Gold nanoparticles

Gold nanoparticles in chemotherapy and radiotherapy is the use of colloidal gold in therapeutic treatments, often for cancer or arthritis.

Gold nanoparticle technology shows promise in the advancement of cancer

treatments. Some of the properties that gold nanoparticles possess,

such as small size, non-toxicity and non-immunogenicity make these

molecules useful candidates for targeted drug delivery systems. With

tumor-targeting delivery vectors

becoming smaller, the ability to by-pass the natural barriers and

obstacles of the body becomes more probable. To increase specificity and

likelihood of drug delivery, tumor specific ligands may be grafted onto

the particles along with the chemotherapeutic drug molecules, to allow

these molecules to circulate throughout the tumor without being

redistributed into the body.

Physical properties

Solutions of gold nanoparticles of various sizes. The size difference causes the difference in colors.

Size

Gold

nanoparticles range in size depending on which therapy they are being

used for.

In photothermal cancer therapy, many gold nanoparticle molecules are

used in each test and they must all be uniform in size. Including PEG

coating, the nanoparticles measured to be ~130 nm in diameter.

Gold nanoparticles that act as drug delivery systems in conjugation

with chemotherapeutic drugs typically range in size from 10 to 100 nm.

Surface area plays a very important role in drug delivery and per

mg of gold, as diameters decrease, the surface areas needed to

transport drugs increase to the point where a single 1mL volume of

1.8 nm spherical gold nanoparticles have the same surface area as a cell

phone.

Drug vectorization requires greater specificity, and are synthesized within the single digit measurements ranging from 3-7 nm.

Antibacterial treatments are testing different sizes for cell type targeting; 10, 20 and 40 nm.

Color

Due to the

ability to tune the size and absorption of AuNPs, these molecules can

vary in the colors they emit. Colors of AuNP solutions typically range

from vibrant red to pale blue. These colors play a necessary role in the

synthesis of AuNPs as indicators of reduction.

Synthesis

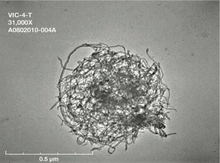

Other synthesis may include cell type targeting.

A tumor consists of a multitude of cell types, and thus targeting a

single type of cell is ineffective and potentially dangerous. At most,

this type of targeting would only have a minor effect on killing the

tumor. Tumors are constantly changing and thus phenotype targeting is

rendered useless. Two main problems persist: how to get to the target

and how to destroy a variety of cells.

Treatments

Photothermal cancer therapy

A direct method of accessing and destroying tumour cells can be

accomplished by photothermal cancer therapy or photodynamic therapy

(PDT). This procedure is known to treat small tumours that are difficult

to access and avoids the drawbacks (adverse effects) of conventional

methods, including the unnecessary destruction of healthy tissues. The cells are destroyed by exposure to light, rupturing membranes causing the release of digestive enzymes. AuNPs have high absorption cross sections requiring only minimal input of irradiation energy. Human breast carcinoma cells infused with metal nanoparticles in vitro have been shown to have an increase in morbidity with exposure to near infrared (NIR). Short term exposure in vivo (4–6 minutes) to NIR had undergone the same effect. Hirsch et al observed that extreme heating in tumours would cause irreversible tissue damage including coagulation, cell shrinkage and loss of nuclear straining. Results of their in vivo nanoshell therapy of mice revealed penetration of the tumor ~5mm.The metal particles were tuned to high absorption and scattering, resulting in effective conversion of light into heat covering a large surface area.

The El-Sayed group studied AuNP effects in vitro and in vivo.

They determined that the NIR wavelengths were converted into heat on the

picosecond timescale, allowing for short exposure of CW to minimize possible exposure to healthy cells. In vitro, photothermal therapy was used in oral epithelial cell lines, (HSC 313 and HOC 3 Clone 8) and one benign epithelial cell line (HaCaT). El-Sayed et al found that the malignant

cells that had undergone incubation in AuNPs conjugated with

anti-epithelial growth factor receptor (EGFR) required half the energy

to destroy a cell than a benign cell. Their material included gold

coated silica nanoshells that could selectively absorb NIR waves. The

particles were tuned by varying the thickness of the Au shell and

changing the size of the silica core. In exposing these particles to

NIR, the efficacy of Au was measured through the decrease of EFGR in

oral squamous carcinoma cells.

There are various biotechnological advances for in vivo delivery of

drugs. To effectively target the malignant cells, the AuNPs were

conjugated by polyethylene glycol, a process known as PEGylation.

This masks the foreign particles from the immune system such that it

arrives at its destination and increases circulation time in the system.

Antibody conjugation lines the surface of the nanoparticle with cell markers to limit spread only to malignant cells. In vivo testing of mice that developed murine colon carcinoma

tumour cells. They were injected with the solution of AuNPs that were

allowed to spread after 6 hours. Surrounding cells were swabbed with PEG

and exposed to laser treatment for detection of abnormal heating

indicating areas where Au nanoshells may have gathered. The injected

area was also swabbed with PEG to maximize light penetration.

Despite the unquestionable success of gold nanorods or nanoshells as photothermal agents in preclinical research, they have yet to obtain the approval for clinical use because their size is above the renal excretion threshold. In 2019, the first NIR-absorbing plasmonic ultrasmall-in-nano architecture has been reported, and jointly combine: (i) an efficient photothermal conversion suitable for multiple hyperthermia treatments, and (ii) renal excretion of the building blocks after the therapeutic action.

Radiofrequency therapy

X-ray radiography procedures involves the diagnosis of cancer cells through the process of image acquisition.

These techniques rely on the absorption of x-rays on the exposed tissue

in order to improve image quality. In certain radiological procedures

such as Radiofrequency therapy, a contrast agent is injected into the

targeted cancer tissue and result in increased x-ray attenuation.

Radiofrequency therapy treatment involves the destruction of

tumor cancer tissue cells through the differential heating of cancer

tissue by radio-frequency diathermy. This differential heating is a result of the blood supply in the body carrying away the heat and cooling the heated tissue.

Gold nanoparticles are excellent absorbers of x-rays, due to its high atomic number of 197Au.

This allows for a higher mass of the element, providing for a greater

area of x-ray absorption. By acting as a contrast agent and injected

into cancerous tumor cells, it would result in a higher dose of the

cancerous tissue being exposed during radiotherapy treatment.

Additionally gold nanoparticles are more efficiently removed from cells

of healthy tissue, in comparison with cancer cells - a feature that

makes them a promising radiosensitizers

Angiogenesis therapy

Angiogenesis is a process involving the formation of new blood

vessels from pre-existing vessels. It involves the degradation of the extracellular matrix, activation, migration, proliferation, and differentiation of endothelial cells into vessels. It is said to play a large part in the growth and spread of cancer cells.

The process of angiogenesis involves the use of both promoters and inhibitors,

balancing the process by only forming new blood vessels when needed.

Examples of promoters include Vascular Endothelial Growth Factor (VEGF)

and fibroblast growth factor (FGF) Examples of inhibitors include Vascular Endothelial Growth Factor Receptor 1, etc.

Tumor progression occurs as a result of the transition from a

tumor in the dormant proliferation stage to the active stage as a result

of oxygen and nutrients. This active stage leads to a state of cellular

hypoxia, which causes an increased regulation of pro-angiogenesis

proteins such as VEGF. This results in the spreading of inflammatory

proteins and cancer cells alongside the newly created blood vessels.

AuNPs have the ability to inhibit angiogenesis by directly

coordinating to heparin binding growth factors. They inhibit

phosphorylation of proteins responsible for angiogenesis in a dose

dependent matter. At concentrations 335-670 nM, almost complete

inhibition of phosphorylation was observed.

As a consequence of angiogenesis, rheumatoid arthritis has been found

to develop due to the greater ability to spread inflammatory proteins.

Through the inhibition of angiogenesis, the reduction of rheumatoid

arthritis is prevalent.

In addition, angiogenic inhibitors have a critical limitation due to

the instability of biological conditions and high dosage required. To

counter this, an emerging strategy for the development of therapies

targeting tumor-associated angiogenesis through the use of

nanotechnology and anti-angiogenic agents was developed, known as

anti-angiogenic therapy. This approach solved the limitation instability

by speeding up the delivery of angiogenesis

inhibitors.

Gold nanoparticles display anti-angiogenic properties by

inhibiting the function of pro-angiogenic heparin-binding growth factors

(HG – GFs), with prime examples being the vascular endothelial growth

factor 165 (VEGF165) and the basic fibroblast growth factor (bFGF) - both of which are pro-angiogenic promoters. Studies by Rochelle R. Arvizo, et al. have shown that the use of AuNPs of various size and surface charge plays an important role in its inhibitory effects.

In today’s biological fields, the use of nanotechnology has

allowed for the indirect use of AuNPs to deliver DNA to mammalian cells;

thereby reducing tumor agents and increasing efficiency of electron

transfer by modulating the activity of glucose oxidase. Current ongoing

research by the Mayo Clinic

laboratories includes the examination of AuNPs as messengers to deliver

reagents capable of manipulating the angiogenic response in vivo.

Current angiogenic inhibitors used today which are approved by the USFDA to treat cancer is Ayastin, Nexavar, Sutent and Affinitor.

Anti-bacterial therapy

Gold

nanoparticles are used as bacteria targeting particles in antibacterial

therapy. The therapy targets bacteria with light absorbing gold

nanoparticles (10 nm, 20 nm, 40 nm) conjugated with specific antibodies,

thus selectively kill bacteria using laser.

Studies has shown the effectiveness of this method on killing Staphylococcus aureus, which is significant human pathogen responsible for a wide range of diseases such as skin and wound infections, toxic shock syndrome, septic arthritis, endocarditis, and osteomyelitis.

In this system, the bacteria damage is caused by inducing strong laser

which leads to overheating effects accompanied by the bubble-formation

phenomena around clustered gold nanoparticles.

The selective targeting of S. aureus was performed using a monoclonal antibody to one of the major surface-clustered proteins, protein A (spa), which is linked to the peptidoglycan

portion of the cell wall. Monoclonal antibodies ensure the targeting of

the specific cell, which is essential to this mechanism. Killing

efficiency depends on local overheating effects accompanied by the

bubble-formation phenomena, the bubble formation would enhance the PT

killing effect.Better heating efficiency results from an enhanced

ability to confine the nanosecond laser-pulse within the nanocluster’s

size. Overlapping of bubbles from different nanoparticles within the

nanoclusters decreases the bubble-formation threshold. An increase in

the cluster’s average local absorption and its potential redshifting (from 525 nm for a single gold spherical nanoparticle to 700–800 nm for nanoclusters) in response to plasmon-plasmon resonance.

Drug vectorization

Another way in which AuNPs can be used in cancer therapy is as agents for targeted drug delivery.

Research shows that AuNPs can be easily functionalized and conjugated

with a variety of molecules, including chemotherapeutic drugs such as Doxorubicin.

One major complication with the current methods of treating cancer with

chemotherapy is that treatment is not optimized to specifically target

cancer cells and the widespread distribution of chemotherapeutic drugs

throughout the body can cause harmful side effects such as naseua, hair loss, and cardiotoxicity.

Since many of the characteristics of AuNPs allow them to target cancer

cells specifically and accumulate within tumor cells, these molecules

can act as tumor-targeting drug delivery systems. Once within the tumor

microenvironment, these complexes dissociate and release the

chemotherapeutic, allowing the drug to take effect and eventually cause apoptosis.

Gold nanoparticles have their advantages in drug vectorization. They can pack several different sizes and types of dendrimers

and several different types of ligands in order to effectively treat

different types of cancers. For example, research shows that 80~90% of breast cancer’s tumor cells have estrogen receptors and 60~70% of prostate cancer’s tumor cells have androgen receptors. These significant amount of hormone receptors play a role in intermolecular actions. This role is now used by targeting and therapeutic ligands on gold nanoparticles to target tissue-selective anti-tumor drug delivery.

In order to have multiple targeting and therapeutic ligands bind with

gold nanoparticles, the gold nanoparticles must first undergo polymer

stabilization. Then, anti-estrogen molecules with thiolated PEG are bound to gold nanoparticles via Au-S bonds, forming thiolate protected gold nanoparticles.

PEGylated gold nanoparticles

Docetaxel is packed into PEGylated gold nanoparticles Docetaxel is an anti-mitotic chemotherapy medicine which is showing great performance in clinical trials. Docetaxel was approved by FDA, to treat several different kinds of cancer. i.e. breast cancer(include locally advanced or metastatic).

Market approval

A

Pilot Study of AuroLase™ Therapy (gold nano shells) in refractory

and/or recurrent tumors of the head and neck was completed in 2009 and two trials are currently using AuroLase™ therapy for the treatment of primary/metastatic lung cancer and for prostate cancer.

Other gold nanoparticles on the market are mostly for synthesis of

nanoparticle complexes in research. Nanocomposix specializes in the

production of various sizes of nanoparticles, controlled by varying the

concentrations of reducing reagent and HAuCl4.

Sigma Aldrich offers six different sizes of spherical gold

nanoparticles and have developed gold nanourchins for similar usage. The

surface causes a red shift in the surface plasmon peak as compared to

spherical gold nanoaprticles.

Nanopartz

offers gold nanoparticles and gold nanorods for preclinical in vivo

therapeutics that have been used extensively in preclinical therapeutics

including photothermal hyperthermia and chemotherapeutic drug delivery.

The pilot study using the Ntracker gold nanorods was completed in 2012 and was used on seven canines with varying degrees of solid cancer tumors.

The results showed significant loading of the gold nanorods after

intravenous injection into the cancer tumors and significant heating of

the tumors from an external laser.

Adverse effects and limitations

Shape

Depending

on the shape of the molecule, the absorbance will vary, i.e. spherical

particles will absorb wavelengths in the NIR region with a relatively

low absorbance compared to long rods. Chan et al

observed that 50 nm spherical nanoparticles were taken up more

efficiently than both larger and smaller particles of the same shape. In

regards to size, the spheres were taken up more efficiently than the

rods.

Ability of greater uptake of nanoshells into the cell will localize in

the perinuclear membrane and accumulate to deliver toxic effects.

Charge

Electrostatic interactions were also investigated by Rotello et al by conjugating AuNPs with anionic and cationic functional groups. Their results showed that toxicity

was more established in AuNPs conjugated with cationic functional

groups as a consequence of electrostatic interactions with the anionic cell membrane.

Concentration

The

concentrations of gold nanoparticles in biological systems for

practical usage range from 1-100 nanoparticles per cell. High

concentrations may lead to adverse effects for cell structure and

function, which may not appear non-toxic in assays but preparation of the particles have been found to produce abnormal effects in the cell. If large concentrations quickly clear the blood vessels, the nanoshells may accumulate in major organs (mainly the liver and spleen). Residual concentrations of these particles were also found in kidneys, lungs, muscle, brain, and bone of mice after 28 days. The concentration of the solution injected intravenously 2.4*1011 nanoshells/mL. Even without complete clearance from the system, the nanoshells did not cause any physiological complications in the mice. Su et al observed a correlation with the concentration of Au3Cu and cell damage. Cells were incubated in concentrations of 0.001 and 200 mg mL−1 Au3Cu.

They concluded a 15% cell viability and dose dependent cell damage.

Reduction in cell viability was detected in vivo experiments; also

related to dosage.

Cytotoxicity is not a major concern in the usage of AuNPs, as they

localize in the vesicles and cytoplasm as opposed to the nucleus. Thus,

no complications spawned due to their aggregation in these parts of the

cell.

Heating

Two key

factors to consider when irradiating gold nanoparticles in cancer cells

are the lattice cooling rate and lattice heat content. The lattice

cooling rate is how fast heat in the particle is distributed to its

surroundings. If the cooling rate for a particle is too low, the lattice

heat content can be increased with moderate energy radiation (40 µJ/fs

with 100-fs laser at 800 nm) to the point where gold nanorods can be melted to create spherical nanoparticles which become photothermally inactive. This decomposition has been shown using gold nanorods coated with phosphatidylcholine ligands in HeLa cells using a pulsed laser and were no longer useful for treatment due to their low NIR radiation absorbance. High energy laser pulses have also been shown to fragment nanorods into smaller particles.

While these structural changes induced by laser pulses could be used to

deactivate the photothermal effects of these particles after treatment,

the resulting spherical particles or other particle fragments could

lead to complications during or after treatment when gold nanoparticles

are used for clinical treatment and imaging of cancer cells.

A limitation of photothermal chemotherapy using gold

nanoparticles involves the choice of laser when conducting treatment.

Pulsed lasers offer very selective treatment of cancer cells within a

small, localized area, but can lead to potential destruction of

particles and have a low heating efficiency due to heat lost during the

single pulse excitation.

Continuous wave lasers have a higher heating efficiency and work better

in heating larger areas with lower risk of destroying the nanoparticles

being heated. However, treatment with continuous wave lasers are much

longer compared to treatment with a pulsed laser.

A limitation of photothermal therapy with respect to the laser used is

the depth of the tumor being treated. Most lasers used to induce tumor

ablation using gold nanoparticles can only reach several centimeters

into soft tissue, making it impossible to reach tumors farther in the

body.

Finding a way to carry out therapy in cells farther into the body

without damaging surrounding cells is essential to making this technique

viable as a cancer treatment in the future.

Toxicity

Toxic precursors

Studies

in human leukemia cells revealed that prolonged exposure in AuNPs did

not harm the cells, even at ~100 μM of Au. Rather they reduced the

amount of reactive oxygen species in the cell. However, precursors to

AuNP synthesis (CTAB and HAuCl4) were found to be toxic at small concentrations (10 μM); free CTAB especially. Studies in HeLa cells by Niidome et al further support this statement by examining the correlation with the removal of excess CTAB and cell viability rose to 90%.

Toxicity of nanoparticles in vivo and in vitro

After using nanoparticles for photothermal therapy, it has been shown in vitro that high concentrations of reactive oxygen species (ROS) are formed within the treated cancer cells.

While these species are not of concern to the dead cancer cells, they

can cause oxidative stress in surrounding healthy cells if enough ROS

are created leading to healthy cell death. This oxidative stress can be passivated using polymers as reducing agents

(after degradation of the nanoparticle) and damage from ROS can be

reduced using targeted uptake of the nanoparticles to the cancer cells.

The mechanism for the oxidative stress caused by nanoparticles in the

body is still the subject of study and provides a possible limitation

when using gold nanoparticles with radiation within the body.

While there are many in vitro studies of gold nanoparticles used for chemotherapy, in vivo studies are both rare and often report conflicting results. For example, one in vivo

study has shown that 13-nm gold nanoparticles circulated in the

bloodstream often “accumulate in the liver and spleen and…have long

blood circulation times."

Also, nanoparticles from 8 to 37 nanometers have been shown to cause

abnormal symptoms leading to death in mice due to medical complications

in the spleen, liver, and lungs. Yet, other studies have shown that

20 nm gold nanoparticles can pass into the retina without causing any

cytotoxic effects and nanoparticles of 13 nm diameter were not toxic in

the body. Many argue that these results differ due to different

concentrations on nanoparticles used for these experiments and requires

further research.

Biosafety

and biokinetics investigations on biodegradable ultrasmall-in-nano

architectures have demonstrated that gold nanoparticles are able to

avoid metal accumulation in organisms through escaping by the renal

pathway.

Part of the issue with these studies is the lack of reliable methods for determining the uptake of gold nanoparticles in vivo

without examining the tumor site post-mortem. Gold nanoparticle uptake

in cells is often carried out by examining the organs of injected mice

post-mortem. This technique cannot be replicated during clinical trials,

so new methods need to be developed to determine the uptake of cells to

avoid higher concentrations of gold nanoparticles in the body leading

to toxic effects. One recently suggested method to counter this limitation is radiolabeling. The uptake of thiolated gold nanoparticles has recently been monitored using 111In-labeled

polymer shells that surround the gold nanoparticle and shows a possible

way around this problem, but these polymer shells can be removed from

the particle making a more stable labeling system required for these

kinds of studies.

Other uses

The ligand used to decrease aggregation of gold nanorods.

Gold nanoparticles may be used in an indirectly therapeutic way. The

issue of angiogenesis describes the formation of new blood vessels,

which not only increased spread of cancerous cells, but may proliferate

the spread of proteins responsible for rheumatoid arthritis. As AuNPs

reduce angiogenesis, rheumatoid arthritis is reduced as a result. Chamberland et al studied the use of anti-TNF conjugated gold nanorods (AuNRs) ex vivo in rat tail joints to reduce the effect of rheumatoid arthritis. They observed the effects of the drug delivery system via PAT

technology. The properties of the AuNRs found to be the most efficient

had measurements of 45 x 15 nm with an absorption peak of 660 nm. This

tuning allowed for better contrast between the targeted areas and

intra-articular tissue. Thus, the etanercept

conjugated AuNRs were seen to increase the light sensitivity. The

imaging technique provides greater opportunities for sensitive in vivo

drug tracking in biothechnology.

Several valences of AuNPs were found to inhibit HIV fusion. 2-nm

AuNP-mercaptobenzoic acid were conjugated to a derivative of a known CCR5 antagonist, which is a small molecule that antagonize CCR5 receptor,

and CCR5 is commonly used by HIV to enter the cell. The CCR5 antagonist

would bind to CCR5, leaving no spots for HIV to bind. This will

ultimately lead to an effect that restrict HIV infection.

Prepared AuNPs-Hepatitis B virus (HBV)

DNA gene probes could be used to detect HBV DNA directly. The

detection-visualized fluorescence-based method is highly sensitive,

simple, low cost, which could potentially apply to multi-gene detection

chips. The probe used here is essentially a biosensor, to specifically detect a certain material.

A successful application of the AuNP-nanoprobe colorimetric method to clinical diagnosis reported by Baptista et al. was the sensitive detection in clinical samples of Mycobacterium tuberculosis, the cause of human tuberculosis.