A diagram showing how the user interacts with application software on a typical desktop computer. The application software layer interfaces with the operating system, which in turn communicates with the hardware. The arrows indicate information flow.

Computer software, or simply software, is a collection of data or computer instructions that tell the computer how to work. This is in contrast to physical hardware, from which the system is built and actually performs the work. In computer science and software engineering, computer software is all information processed by computer systems, programs and data. Computer software includes computer programs, libraries and related non-executable data, such as online documentation or digital media. Computer hardware and software require each other and neither can be realistically used on its own.

At the lowest programming level, executable code consists of machine language instructions supported by an individual processor—typically a central processing unit (CPU) or a graphics processing unit (GPU). A machine language consists of groups of binary values signifying processor instructions

that change the state of the computer from its preceding state. For

example, an instruction may change the value stored in a particular

storage location in the computer—an effect that is not directly

observable to the user. An instruction may also invoke one of many input or output operations, for example displaying some text on a computer screen; causing state changes which should be visible to the user. The processor executes the instructions in the order they are provided, unless it is instructed to "jump" to a different instruction, or is interrupted by the operating system. As of 2015, most personal computers, smartphone devices and servers have processors with multiple execution units or multiple processors performing computation together, and computing has become a much more concurrent activity than in the past.

The majority of software is written in high-level programming languages. They are easier and more efficient for programmers because they are closer to natural languages than machine languages. High-level languages are translated into machine language using a compiler or an interpreter or a combination of the two. Software may also be written in a low-level assembly language,

which has strong correspondence to the computer's machine language

instructions and is translated into machine language using an assembler.

History

An outline (algorithm) for what would have been the first piece of software was written by Ada Lovelace in the 19th century, for the planned Analytical Engine. She created proofs to show how the engine would calculate Bernoulli Numbers. Because of the proofs and the algorithm, she is considered the first computer programmer.

The first theory about software—prior to the creation of computers as we know them today—was proposed by Alan Turing in his 1935 essay On Computable Numbers, with an Application to the Entscheidungsproblem (decision problem).

This eventually led to the creation of the academic fields of computer science and software engineering;

Both fields study software and its creation. Computer science is the

theoretical study of computer and software (Turing's essay is an example

of computer science), whereas software engineering is the application

of engineering and development of software.

However, prior to 1946, software was not yet the programs stored

in the memory of stored-program digital computers, as we now understand

it. The first electronic computing devices were instead rewired in order

to "reprogram" them.

In 2000, Fred Shapiro, a librarian at the Yale Law School, published a letter revealing that John Wilder Tukey's 1958 paper "The Teaching of Concrete Mathematics" contained the earliest known usage of the term "software" found in a search of JSTOR's electronic archives, predating the OED's citation by two years. This led many to credit Tukey with coining the term, particularly in obituaries published that same year,

although Tukey never claimed credit for any such coinage. In 1995, Paul

Niquette claimed he had originally coined the term in October 1953,

although he could not find any documents supporting his claim. The earliest known publication of the term "software" in an engineering context was in August 1953 by Richard R. Carhart, in a Rand Corporation Research Memorandum.

Types

On virtually all computer platforms, software can be grouped into a few broad categories.

Purpose, or domain of use

Based on the goal, computer software can be divided into:

- Application software

which is software that uses the computer system to perform special functions or provide entertainment functions beyond the basic operation of the computer itself. There are many different types of application software, because the range of tasks that can be performed with a modern computer is so large. - System software

which is software for managing computer hardware behaviour, as to provide basic functionalities that are required by users, or for other software to run properly, if at all. System software is also designed for providing a platform for running application software, and it includes the following:- Operating systems

which are essential collections of software that manage resources and provide common services for other software that runs "on top" of them. Supervisory programs, boot loaders, shells and window systems are core parts of operating systems. In practice, an operating system comes bundled with additional software (including application software) so that a user can potentially do some work with a computer that only has one operating system. - Device drivers

which operate or control a particular type of device that is attached to a computer. Each device needs at least one corresponding device driver; because a computer typically has at minimum at least one input device and at least one output device, a computer typically needs more than one device driver. - Utilities

which are computer programs designed to assist users in the maintenance and care of their computers.

- Operating systems

- Malicious software or malware

which is software that is developed to harm and disrupt computers. As such, malware is undesirable. Malware is closely associated with computer-related crimes, though some malicious programs may have been designed as practical jokes.

Nature or domain of execution

- Desktop applications such as web browsers and Microsoft Office, as well as smartphone and tablet applications (called "apps"). (There is a push in some parts of the software industry to merge desktop applications with mobile apps, to some extent. Windows 8, and later Ubuntu Touch, tried to allow the same style of application user interface to be used on desktops, laptops and mobiles.)

- JavaScript scripts are pieces of software traditionally embedded in web pages that are run directly inside the web browser when a web page is loaded without the need for a web browser plugin. Software written in other programming languages can also be run within the web browser if the software is either translated into JavaScript, or if a web browser plugin that supports that language is installed; the most common example of the latter is ActionScript scripts, which are supported by the Adobe Flash plugin.

- Server software, including:

- Web applications, which usually run on the web server and output dynamically generated web pages to web browsers, using e.g. PHP, Java, ASP.NET, or even JavaScript that runs on the server. In modern times these commonly include some JavaScript to be run in the web browser as well, in which case they typically run partly on the server, partly in the web browser.

- Plugins and extensions are software that extends or modifies the functionality of another piece of software, and require that software be used in order to function;

- Embedded software resides as firmware within embedded systems, devices dedicated to a single use or a few uses such as cars and televisions (although some embedded devices such as wireless chipsets can themselves be part of an ordinary, non-embedded computer system such as a PC or smartphone). In the embedded system context there is sometimes no clear distinction between the system software and the application software. However, some embedded systems run embedded operating systems, and these systems do retain the distinction between system software and application software (although typically there will only be one, fixed application which is always run).

- Microcode is a special, relatively obscure type of embedded software which tells the processor itself how to execute machine code, so it is actually a lower level than machine code. It is typically proprietary to the processor manufacturer, and any necessary correctional microcode software updates are supplied by them to users (which is much cheaper than shipping replacement processor hardware). Thus an ordinary programmer would not expect to ever have to deal with it.

Programming tools

Programming tools are also software in the form of programs or applications that software developers (also known as

programmers, coders, hackers or software engineers) use to create, debug, maintain (i.e. improve or fix), or otherwise support software.

Software is written in one or more programming languages; there

are many programming languages in existence, and each has at least one

implementation, each of which consists of its own set of programming

tools. These tools may be relatively self-contained programs such as compilers, debuggers, interpreters, linkers, and text editors, that can be combined together to accomplish a task; or they may form an integrated development environment

(IDE), which combines much or all of the functionality of such

self-contained tools. IDEs may do this by either invoking the relevant

individual tools or by re-implementing their functionality in a new way.

An IDE can make it easier to do specific tasks, such as searching in

files in a particular project. Many programming language implementations

provide the option of using both individual tools or an IDE.

Topics

Architecture

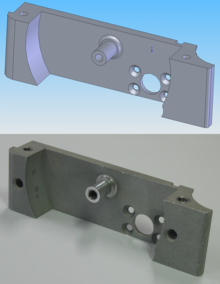

Users often see things differently from programmers. People who use modern general purpose computers (as opposed to embedded systems, analog computers and supercomputers) usually see three layers of software performing a variety of tasks: platform, application, and user software.

- Platform software

The Platform includes the firmware, device drivers, an operating system, and typically a graphical user interface which, in total, allow a user to interact with the computer and its peripherals (associated equipment). Platform software often comes bundled with the computer. On a PC one will usually have the ability to change the platform software. - Application software

Application software or Applications are what most people think of when they think of software. Typical examples include office suites and video games. Application software is often purchased separately from computer hardware. Sometimes applications are bundled with the computer, but that does not change the fact that they run as independent applications. Applications are usually independent programs from the operating system, though they are often tailored for specific platforms. Most users think of compilers, databases, and other "system software" as applications. - User-written software

End-user development tailors systems to meet users' specific needs. User software includes spreadsheet templates and word processor templates. Even email filters are a kind of user software. Users create this software themselves and often overlook how important it is. Depending on how competently the user-written software has been integrated into default application packages, many users may not be aware of the distinction between the original packages, and what has been added by co-workers.

Execution

Computer software has to be "loaded" into the computer's storage (such as the hard drive or memory). Once the software has loaded, the computer is able to execute the software. This involves passing instructions from the application software, through the system software, to the hardware which ultimately receives the instruction as machine code. Each instruction causes the computer to carry out an operation—moving data, carrying out a computation, or altering the control flow of instructions.

Data movement is typically from one place in memory to another.

Sometimes it involves moving data between memory and registers which

enable high-speed data access in the CPU. Moving data, especially large

amounts of it, can be costly. So, this is sometimes avoided by using

"pointers" to data instead. Computations include simple operations such

as incrementing the value of a variable data element. More complex

computations may involve many operations and data elements together.

Quality and reliability

Software quality is very important, especially for commercial and system software like Microsoft Office, Microsoft Windows and Linux.

If software is faulty (buggy), it can delete a person's work, crash the

computer and do other unexpected things. Faults and errors are called "bugs" which are often discovered during alpha and beta testing. Software is often also a victim to what is known as software aging, the progressive performance degradation resulting from a combination of unseen bugs.

Many bugs are discovered and eliminated (debugged) through software testing.

However, software testing rarely—if ever—eliminates every bug; some

programmers say that "every program has at least one more bug"

(Lubarsky's Law). In the waterfall method of software development, separate testing teams are typically employed, but in newer approaches, collectively termed agile software development,

developers often do all their own testing, and demonstrate the software

to users/clients regularly to obtain feedback. Software can be tested

through unit testing, regression testing

and other methods, which are done manually, or most commonly,

automatically, since the amount of code to be tested can be quite large.

For instance, NASA

has extremely rigorous software testing procedures for many operating

systems and communication functions. Many NASA-based operations interact

and identify each other through command programs. This enables many

people who work at NASA to check and evaluate functional systems

overall. Programs containing command software enable hardware

engineering and system operations to function much easier together.

License

The software's license gives the user the right to use the software in the licensed environment, and in the case of free software licenses, also grants other rights such as the right to make copies.

Proprietary software can be divided into two types:

- freeware, which includes the category of "free trial" software or "freemium" software (in the past, the term shareware was often used for free trial/freemium software). As the name suggests, freeware can be used for free, although in the case of free trials or freemium software, this is sometimes only true for a limited period of time or with limited functionality.

- software available for a fee, often inaccurately termed "commercial software", which can only be legally used on purchase of a license.

Open-source software, on the other hand, comes with a free software license, granting the recipient the rights to modify and redistribute the software.

Patents

Software patents, like other types of patents, are theoretically

supposed to give an inventor an exclusive, time-limited license for a detailed idea (e.g. an algorithm) on how to implement a piece of software, or a component of a piece of software. Ideas for useful things that software could do, and user requirements,

are not supposed to be patentable, and concrete implementations (i.e.

the actual software packages implementing the patent) are not supposed

to be patentable either—the latter are already covered by copyright,

generally automatically. So software patents are supposed to cover the

middle area, between requirements and concrete implementation. In some

countries, a requirement for the claimed invention to have an effect on

the physical world may also be part of the requirements for a software

patent to be held valid—although since all useful software has

effects on the physical world, this requirement may be open to debate.

Meanwhile, American copyright law was applied to various aspects of the

writing of the software code.

Software patents are controversial in the software industry with

many people holding different views about them. One of the sources of

controversy is that the aforementioned split between initial ideas and

patent does not seem to be honored in practice by patent lawyers—for

example the patent for Aspect-Oriented Programming (AOP), which purported to claim rights over any

programming tool implementing the idea of AOP, howsoever implemented.

Another source of controversy is the effect on innovation, with many

distinguished experts and companies arguing that software is such a

fast-moving field that software patents merely create vast additional

litigation costs and risks, and actually retard innovation. In the case

of debates about software patents outside the United States, the

argument has been made that large American corporations and patent

lawyers are likely to be the primary beneficiaries of allowing or

continue to allow software patents.

Design and implementation

Design and implementation of software varies depending on the

complexity of the software. For instance, the design and creation of Microsoft Word took much more time than designing and developing Microsoft Notepad because the latter has much more basic functionality.

Software is usually designed and created (aka coded/written/programmed) in integrated development environments (IDE) like Eclipse, IntelliJ and Microsoft Visual Studio that can simplify the process and compile the software (if applicable). As noted in a different section, software is usually created on top of existing software and the application programming interface (API) that the underlying software provides like GTK+, JavaBeans or Swing. Libraries (APIs) can be categorized by their purpose. For instance, the Spring Framework is used for implementing enterprise applications, the Windows Forms library is used for designing graphical user interface (GUI) applications like Microsoft Word, and Windows Communication Foundation is used for designing web services.

When a program is designed, it relies upon the API. For instance, a

Microsoft Windows desktop application might call API functions in the .NET Windows Forms library like Form1.Close() and Form1.Show()

to close or open the application. Without these APIs, the programmer

needs to write these functionalities entirely themselves. Companies like

Oracle and Microsoft provide their own APIs so that many applications are written using their software libraries that usually have numerous APIs in them.

Data structures such as hash tables, arrays, and binary trees, and algorithms such as quicksort, can be useful for creating software.

Computer software has special economic characteristics that make

its design, creation, and distribution different from most other

economic goods.

A person who creates software is called a programmer, software engineer

or software developer, terms that all have a similar meaning. More

informal terms for programmer also exist such as "coder" and "hacker" – although use of the latter word may cause confusion, because it is more often used to mean someone who illegally breaks into computer systems.

Industry and organizations

A great variety of software companies and programmers in the world

comprise a software industry. Software can be quite a profitable

industry: Bill Gates, the co-founder of Microsoft

was the richest person in the world in 2009, largely due to his

ownership of a significant number of shares in Microsoft, the company

responsible for Microsoft Windows and Microsoft Office software products - both market leaders in their respective product categories.

Non-profit software organizations include the Free Software Foundation, GNU Project and the Mozilla Foundation. Software standard organizations like the W3C, IETF develop recommended software standards such as XML, HTTP and HTML, so that software can interoperate through these standards.