are better addressed to build confidence in system

bankability.

Installations

Concentrator

photovoltaics technology has established its presence in the solar

industry over the last several years. The first CPV power plant that

exceeded 1 MW-level was commissioned in Spain in 2006. By the end of

2015, the number of CPV power plants around the world accounted for a

total installed capacity of 350 MW. Field data collected over six years

is also starting to benchmark the prospects for long-term system

reliability.

The emerging CPV segment has comprised ~0.1% of the fast-growing

utility market for PV installations over the past decade.

Unfortunately, by the end of 2015, the near term outlook for CPV

industry growth has faded with closure of all of the largest CPV

manufacturing facilities: including those of Suncore, Soitec, Amonix,

and Solfocus. Nevertheless, the growth outlook for the overall PV

industry continues to appear strong.

List of large CPV systems

The largest CPV power plant currently in operation is of 80 MWp capacity located in Golmud, China, hosted by Suncore Photovoltaics.

| Power station | Capacity (MWp) | Location | Vendor/Builder |

|---|---|---|---|

| Golmud 2 | 79.83 | in Golmud/Qinghai province/China | Suncore |

| Golmud 1 | 57.96 | in Golmud/Qinghai province/China | Suncore |

| Touwsrivier | 44.19 | in Touwsrivier/Western Cape/South Africa | Soitec |

| Alamosa Solar Project | 35.28 | in Alamosa, Colorado/San Luis Valley/United States | Amonix |

Concentrated photovoltaics and thermal

Concentrator photovoltaics and thermal (CPVT), also sometimes called combined heat and power solar (CHAPS) or hybrid thermal CPV, is a cogeneration or micro cogeneration

technology used in the field of concentrator photovoltaics that

produces usable heat and electricity within the same system. CPVT at

high concentrations of over 100 suns (HCPVT) utilizes similar components

as HCPV, including dual-axis tracking and multi-junction photovoltaic cells. A fluid actively cools the integrated thermal–photovoltaic receiver, and simultaneously transports the collected heat.

Typically, one or more receivers and a heat exchanger operate within a closed thermal loop. To maintain efficient overall operation and avoid damage from thermal runaway,

the demand for heat from the secondary side of the exchanger must be

consistently high. Under such optimal operating conditions, collection

efficiencies exceeding 70% (up to ~35% electric, ~40% thermal for HCPVT)

are anticipated. Net operating efficiencies may be substantially lower

depending on how well a system is engineered to match the demands of the

particular thermal application.

The maximum temperature of CPVT systems is typically too low

alone to power a boiler for additional steam-based cogeneration of

electricity. Such systems may be economical to power lower temperature

applications having a constant high heat demand. The heat may be

employed in district heating, water heating and air conditioning, desalination or process heat.

For applications having lower or intermittent heat demand, a system may

be augmented with a switchable heat dump to the external environment in

order to maintain reliable electrical output and safeguard cell life,

despite the resulting reduction in net operating efficiency.

HCPVT active cooling enables the use of much higher power

thermal–photovoltaic receiver units, generating typically 1–100

kilowatts electric, as compared to HCPV systems that mostly rely upon

passive cooling of single ~20W cells. Such high-power receivers utilize

dense arrays of cells mounted on a high-efficiency heat sink.

Minimizing the number of individual receiver units is a simplification

that should ultimately yield improvement in the overall balance of

system costs, manufacturability, maintainability/upgradeability, and

reliability.

This 240 x 80 mm 1,000 suns CPV heat sink design thermal animation, was created using high resolution CFD analysis, and shows temperature contoured heat sink surface and flow trajectories as predicted.

Demonstration projects

The

economics of a mature CPVT industry is anticipated to be competitive,

despite the large recent cost reductions and gradual efficiency

improvements for conventional silicon PV (which can be installed

alongside conventional CSP to provide for similar electrical+thermal

generation capabilities). CPVT may currently be economical for niche markets having all of the following application characteristics:

- high solar direct normal incidence (DNI)

- tight space constraints for placement of a solar collector array

- high and constant demand for low-temperature (less than 80 °C) heat

- high cost of grid electricity

- access to backup sources of power or cost-efficient storage (electrical and thermal)

Utilization of a power purchase agreement

(PPA), government assistance programs, and innovative financing schemes

are also helping potential manufacturers and users to mitigate the

risks of early CPVT technology adoption.

CPVT equipment offerings ranging from low (LCPVT) to high (HCPVT) concentration are now being deployed by several startup ventures.

As such, longer-term viability of the technical and/or business

approach being pursued by any individual system provider is typically

speculative. Notably, the minimum viable products of startups can vary widely in their attention to reliability engineering.

Nevertheless, the following incomplete compilation is offered to

assist with the identification of some early industry trends.

LCPVT systems at ~14x concentration using reflective trough

concentrators, and receiver pipes clad with silicon cells having dense

interconnects, have been assembled by Cogenra with a claimed 75%

efficiency (~15-20% electric, 60% thermal). Several such systems are in operation for more than 5 years as of 2015, and similar systems are being produced by Absolicon and Idhelio at 10x and 50x concentration, respectively.

HCPVT offerings at over 700x concentration have more recently

emerged, and may be classified into three power tiers. Third tier

systems are distributed generators consisting of large arrays of ~20W

single-cell receiver/collector units, similar to those previously

pioneered by Amonix and SolFocus for HCPV. Second tier systems utilize

localized dense-arrays of cells that produce 1-100 kW of electrical

power output per receiver/generator unit. First tier systems exceed

100 kW of electrical output and are most aggressive in targeting the

utility market.

Several HCPVT system providers are listed in the following table.

Nearly all are early demonstration systems which have been in service

for under 5 years as of 2015. Collected thermal power is typically

1.5x-2x the rated electrical power.

| Provider | Country | Concentrator Type | Unit Size in kWe | |

|---|---|---|---|---|

| Generator | Receiver | |||

| - Tier 1 - | ||||

| Raygen | Australia | Large Heliostat Array | 250 | 250 |

| - Tier 2 - | ||||

| Airlight Energy/dsolar | Switzerland | Large Dish | 12 | 12 |

| Rehnu | United States | Large Dish | 6.4 | 0.8 |

| Solartron | Canada | Large Dish | 20 | 20 |

| Southwest Solar | United States | Large Dish | 20 | 20 |

| Sun Oyster | Germany | Large Trough + Lens | 4.7 | 2.35 |

| Zenith Solar/Suncore | Israel/China/USA | Large Dish | 4.5 | 2.25 |

| - Tier 3 - | ||||

| BSQ Solar | Spain | Small Lens Array | 13,44 | 0.02 |

| Silex Power | Malta | Small Dish Array | 16 | 0.04 |

| Solergy | Italy/USA | Small Lens Array | 20 | 0.02 |