A selection of dye-sensitized solar cells.

A dye-sensitized solar cell (DSSC, DSC, DYSC or Grätzel cell) is a low-cost solar cell belonging to the group of thin film solar cells. It is based on a semiconductor formed between a photo-sensitized anode and an electrolyte, a photoelectrochemical system. The modern version of a dye solar cell, also known as the Grätzel cell, was originally co-invented in 1988 by Brian O'Regan and Michael Grätzel at UC Berkeley and this work was later developed by the aforementioned scientists at the École Polytechnique Fédérale de Lausanne until the publication of the first high efficiency DSSC in 1991. Michael Grätzel has been awarded the 2010 Millennium Technology Prize for this invention.

The DSSC has a number of attractive features; it is simple to

make using conventional roll-printing techniques, is semi-flexible and

semi-transparent which offers a variety of uses not applicable to

glass-based systems, and most of the materials used are low-cost. In

practice it has proven difficult to eliminate a number of expensive

materials, notably platinum and ruthenium, and the liquid electrolyte presents a serious challenge to making a cell suitable for use in all weather. Although its conversion efficiency is less than the best thin-film cells, in theory its price/performance ratio should be good enough to allow them to compete with fossil fuel electrical generation by achieving grid parity. Commercial applications, which were held up due to chemical stability problems,[6] are forecast in the European Union Photovoltaic Roadmap to significantly contribute to renewable electricity generation by 2020.

Current technology: semiconductor solar cells

In a traditional solid-state semiconductor, a solar cell is made from two doped crystals, one doped with n-type impurities (n-type semiconductor), which add additional free conduction band electrons, and the other doped with p-type impurities (p-type semiconductor), which add additional electron holes.

When placed in contact, some of the electrons in the n-type portion

flow into the p-type to "fill in" the missing electrons, also known as

electron holes. Eventually enough electrons will flow across the

boundary to equalize the Fermi levels of the two materials. The result is a region at the interface, the p-n junction,

where charge carriers are depleted and/or accumulated on each side of

the interface. In silicon, this transfer of electrons produces a potential barrier of about 0.6 to 0.7 V.

When placed in the sun, photons of the sunlight can excite electrons on the p-type side of the semiconductor, a process known as photoexcitation. In silicon, sunlight can provide enough energy to push an electron out of the lower-energy valence band into the higher-energy conduction band.

As the name implies, electrons in the conduction band are free to move

about the silicon. When a load is placed across the cell as a whole,

these electrons will flow out of the p-type side into the n-type side,

lose energy while moving through the external circuit, and then flow

back into the p-type material where they can once again re-combine with

the valence-band hole they left behind. In this way, sunlight creates an

electric current.

In any semiconductor, the band gap

means that only photons with that amount of energy, or more, will

contribute to producing a current. In the case of silicon, the majority

of visible light from red to violet has sufficient energy to make this

happen. Unfortunately higher energy photons, those at the blue and

violet end of the spectrum, have more than enough energy to cross the

band gap; although some of this extra energy is transferred into the

electrons, the majority of it is wasted as heat. Another issue is that

in order to have a reasonable chance of capturing a photon, the n-type

layer has to be fairly thick. This also increases the chance that a

freshly ejected electron will meet up with a previously created hole in

the material before reaching the p-n junction. These effects produce an

upper limit on the efficiency of silicon solar cells, currently around

12 to 15% for common modules and up to 25% for the best laboratory cells

(33.16% is the theoretical maximum efficiency for single band gap solar

cells).

By far the biggest problem with the conventional approach is

cost; solar cells require a relatively thick layer of doped silicon in

order to have reasonable photon capture rates, and silicon processing is

expensive. There have been a number of different approaches to reduce

this cost over the last decade, notably the thin-film

approaches, but to date they have seen limited application due to a

variety of practical problems. Another line of research has been to

dramatically improve efficiency through the multi-junction

approach, although these cells are very high cost and suitable only for

large commercial deployments. In general terms the types of cells

suitable for rooftop deployment have not changed significantly in

efficiency, although costs have dropped somewhat due to increased

supply.

Dye-sensitized solar cells

Type of cell made at the EPFL by Grätzel and O'Regan

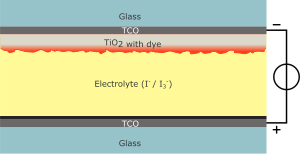

Operation of a Grätzel cell.

In the late 1960s it was discovered that illuminated organic dyes can

generate electricity at oxide electrodes in electrochemical cells.

In an effort to understand and simulate the primary processes in

photosynthesis the phenomenon was studied at the University of

California at Berkeley with chlorophyll extracted from spinach

(bio-mimetic or bionic approach).

On the basis of such experiments electric power generation via the dye

sensitization solar cell (DSSC) principle was demonstrated and discussed

in 1972.

The instability of the dye solar cell was identified as a main

challenge. Its efficiency could, during the following two decades, be

improved by optimizing the porosity of the electrode prepared from fine

oxide powder, but the instability remained a problem.

A modern DSSC is composed of a porous layer of titanium dioxide nanoparticles, covered with a molecular dye that absorbs sunlight, like the chlorophyll in green leaves. The titanium dioxide is immersed under an electrolyte solution, above which is a platinum-based catalyst. As in a conventional alkaline battery, an anode (the titanium dioxide) and a cathode (the platinum) are placed on either side of a liquid conductor (the electrolyte).

Sunlight passes through the transparent electrode into the dye

layer where it can excite electrons that then flow into the titanium

dioxide. The electrons flow toward the transparent electrode where they

are collected for powering a load. After flowing through the external

circuit, they are re-introduced into the cell on a metal electrode on

the back, flowing into the electrolyte. The electrolyte then transports

the electrons back to the dye molecules.

Dye-sensitized solar cells separate the two functions provided by

silicon in a traditional cell design. Normally the silicon acts as both

the source of photoelectrons, as well as providing the electric field

to separate the charges and create a current. In the dye-sensitized

solar cell, the bulk of the semiconductor is used solely for charge

transport, the photoelectrons are provided from a separate photosensitive dye. Charge separation occurs at the surfaces between the dye, semiconductor and electrolyte.

The dye molecules are quite small (nanometer sized), so in order

to capture a reasonable amount of the incoming light the layer of dye

molecules needs to be made fairly thick, much thicker than the molecules

themselves. To address this problem, a nanomaterial is used as a

scaffold to hold large numbers of the dye molecules in a 3-D matrix,

increasing the number of molecules for any given surface area of cell.

In existing designs, this scaffolding is provided by the semiconductor

material, which serves double-duty.

Construction

In the case of the original Grätzel and O'Regan design, the cell has 3 primary parts. On top is a transparent anode made of fluoride-doped tin dioxide (SnO2:F) deposited on the back of a (typically glass) plate. On the back of this conductive plate is a thin layer of titanium dioxide (TiO2), which forms into a highly porous structure with an extremely high surface area. The (TiO2) is chemically bound by a process called sintering. TiO2 only absorbs a small fraction of the solar photons (those in the UV). The plate is then immersed in a mixture of a photosensitive ruthenium-polypyridine dye (also called molecular sensitizers) and a solvent. After soaking the film in the dye solution, a thin layer of the dye is left covalently bonded to the surface of the TiO2. The bond is either an ester, chelating, or bidentate bridging linkage.

A separate plate is then made with a thin layer of the iodide electrolyte spread over a conductive sheet, typically platinum

metal. The two plates are then joined and sealed together to prevent

the electrolyte from leaking. The construction is simple enough that

there are hobby kits available to hand-construct them.

Although they use a number of "advanced" materials, these are

inexpensive compared to the silicon needed for normal cells because they

require no expensive manufacturing steps. TiO2, for instance, is already widely used as a paint base.

One of the efficient DSSCs devices uses ruthenium-based molecular dye, e.g. [Ru(4,4'-dicarboxy-2,2'-bipyridine)2(NCS)2]

(N3), that is bound to a photoanode via carboxylate moieties. The

photoanode consists of 12 μm thick film of transparent 10–20 nm diameter

TiO2 nanoparticles covered with a 4 μm thick film of much

larger (400 nm diameter) particles that scatter photons back into the

transparent film. The excited dye rapidly injects an electron into the

TiO2 after light absorption. The injected electron diffuses

through the sintered particle network to be collected at the front side

transparent conducting oxide (TCO) electrode, while the dye is

regenerated via reduction by a redox shuttle, I3/I, dissolved in a solution. Diffusion of the oxidized form of the shuttle to the counter electrode completes the circuit.

Mechanism of DSSCs

The main processes that occur in a DSSC to convert photons(light) to current are:- The incident photon is absorbed by Ru complex photosensitizers adsorbed on the TiO2 surface.

- The photosensitizers are excited from the ground state (S) to the excited state (S∗). The excited electrons are injected into the conduction band of the TiO2 electrode. This results in the oxidation of the photosensitizer (S+).

-

S+hν→S∗

-

- The injected electrons in the conduction band of TiO2 are transported between TiO2 nanoparticles with diffusion toward the back contact (TCO). And the electrons finally reach the counter electrode through the circuit.

- The oxidized photosensitizer (S+) accepts electrons from the I− ion redox mediator leading to regeneration of the ground state (S), and two I−-Ions are oxidized to elementary Iodine which reacts with I− to the oxidized state, I3−.

-

S++e−→S

-

- The oxidized redox mediator, I3−, diffuses toward the counter electrode and then it is reduced to I− ions.

-

I3−+2e−→3I−

-

The efficiency of a DSSC depends on four energy levels of the

component: the excited state (approximately LUMO) and the ground state

(HOMO) of the photosensitizer, the Fermi level of the TiO2 electrode and the redox potential of the mediator (I−/I3−) in the electrolyte.

Nanoplant-like morphology

In DSSC, electrodes consisted of sintered semiconducting nanoparticles, mainly TiO2

or ZnO. These nanoparticle DSSCs rely on trap-limited diffusion through

the semiconductor nanoparticles for the electron transport. This limits

the device efficiency since it is a slow transport mechanism.

Recombination is more likely to occur at longer wavelengths of

radiation. Moreover, sintering of nanoparticles requires a high

temperature of about 450 °C, which restricts the fabrication of these

cells to robust, rigid solid substrates. It has been proven that there

is an increase in the efficiency of DSSC, if the sintered nanoparticle

electrode is replaced by a specially designed electrode possessing an

exotic 'nanoplant-like' morphology.

Operation

Sunlight enters the cell through the transparent SnO2:F top contact, striking the dye on the surface of the TiO2.

Photons striking the dye with enough energy to be absorbed create an

excited state of the dye, from which an electron can be "injected"

directly into the conduction band of the TiO2. From there it moves by diffusion (as a result of an electron concentration gradient) to the clear anode on top.

Meanwhile, the dye molecule has lost an electron and the molecule

will decompose if another electron is not provided. The dye strips one

from iodide in electrolyte below the TiO2, oxidizing it into triiodide.

This reaction occurs quite quickly compared to the time that it takes

for the injected electron to recombine with the oxidized dye molecule,

preventing this recombination reaction that would effectively short-circuit the solar cell.

The triiodide then recovers its missing electron by mechanically diffusing to the bottom of the cell, where the counter electrode re-introduces the electrons after flowing through the external circuit.

Efficiency

Several important measures are used to characterize solar cells. The

most obvious is the total amount of electrical power produced for a

given amount of solar power shining on the cell. Expressed as a

percentage, this is known as the solar conversion efficiency. Electrical power is the product of current and voltage, so the maximum values for these measurements are important as well, Jsc and Voc

respectively. Finally, in order to understand the underlying physics,

the "quantum efficiency" is used to compare the chance that one photon

(of a particular energy) will create one electron.

In quantum efficiency

terms, DSSCs are extremely efficient. Due to their "depth" in the

nanostructure there is a very high chance that a photon will be

absorbed, and the dyes are very effective at converting them to

electrons. Most of the small losses that do exist in DSSC's are due to

conduction losses in the TiO2 and the clear electrode, or

optical losses in the front electrode. The overall quantum efficiency

for green light is about 90%, with the "lost" 10% being largely

accounted for by the optical losses in the top electrode. The quantum

efficiency of traditional designs vary, depending on their thickness,

but are about the same as the DSSC.

In theory, the maximum voltage generated by such a cell is simply the difference between the (quasi-)Fermi level of the TiO2 and the redox potential of the electrolyte, about 0.7 V under solar illumination conditions (Voc).

That is, if an illuminated DSSC is connected to a voltmeter in an "open

circuit", it would read about 0.7 V. In terms of voltage, DSSCs offer

slightly higher Voc than silicon, about 0.7 V compared to

0.6 V. This is a fairly small difference, so real-world differences are

dominated by current production, Jsc.

Although the dye is highly efficient at converting absorbed photons into free electrons in the TiO2,

only photons absorbed by the dye ultimately produce current. The rate

of photon absorption depends upon the absorption spectrum of the

sensitized TiO2 layer and upon the solar flux spectrum. The

overlap between these two spectra determines the maximum possible

photocurrent. Typically used dye molecules generally have poorer

absorption in the red part of the spectrum compared to silicon, which

means that fewer of the photons in sunlight are usable for current

generation. These factors limit the current generated by a DSSC, for

comparison, a traditional silicon-based solar cell offers about 35 mA/cm2, whereas current DSSCs offer about 20 mA/cm2.

Overall peak power conversion efficiency for current DSSCs is about 11%. Current record for prototypes lies at 15%.

Degradation

DSSCs degrade when exposed to ultraviolet

radiation. In 2014 air infiltration of the commonly-used amorphous

Spiro-MeOTAD hole-transport layer was identified as the primary cause of

the degradation, rather than oxidation. The damage could be avoided by

the addition of an appropriate barrier.

The barrier layer may include UV stabilizers and/or UV absorbing luminescent chromophores (which emit at longer wavelengths which may be reabsorbed by the dye) and antioxidants to protect and improve the efficiency of the cell.

Advantages

DSSCs are currently the most efficient third-generation

(2005 Basic Research Solar Energy Utilization 16) solar technology

available. Other thin-film technologies are typically between 5% and

13%, and traditional low-cost commercial silicon panels operate between

14% and 17%. This makes DSSCs attractive as a replacement for existing

technologies in "low density" applications like rooftop solar

collectors, where the mechanical robustness and light weight of the

glass-less collector is a major advantage. They may not be as attractive

for large-scale deployments where higher-cost higher-efficiency cells

are more viable, but even small increases in the DSSC conversion

efficiency might make them suitable for some of these roles as well.

There is another area where DSSCs are particularly attractive. The process of injecting an electron directly into the TiO2

is qualitatively different from that occurring in a traditional cell,

where the electron is "promoted" within the original crystal. In theory,

given low rates of production, the high-energy electron in the silicon

could re-combine with its own hole, giving off a photon (or other form

of energy) which does not result in current being generated. Although

this particular case may not be common, it is fairly easy for an

electron generated by another atom to combine with a hole left behind in

a previous photoexcitation.

In comparison, the injection process used in the DSSC does not introduce a hole in the TiO2,

only an extra electron. Although it is energetically possible for the

electron to recombine back into the dye, the rate at which this occurs

is quite slow compared to the rate that the dye regains an electron from

the surrounding electrolyte. Recombination directly from the TiO2 to species in the electrolyte is also possible although, again, for optimized devices this reaction is rather slow. On the contrary, electron transfer from the platinum coated electrode to species in the electrolyte is necessarily very fast.

As a result of these favorable "differential kinetics", DSSCs

work even in low-light conditions. DSSCs are therefore able to work

under cloudy skies and non-direct sunlight, whereas traditional designs

would suffer a "cutout" at some lower limit of illumination, when charge

carrier mobility is low and recombination becomes a major issue. The

cutoff is so low they are even being proposed for indoor use, collecting

energy for small devices from the lights in the house.

A practical advantage which DSSCs share with most thin-film

technologies, is that the cell's mechanical robustness indirectly leads

to higher efficiencies at higher temperatures. In any semiconductor,

increasing temperature will promote some electrons into the conduction

band "mechanically". The fragility of traditional silicon cells requires

them to be protected from the elements, typically by encasing them in a

glass box similar to a greenhouse,

with a metal backing for strength. Such systems suffer noticeable

decreases in efficiency as the cells heat up internally. DSSCs are

normally built with only a thin layer of conductive plastic on the front

layer, allowing them to radiate away heat much easier, and therefore

operate at lower internal temperatures.

Disadvantages

The

major disadvantage to the DSSC design is the use of the liquid

electrolyte, which has temperature stability problems. At low

temperatures the electrolyte can freeze, ending power production and

potentially leading to physical damage. Higher temperatures cause the

liquid to expand, making sealing the panels a serious problem. Another

disadvantage is that costly ruthenium (dye), platinum (catalyst) and

conducting glass or plastic (contact) are needed to produce a DSSC. A

third major drawback is that the electrolyte solution contains volatile organic compounds (or VOC's),

solvents which must be carefully sealed as they are hazardous to human

health and the environment. This, along with the fact that the solvents

permeate plastics, has precluded large-scale outdoor application and

integration into flexible structure.

Replacing the liquid electrolyte with a solid has been a major

ongoing field of research. Recent experiments using solidified melted

salts have shown some promise, but currently suffer from higher

degradation during continued operation, and are not flexible.

Photocathodes and tandem cells

Dye

sensitised solar cells operate as a photoanode (n-DSC), where

photocurrent result from electron injection by the sensitized dye.

Photocathodes (p-DSCs) operate in an inverse mode compared to the

conventional n-DSC, where dye-excitation is followed by rapid electron

transfer from a p-type semiconductor to the dye (dye-sensitized hole

injection, instead of electron injection). Such p-DSCs and n-DSCs can be

combined to construct tandem solar cells (pn-DSCs) and the theoretical

efficiency of tandem DSCs is well beyond that of single-junction DSCs.

A standard tandem cell consists of one n-DSC and one p-DSC in a

simple sandwich configuration with an intermediate electrolyte layer.

n-DSC and p-DSC are connected in series, which implies that the

resulting photocurrent will be controlled by the weakest photoelectrode,

whereas photovoltages are additive. Thus, photocurrent matching is very

important for the construction of highly efficient tandem pn-DSCs.

However, unlike n-DSCs, fast charge recombination following

dye-sensitized hole injection usually resulted in low photocurrents in

p-DSC and thus hampered the efficiency of the overall device.

Researchers have found that using dyes comprising a perylenemonoimide

(PMI) as the acceptor and an oligothiophene coupled to triphenylamine

as the donor greatly improve the performance of p-DSC by reducing charge

recombination rate following dye-sensitized hole injection. The

researchers constructed a tandem DSC device with NiO on the p-DSC side

and TiO2 on the n-DSC side. Photocurrent matching was achieved through adjustment of NiO and TiO2

film thicknesses to control the optical absorptions and therefore match

the photocurrents of both electrodes. The energy conversion efficiency

of the device is 1.91%, which exceeds the efficiency of its individual

components, but is still much lower than that of high performance n-DSC

devices (6%–11%). The results are still promising since the tandem DSC

was in itself rudimentary. The dramatic improvement in performance in

p-DSC can eventually lead to tandem devices with much greater efficiency

than lone n-DSCs.

Development

"Black Dye", an anionic Ru-terpyridine complex

The dyes used in early experimental cells (circa 1995) were sensitive

only in the high-frequency end of the solar spectrum, in the UV and

blue. Newer versions were quickly introduced (circa 1999) that had much

wider frequency response, notably "triscarboxy-ruthenium terpyridine"

[Ru(4,4',4"-(COOH)3-terpy)(NCS)3], which is efficient right into the low-frequency range of red and IR light. The wide spectral response results in the dye having a deep brown-black color, and is referred to simply as "black dye".

The dyes have an excellent chance of converting a photon into an

electron, originally around 80% but improving to almost perfect

conversion in more recent dyes, the overall efficiency is about 90%,

with the "lost" 10% being largely accounted for by the optical losses in

top electrode.

A solar cell must be capable of producing electricity for at least twenty years, without a significant decrease in efficiency.

The "black dye" system was subjected to 50 million cycles, the

equivalent of ten years' exposure to the sun in Switzerland. No

discernible performance decrease was observed. However the dye is

subject to breakdown in high-light situations. Over the last decade an

extensive research program has been carried out to address these

concerns. The newer dyes included 1-ethyl-3 methylimidazolium

tetrocyanoborate [EMIB(CN)4] which is extremely light- and temperature-stable, copper-diselenium [Cu(In,GA)Se2] which offers higher conversion efficiencies, and others with varying special-purpose properties.

DSSCs are still at the start of their development cycle.

Efficiency gains are possible and have recently started more widespread

study. These include the use of quantum dots

for conversion of higher-energy (higher frequency) light into multiple

electrons, using solid-state electrolytes for better temperature

response, and changing the doping of the TiO2 to better match it with the electrolyte being used.

New developments

2003

A

group of researchers at the Swiss Federal Institute of Technology has

reportedly increased the thermostability of DSC by using amphiphilic

ruthenium sensitizer in conjunction with quasi-solid-state gel

electrolyte. The stability of the device matches that of a conventional

inorganic silicon-based solar cell. The cell sustained heating for 1,000

h at 80 °C.

The group has previously prepared a ruthenium amphiphilic dye Z-907 (cis-Ru(H2dcbpy)(dnbpy)(NCS)2, where the ligand H2dcbpy

is 4,4′-dicarboxylic acid-2,2′-bipyridine and dnbpy is

4,4′-dinonyl-2,2′-bipyridine) to increase dye tolerance to water in the

electrolytes. In addition, the group also prepared a quasi-solid-state

gel electrolyte with a 3-methoxypropionitrile (MPN)-based liquid

electrolyte that was solidified by a photochemically stable fluorine

polymer, polyvinylidenefluoride-co-hexafluoropropylene (PVDF-HFP).

The use of the amphiphilic Z-907 dye in conjunction with the

polymer gel electrolyte in DSC achieved an energy conversion efficiency

of 6.1%. More importantly, the device was stable under thermal stress

and soaking with light. The high conversion efficiency of the cell was

sustained after heating for 1,000 h at 80 °C, maintaining 94% of its

initial value. After

accelerated testing in a solar simulator for 1,000 h of light-soaking at 55 °C (100 mW cm−2)

the efficiency had decreased by less than 5% for cells covered with an

ultraviolet absorbing polymer film. These results are well within the

limit for that of traditional inorganic silicon solar cells.

The enhanced performance may arise from a decrease in solvent

permeation across the sealant due to the application of the polymer gel

electrolyte. The polymer gel electrolyte is quasi-solid at room

temperature, and becomes a viscous liquid (viscosity: 4.34 mPa·s) at

80 °C compared with the traditional liquid electrolyte (viscosity: 0.91

mPa·s). The much improved stabilities of the device under both thermal

stress and soaking with light has never before been seen in DSCs, and

they match the durability criteria applied to solar cells for outdoor

use, which makes these devices viable for practical application.

2006

The first successful solid-hybrid dye-sensitized solar cells were reported.

To improve electron transport in these solar cells, while

maintaining the high surface area needed for dye adsorption, two

researchers have designed alternate semiconductor morphologies, such as

arrays of nanowires and a combination of nanowires and nanoparticles,

to provide a direct path to the electrode via the semiconductor

conduction band. Such structures may provide a means to improve the

quantum efficiency of DSSCs in the red region of the spectrum, where

their performance is currently limited.

On August 2006, to prove the chemical and thermal robustness of

the 1-ethyl-3 methylimidazolium tetracyanoborate solar cell, the

researchers subjected the devices to heating at 80 °C in the dark for

1000 hours, followed by light soaking at 60 °C for 1000 hours. After dark heating

and light soaking, 90% of the initial photovoltaic efficiency was

maintained – the first time such excellent thermal stability has been

observed for a liquid electrolyte that exhibits such a high conversion

efficiency. Contrary to silicon solar cells,

whose performance declines with increasing temperature, the

dye-sensitized solar-cell devices were only negligibly influenced when

increasing the operating temperature from ambient to 60 °C.

April 2007

Wayne Campbell at Massey University, New Zealand, has experimented with a wide variety of organic dyes based on porphyrin. In nature, porphyrin is the basic building block of the hemoproteins, which include chlorophyll in plants and hemoglobin in animals. He reports efficiency on the order of 5.6% using these low-cost dyes.

June 2008

An article published in Nature Materials

demonstrated cell efficiencies of 8.2% using a new solvent-free liquid

redox electrolyte consisting of a melt of three salts, as an alternative

to using organic solvents as an electrolyte solution. Although the

efficiency with this electrolyte is less than the 11% being delivered

using the existing iodine-based solutions, the team is confident the

efficiency can be improved.

2009

A group of researchers at Georgia Tech made dye-sensitized solar cells with a higher effective surface area by wrapping the cells around a quartz optical fiber. The researchers removed the cladding from optical fibers, grew zinc oxide nanowires along the surface, treated them with dye molecules, surrounded the fibers by an electrolyte

and a metal film that carries electrons off the fiber. The cells are

six times more efficient than a zinc oxide cell with the same surface

area.

Photons bounce inside the fiber as they travel, so there are more

chances to interact with the solar cell and produce more current. These

devices only collect light at the tips, but future fiber cells could be

made to absorb light along the entire length of the fiber, which would

require a coating that is conductive as well as transparent. Max Shtein of the University of Michigan said a sun-tracking system would not be necessary for such cells, and would work on cloudy days when light is diffuse.

2010

Researchers at the École Polytechnique Fédérale de Lausanne and at the Université du Québec à Montréal claim to have overcome two of the DSC's major issues:

- "New molecules" have been created for the electrolyte, resulting in a liquid or gel that is transparent and non-corrosive, which can increase the photovoltage and improve the cell's output and stability.

- At the cathode, platinum was replaced by cobalt sulfide, which is far less expensive, more efficient, more stable and easier to produce in the laboratory.

2011

Dyesol and Tata Steel Europe

announced in June the development of the world's largest dye sensitized

photovoltaic module, printed onto steel in a continuous line.

Dyesol and CSIRO

announced in October a Successful Completion of Second Milestone in

Joint Dyesol / CSIRO Project.

Dyesol Director Gordon Thompson said, "The materials developed during

this joint collaboration have the potential to significantly advance the

commercialisation of DSC in a range of applications where performance

and stability are essential requirements.

Dyesol is extremely encouraged by the breakthroughs in the chemistry

allowing the production of the target molecules. This creates a path to

the immediate commercial utilisation of these new materials."

Dyesol and Tata Steel Europe

announced in November the targeted development of Grid Parity

Competitive BIPV solar steel that does not require government subsidised

feed in tariffs. TATA-Dyesol "Solar Steel" Roofing is currently being

installed on the Sustainable Building Envelope Centre (SBEC) in Shotton,

Wales.

2012

Northwestern University researchers announced

a solution to a primary problem of DSSCs, that of difficulties in using

and containing the liquid electrolyte and the consequent relatively

short useful life of the device. This is achieved through the use of nanotechnology

and the conversion of the liquid electrolyte to a solid. The current

efficiency is about half that of silicon cells, but the cells are

lightweight and potentially of much lower cost to produce.

2013

During the

last 5–10 years, a new kind of DSSC has been developed — the solid state

dye-sensitized solar cell. In this case the liquid electrolyte is

replaced by one of several solid hole conducting materials. From 2009 to

2013 the efficiency of Solid State DSSCs has dramatically increased

from 4% to 15%. Michael Grätzel announced the fabrication of Solid State

DSSCs with 15.0% efficiency, reached by the means of a hybrid perovskite CH3NH3PbI3 dye, subsequently deposited from the separated solutions of CH3NH3I and PbI2.

The first architectural integration was demonstrated at EPFL's

new convention center in partnership with Romande Energie. The total

surface is 300 m2, in 1400 modules of 50 cm x 35 cm. Designed by artists Daniel Schlaepfer and Catherine Bolle.

2018

Researchers have investigated the role of surface plasmon resonances present on gold nanorods

in the performance of dye-sensitized solar cells. They found that with

an increase nanorod concentration, the light absorption grew linearly;

however, charge extraction was also dependent on the concentration.

With an optimized concentration, they found that the overall power

conversion efficiency improved from 5.31 to 8.86% for Y123

dye-sensitized solar cells.

The synthesis of one-dimensional TiO2 nanostructures directly on fluorine-doped tin oxide glass substrates was successful demonstrated via a two-stop solvothermal reaction. Additionally, through a TiO2 sol treatment, the performance of the dual TiO2 nanowire cells was enhanced, reaching a power conversion efficiency of 7.65%.

Stainless steel based counter-electrodes for DSSCs have been

reported which further reduce cost compared to conventional platinum

based counter electrode and are suitable for outdoor application.

Researchers from EPFL have advanced the DSSCs based on copper complexes redox electrolytes, which have achieved 13.1% efficiency under standard AM1.5G, 100 mW/cm2 conditions and record 32% efficiency under 1000 lux of indoor light.

Market introduction

Several commercial providers are promising availability of DSCs in the near future:

- Dyesol officially opened its new manufacturing facilities in Queanbeyan Australia on 7 October 2008. It has subsequently announced partnerships with Tata Steel (TATA-Dyesol) and Pilkington Glass (Dyetec-Solar) for the development and large scale manufacture of DSC BIPV. Dyesol has also entered working relationships with Merck, Umicore, CSIRO, Japanese Ministry of Economy and Trade, Singapore Aerospace Manufacturing and a joint Venture with TIMO Korea (Dyesol-TIMO).

- Solaronix, a Swiss company specialized in the production of DSC materials since 1993, has extended their premises in 2010 to host a manufacturing pilot line of DSC modules.[57]

- SolarPrint was founded in Ireland in 2008 by Dr. Mazhar Bari, Andre Fernon and Roy Horgan. SolarPrint was the first Ireland-based commercial entity involved in the manufacturing of PV technology. SolarPrint's innovation was the solution to the solvent-based electrolyte which to date has prohibited the mass commercialization of DSSC. The company went into receivership in 2014 and was wound up.

- G24innovations founded in 2006, based in Cardiff, South Wales, UK. On 17 October 2007, claimed the production of the first commercial grade dye sensitized thin films.

- Sony Corporation has developed dye-sensitized solar cells with an energy conversion efficiency of 10%, a level seen as necessary for commercial use.

- Tasnee Enters Strategic Investment Agreement with Dyesol.

- H.Glass was founded 2011 in Switzerland. H.Glass has put enormous efforts to create industrial process for the DSSC technologie - the first results where shown at the EXPO 2015 in Milano at the Austrian Pavilion. The milestone for DSSC is the Science Tower in Austria - it is the largest installation of DSSC in the world - carried out by SFL technologies.

![{\displaystyle {\ce {S^{.}->[{} \atop {\ce {TiO2}}]{S+}+e-}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/4a8461f7deace264f9b77a6e9f2d2a67e729f5fa)