From Wikipedia, the free encyclopedia

|

|

|

|

| Names | |

|---|---|

| IUPAC name

poly(1,1,2,2-tetrafluoroethylene)[1]

|

|

| Other names

Syncolon, Fluon, Poly(tetrafluoroethene), Poly(difluoromethylene), Poly(tetrafluoroethylene)

|

|

| Identifiers | |

| Abbreviations | PTFE |

| 9002-84-0 |

|

| ChEBI | CHEBI:53251 |

| ChemSpider | |

| KEGG | D08974 |

| Properties | |

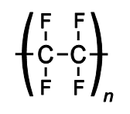

| (C2F4)n | |

| Density | 2200 kg/m3 |

| Melting point | 600 K 327 °C |

| Thermal conductivity | 0.25 W/(m·K) |

| Hazards | |

| MSDS | External MSDS |

| NFPA 704 | |

| Supplementary data page | |

| Refractive index (n), Dielectric constant (εr), etc. |

|

Thermodynamic

data |

Phase behaviour solid–liquid–gas |

| UV, IR, NMR, MS | |

Except where noted otherwise, data is given for materials in their standard state (at 25 °C (77 °F), 100 kPa)

|

|

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. The best-known brand name of PTFE-based formulas is Teflon by DuPont Co., which discovered the compound.

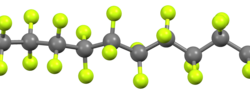

PTFE is a fluorocarbon solid, as it is a high-molecular-weight compound consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons demonstrate mitigated London dispersion forces due to the high electronegativity of fluorine. PTFE has one of the lowest coefficients of friction against any solid.

PTFE is used as a non-stick coating for pans and other cookware. It is very non-reactive, partly because of the strength of carbon–fluorine bonds and so it is often used in containers and pipework for reactive and corrosive chemicals. Where used as a lubricant, PTFE reduces friction, wear and energy consumption of machinery. It is also commonly used as a graft material in surgical interventions.

History

PTFE was accidentally discovered in 1938 by Roy Plunkett while he was working in New Jersey for DuPont. As Plunkett attempted to make a new chlorofluorocarbon refrigerant, the tetrafluoroethylene gas in its pressure bottle stopped flowing before the bottle's weight had dropped to the point signaling "empty." Since Plunkett was measuring the amount of gas used by weighing the bottle, he became curious as to the source of the weight, and finally resorted to sawing the bottle apart. He found the bottle's interior coated with a waxy white material that was oddly slippery. Analysis showed that it was polymerized perfluoroethylene, with the iron from the inside of the container having acted as a catalyst at high pressure. Kinetic Chemicals patented the new fluorinated plastic (analogous to the already known polyethylene) in 1941,[2] and registered the Teflon trademark in 1945.[3][4]

By 1948, DuPont, which founded Kinetic Chemicals in partnership with General Motors, was producing over two million pounds (900 tons) of Teflon brand PTFE per year in Parkersburg, West Virginia.[5] An early use was in the Manhattan Project as a material to coat valves and seals in the pipes holding highly reactive uranium hexafluoride at the vast K-25 uranium enrichment plant in Oak Ridge, Tennessee.[6]

In 1954, the wife of French engineer Marc Grégoire urged him to try the material he had been using on fishing tackle on her cooking pans. He subsequently created the first Teflon-coated, non-stick pans under the brandname Tefal (combining "Tef" from "Teflon" and "al" from aluminum).[7] In the United States, Marion A. Trozzolo, who had been using the substance on scientific utensils, marketed the first US-made Teflon-coated pan, "The Happy Pan", in 1961.[8]

However, Tefal was not the only company to utilize PTFE in nonstick cookware coatings. In subsequent years, many cookware manufacturers developed proprietary PTFE-based formulas, including Swiss Diamond International, which uses a diamond-reinforced PTFE formula,[9] Scanpan which uses a titanium-reinforced PTFE formula,[10] and All-Clad[11] and Newell Rubbermaid's Calphalon which use a non-reinforced PTFE-based nonstick.[12] Other cookware companies, such as Meyer Corporation's Anolon, use Teflon[13] nonstick coatings purchased from DuPont.

In the 1990s, it was found that PTFE could be radiation cross-linked above its melting point in an oxygen-free environment.[14] Electron beam processing is one example of radiation processing. Cross-linked PTFE has improved high-temperature mechanical properties and radiation stability. This was significant because, for many years, irradiation at ambient conditions had been used to break down PTFE for recycling.[15] The radiation-induced chain scissioning allows it to be more easily reground and reused.

Production

PTFE is produced by free-radical polymerization of tetrafluoroethylene. The net equation is:- n F2C=CF2 → 1/n —{ F2C—CF2}n—

- [O3SO-OSO3]2−⇌ 2 SO4•−

Because PTFE is poorly soluble in almost all solvents, the polymerization is conducted as an emulsion in water. This process gives a suspension of polymer particles. Alternatively, the polymerization is conducted using a surfactant such as PFOS.

Properties

PTFE is often used to coat non-stick pans as it is hydrophobic and possesses fairly high heat resistance.

PTFE is a thermoplastic polymer, which is a white solid at room temperature, with a density of about 2200 kg/m3. According to DuPont, its melting point is 600 K (327 °C; 620 °F).[17] It maintains high strength, toughness and self-lubrication at low temperatures down to 5 K (−268.15 °C; −450.67 °F), and good flexibility at temperatures above 194 K (−79 °C; −110 °F).[18] PTFE gains its properties from the aggregate effect of carbon-fluorine bonds, as do all fluorocarbons. The only chemicals known to affect these carbon-fluorine bonds are certain alkali metals and fluorinating agents such as xenon difluoride and cobalt(III) fluoride.[19]

| Property | Value |

|---|---|

| Density | 2200 kg/m3 |

| Melting point | 600 K |

| Thermal expansion | 135 · 10−6 K−1 [20] |

| Thermal diffusivity | 0.124 mm²/s [21] |

| Young's modulus | 0.5 GPa |

| Yield strength | 23 MPa |

| Bulk resistivity | 1016 Ω·m [22] |

| Coefficient of friction | 0.05–0.10 |

| Dielectric constant | ε=2.1,tan(δ)<5(-4) |

| Dielectric constant (60 Hz) | ε=2.1,tan(δ)<2(-4) |

| Dielectric strength (1 MHz) | 60 MV/m |

The coefficient of friction of plastics is usually measured against polished steel.[23] PTFE's coefficient of friction is 0.05 to 0.10,[17] which is the third-lowest of any known solid material (BAM being the first, with a coefficient of friction of 0.02; diamond-like carbon being second-lowest at 0.05). PTFE's resistance to van der Waals forces means that it is the only known surface to which a gecko cannot stick.[24] In fact, PTFE can be used to prevent insects climbing up surfaces painted with the material. PTFE is so slippery that insects cannot get a grip and tend to fall off. For example, PTFE is used to prevent ants climbing out of formicaria.

Because of its chemical inertness, PTFE cannot be cross-linked like an elastomer. Therefore, it has no "memory" and is subject to creep. Because of its superior chemical and thermal properties, PTFE is often used as a gasket material. However, because of the propensity to creep, the long-term performance of such seals is worse than for elastomers which exhibit zero, or near-zero, levels of creep. In critical applications, Belleville washers are often used to apply continuous force to PTFE gaskets, ensuring a minimal loss of performance over the lifetime of the gasket.[25]

Applications and uses

The major application of PTFE, consuming about 50% of production, is for wiring in aerospace and computer applications (e.g. hookup wire, coaxial cables). This application exploits the fact that PTFE has excellent dielectric properties. This is especially true at high radio frequencies, making it suitable for use as an insulator in cables and connector assemblies and as a material for printed circuit boards used at microwave frequencies. Combined with its high melting temperature, this makes it the material of choice as a high-performance substitute for the weaker and lower-melting-point polyethylene commonly used in low-cost applications.In industrial applications, owing to its low friction, PTFE is used for applications where sliding action of parts is needed: plain bearings, gears, slide plates, etc. In these applications, it performs significantly better than nylon and acetal; it is comparable to ultra-high-molecular-weight polyethylene (UHMWPE). Although UHMWPE is more resistant to wear than PTFE, for these applications, versions of PTFE with mineral oil or molybdenum disulfide embedded as additional lubricants in its matrix are being manufactured. Its extremely high bulk resistivity makes it an ideal material for fabricating long-life electrets, useful devices that are the electrostatic analogues of magnets.

Gore-Tex is a material incorporating a fluoropolymer membrane with micropores. The roof of the Hubert H. Humphrey Metrodome in *Minneapolis, US, was one of the largest applications of PTFE coatings. 20 acres (81,000 m2) of the material was used in the creation of the white double-layered PTFE-coated fiberglass dome.

Other

PTFE (Teflon) is best known for its use in coating non-stick frying pans and other cookware, as it is hydrophobic and possesses fairly high heat resistance.Niche

PTFE is a versatile material that is found in many niche applications:- It can be stretched to contain small pores of varying sizes and is then placed between fabric layers to make a waterproof, breathable fabric in outdoor apparel.

- It is used widely as a fabric protector to repel stains on formal school-wear, like uniform blazers, in the UK.

- It is used as a film interface patch for sports and medical applications, featuring a pressure-sensitive adhesive backing, which is installed in strategic high friction areas of footwear, insoles, ankle-foot orthosis, and other medical devices to prevent and relieve friction-induced blisters, calluses and foot ulceration.

- Powdered PTFE is used in pyrotechnic compositions as an oxidizer with powdered metals such as aluminium and magnesium. Upon ignition, these mixtures form carbonaceous soot and the corresponding metal fluoride, and release large amounts of heat. They are used in infrared decoy flares and as igniters for solid-fuel rocket propellants.[26]

- In optical radiometry, sheets of PTFE are used as measuring heads in spectroradiometers and broadband radiometers (e.g., illuminance meters and UV radiometers) due to PTFE's capability to diffuse a transmitting light nearly perfectly. Moreover, optical properties of PTFE stay constant over a wide range of wavelengths, from UV down to near infrared. In this region, the relation of its regular transmittance to diffuse transmittance is negligibly small, so light transmitted through a diffuser (PTFE sheet) radiates like Lambert's cosine law. Thus PTFE enables cosinusoidal angular response for a detector measuring the power of optical radiation at a surface, e.g. in solar irradiance measurements.

- Certain types of hardened, armor-piercing bullets are coated with PTFE to reduce wear on firearms's rifling that harder projectiles would cause. PTFE itself does not give a projectile an armor-piercing property.[27]

- Its high corrosion resistance makes PTFE useful in laboratory environments, where it is used for lining containers, as a coating for magnetic stirrers, and as tubing for highly corrosive chemicals such as hydrofluoric acid, which will dissolve glass containers. It is used in containers for storing fluoroantimonic acid, a superacid.[citation needed]

- PTFE tubes are used in gas-gas heat exchangers in gas cleaning of waste incinerators. Unit power capacity is typically several megawatts.

- PTFE is widely used as a thread seal tape in plumbing applications, largely replacing paste thread dope.

- PTFE membrane filters are among the most efficient industrial air filters. PTFE-coated filters are often used in dust collection systems to collect particulate matter from air streams in applications involving high temperatures and high particulate loads such as coal-fired power plants, cement production and steel foundries.

- PTFE grafts can be used to bypass stenotic arteries in peripheral vascular disease if a suitable autologous vein graft is not available.

- Many bicycle lubricants contain PTFE and are used on chains and other moving parts.

- PTFE can also be used for dental fillings to isolate the contacts of the anterior tooth so the filling materials will not stick to the adjacent tooth.

Safety

The pyrolysis of PTFE is detectable at 200 °C (392 °F), and it evolves several fluorocarbon gases and a sublimate. An animal study conducted in 1955 concluded that it is unlikely that these products would be generated in amounts significant to health at temperatures below 250 °C (482 °F).[28] More recently, however, a study documented birds having been killed by these decomposition products at 202 °C (396 °F), with unconfirmed reports of bird deaths as a result of non-stick cookware heated to as little as 163 °C (325 °F).[29]While PTFE is stable and nontoxic at lower temperatures, it begins to deteriorate after the temperature of cookware reaches about 260 °C (500 °F), and decomposes above 350 °C (662 °F).[citation needed] These degradation by-products can be lethal to birds,[30] and can cause flu-like symptoms[31] in humans. In May, 2003, the environmental research and advocacy organization Environmental Working Group filed a 14-page brief with the U.S. Consumer Product Safety Commission petitioning for a rule requiring that cookware and heated appliances bearing non-stick coatings carry a label warning of hazards to people and to birds.

Meat is usually fried between 204 and 232 °C (399 and 450 °F), and most oils start to smoke before a temperature of 260 °C (500 °F) is reached, but there are at least two cooking oils (refined safflower oil and avocado oil) that have a higher smoke point than 260 °C (500 °F). Empty cookware can also exceed this temperature when heated.

PFOA

Perfluorooctanoic acid (PFOA, or C8) has been used as a surfactant in the emulsion polymerization of PTFE, although several manufacturers have entirely discontinued its use. Overall, PTFE cookware is considered an insignificant exposure pathway to PFOA.[32][33]Similar polymers

- Perfluoroalkoxy (PFA)

- Fluorinated ethylene propylene (FEP)