From Wikipedia, the free encyclopedia

Coordinates: 21°01′42.5″N 105°51′15.0″E / 21.028472°N 105.854167°E

| Hanoi Hà Nội |

|

|---|---|

| Municipality (Thành phố trực thuộc trung ương) |

|

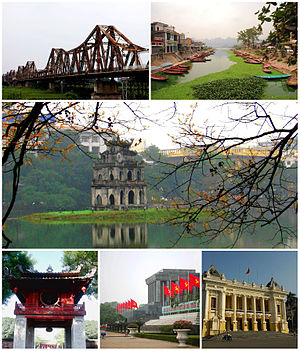

(from left) top: Long Biên Bridge, river near Perfume Pagoda; middle: Turtle Tower, bottom: Temple of Literature, Ho Chi Minh Mausoleum, Hanoi Opera House

|

|

Provincial location in Vietnam |

|

| Coordinates: 21°01′42.5″N 105°51′15.0″E / 21.028472°N 105.854167°E | |

| Country | |

| Central city | Hà Nội |

| Foundation as capital of the Đại Việt | 1010 |

| Establishment as capital of Vietnam | September 2, 1945 |

| Demonym | Hanoians |

| Government | |

| • Party's Secretary | Phạm Quang Nghị |

| • People's Council's President | Ngô Thị Doãn Thanh |

| • People's Committee's President | Nguyễn Thế Thảo |

| Area | |

| • Total | 3,324,3 km2 (186.22 sq mi) |

| Population (2014)[1] | |

| • Total | 7,067,000[1] |

| • Rank | 2nd in Vietnam |

| • Density | 2,126.05/km2 (5,506.4/sq mi) |

| Time zone | ICT (UTC+07:00) |

| • Summer (DST) | No DST (UTC+7) |

| Area codes | 24 |

| GDP (nominal) | 2013 estimate |

| - Total | 21.48 billion USD |

| - Per capita | 3,000 USD [1] |

| - Growth | |

| Website | hanoi.gov.vn |

Hanoi (/hæˈnɔɪ/[2] or US /həˈnɔɪ/)[3] is the capital of Vietnam and the country's second largest city. Its population in 2009 was estimated at 2.6 million for urban districts,[4] 6.5 million for the metropolitan jurisdiction.[5] From 1010 until 1802, it was the most important political centre of Vietnam. It was eclipsed by Huế, the imperial capital of Vietnam during the Nguyễn Dynasty (1802–1945), but Hanoi served as the capital of French Indochina from 1902 to 1954. From 1954 to 1976, it was the capital of North Vietnam, and it became the capital of a reunified Vietnam in 1976, after the North's victory in the Vietnam War.

The city lies on the right bank of the Red River. Hanoi is 1,760 km (1,090 mi) north of Ho Chi Minh City and 120 km (75 mi) west of Hai Phong city.

October 2010 officially marked 1000 years since the establishment of the city.[6] The Hanoi Ceramic Mosaic Mural is a 4 km ceramic mosaic mural created to mark the occasion.

Names

Hanoi (河內) has had many names throughout history, all of them of Sino-Vietnamese origin. During the Chinese domination of Vietnam, it was known first as Long Biên, then Tống Bình (宋平, "Song Peace") and Long Đỗ (龍肚, "Dragonbelly"). In 866, it was turned into a citadel and named Đại La (大羅, "Big Net").History

Pre-Thăng Long period

Hanoi has been inhabited since at least 3000 BC. One of the first known permanent settlements is the Cổ Loa Citadel founded around 200 BC.In 197 BC, Âu Lạc Kingdom was annexed by Nanyue, which ushered in more than a millennium of Chinese domination. By the middle of the 5th century, in the center of ancient Hanoi, the Liu Song Dynasty set up a new district (縣) called Songping (Tong Binh), which later became a commandery (郡), including two districts Yihuai (義懷) and Suining (綏寧) in the south of the Red River (now Từ Liêm and Hoài Đức districts) with a metropolis (the domination centre) in the present inner Hanoi. By the year 679, the Tang dynasty changed the region's name into Annan (Pacified South), with Songping as its capital.[7]

In order to defeat the people’s uprisings, in the later half of the 8th century, Zhang Boyi (張伯儀), a Tang dynasty viceroy, built Luocheng (羅城, La Thanh or La citadel, from Thu Le to Quan Ngua in present-day Ba Dinh precinct). In the earlier half of the 9th century, it was further built up and called Jincheng (金城, Kim Thanh or Kim Citadel). In 866, Gao Pian, the Chinese Jiedushi, consolidated and named it Daluocheng (大羅城, Dai La citadel, running from Quan Ngua to Bach Thao), the then largest citadel ancient Hanoi.[7]

Thăng Long, Đông Đô, Đông Quan, Đông Kinh

In 1010, Lý Thái Tổ, the first ruler of the Lý Dynasty, moved the capital of Đại Việt to the site of the Đại La Citadel. Claiming to have seen a dragon ascending the Red River, he renamed the site Thăng Long (昇龍, "Soaring Dragon") - a name still used poetically to this day. Thăng Long remained the capital of Đại Việt until 1397, when it was moved to Thanh Hóa, then known as Tây Đô (西都), the "Western Capital". Thăng Long then became Đông Đô (東都), the "Eastern Capital."In 1408, the Chinese Ming Dynasty attacked and occupied Vietnam, changing Đông Đô's name to Dongguan (Chinese: 東關, Eastern Gateway), or Đông Quan in Sino-Vietnamese. In 1428, the Vietnamese overthrew the Chinese under the leadership of Lê Lợi, who later founded the Lê Dynasty and renamed Đông Quan Đông Kinh (東京, "Eastern Capital") or Tonkin. Right after the end of the Tây Sơn Dynasty, it was named Bắc Thành (北城, "Northern Citadel").

During Nguyễn Dynasty and French colonial

In 1802, when the Nguyễn Dynasty was established and moved the capital to Huế, the old name Thăng Long was modified to become Thăng Long (昇龍, "Soaring Dragon"). In 1831, the Nguyễn emperor Minh Mạng renamed it Hà Nội (河内, "Between Rivers" or "River Interior"). Hanoi was occupied by the French in 1873 and passed to them ten years later. As Hanoï, it became the capital of French Indochina after 1887.

During two wars

The city was occupied by the Japanese in 1940 and liberated in 1945, when it briefly became the seat of the Viet Minh government after Ho Chi Minh proclaimed the independence of Vietnam. However, the French returned and reoccupied the city in 1946. After nine years of fighting between the French and Viet Minh forces, Hanoi became the capital of an independent North Vietnam in 1954.During the Vietnam War, Hanoi's transportation facilities were disrupted by the bombing of bridges and railways. These were all, however, promptly repaired. Following the end of the war, Hanoi became the capital of a reunified Vietnam when North and South Vietnam were reunited on July 2, 1976.

Modern Hanoi

On May 29, 2008, it was decided that Hà Tây Province, Vĩnh Phúc Province's Mê Linh District and 4 communes of Lương Sơn District, Hòa Bình Province be merged into the metropolitan area of Hanoi from August 1, 2008.[8] Hanoi's total area then increased to 334,470 hectares in 29 subdivisions[9] with the new population being 6,232,940.,[9] effectively tripling its size. The Hanoi Capital Region (Vùng Thủ đô Hà Nội), a metropolitan area covering Hanoi and 6 surrounding provinces under its administration, will have an area of 13,436 square kilometres (5,188 sq mi) with a population of 15 million by 2020.Hanoi experienced a rapid construction boom recently. Skyscrapers, popping up in new urban areas, dramatically change the citiscape and form a modern skyline. In 2014, Hanoi is ranked # 39 by Emporis in the list of world cities with most skyscrapers, two tallest buildings are Hanoi Landmark 72 Tower (336m, tallest in Vietnam and second tallest in Southeast Asia after Malaysia's Petronas Twin Towers) and Hanoi Lotte Center (267m, also second tallest in Vietnam)

Geography

Location, topography

Hanoi is located in northern region of Vietnam, situated in the Vietnam’s Red River delta, nearly 90 km (56 mi) away from the coastal area. Hanoi contains three basic kind of terrain, which are the delta area, the midland area and mountainous zone. In general, the terrain is gradually lower from the north to the south and from the west to the east, with the average height ranging from 5 to 20 meters above the sea level. The hills and mountainous zones are located in the northern and western part of the city. The highest peak is at Ba Vi with 1281 m, located in the western part of the region.Districts

Hanoi is divided into 12 urban districts, 1 district-level town and 17 rural districts. (Hà Đông has been transform to an urban district, and Sơn Tây has been degraded to a district-level town)| Subdivisions of Hanoi | ||||

|---|---|---|---|---|

| Provincial Cities/Districts[10] | Wards[10] | Area (km2)[10] | Population[10] | |

| 1 town | ||||

| Sơn Tây | 15 | 113.474 | 181,831 | |

| 12 urban districts (Quận) | ||||

| Ba Đình District | 14 | 9.224 | 228,352 | |

| Bắc Từ Liêm District | 13 | 43.35 | 320,414 | |

| Cầu Giấy District | 8 | 12.04 | 147,000 | |

| Đống Đa District | 21 | 9.96 | 352,000 | |

| Hai Bà Trưng | 20 | 14.6 | 378,000 | |

| Hà Đông District | 17 | 47.917 | 198,687 | |

| Hoàn Kiếm District | 18 | 5.29 | 178,073 | |

| Hoàng Mai District | 14 | 41.04 | 216,277 | |

| Long Biên District | 14 | 60.38 | 170,706 | |

| Nam Từ Liêm District | 10 | 32.27 | 232,894 | |

| Tây Hồ District (West Lake) | 8 | 24 | 115,163 | |

| Thanh Xuân District | 11 | 9.11 | 185,000 | |

| Subtotal | 145 | 233.56 | 2,178,258 | |

| 17 rural districts (Huyện) | ||||

| Ba Vì District | 31 + 1 town | 428.0 | 242,600 (1999) | |

| Chương Mỹ District | 30 + 2 towns | 232.9 | 261,000 (1999) | |

| Đan Phượng District | 15 + 1 town | 76.8 | 124,900 | |

| Đông Anh District | 23 + 1 town | 182.3 | 276,750 | |

| Gia Lâm District | 20 + 2 towns | 114.0 | 205,275 | |

| Hoài Đức District | 19 + 1 town | 95.3 | 188,800 | |

| Mê Linh District | 16 + 2 towns | 141.26 | 187,536 (2008) | |

| Mỹ Đức District | 21 + 1 town | 230.0 | 167,700 (1999) | |

| Phú Xuyên District | 26 + 2 towns | 171.1 | 181,500 | |

| Phúc Thọ District | 25 + 1 town | 113.2 | 154,800 (2001) | |

| Quốc Oai District | 20 + 1 town | 136.0 (2001) | 146,700 (2001) | |

| Sóc Sơn District | 25 + 1 town | 306.51 | 254,000 | |

| Thạch Thất District | 22 + 1 town | 128.1 | 149,000 (2003) | |

| Thanh Oai District | 20 + 1 town | 129.6 | 142,600 (1999) | |

| Thanh Trì District (Green Ponds) | 15 + 1 town | 98.22 | 241,000 | |

| Thường Tín District | 28 + 1 town | 127.7 | 208,000 | |

| Ứng Hòa District | 28 + 1 town | 183.72 | 193,731 (2005) | |

| Subtotal | 399 + 22 towns | 3,266.186 | 3,872,851 | |

| Total | 559 + 22 towns | 3,344.47 | 6,232,940 | |

Climate

Hanoi features a warm humid subtropical climate (Köppen Cwa) with plentiful precipitation. The city experiences the typical climate of northern Vietnam, where summers are hot and humid, and winters are, by national standards, relatively cold and dry. Hanoi averages 1,680 millimetres (66.1 in) of rainfall per year, the majority falling from May to September. The city is usually cloudy and foggy in winter, averaging only 1.5 hours of sunshine per day in February.

Extreme temperatures have ranged from 2.7 °C (36.9 °F) to 40.4 °C (105 °F).[11]

| Climate data for Hanoi (1898-1990) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Month | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | Year |

| Average high °C (°F) | 19.3 (66.7) |

19.9 (67.8) |

22.8 (73) |

27.0 (80.6) |

31.5 (88.7) |

32.6 (90.7) |

32.9 (91.2) |

31.9 (89.4) |

30.9 (87.6) |

28.6 (83.5) |

25.2 (77.4) |

21.8 (71.2) |

27.0 (80.6) |

| Daily mean °C (°F) | 16.5 (61.7) |

17.5 (63.5) |

20.5 (68.9) |

24.2 (75.6) |

27.9 (82.2) |

29.2 (84.6) |

29.5 (85.1) |

28.8 (83.8) |

27.8 (82) |

25.3 (77.5) |

21.9 (71.4) |

18.6 (65.5) |

23.98 (75.15) |

| Average low °C (°F) | 13.7 (56.7) |

15.0 (59) |

18.1 (64.6) |

21.4 (70.5) |

24.3 (75.7) |

25.8 (78.4) |

26.1 (79) |

25.7 (78.3) |

24.7 (76.5) |

21.9 (71.4) |

18.5 (65.3) |

15.3 (59.5) |

20.9 (69.6) |

| Rainfall mm (inches) | 18.6 (0.732) |

26.2 (1.031) |

43.8 (1.724) |

90.1 (3.547) |

188.5 (7.421) |

239.9 (9.445) |

288.2 (11.346) |

318.0 (12.52) |

265.4 (10.449) |

130.7 (5.146) |

43.4 (1.709) |

23.4 (0.921) |

1,676.2 (65.992) |

| Avg. rainy days | 8.4 | 11.3 | 15.0 | 13.3 | 14.2 | 14.7 | 15.7 | 16.7 | 13.7 | 9.0 | 6.5 | 6.0 | 144.5 |

| % humidity | 78 | 82 | 83 | 83 | 77 | 78 | 79 | 82 | 79 | 75 | 74 | 75 | 78.8 |

| Mean monthly sunshine hours | 68.2 | 45.2 | 43.4 | 81.0 | 164.3 | 156.0 | 182.9 | 164.3 | 162.0 | 164.3 | 126.0 | 108.5 | 1,466.1 |

| Source #1: World Meteorological Organisation (UN),[12] BBC Weather (humidity) [13] | |||||||||||||

| Source #2: (sunshine hours only)[14] | |||||||||||||

Demographics

Hanoi's population is constantly growing (about 3.5% per year), a reflection of the fact that the city is both a major metropolitan area of Northern Vietnam, and also the country's political centre. This population growth also puts a lot of pressure onto the infrastructure, some of which is antiquated and dates back from the early 20th century.

The number of Hanoians who settled down for more than three generations is likely to be very small as compared to the overall population of the city. Even in the Old Quarter, where commerce started hundreds years ago and was mostly a family business, many of the street-front stores nowadays are owned by merchants and retailers from other provinces. The original owner family may have either rented out the store and moved to live further inside the house, or just moved out of the neighbourhood altogether. The pace of change has especially escalated after the abandonment of central-planning economic policies, and relaxing of the district-based household registrar system.[citation needed]

Hanoi's telephone numbers have been increased to 8 digits to cope with demand (October 2008). Subscribers telephone numbers have been changed in a haphazard way; however, mobile phones and SIM cards are readily available in Vietnam, with pre-paid mobile phone credit available in all areas of Hanoi.

Economy

Hanoi has the highest Human Development Index among the cities in Vietnam.[citation needed]According to a recent ranking by PricewaterhouseCoopers, Hanoi will be the fastest growing city in the world in term of GDP growth from 2008 to 2025.[15] In the year 2013, Hanoi has contributed 12.6% to GDP, exported 7.5% of total exports, contributed to 17% of national budget and attracted 22% investment capital of Vietnam. The city's nominal GDP at current price reached 451,213 billion VND (21.48 billion USD) in 2013, which made per capita GDP stand at 63.3 million VND (3,000 USD).[16] Industrial production in the city has experienced a rapid boom since the 1990s, with average annual growth of 19.1 percent from 1991–95, 15.9 percent from 1996–2000, and 20.9 percent during 2001–2003.[citation needed] In addition to eight existing industrial parks, Hanoi is building five new large-scale industrial parks and 16 small- and medium-sized industrial clusters. The non-state economic sector is expanding fast, with more than 48,000 businesses currently operating under the Enterprise Law (as of 3/2007).[17]

Trade is another strong sector of the city. In 2003, Hanoi had 2,000 businesses engaged in foreign trade, having established ties with 161 countries and territories. The city's export value grew by an average 11.6 percent each year from 1996–2000 and 9.1 percent during 2001–2003.[citation needed] The economic structure also underwent important shifts, with tourism, finance, and banking now playing an increasingly important role. Hanoi's business districts are traditionally Hoàn Kiếm and the neighborhood; and a newly developing Cầu Giấy and Từ Liêm in the western part.

Similar to Ho Chi Minh City, Hanoi enjoys a rapidly developing real estate market.[18] The current most notable new urban areas are central Trung Hoa Nhan Chinh, Mỹ Đình, the luxurious zones of The Manor and Ciputra.

Agriculture, previously a pillar in Hanoi's economy, has striven to reform itself, introducing new high-yield plant varieties and livestock, and applying modern farming techniques.[citation needed]

Together with economic growth, Hanoi's appearance has also changed significantly, especially in recent years. Infrastructure is constantly being upgraded, with new roads and an improved public transportation system.[citation needed]

On February 2013 Dubai-based property developer Global Sphere announced a mega-project to build about 70 residential towers in Hanoi in an area dubbed the Hanoi Wall Street. .[19] The first phase, valued at $10 billion, is expected to be finished by 2020.

Landmarks

As the capital of Vietnam for almost a thousand years, Hanoi is considered one of the main cultural centres of Vietnam, where most Vietnamese dynasties have left their imprint. Even though some relics have not survived through wars and time, the city still has many interesting cultural and historic monuments for visitors and residents alike. Even when the nation's capital moved to Huế under the Nguyễn Dynasty in 1802, the city of Hanoi continued to flourish, especially after the French took control in 1888 and modeled the city's architecture to their tastes, lending an important aesthetic to the city's rich stylistic heritage. The city hosts more cultural sites than any city in Vietnam,[20] and boasts more than 1,000 years of history, and that of the past few hundred years has been well preserved.[21]

Old Quarter

The Old Quarter, near Hoàn Kiếm Lake, has the original street layout and architecture of old Hanoi. At the beginning of the 20th century the city consisted of only about 36 streets, most of which are now part of the old quarter. Each street then had merchants and households specialised in a particular trade, such as silk traders, jewellery, etc. The street names nowadays still reflect these specializations, although few of them remain exclusively in their original commerce.[22] The area is famous for its small artisans and merchants, including many silk shops. Local cuisine specialties as well as several clubs and bars can be found here also. A night market (near Đồng Xuân Market) in the heart of the district opens for business every Friday, Saturday, and Sunday evening with a variety of clothing, souvenirs and food.

Some others prominent places are: The Temple of Literature (Văn Miếu), site of the oldest university in Vietnam 1010; One Pillar Pagoda (Chùa Một Cột); Flag Tower of Hanoi (Cột cờ Hà Nội). In 2004, a massive part of the 900 year old Hanoi Citadel was discovered in central Hanoi, near the site of Ba Đình Square.[23]

Lakes

A city between the rivers, built from lowland, Hanoi has many scenic lakes and it is sometimes called "city of lakes". Among its lakes, the most famous are Hoàn Kiếm Lake, West Lake, Halais Lake (Hồ Thiền Quang in Vietnamese), and Bay Mau Lake. Hoan Kiem Lake, also known as Sword Lake, is the historical and cultural center of Hanoi, and is linked to the legend of the magic sword. West Lake (Hồ Tây) is a popular place for people to spend time. It is the largest lake in Hanoi and there are many temples in the area. There are swanboats for hire. The lakeside road in Quang An area is perfect for bicycling, jogging and viewing the cityscape especially in the sunset or enjoying lotus ponds in the summerColonial Hanoi

Under French rule, as an administrative centre for the French colony of Indochina, the French colonial architecture style became dominant, many examples remain today: the tree-lined boulevards (e.g. Phan Dinh Phung street) and its many villas and mansions, Grand Opera House, State Bank of Vietnam (formerly The Bank of Indochina), Presidential Palace (formerly Palace of the Governor-General of French Indochina), St. Joseph's Cathedral, and the historic Hotel Metropole. Many of the colonial structures are an eclectic mixture of French and traditional Vietnamese architectural styles, such as the National Museum of Vietnamese History, the Vietnam National Museum of Fine Arts and the old Indochina Medical College. Gouveneur-Général Paul Doumer (1898-1902) played a crucial in colonial Hanoi's urban planning. Under his tenure there was a major construction boom.[24]

Critical historians of empire have noted that French colonial rule imposed a system of white supremacy on the city. Vietnamese subjects supplied labor and tax revenue but the privileges and comforts of the city went to the white population. French efforts at rat eradication revealed some of the colonial city's racial double-standards.[25]

Museums

Hanoi is also home to a number of museums:- National Museum of Vietnamese History

- Vietnam National Museum of Fine Arts

- Vietnam Museum of Ethnology

- Vietnam Museum of Revolution

- Hỏa Lò Prison (Hanoi Hilton)

- Ho Chi Minh Museum

- Hanoi Contemporary Arts Centre

- Vietnam Military History Museum

- Hanoi Museum

Tourism

According to TripIndex by TripAdvisor, for the period between June 1 and August 31, 2012 Hanoi was the cheapest city in the world for a one-night stay for two in a four-star hotel. This included cocktails, a two-course dinner with a bottle of wine, and taxi transport (two return journeys of about 3.2 km (2.0 mi) each). It cost $141.12; about 27 percent of the cost in the most expensive city, London, which cost $518.01.[26]

In 2014, Hanoi ranked #8 in TripAdvisor's list of World Best Destinations (by Travellers' Choice).

Entertainment

A variety of options for entertainment in Hanoi can be found throughout the city. Modern and traditional theaters, cinemas, karaoke bars, dance clubs, bowling alleys, and an abundance of opportunities for shopping provide leisure activity for both locals and tourists. Hanoi has been named as one of the top 10 cities for shopping in Asia by Water Puppet Tours.[27] The number of art galleries exhibiting Vietnamese art has dramatically increased in recent years, including galleries such as "Nhat Huy" of Huynh Thong Nhat.

A popular traditional form of entertainment is Water puppetry, which is shown for example at the Thăng Long Water Puppet Theatre.

Shopping

With rapid economic growth and extremely high population density, many modern shopping centers and megamalls have been opened in Hanoi.Major malls are:

- Trang Tien Plaza, Trang Tien street (right next to Hoàn Kiếm Lake), Hoàn Kiếm District

- Vincom Center, a modern mall with hi-end CGV cineplex, Ba Trieu Street (just 2 km from Hoan Kiem lake), Hai Bà Trưng District

- Parkson Department Store, Tây Sơn Street, Đống Đa District; and Landmark Parkson Department Store at Vietnam's tallest building, Hanoi Landmark Tower (Pham Hung Road)

- The Garden Shopping Center, Me Tri - Mỹ Đình, Từ Liêm District

- Indochina Plaza, Xuan Thuy street, Cầu Giấy District

- Vincom Royal City Megamall, the largest underground mall in Asia with 230,000 sqm of shops, restaurants, cineplex, waterpark, ice skating rink; Nguyen Trai street (appox 6 km from Hoan Kiem Lake), Thanh Xuân District

- Vincom Times City Megamall, another megamall of 230,000 sqm including shops, restaurants, cineplex, huge musical fountain on central square and a giant aquarium; Minh Khai street (approx 5 km from Hoan Kiem Lake), Hai Ba Trung district

- Lotte Department Store, opened September 2014, Liễu Giai Street, Ba Đình District

Cuisine

Hanoi has rich culinary traditions. Many of Vietnam's most famous dishes, such as phở, chả cá, bánh cuốn and cốm are believed to have originated from Hanoi. Perhaps most widely known is Phở, a simple rice noodle soup often eaten as breakfast at home or street-side cafes, but also served in restaurants as a meal. Two varieties dominate the Hanoi scene: Phở Bò, containing beef, and Phở Gà, containing chicken.

Vietnam's national dish phở has been named as one of the Top5 streetfood in the world by globalpost.[28]

Hanoi has a number of restaurants whose menus specifically offer dishes containing dog, snake[29][30] and various species of insects. Insect inspired menus can be found at a number of restaurants in Khuong Thuong village, Hanoi.[31] The signature dishes at these restaurant are those containing processed ant-eggs, often in the culinary styles of Thai people or Vietnam's Muong and Tay ethnic people.[32]

Education

Hanoi, as the capital of French Indochina, was home to the first Western-style universities in Indochina, including: Indochina Medical College (1902) - now Hanoi Medical University, Indochina University (1904) - now Hanoi National University (the largest), and École Supérieure des Beaux-Arts de L'Indochine (1925) - now Hanoi University of Fine Art.

After the Communist Party took control over Hanoi in 1954 with support from the Soviet Union, many new universities were built, among them, Hanoi University of Technology remains the largest technical university in Vietnam. Recently ULIS (University of Languages and International Studies) was rated as one of the top universities in South East Asia for Languages and language studies at the undergraduate level.[33] Other universities that are not apart of Vietnam National University nor Hanoi University also include Hanoi School for Public Health and Hanoi School of Agriculture.

Hanoi is the largest centre of education in Vietnam. It is estimated that 62% of the scientists in the whole country are living and working in Hanoi.[34] Admissions to undergraduate study are through entrance examinations, which are conducted annually and open for everyone (who has successfully completed his/her secondary education) in the country. The majority of universities in Hanoi are public, although in recent years a number of private universities have started their operation. Thăng Long University, founded in 1988, by some Vietnamese mathematics professors in Hanoi and France[35] is the first private university in Vietnam. Because many of Vietnam's major universities are located in Hanoi, students from other provinces (especially in the northern part of the country) wishing to enter university often travel to Hanoi for the annual entrance examination. Such events often take place in June and July, during which a large number of students and their families converge on the city for several weeks around this intense examination period. In recent years, these entrance exams have been centrally coordinated by the Ministry of Education, but passing marks are decided independently by each university.

Although there are state owned kindergartens, there are also many private ventures that serve both local and international needs. Pre-tertiary (elementary and secondary) schools in Hanoi are generally state run although there are some independent schools. Education is equivalent to the K–12 system in the US, with elementary school between grades 1 and 5, middle school (or junior high) between grades 6 and 9, and high school from grades 10 to 12.

Transport

Hanoi is served by Noi Bai International Airport, located in the Soc Son District, approximately 40 km (25 mi) north of Hanoi. Noi Bai is the only international airport for the northern regions of Vietnam.

Hanoi will add another international airport which will cost $8 billion, the highest foreign investment so far in the history of Vietnam.[36] The construction will be carried out in three stages, starting in 2011 and continuing until 2015.

There are two main highways linking the airport and city. The route to the city via Thăng Long Bridge is more direct than Highway 1, which runs along the outskirts of the city. The main highways are shared by cars, motor scooters, with separate lanes by the side for bicycles. Taxis are plentiful and usually have trip meters, although it is also common to agree on the trip price before taking a taxi from airport to the city centre. Tourists also sometimes tour the city on cyclos especially in the Old Quarter.

Hanoi is also the origin departure point for many Vietnam Railways train routes in the country. The Reunification Express (tàu Thống Nhất) runs from Hanoi to Ho Chi Minh City from Hanoi station (formerly Hang Co station), with stops at cities and provinces along the line. Trains also depart Hanoi frequently for Hai Phong and other northern cities.The Reunification Express line was established during French colonial rule, and was completed over a period of nearly forty years, from 1899 to 1936.[37] The Reunification Express between Hanoi and Ho Chi Minh City covers a distance of 1,726 km (1,072 mi) and takes approximately 33 hours.[38] As of 2005, there were 278 stations on the Vietnamese railway network, of which 191 were located along the North-South line.

The main means of transport within Hanoi city are motorbikes, buses, taxis, and bicycles. Over the preceding decades, motorbikes have overtaken bicycles as the main form of transportation. The increased number of motorcycles can cause gridlocks. To reduce them and the negative consequences for environment and health the local government tries to increase public transportation.[39] Public buses run on many routes and fare can be purchased on the bus, with very cheap prices (20 cents for a journey where a taxi might cost $10.)

Persons on their own or traveling in a pair who wish to make a fast trip around Hanoi, to avoid traffic jams or to travel at an irregular time or by way of an irregular route, often use "xe ôm" (literally, "hug vehicle") motorbikes, which are unofficial, unregulated motorcycle taxis that involve the passenger sitting on the rear of a motorbike. Idle xe ôm riders often yell "xe ôm" at paedestrians that pass by, and signs saying "xe ôm" adorn many a tree, pole or post around the city (as with all Vietnamese cities, towns and villages,etc.) to advertise that a xe ôm vehicle and rider is often parked there. It is customary to negotiate the price of a xe ôm trip with xe ôm riders. Motorbikes can also be rented from agents within the Old Quarter of Hanoi.[40]

Sport

There are several gymnasiums and stadiums throughout the city of Hanoi. The biggest ones are Mỹ Đình National Stadium (Lê Đức Thọ Boulevard), Quan Ngua Sporting Palace (Văn Cao Avenue), Hanoi Aquatics Sports Complex and Mỹ Đình Indoor Athletics Gymnasium. The others include Hà Nội Stadium (as known as Hàng Đẫy stadium). The third Asian Indoor Games was held at Hanoi in 2009. The others are Hai Bà Trưng Gymnasium, Trịnh Hoài Đức Gymnasium, Vạn Bảo Sports Complex.

Health care and other facilities

Some medical facilities in Hanoi:- Bạch Mai Hospital

- Viet Duc Hospital

- Saint Paul Hospital

- 108 Hospital

- Hôpital Français de Hanoi

- International SOS

- Hanoi Medical University Hospital

- Thanh Nhan Hospital

International relations

Hanoi is a member of the Asian Network of Major Cities 21 and the C40 Cities Climate Leadership Group.Twin towns and sister cities

Hanoi is twinned with:Gallery

-

Presidential Palace, Hanoi (formerly Place of The Governor-General of French Indochina)

-

Vietnam National Convention Center on Pham Hung Boulevard

-

Park of Reunification (former Vladimir Lenin park)