The health and safety hazards of nanomaterials include the potential toxicity of various types of nanomaterials, as well as fire and dust explosion hazards. Because nanotechnology

is a recent development, the health and safety effects of exposures to

nanomaterials, and what levels of exposure may be acceptable, are

subjects of ongoing research. Of the possible hazards, inhalation exposure appears to present the most concern, with animal studies showing pulmonary effects such as inflammation, fibrosis, and carcinogenicity for some nanomaterials. Skin contact and ingestion exposure, and dust explosion hazards, are also a concern.

Guidance has been developed for hazard controls that are effective in reducing exposures to safe levels, including substitution with safer forms of a nanomaterial, engineering controls such as proper ventilation, and personal protective equipment as a last resort. For some materials, occupational exposure limits have been developed to determine a maximum safe airborne concentration of nanomaterials, and exposure assessment is possible using standard industrial hygiene sampling methods. An ongoing occupational health surveillance program can also help to protect workers.

Guidance has been developed for hazard controls that are effective in reducing exposures to safe levels, including substitution with safer forms of a nanomaterial, engineering controls such as proper ventilation, and personal protective equipment as a last resort. For some materials, occupational exposure limits have been developed to determine a maximum safe airborne concentration of nanomaterials, and exposure assessment is possible using standard industrial hygiene sampling methods. An ongoing occupational health surveillance program can also help to protect workers.

Background

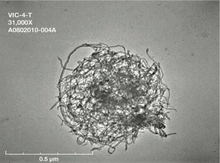

Optical micrographs of several nanomaterials present in aerosol particles. From left, silver nanoparticles, nickel nanoparticles, and multiwalled carbon nanotubes

Nanotechnology

is the manipulation of matter at the atomic scale to create materials,

devices, or systems with new properties or functions, with potential applications in energy, healthcare, industry, communications, agriculture, consumer products, and other sectors. Nanomaterials have at least one primary dimension of less than 100 nanometers,

and often have properties different from those of their bulk components

that are technologically useful. The classes of materials of which nanoparticles are typically composed include elemental carbon, metals or metal oxides, and ceramics. According to the Woodrow Wilson Center,

the number of consumer products or product lines that incorporate

nanomaterials increased from 212 to 1317 from 2006 to 2011. Worldwide

investment in nanotechnology increased from $432 million in 1997 to

about $4.1 billion in 2005.

Because nanotechnology is a recent development, the health and

safety effects of exposures to nanomaterials, and what levels of

exposure may be acceptable, is not yet fully understood. Research

concerning the handling of nanomaterials is underway, and guidance for

some nanomaterials has been developed.

As with any new technology, the earliest exposures are expected to

occur among workers conducting research in laboratories and pilot

plants, making it important that they work in a manner that is

protective of their safety and health.

A risk management system is composed of three parts. Hazard identification

involves determining what health and safety concerns are present for

both the nanomaterial and its corresponding bulk material, based on a

review of safety data sheets,

peer-reviewed literature, and guidance documents on the material. For

nanomaterials, toxicity hazards are the most important, but dust explosion hazards may also be relevant. Exposure assessment

involves determining actual routes of exposure in a specific workplace,

including a review of which areas and tasks are most likely to cause

exposure. Exposure control involves putting procedures in places to minimize or eliminate exposures according to the hierarchy of hazard controls. Ongoing verification of hazard controls can occur through monitoring of airborne nanomaterial concentrations using standard industrial hygiene sampling methods, and an occupational health surveillance program may be instituted.

Hazards

Toxicity

Respiratory

A scanning electron microscope image of bundles of multiwalled carbon nanotube piercing an alveolar epithelial cell.

Inhalation exposure

is the most common route of exposure to airborne particles in the

workplace. The deposition of nanoparticles in the respiratory tract is

determined by the shape and size of particles or their agglomerates, and

they are deposited in the alveolar compartment to a greater extent than

larger respirable particles. Based on animal studies, nanoparticles may enter the bloodstream from the lungs and translocate to other organs, including the brain. The inhalation risk is affected by the dustiness

of the material, the tendency of particles to become airborne in

response to a stimulus. Dust generation is affected by the particle

shape, size, bulk density, and inherent electrostatic forces, and

whether the nanomaterial is a dry powder or incorporated into a slurry or liquid suspension.

Animal studies indicate that carbon nanotubes and carbon nanofibers can cause pulmonary effects including inflammation, granulomas, and pulmonary fibrosis, which were of similar or greater potency when compared with other known fibrogenic materials such as silica, asbestos, and ultrafine carbon black. Some studies in cells or animals have shown genotoxic or carcinogenic effects, or systemic cardiovascular

effects from pulmonary exposure. Although the extent to which animal

data may predict clinically significant lung effects in workers is not

known, the toxicity seen in the short-term animal studies indicate a

need for protective action for workers exposed to these nanomaterials.

As of 2013, further research was needed in long-term animal studies and epidemiologic

studies in workers. No reports of actual adverse health effects in

workers using or producing these nanomaterials were known as of 2013. Titanium dioxide (TiO2) dust is considered a lung tumor risk, with ultrafine (nanoscale) particles having an increased mass-based potency relative to fine TiO2, through a secondary genotoxicity mechanism that is not specific to TiO2 but primarily related to particle size and surface area.

Dermal

Some

studies suggest that nanomaterials could potentially enter the body

through intact skin during occupational exposure. Studies have shown

that particles smaller than 1 μm in diameter may penetrate into

mechanically flexed skin samples, and that nanoparticles with varying

physicochemical properties were able to penetrate the intact skin of

pigs. Factors such as size, shape, water solubility, and surface

coating directly affect a nanoparticle’s potential to penetrate the

skin. At this time, it is not fully known whether skin penetration of

nanoparticles would result in adverse effects in animal models, although

topical application of raw SWCNT to nude mice has been shown to cause

dermal irritation, and in vitro studies using primary or cultured human skin cells have shown that carbon nanotubes can enter cells and cause release of pro-inflammatory cytokines, oxidative stress,

and decreased viability. It remains unclear, however, how these

findings may be extrapolated to a potential occupational risk. In addition, nanoparticles may enter the body through wounds, with particles migrating into the blood and lymph nodes.

Gastrointestinal

Ingestion

can occur from unintentional hand-to-mouth transfer of materials; this

has been found to happen with traditional materials, and it is

scientifically reasonable to assume that it also could happen during

handling of nanomaterials. Ingestion may also accompany inhalation

exposure because particles that are cleared from the respiratory tract

via the mucociliary escalator may be swallowed.

Fire and explosion

The explosion pentagon is a representation of the five requirements for a dust explosion.

There is concern that engineered carbon nanoparticles, when manufactured on an industrial scale, could pose a dust explosion

hazard, especially for processes such as mixing, grinding, drilling,

sanding, and cleaning. Knowledge remains limited about the potential

explosivity of materials when subdivided down to the nanoscale. The explosion characteristics of nanoparticles are highly dependent on the manufacturer and the humidity.

For microscale particles, as particle size decreases and the

specific surface area increases, the explosion severity increases.

However, for dusts of organic materials such as coal, flour, methylcellulose, and polyethylene,

severity ceases to increase as the particle size is reduced below ∼50

μm. This is because decreasing particle size primarily increases the volatilization rate, which becomes rapid enough that that gas phase combustion becomes the rate limiting step, and further decrease in particle size will not increase the overall combustion rate.

While the minimum explosion concentration does not vary significantly

with nanoparticle size, the minimum ignition energy and temperature have

been found to decrease with particle size.

Metal-based nanoparticles exhibit more severe explosions than do

carbon nanomaterials, and their chemical reaction pathway is

qualitatively different. Studies on aluminum nanoparticles and titanium nanoparticles indicate that they are explosion hazards.

One study found that the likelihood of an explosion but not its

severity increases significantly for nanoscale metal particles, and they

can spontaneously ignite under certain conditions during laboratory testing and handling.

High-resistivity powders can accumulate electric charge causing a spark hazard, and low-resistivity powders can build up in electronics causing a short circuit

hazard, both of which can provide an ignition source. In general,

powders of nanomaterials have higher resistivity than the equivalent

micron-scale powders, and humidity decreases their resistivity. One

study found powders of metal-based nanoparticles to be mid- to

high-resistivity depending on humidity, while carbon-based nanoparticles

were found to be low-resistivity regardless of humidity. Powders of

nanomaterials are unlikely to present an unusual fire hazard as compared

to their cardboard or plastic packaging, as they are usually produced

in small quantities, with the exception of carbon black.

However, the catalytic properties of nanoparticles and nanostructured

porous materials may cause untended catalytic reactions that, based on

their chemical composition, would not otherwise be anticipated.

Radioactivity

Engineered radioactive nanoparticles have applications in medical diagnostics, medical imaging, toxicokinetics, and environmental health, and are being investigated for applications in nuclear medicine. Radioactive nanoparticles present special challenges in operational health physics and internal dosimetry

that are not present for vapors or larger particles, as the

nanoparticles' toxicokinetics depend on their physical and chemical

properties including size, shape, and surface chemistry. In some cases, the inherent physicochemical toxicity of the nanoparticle itself may lead to lower exposure limits

than those associated with the radioactivity alone, which is not the

case with most radioactive materials. In general, however, most

elements of a standard radiation protection

program are applicable to radioactive nanomaterials, and many hazard

controls for nanomaterials will be effective with the radioactive

versions.

Hazard controls

The hierarchy of hazard controls

contains methods for controlling exposures to hazards. Methods listed

towards the top potentially more effective than those at the bottom at

reducing the risk of illness or injury.

Controlling exposures to hazards is the fundamental method of protecting workers. The hierarchy of hazard control

is a framework that encompasses a succession of control methods to

reduce the risk of illness or injury. In decreasing order of

effectiveness, these are elimination of the hazard, substitution with another material or process that is a lesser hazard, engineering controls that isolate workers from the hazard, administrative controls that change workers' behavior to limit the quantity or duration of exposure, and personal protective equipment worn on the workers' body.

Prevention through design

is the concept of applying control methods to minimize hazards early in

the design process, with an emphasis on optimizing employee health and

safety throughout the life cycle

of materials and processes. It increases the cost-effectiveness of

occupational safety and health because hazard control methods are

integrated early into the process, rather than needing to disrupt

existing procedures to include them later. In this context, adopting

hazard controls earlier in the design process and higher on the

hierarchy of controls leads to faster time to market, improved

operational efficiency, and higher product quality.

Elimination and substitution

An aerosol droplet containing nanomaterials ejected from a vial during sonication. Eliminating or limiting sonication and other handling processes reduces inhalation hazards.

Elimination and substitution

are the most desirable approaches to hazard control, and are most

effective early in the design process. Nanomaterials themselves often

cannot be eliminated or substituted with conventional materials because

their unique properties are necessary to the desired product or process. However, it may be possible to choose properties of the nanoparticle such as size, shape, functionalization, surface charge, solubility, agglomeration, and aggregation state

to improve their toxicological properties while retaining the desired

functionality. Other materials used incidentally in the process, such

as solvents, are also amenable to substitution.

In addition to the materials themselves, procedures used to handle them can be improved. For example, using a nanomaterial slurry or suspension

in a liquid solvent instead of a dry powder will reduce dust exposure.

Reducing or eliminating steps that involve transfer of powder or

opening packages containing nanomaterials also reduces aerosolization and thus the potential hazard to the worker. Reducing agitation procedures such as sonication, and reducing the temperature of reactors to minimize release of nanomaterials in exhaust, also reduce hazards to workers.

Engineering controls

A fume hood is an engineering control using local exhaust ventilation combined with an enclosure.

A sticky mat in a nanomaterials production facility. Ideally, other engineering controls should lessen the amount of dust collecting on the floor and being tracked onto the sticky mat, unlike this example.

Engineering controls

are physical changes to the workplace that isolate workers from hazards

by containing them in an enclosure, or removing contaminated air from

the workplace through ventilation and filtering.

They are used when hazardous substances and processes cannot be

eliminated or replaced with less hazardous substitutes. Well-designed

engineering controls are typically passive, in the sense of being

independent of worker interactions, which reduces the potential for

worker behavior to impact exposure levels. The initial cost of

engineering controls can be higher than administrative controls or

personal protective equipment, but the long-term operating costs are

frequently lower and can sometimes provide cost savings in other areas

of the process.

The type of engineering control optimal for each situation is

influenced by the quantity and dustiness of the material as well as the

duration of the task.

Ventilation systems can be local or general. General exhaust ventilation operates on an entire room through a building's HVAC system.

It is inefficient and costly as compared to local exhaust ventilation,

and is not suitable by itself for controlling exposure, although it can

provide negative room pressure

to prevent contaminants from exiting the room. Local exhaust

ventilation operates at or near the source of contamination, often in

conjunction with an enclosure. Examples of local exhaust systems include fume hoods, gloveboxes, biosafety cabinets, and vented balance enclosures. Exhaust hoods lacking an enclosure are less preferable, and laminar flow hoods are not recommended because they direct air outwards towards the worker. Several control verification techniques can be used with ventilation systems, including pitot tubes, hot-wire anemometers, smoke generators, tracer-gas leak testing, and standardized testing and certification procedures.

Examples of non-ventilation engineering controls include placing

equipment that may release nanomaterials in a separate room, and placing

walk-off sticky mats at room exits. Antistatic devices

can be used when handling nanomaterials to reduce their electrostatic

charge, making them less likely to disperse or adhere to clothing. Standard dust control methods such as enclosures for conveyor systems, using a sealed system for bag filling, and water spray application are effective at reducing respirable dust concentrations.

Administrative controls

Administrative controls are changes to workers' behavior to mitigate a hazard. They include training on best practices

for safe handling, storage, and disposal of nanomaterials, proper

awareness of hazards through labeling and warning signage, and

encouraging a general safety culture.

Administrative controls can complement engineering controls should

they fail, or when they are not feasible or do not reduce exposures to

an acceptable level. Some examples of good work practices include

cleaning work spaces with wet-wiping methods or a HEPA-filtered vacuum cleaner instead of dry sweeping with a broom,

avoiding handling nanomaterials in a free particle state, storing

nanomaterials in containers with tightly closed lids. Normal safety

procedures such as hand washing, not storing or consuming food in the laboratory, and proper disposal of hazardous waste are also administrative controls.

Other examples are limiting the time workers are handling a material

or in a hazardous area, and exposure monitoring for the presence of

nanomaterials.

Personal protective equipment

A worker weighing carbon nanotubes. The worker is using personal protective equipment including a respirator, but is not using local engineering controls such as a fume hood.

Personal protective equipment

(PPE) must be worn on the worker's body and is the least desirable

option for controlling hazards. It is used when other controls are not

effective, have not been evaluated, or while doing maintenance or in

emergency situations such as spill response. PPE normally used for

typical chemicals are also appropriate for nanomaterials, including

wearing long pants, long-sleeve shirts, and closed-toed shoes, and the

use of safety gloves, goggles, and impervious laboratory coats. Nitrile gloves are preferred because latex gloves do not provide protection from most chemical solvents and may present an allergy hazard. Face shields

are not an acceptable replacement for goggles because they do not

protect against unbound dry materials. Woven cotton lab coats are not

recommended for nanomaterials, as they can become contaminated with

nanomaterials and release them later. Donning and removing PPE in a

changing room prevents contamination of outside areas.

Respirators are another form of PPE. Respirator filters with a NIOSH air filtration rating

of N95 or P100 have been shown to be effective at capturing

nanoparticles, although leakage between the respirator seal and the skin

may be more significant, especially with half-mask respirators. Surgical masks are not effective against nanomaterials. Smaller nanoparticles of size 4–20 nm are captured more efficiently by filters than larger ones of size 30–100 nm, because Brownian motion results in the smaller particles being more likely to contact a filter fiber. In the United States, the Occupational Safety and Health Administration requires fit testing and medical clearance for use of respirators, and the Environmental Protection Agency requires the use of full face respirators with N100 filters for multi-walled carbon nanotubes not embedded in a solid matrix, if exposure is not otherwise controlled.

Industrial hygiene

Occupational exposure limits

An occupational exposure limit

(OEL) is an upper limit on the acceptable concentration of a hazardous

substance in workplace air. As of 2016, quantitative OELs have not been

determined for most nanomaterials. The U.S. National Institute for Occupational Safety and Health has determined non-regulatory recommended exposure limits (RELs) of 1.0 μg/m3 for carbon nanotubes and carbon nanofibers as background-corrected elemental carbon as an 8-hour time-weighted average (TWA) respirable mass concentration, and 300 μg/m3 for ultrafine titanium dioxide as TWA concentrations for up to 10 hr/day during a 40-hour work week.

A properly tested, half-face particulate respirator will provide

protection at exposure concentrations 10 times the REL, while an

elastomeric full facepiece respirator with P100 filters will provide

protection at 50 times the REL. Agencies and organizations from other countries, including the British Standards Institute and the Institute for Occupational Safety and Health in Germany, have established OELs for some nanomaterials, and some companies have supplied OELs for their products.

In the absence of OELs, a control banding

scheme may be used. Control banding is a qualitative strategy that uses

a rubric to place hazards into one of four categories, or "bands", and

each of which has a recommended level of hazard controls. Organizations

including GoodNanoGuide, Lawrence Livermore National Laboratory, and Safe Work Australia have developed control banding tools that are specific for nanomaterials.

The GoodNanoGuide control banding scheme is based only on exposure

duration, whether the material is bound, and the extent of knowledge of

the hazards. The LANL scheme assigns points for 15 different hazard parameters and 5 exposure potential factors. Alternatively, the "As Low As Reasonably Achievable" concept may be used.

Exposure assessment

Equipment used for area sampling of airborne nanomaterials. The instruments shown here include a condensation particle counter, aerosol photometer, and two air sampling pumps for filter-based analysis.

Exposure assessment

is a set of methods used to monitor contaminant release and exposures

to workers. These methods include personal sampling, where samplers are

located in the personal breathing zone of the worker, often attached to

a shirt collar to be as close to the nose and mouth as possible; and

area/background sampling, where they are placed at static locations.

Assessment generally use both particle counters,

which monitor the real-time quantity of nanomaterials and other

background particles; and filter-based samples, which can be used to

identify the nanomaterial, usually using electron microscopy and elemental analysis.

Not all instruments used to detect aerosols are suitable for

monitoring occupational nanomaterial emissions because they may not be

able to detect smaller particles, or may be too large or difficult to

ship to a workplace.

Suitable particle counters can detect a wide range of particle sizes,

as nanomaterials may aggregate in the air. It is recommended to

simultaneously test adjacent work areas to establish a background

concentration, as direct reading instruments cannot distinguish the

target nanomaterial from incidental background nanoparticles from motor

or pump exhaust or heating vessels.

While mass-based metrics are traditionally used to characterize

toxicological effects of exposure to air contaminants, as of 2013 it was

unclear which metrics are most important with regard to engineered

nanomaterials. Animal and cell-culture studies have shown that size and

shape are the two major factors in their toxicological effects. Surface area and surface chemistry also appeared to be more important than mass concentration.

The NIOSH Nanomaterial Exposure Assessment Technique (NEAT 2.0)

is a sampling strategy to determine exposure potential for engineered

nanomaterials. It includes filter-based and area samples, as well as a

comprehensive assessment of emissions at processes and job tasks to

better understand peak emission periods. Evaluation of worker practices,

ventilation efficacy, and other engineering exposure control systems

and risk management strategies serve to allow for a comprehensive

exposure assessment. The NIOSH Manual of Analytical Methods includes guidance on electron microscopy of filter samples of carbon nanotubes and nanofibers,

and additionally some NIOSH methods developed for other chemicals can

be used for off-line analysis of nanomaterials, including their

morphology and geometry, elemental carbon content (relevant for

carbon-based nanomaterials), and elemental makeup. Efforts to create reference materials are ongoing.

Occupational health surveillance

Occupational health surveillance

involves the ongoing systematic collection, analysis, and dissemination

of exposure and health data on groups of workers, for the purpose of

preventing disease and evaluating the effectiveness of intervention

programs. It encompasses both medical surveillance and hazard

surveillance. A basic medical surveillance program contains a baseline

medical evaluation and periodic follow-up examinations, post-incident

evaluations, worker training, and identification of trends or patterns

from medical screening data.

The related topic of medical screening

focuses on the early detection of adverse health effects for individual

workers, to provide an opportunity for intervention before disease

processes occur. Screening may involve obtaining and reviewing an

occupational history, medical examination, and medical testing. As of

2016, there were no specific screening tests or health evaluations to

identify health effects in people that are caused solely by exposure to

engineered nanomaterials. However, any medical screening recommendations for the bulk material that a nanoparticle is made of still apply, and in 2013 NIOSH concluded that the toxicologic evidence on carbon nanotubes and carbon nanofibers had advanced enough to make specific recommendations for the medical surveillance and screening of exposed workers.

Medical screening and resulting interventions represent secondary

prevention and do not replace primary prevention efforts based on direct

hazard controls to minimize employee exposures to nanomaterials.

Emergency preparedness

It is recommended that a nanomaterial spill kit be assembled prior to an emergency and include barricade tape, nitrile

or other chemically impervious gloves, an elastomeric full-facepiece

respirator with P100 or N100 filters (fitted appropriately to the

responder), adsorbent materials such as spill mats, disposable wipes, sealable plastic bags, walk-off sticky mats, a spray bottle with deionized water or another appropriate liquid to wet dry powders, and a HEPA-filtered vacuum. It is considered unsafe to use compressed air, dry sweeping, and vacuums without a HEPA filter to clear dust.

Regulation

United States

The Food and Drug Administration regulates nanomaterials under the Federal Food, Drug, and Cosmetic Act when used as food additives, drugs, or cosmetics. The Consumer Product Safety Commission

requires testing and certification of many consumer products for

compliance with consumer product safety requirements, and cautionary

labeling of hazardous substances under the Federal Hazardous Substances Act.

The General Duty Clause of the Occupational Safety and Health Act requires all employers to keep their workplace free of serious recognized hazards. The Occupational Safety and Health Administration also has recording and reporting requirements for occupational injuries and illness under 29 C.F.R. 1904 for businesses with more than 10 employees, and protection and communication regulations under 29 C.F.R. 1910. Companies producing new products containing nanomaterials must use the Hazard Communication Standard to create safety data sheets

containing 16 sections for downstream users such as customers, workers,

disposal services, and others. This may require toxicological or other

testing, and all data or information provided must be vetted by

properly controlled testing The ISO/TR 13329 standard provides guidance specifically on the preparation of safety data sheets for nanomaterials. The National Institute for Occupational Safety and Health

does not issue regulations, but conducts research and makes

recommendations to prevent worker injury and illness. State and local

governments may have additional regulations.

The Environmental Protection Agency (EPA) regulates nanomaterials under the Toxic Substances Control Act, and has permitted limited manufacture of new chemical nanomaterials through the use of consent orders or Significant New Use Rules (SNURs). In 2011 EPA issued a SNUR on multi-walled carbon nanotubes, codified as 40 C.F.R. 721.10155. Other statutes falling in the EPA's jurisdiction may apply, such as Federal Insecticide, Fungicide, and Rodenticide Act (if bacterial claims are being made), Clean Air Act, or Clean Water Act. EPA regulates nanomaterials under the same provisions as other hazardous chemical substances.

Other countries

In the European Union, nanomaterials classified by the European Commission as hazardous chemical substances are regulated under the European Chemical Agency's Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation, as well as the Classification, Labeling, and Packaging (CLP) regulations.

Under the REACH regulation, companies have the responsibility of

collecting information on the properties and uses of substances that

they manufacture or import at or above quantities of 1 ton per year,

including nanomaterials. There are special provisions for cosmetics that contain nanomaterials, and for biocidal materials under the Biocidal Products Regulation (BPR) when at least 50% of their primary particles are nanoparticles.

In the United Kingdom, powders of nanomaterials may fall under the Chemicals (Hazard Information and Packaging for Supply) Regulations 2002, as well as the Dangerous Substances and Explosive Atmosphere Regulations 2002 if they are capable of fueling a dust explosion.