From Wikipedia, the free encyclopedia

Hemp grown for animal feed

Hemp or

industrial hemp (from

Old English hænep),

[1] typically found in the northern hemisphere, is a

variety of the

Cannabis sativa plant species that is grown specifically for the industrial uses of its derived products.

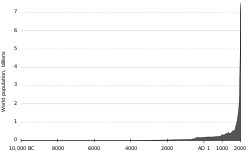

[2] It is one of the fastest growing plants

[3] and was one of the first plants to be spun into usable

fiber 10,000 years ago.

[4] It can be refined into a variety of commercial items including paper,

textiles, clothing, biodegradable plastics, paint, insulation, biofuel, food, and animal feed.

[5]

Although

cannabis as a drug and industrial hemp are both members of the species

Cannabis sativa and contain the psychoactive component

tetrahydrocannabinol (THC), they are distinct strains with unique biochemical compositions and uses. Hemp has lower concentrations of THC and higher concentrations of

cannabidiol (CBD), which decreases or eliminates its psychoactive effects. The

legality of industrial hemp

varies widely between countries. Some governments regulate the

concentration of THC and permit only hemp that is bred with an

especially low THC content.

[7][8]

Etymology

The etymology is uncertain but there appears to be no common

Proto-Indo-European source for the various forms of the word; the Greek term

kánnabis is the oldest attested form, which may have been borrowed from an earlier

Scythian or

Thracian word.

[9][10] Then it appears to have been borrowed into Latin, and separately into Slavic and from there into Baltic, Finnish, and

Germanic languages.

[11] Following

Grimm's law, the "k" would have changed to "h" with the first Germanic sound shift,

[9][12] after which it may have been adapted into the Old English form,

hænep.

However, this theory assumes that hemp was not widely spread among

different societies until after it was already being used as a

psychoactive drug, which Adams and Mallory (1997) believe to be unlikely

based on archaeological evidence.

[9] Barber

(1991) however, argued that the spread of the name "kannabis" was due

to its historically more recent drug use, starting from the south,

around Iran, whereas non-THC varieties of hemp are older and

prehistoric.

[11] Another possible source of origin is Assyrian

qunnabu, which was the name for a source of oil, fiber, and medicine in the 1st millennium BC.

[11]

Cognates of hemp in other Germanic languages, include Dutch

hennep, Danish and Norwegian

hamp, German

Hanf, and Swedish

hampa.

[9]

Uses

Hemp is used to make a variety of commercial and industrial products

including rope, clothes, food, paper, textiles, plastics, insulation and

biofuel.

[5] The

bast fibers can be used to make textiles that are 100% hemp, but they are commonly blended with other organic fibers such as

flax,

cotton or silk, to make woven fabrics for apparel and furnishings. The

inner two fibers of the plant are more woody and typically have

industrial applications, such as mulch, animal bedding and litter. When

oxidized (commonly referred to as "drying"),

hemp oil

from the seeds becomes solid and can be used in the manufacture of

oil-based paints, in creams as a moisturizing agent, for cooking, and in

plastics. Hemp seeds have been used in bird feed mix as well.

[13] A survey in 2003 showed that more than 95% of hemp seed sold in the

European Union was used in animal and bird feed.

[14]

Food

Hemp seeds can be eaten raw, ground into a meal,

sprouted,

or made into dried sprout powder. The leaves of the hemp plant can be

consumed raw in salads. Hemp can also be made into a liquid and used for

baking or for beverages such as

hemp milk,

hemp juice,

[citation needed] and tea.

[15] Hempseed oil is cold-pressed from the seed and is high in unsaturated fatty acids.

[16]

In 2011, the U.S. imported $11.5 million worth of hemp products, mostly

driven by growth in demand for hemp seed and hemp oil for use as

ingredients in foods such as granola.

[17]

In the UK, the

Department for Environment, Food and Rural Affairs

(Defra) treats hemp as a purely non-food crop, but with proper

licensing and proof of less than 0.2% THC concentration, hemp seeds can

be imported for sowing or for sale as a food or food ingredient.

[18] In the U.S., imported hemp can be used legally in food products and as of 2000, was typically sold in health food stores or through mail order.

[16]

Nutrition

100 grams of hulled hemp seeds supply 586

calories. They are 5% water, 5%

carbohydrates, 49% total

fat and 31%

protein. Hemp seeds are notable in providing 64% of the

Daily Value (DV) of protein per 100 gram serving.

[19]

Hempseed

amino acid profile is comparable to other sources of protein such as meat, milk, eggs and

soy.

[20] Protein Digestibility Corrected Amino Acid Score values (

PDCAAS),

which measure the degree to which a food for humans is a "complete

protein", were 0.49-0.53 for whole hemp seed, 0.46-0.51 for hemp seed

meal, and 0.63-0.66 for dehulled hemp seed.

[21]

Hemp seeds are a rich source of

B vitamins, the

dietary minerals,

manganese (362% DV),

phosphorus (236% DV),

magnesium (197% DV),

zinc (104% DV),

iron (61% DV) and

dietary fiber (20% DV) (table).

Approximately 73% of the energy in hemp seeds is in the form of fats and

essential fatty acids,

[19] mainly

polyunsaturated fatty acids,

linoleic,

oleic and

alpha-linolenic acids.

[20]

Storage

Hemp oil oxidizes and turns rancid within a short period of time if not stored properly;

[16] its shelf life is extended when stored in a dark airtight container and refrigerated.

Fiber

Hemp fiber has been used extensively throughout history, with

production climaxing soon after being introduced to the New World. Items

ranging from rope, to fabrics, to industrial materials were made from

hemp fiber. Hemp was often used to make sail

canvas, and the word

canvas derives from

cannabis.

[22][23] Today, a modest hemp fabric industry exists, and hemp fibers can be used in clothing.

[24] Pure hemp has a texture similar to

linen.

[25]

Processing

Traditionally the hemp stalks would be water-

retted first before the fibers were beaten off the inner

hurd by hand; a process known as

scutching. As mechanical technology evolved, separating the fiber from the core was accomplished by

crushing rollers and

brush rollers that would produce a nearly clean fiber. After the

Marijuana Tax Act was implemented in 1938, the technology for separating the fibers from the core remained "frozen in time".

Only in 1997, starting with Ireland, did the

Commonwealth countries and then other countries begin to legally grow

industrial hemp again. Reiterations of the 1930s

decorticator have been met with limited success, along with

steam explosion and chemical processing known as

thermomechanical pulping.

[citation needed]

Building material

Concrete-like blocks made with hemp and lime have been used as an

insulating material for construction. Such blocks are not strong enough

to be used for structural elements; they must be supported by a brick,

wood, or steel frame.

[26]

However hemp fibres are extremely strong and durable, and have been

shown to be usable as a replacement for wood for many jobs including

creating very durable and breathable homes.

The first example of the use of hempcrete was in 1986 in France with the renovation of the Maison de la Turque in

Nogent-sur-Seine by the innovator Charles Rasetti.

[27] In the UK hemp lime was first used in 2000 for the construction of two test dwellings in Haverhill.

[28] Designed by Modece Architects,

[29]

who pioneered hemp's use in UK construction, the hemp houses were

monitored in comparison with other standard dwellings by BRE. Completed

in 2009, The Renewable House is one of the most technologically advanced

made from hemp-based materials.

[30] The first US home made of hemp-based materials was completed in August 2010 in Asheville, North Carolina.

[31]

A panellized system of hemp-lime panels for use in building

construction is currently under test in a European Union funded research

collaboration led by the

University of Bath.

The panels are being designed to assure high quality construction,

rapid on-site erection, optimal hygrothermal performance from day one

and energy and resource efficient buildings. The 36-month-long work

programme aims to refine product and manufacturing protocols, produce

data for certification and marketing, warranty, insurance cover and

availability of finance. It also includes the development of markets in

Britain, France and Spain.

[32]

Hemp is used as an internal plaster and is a mixture of hemp hurd

(shive) mixed with larger proportions of a lime based binder. Hemp

plaster has insulative qualities.

[33]

-

-

-

Hemp interior thermal insulation blocks

-

Hemp acoustic ceiling insulation

-

Plastic and composite materials

A mixture of

fiberglass, hemp fiber,

kenaf, and

flax has been used since 2002 to make composite panels for automobiles.

[34] The choice of which

bast fiber to use is primarily based on cost and availability. Various car makers are beginning to use hemp in their cars, including

Audi,

BMW,

Ford,

GM,

Chrysler,

Honda,

Iveco,

Lotus,

Mercedes,

Mitsubishi,

Porsche, Saturn,

Volkswagen[35] and Volvo. For example, the Lotus Eco Elise

[36] and the Mercedes C-Class both contain hemp (up to 20 kg in each car in the case of the latter).

[37]

-

Hemp plastic interior of a car door

-

Hemp plastic automobile glove box

-

Hemp plastic column, automobile

-

Hemp composite sink basin

Paper

Hemp paper,

Hemp Heritage, is being manufactured by one company in North America.

This Company, Green Field Paper Company, makes paper in both text and

cover weights. The paper is used for packaging, stationery, journals,

fine art papers and business cards.

Fiber sources

Ancient Sanskrit on hemp based paper. Hemp fiber was commonly used in the production of paper from 200 BCE to the late 1800s.

Before the industrialisation of the paper production the most common

fibre source was recycled fibres from used textiles, called rags. The

rags were from hemp,

linen and

cotton.

[38] A process for removing printing inks from

recycled paper was invented by German jurist

Justus Claproth in 1774.

[38] Today this method is called

deinking. It was not until the introduction of

wood pulp in 1843 that paper production was not dependent on recycled materials from

ragpickers.

[38]

History and development

The first identified coarse

paper, made from hemp, dates to the early

Western Han Dynasty, two hundred years before the nominal invention of

papermaking by

Cai Lun,

who improved and standardized paper production using a range of

inexpensive materials, including hemp ends, approximately 2000 years

ago.

[39] Recycled hemp clothing, rags and fishing nets were used as inputs for paper production.

The

Saint Petersburg, Russia,

paper mill of Goznak opened in 1818. It used hemp as its main input

material. Paper from the mill was used in the printing of "

bank notes, stamped paper, credit bills, postal stamps, bonds, stocks, and other

watermarked paper."

[40]

In 1916, U.S. Department of Agriculture chief scientists

Lyster Hoxie Dewey

and Jason L. Merrill created paper made from hemp pulp and concluded

that paper from hemp hurds was "favorable in comparison with those used

with pulp wood."

[41][42] The chemical composition of hemp hurds is similar to that of wood,

[43]

making hemp a good choice as a raw material for manufacturing paper. Modern research has not confirmed the positive finding about hemp hurds

from 1916. A later book about hemp and other fibers by the same L.H.

Dewey(1943) have no words about hemp as a raw material for production of

paper.

[44] Dried hemp has about 57%

cellulose (the principal ingredient in paper), compared to about 40-50% in wood.

[45][46][47] Hemp also has the advantage of a lower lignin content: hemp contains only 5-24% lignin

[48] against the 20-35% found in wood.

[49] This lignin must be removed chemically and wood requires more use of chemicals in the process.

[50]

The actual production of hemp fiber in the U.S continued to decline

until 1933 to around 500 tons/year. Between 1934 and 1935, the

cultivation of hemp began to increase but still at a very low level and

with no significant increase of paper from hemp.

[51][52]

Contemporary

Currently there is a small niche market for hemp pulp, for example as cigarette paper.

[53]

Hemp fiber is mixed with fiber from other sources than hemp. In 1994

there was no significant production of 100% true hemp paper.

[54]

World hemp pulp production was believed to be around 120,000 tons per

year in 1991 which was about 0.05% of the world's annual pulp production

volume.

[55] The total world production of hemp fiber had in 2003 declined to about 60,000 from 80,000 tons.

[53] This can be compared to a typical pulp mill for wood fiber, which is never smaller than 250,000 tons per annum.

[54][56] The cost of hemp pulp is approximately six times that of wood pulp,

[55]

mostly because of the small size and outdated equipment of the few hemp

processing plants in the Western world, and because hemp is harvested

once a year (during August)

[citation needed]

and needs to be stored to feed the mill the whole year through. This

storage requires a lot of (mostly manual) handling of the bulky stalk

bundles. Another issue is that the entire hemp plant cannot be

economically prepared for paper production. While the wood products

industry uses nearly 100% of the fiber from harvested trees, only about

25% of the dried hemp stem—the bark, called bast—contains the long,

strong fibers desirable for paper production.

[57] All this accounts for a high raw material cost. Hemp pulp is bleached with

hydrogen peroxide, a process today also commonly used for wood pulp.

Market share

Around

the year 2000, the production quantity of flax and hemp pulp total

25000-30000 tons per year, having been produced from approximately

37000-45000 tonnes fibers. Up to 80% of the produced pulp is used for

specialty papers (including 95% of

cigarette paper). Only about 20% hemp fiber input goes into the standard pulp area and are here mostly in lower quality (untreated

oakum high

shive

content added) wood pulps. With hemp pulp alone, the proportion of

specialty papers probably at about 99%. The market is considered

saturated with little or no growth in this area.

[58][59]

Jewelry

Hemp jewelry

Hemp jewelry is the product of knotting hemp twine through the practice of

macramé.

Hemp jewellery includes bracelets, necklaces, anklets, rings, watches

and other adornments. Some jewellery features beads made from

glass,

stone,

wood and

bones. The hemp twine varies in thickness and comes in a variety of colors. There are many different

stitches used to create hemp jewellery, however, the half knot and full knot stitches are most common.

Cordage

Hemp rope was used in the

age of sailing ships, though the rope had to be protected by

tarring, since hemp rope has a propensity for breaking from

rot, as the capillary effect of the rope-woven fibers tended to hold liquid at the interior, while seeming dry from the outside.

[60] Tarring was a labor-intensive process, and earned sailors the nickname "

Jack Tar".

Hemp rope was phased out when Manila, which does not require tarring,

became widely available. Manila is sometimes referred to as

Manila hemp, but is not related to hemp; it is

abacá, a species of

banana.

Animal bedding

Hemp straw animal bedding

Hemp shives are the core of the stem, hemp hurds are broken parts of

the core. In the EU, they are used for animal bedding (horses, for

instance), or for horticultural mulch.

[61] Industrial hemp is much more profitable if both fibers and shives (or even seeds) can be used.

Water and soil purification

Hemp

can be used as a "mop crop" to clear impurities out of wastewater, such

as sewage effluent, excessive phosphorus from chicken litter, or other

unwanted substances or chemicals. Additionally Hemp is being used to

clean contaminants at the

Chernobyl nuclear disaster site. By way of a process which is known as

phytoremediation - the process of clearing radioisotopes as well as a variety of other toxins from the soil, water, and air.

[62]

Weed control

The dense growth of hemp helps kill weeds, even

thistle.

Hemp, because of its height, dense foliage and its high planting

density as a crop, is a very effective and long used method of killing

tough weeds in farming by minimizing the pool of weed seeds of the soil.

[63] Using hemp this way can help farmers avoid the use of herbicides, to help gain

organic certification and to gain the benefits of

crop rotation. Due to its rapid, dense growth characteristics, in some jurisdictions hemp is considered a prohibited noxious weed, much like

Scotch Broom.

[citation needed]

Biofuels

Biodiesel can be made from the oils in hemp seeds and stalks and

alcohol fuel

(ethanol or, less commonly, methanol) from the fermentation of the

whole plant. Biodiesel produced from hemp is sometimes known as

"hempoline".

[64]

Filtered hemp oil can be used directly to power

diesel engines. In 1892,

Rudolf Diesel

invented the diesel engine, which he intended to power "by a variety of

fuels, especially vegetable and seed oils, which earlier were used for

oil lamps, i.e. the

Argand lamp."

[65][66][67]

Production of vehicle fuel from hemp is very small. Commercial

biodiesel and

biogas

is typically produced from cereals, coconuts, palmseeds and cheaper raw

materials like garbage, wastewater, dead plant and animal material,

animal

feces and kitchen waste.

[68]

Cultivation

Harvesting industrial hemp (Cannabis sativa) - this is a separate

harvest for a different form of processing: The upper part of the plant

with the leaves will be collected for cold pressing, while the lower

part remains for producing fiber and initially it is left on the field.

Hemp is usually planted between March and May in the northern

hemisphere, between September and November in the southern hemisphere.

[69] It matures in about three to four months.

Millennia of

selective breeding have resulted in

varieties

that look quite different. Also, breeding since circa 1930 has focused

quite specifically on producing strains which would perform very poorly

as sources of drug material. Hemp grown for fiber is planted closely,

resulting in tall, slender plants with long fibers. "Until the early

1900s industrial hemp was a valuable crop used all over the world for

its strong fibers and oil seeds. Today, however, the common perception

of the industrial hemp plant is generally negative and associated with

the drug

marijuana.

This perception is the legacy of a century of powerful influences

construing hemp as a dangerous drug, even though it is not a drug and it

has the potential to be a profitable alternative crop. In the United

States, the public's perception of hemp as marijuana has blocked hemp

from becoming a useful crop and product,"

[70] in spite of its vital importance prior to World War II.

[71] Ideally, according to Britain's

Department for Environment, Food and Rural Affairs,

the herb should be desiccated and harvested towards the end of

flowering. This early cropping reduces the seed yield but improves the

fiber yield and quality.

[72] In these strains of industrial hemp the

tetrahydrocannabinol (THC) content would have been very low.

[70]

The seeds are sown from mid-April to mid-May with grain drills to

4–6 cm sowing depth. Hemp needs less fertilizer than corn does. A total

of 60–150 kg of nitrogen, 40–140 kg phosphorus (P

2O

5)

and 75–200 kg of potassium [5] per acre for hemp fiber made before

sowing and again later, maybe three to four weeks. When practiced,

especially in France double use of fiber and seed fertilization with

nitrogen doses up to 100 kg /

ha

rather low. Organic fertilizers such as manure can utilize industrial

hemp well. Neither weeds nor crop protection measures are necessary.

[70]

Cultivars

Hemp strains USO-xx and Zolotoniski-xx

A total of 26 varieties of hemp with low levels of tetrahydrocannabinol (THC) are certified by the

European Union (EU).

[73]

They have, unlike other types, a very high fiber content of 30-40%. In

contrast to cannabis for medical use, varieties grown for fiber and seed

have less than 0.2% THC and they are unsuitable for producing hashish

and marijuana.

[74] The most important cannabinoid in industrial hemp is

cannabidiol (CBD) with a proportion of 1 to 5%.

[citation needed]

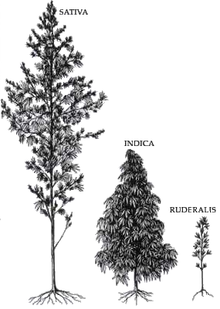

The variety of appearances for cannabis. Only C. sativa (left) is suited for industrial hemp, but it also has medicinal varieties.

Cannabis sativa L. subsp.

sativa var.

sativa is the variety grown for industrial use, while

C. sativa subsp.

indica

generally has poor fiber quality and female buds from this variety are

primarily used for recreational and medicinal purposes. The major

differences between the two types of plants are the appearance, and the

amount of Δ

9-

tetrahydrocannabinol (THC) secreted in a resinous mixture by

epidermal hairs called glandular

trichomes, although they can also be distinguished genetically.

[75] Oilseed and fiber varieties of

Cannabis

approved for industrial hemp production produce only minute amounts of

this psychoactive drug, not enough for any physical or psychological

effects. Typically, hemp contains below 0.3% THC, while cultivars of

Cannabis grown for medicinal or recreational use can contain anywhere from 2% to over 20%.

[76]

Harvesting

Industrial hempseed harvesting machine in

France

Smallholder plots are usually harvested by hand. The plants are cut

at 2 to 3 cm above the soil and left on the ground to dry. Mechanical

harvesting is now common, using specially adapted cutter-binders or

simpler cutters.

The cut hemp is laid in swathes to dry for up to four days. This was traditionally followed by

retting,

either water retting (the bundled hemp floats in water) or dew retting

(the hemp remains on the ground and is affected by the moisture in dew,

and by molds and

bacterial action).

Location and crop rotation

For profitable hemp farming, particularly deep,

humus-rich,

nutrient-rich soil with controlled water flow is preferable.

Waterlogged acidic, compressed or extremely light (sandy) soils

primarily affect the early development of plants.

[citation needed]

Steep and high altitudes of more than 400 m above sea level are best

avoided. Hemp is relatively insensitive to cold temperatures and can

withstand frost down to −5 °C.

[citation needed] Seeds can germinate down to 1–3 °C.

[citation needed] Hemp needs a lot of heat, so earlier varieties come to maturation. The water requirement is 300–500 l/kg dry matter.

[citation needed]

Up to 3 feet growing roots into the soil can also use water supplies

from deeper soil layers. Worth noting is that the water requirement of

hemp is at least 14 times lower than that of cotton, which takes between

7,000 and 29,000 l/kg, according to WWF.

[citation needed]

Hemp benefits crops grown after it. For this reason, it is generally

grown before winter cereals. Advantageous changes are high weed

suppression, soil loosening by the large hemp root system and the

positive effect on soil

tilth. Since hemp is very self-compatible, it can also be grown several years in a row in the same fields (monoculture).

Diseases

Hemp plants can be vulnerable to various

pathogens, including

bacteria,

fungi,

nematodes,

viruses

and other miscellaneous pathogens. Such diseases often lead to reduced

fiber quality, stunted growth, and death of the plant. These diseases

rarely affect the yield of a hemp field, so hemp production is not

traditionally dependent on the use of pesticides.

Environmental impact

Hemp is considered by a 1998 study in

Environmental Economics to be

environmentally friendly due to a decrease of

land use and other environmental impacts, indicating a possible decrease of

ecological footprint in a US context compared to typical benchmarks.

[77] A 2010 study, however, that compared the production of

paper specifically from hemp and

eucalyptus

concluded that "industrial hemp presents higher environmental impacts

than eucalyptus paper"; however, the article also highlights that "there

is scope for improving industrial hemp paper production".

[78] Hemp is also claimed to require few

pesticides and no herbicides, and it has been called a

carbon negative raw material.

[79][80]

Results indicate that high yield of hemp may require high total

nutrient levels (field plus fertilizer nutrients) similar to a high

yielding wheat crop.

[81]

Producers

Hemp production in tonnes 2003 & 2013

FAOSTAT (FAO)

|

France France |

4300 |

14 % |

48264 |

71 % |

China China |

24000 |

79 % |

16000 |

24 % |

Chile Chile |

1250 |

4 % |

1450 |

2% |

Ukraine Ukraine |

150 |

< 1% |

1450 |

1% |

Hungary Hungary |

40 |

< 1% |

600 |

< 1% |

Russia Russia |

300 |

1 % |

300 |

<1 nbsp="" td="">

|

Romania Romania |

100 |

< 1% |

150 |

< 1% |

Poland Poland |

15 |

< 1% |

30 |

< 1% |

Turkey Turkey |

150 |

< 1% |

1 |

< 1% |

Spain Spain |

8 |

< 1% |

0 |

0% |

Serbia Serbia |

2 |

< 1% |

|

0% |

| Total |

30315 |

100 % |

67785 |

100% |

The world-leading producer of hemp is

France, which produces more than 70% of the world output.

China ranks second with approximately a quarter of the world production. There is smaller production in

Europe,

Chile and

North Korea. Over thirty countries produce industrial hemp, including

Australia,

Austria,

Canada,

Chile,

China,

Denmark,

Egypt,

Finland,

Great Britain,

Germany,

Greece,

[82] Hungary,

India,

Italy,

Japan,

Korea,

Netherlands,

New Zealand,

Poland,

Portugal,

Romania,

Russia,

Slovenia,

Spain,

Sweden,

Switzerland,

Thailand,

Turkey and

Ukraine.

[83][84]

The

United Kingdom and Germany resumed commercial production in the 1990s. British production is mostly used as bedding for

horses;

other uses are under development. Companies in Canada, the UK, the

United States and Germany, among many others, process hemp seed into a

growing range of

food products and

cosmetics; many traditional growing countries still continue to produce

textile-grade fibre.

Dried hemp stalks displayed at the International Hemp Fair in

Vienna.

Air dry stem yields in Ontario have from 1998 and onward ranged from

2.6-14.0 tonnes of dry, retted stalks per hectare (1-5.5 t/ac) at 12%

moisture. Yields in Kent County, have averaged 8.75 t/ha (3.5 t/ac).

Northern Ontario crops averaged 6.1 t/ha (2.5 t/ac) in 1998. Statistic

for the European Union for 2008 to 2010 say that the average yield of

hemp straw has varied between 6.3 and 7.3 ton per ha.

[85][86]

Only a part of that is bast fiber. Approximately one tonne of bast

fiber and 2-3 tonnes of core material can be decorticated from 3-4

tonnes of good quality, dry retted straw. For an annual yield of this

level is it in Ontario recommended to add nitrogen (N):70–110 kg/ha,

phosphate (P

2O

5): up to 80 kg/ha and

potash (K

2O): 40–90 kg/ha.

[87] The average yield of dry hemp stalks in Europe was 6 ton/ha (2.4 ton/ac) in 2001 and 2002.

[14]

FAO argue that an optimum yield of hemp fiber is more than 2 tonnes per ha, while average yields are around 650 kg/ha.

[88]

Australia

In the Australian states of

Tasmania,

Victoria,

Queensland and, most recently,

New South Wales,

the state governments have issued licences to grow hemp for industrial

use. The first to initiate modern research into the potential of

cannabis was the state of Tasmania pioneered the licensing of hemp

during the early 1990s. The state of Victoria was an early adopter in

1998, and has reissued the regulation in 2008.

[89]

Queensland has allowed industrial production under licence since 2002,

[90] where the issuance is controlled under the Drugs Misuse Act 1986.

[91] Most recently, New South Wales now issues licences

[92] under a law, the Hemp Industry Regulations Act 2008 (No 58), that came into effect as of 6 November 2008.

[93]

Canada

Commercial

production (including cultivation) of industrial hemp has been

permitted in Canada since 1998 under licenses and authorization issued

by Health Canada (9,725 ha in 2004, 5450 ha in 2009).

[94]

In the early 1990s, industrial hemp agriculture in North America began with the

Hemp Awareness Committee at the

University of Manitoba.

The Committee worked with the provincial government to get research and

development assistance, and was able to obtain test plot permits from

the

Canadian government. Their efforts led to the legalization of

industrial hemp (hemp with only minute amounts of

tetrahydrocannabinol) in

Canada and the first harvest in 1998.

[95][96]

The cultivated area for hemp in the

Prairie provinces of Canada is stable at about 90,000 acres (36,000 ha) over 2013–15.

[97]

France

Industrial hemp production in France

France is the world's biggest producer with 8,000 hectares cultivated.

[citation needed]

70-80% of the hemp fibre produced in Europe in 2003 was used for

specialty pulp for cigarette papers and technical applications. About

15% is used in the automotive sector and 5-6% were used for insulation

mats. Approximately 95% of hurds were used as animal bedding, while

almost 5% were used in the building sector.

[14] In 2010/2011, a total of 11 000 ha was cultivated with hemp in the

EU, a decline compared with previous year.

[86][98]

Russia and Ukraine

Harvesting hemp in the USSR, 1956

From the 1950s to the 1980s, the

Soviet Union was the world's largest producer of hemp (3,000 km² in 1970). The main production areas were in

Ukraine,

[99] the

Kursk and

Orel regions of

Russia, and near the

Polish border. Since its inception in 1931, the Hemp Breeding Department at the Institute of

Bast Crops in

Hlukhiv

(Glukhov), Ukraine, has been one of the world's largest centers for

developing new hemp varieties, focusing on improving fiber quality,

per-hectare yields, and low

THC content.

[100][101]

After the collapse of the

Soviet Union,

the commercial cultivation of hemp declined sharply. However, it is

estimated that at least 2.5 million acres of hemp grows wild in the

Russian Far East and Black Sea regions.

[102]

United Kingdom

In the

United Kingdom, cultivation licences are issued by the

Home Office under the

Misuse of Drugs Act 1971. When grown for non-drug purposes, hemp is referred to as industrial hemp, and a common product is

fibre

for use in a wide variety of products, as well as the seed for

nutritional aspects and for the oil. Feral hemp or ditch weed is usually

a naturalized fibre or oilseed strain of

Cannabis that has escaped from cultivation and is self-seeding.

[103]

United States

Hemp was made illegal to grow without a permit in the U.S. under the

Controlled Substances Act passed in 1970 because of its relation to marijuana,

[17] and any imported hemp products must meet a

zero tolerance level.

[104]

Some states have made the cultivation of industrial hemp legal, but

farmers in many states have not yet begun to grow it because of

resistance from the federal

Drug Enforcement Administration,

[105] making "large-scale hemp growing" in the United States "not viable" as late as 2013.

[106]

In 2013, after the legalization of cannabis in the state, several

farmers in Colorado planted and harvested several acres of hemp,

bringing in the first hemp crop in the United States in over half a

century.

[107] Colorado,

[108]

Vermont, California, and North Dakota have passed laws enabling hemp

licensure. All four states are waiting for permission to grow hemp from

the DEA. Currently,

[109] Oregon has licensed industrial hemp as of August 2009.

[110] Congress included a provision in the

Agricultural Act of 2014 that allowed colleges and state agencies to grow and conduct research on hemp in states where it is legal.

[17] Hemp production in Kentucky, formerly the United States' leading producer, resumed in 2014.

[111]

As of 2015 the hemp industry estimated that annual sales of hemp

products were around US$580 million annually; hemp seeds have been the

major force driving this growth.

[112]

Yet, even with this progress, hemp businesses seem to face difficulty

expanding in the US as they face challenges in traditional marketing

and sales approaches. According to a case study done by

Forbes,

hemp businesses and startups have had difficulty marketing and selling

non-psychoactive hemp products, as social media and financial

institutions refuse to distinguish between hemp and marijuana.

[113]

History

Hemp is possibly one of the earliest plants to be cultivated.

[115][116] An archeological site in the

Oki Islands near Japan contained cannabis

achenes from about 8000 BC, probably signifying use of the plant.

[117] Hemp use archaeologically dates back to the

Neolithic Age in China, with hemp fiber imprints found on

Yangshao culture pottery dating from the

5th millennium BC.

[114][118] The Chinese later used hemp to make clothes, shoes, ropes, and an early form of

paper.

[114] The classical Greek historian

Herodotus (ca. 480 BC) reported that the inhabitants of

Scythia would often inhale the vapors of hemp-seed smoke, both as ritual and for their own pleasurable recreation.

[119]

Textile expert

Elizabeth Wayland Barber summarizes the historical evidence that

Cannabis sativa,

"grew and was known in the Neolithic period all across the northern

latitudes, from Europe (Germany, Switzerland, Austria, Romania, Ukraine)

to East Asia (Tibet and China)," but, "textile use of Cannabis sativa

does not surface for certain in the West until relatively late, namely

the Iron Age."

[120]

"I strongly suspect, however, that what catapulted hemp to sudden fame

and fortune as a cultigen and caused it to spread rapidly westwards in

the first millennium B.C. was the spread of the habit of pot-smoking

from somewhere in south-central Asia, where the drug-bearing variety of

the plant originally occurred. The linguistic evidence strongly supports

this theory, both as to time and direction of spread and as to cause."

[121]

Jews living in

Palestine in the 2nd century were familiar with the cultivation of hemp, as witnessed by a reference to it in the

Mishna (

Kil'ayim 2:5) as a variety of plant, along with

Arum, that sometimes takes as many as three years to grow from a seedling. In

late medieval Germany and

Italy, hemp was employed in cooked dishes, as filling in

pies and

tortes, or boiled in a

soup.

[122] Hemp in later Europe was mainly cultivated for its fibers, and was used for ropes on many ships, including those of

Christopher Columbus. The use of hemp as a cloth was centered largely in the countryside, with higher quality

textiles being available in the towns.

The Spaniards brought hemp to the Western Hemisphere and cultivated it in

Chile starting about 1545.

[123] However, in May 1607, "hempe" was among the crops Gabriel Archer observed being cultivated by the natives at the main

Powhatan village, where

Richmond, Virginia is now situated;

[124] and in 1613,

Samuell Argall reported wild hemp "better than that in England" growing along the shores of the upper

Potomac. As early as 1619, the first Virginia

House of Burgesses passed an Act requiring all planters in Virginia to sow "both English and Indian" hemp on their plantations.

[125] The

Puritans are first known to have cultivated hemp in

New England in 1645.

[123]

United States "Marihuana" production permit. In the United States, hemp cultivation is

legally prohibited, but during

World War II farmers were encouraged to grow hemp for cordage, to replace

Manila hemp previously obtained from

Japanese-controlled areas. The U.S. government produced a film explaining the uses of hemp, called

Hemp for Victory.

George Washington pushed for the growth of hemp and even grew hemp himself, as it was a

cash crop

commonly used to make rope and fabric. In May 1765 he noted in his

diary about the sowing of seeds each day until mid-April. Then he

recounts the harvest in October which he grew 27 bushels that year.

There is some speculation that

George Washington

smoked the flower of the cannabis plant in order to achieve a

recreational high ("Like all farmers, Washington probably sampled the

quality and potency of what he grew, and he may have used this hemp to

treat his chronic tooth aches"),

[71]

but there is no evidence in any of his writings that he grew hemp for

anything other than industrial purposes. It is sometimes supposed that

an excerpt from Washington's diary, which reads "Began to seperate [

sic] the Male from the Female hemp at Do.&—rather too late" is evidence that he was trying to grow female plants for the

THC

found in the flowers. However, the editorial remark accompanying the

diary states that "This may arise from their [the male] being coarser,

and the stalks larger"

[126] In subsequent days, he describes soaking the hemp

[127] (to make the fibers usable) and harvesting the seeds,

[128] suggesting that he was growing hemp for industrial purposes, not recreational.

George Washington also imported the Indian Hemp plant from Asia,

which was used for fiber and, by some growers, for intoxicating resin

production. In a letter to William Pearce who managed the plants for him

Washington says, "What was done with the Indian Hemp plant from last

summer? It ought, all of it, to be sown again; that not only a stock of

seed sufficient for my own purposes might have been raised, but to have

disseminated seed to others; as it is more valuable than common hemp."

[citation needed]

Additional presidents known to have farmed hemp include

Thomas Jefferson,

[129] James Madison,

James Monroe,

Andrew Jackson,

Zachary Taylor, and

Franklin Pierce.

[130]

Historically, hemp production had made up a significant portion of

antebellum Kentucky's economy. Before the

American Civil War, many slaves worked on

plantations producing hemp.

[131]

In 1937, the

Marihuana Tax Act of 1937

was passed in the United States, levying a tax on anyone who dealt

commercially in cannabis, hemp, or marijuana. The passing of the Act to

destroy the US hemp industry has been disputed to involve businessmen

Andrew Mellon,

Randolph Hearst and the

Du Pont family.

[132][133][134]

One claim is that Hearst believed

[dubious – discuss] that his extensive timber holdings were threatened by the invention of the

decorticator which he feared would allow hemp to become a cheap substitute for the

paper pulp used for newspaper.

[132][135] Historical research indicates this fear was unfounded because improvements of the

decorticators

in the 1930s – machines that separated the fibers from the hemp stem –

could not make hemp fiber a cheaper substitute for fibers from other

sources. Further, decorticators did not perform satisfactorily in

commercial production.

[44][132]

Another claim is that Mellon,

Secretary of the Treasury and the wealthiest man in America at that time, had invested heavily in

DuPont's new synthetic fiber,

nylon, and believed

[dubious – discuss] that the replacement of the traditional resource, hemp, was integral to the new product's success.

[132][136][137][138][139][140][141][142] The company DuPont and many industrial historians dispute a link between

nylon and hemp, nylon became immediately a scarce commodity.

[clarification needed] Nylon had characteristics that could be used for

toothbrushes (sold from 1938) and very thin nylon fiber could compete with

silk and

rayon in various textiles normally not produced from hemp fiber, such as very thin stockings for women.

[44][143][144][145][146]

Hemp was used extensively by the United States during World War II to make uniforms, canvas, and rope.

[147] Much of the hemp used was cultivated in

Kentucky and the

Midwest. During World War II, the U.S. produced a short 1942 film,

Hemp for Victory, promoting hemp as a necessary crop to win the war.

Historical cultivation

Hemp

has been grown for millennia in Asia and the Middle East for its fibre.

Commercial production of hemp in the West took off in the eighteenth

century, but was grown in the sixteenth century in eastern England.

[148] Because of colonial and naval expansion of the era, economies needed large quantities of hemp for rope and

oakum. In the early 1940s, world production of hemp fiber ranged from 250 000 to 350 000 metric tonnes,

Russia was the biggest producer.

[44]

In Western Europe, the cultivation of hemp was not legally banned by

the 1930s, but the commercial cultivation stopped by then, due to

decreased demand compared to increasingly popular artificial fibers.

[149]

Speculation about the potential for commercial cultivation of hemp in

large quantities has been criticized due to successful competition from

other fibers for many products. The world production of hemp fiber fell

from over 300,000 metric tons 1961 to about 75,000 metric tons in the

early 1990s and has after that been stable at that level.

[150]

Japan

In

Japan,

hemp was historically used as paper and a fiber crop. There is

archaeological evidence cannabis was used for clothing and the seeds

were eaten in Japan back to the

Jōmon period (10,000 to 300 BCE). Many

Kimono designs portray hemp, or

asa (

Japanese:

麻),

as a beautiful plant. In 1948, marijuana was restricted as a narcotic

drug. The ban on marijuana imposed by the United States authorities was

alien to Japanese culture, as the drug had never been widely used in

Japan before. Though these laws against marijuana are some of the

world's strictest, allowing five years imprisonment for possession of

the drug, they exempt hemp growers, whose crop is used to make robes for

Buddhist monks and

loincloths for

Sumo wrestlers. Because marijuana use in Japan has doubled in the past decade, these exemptions have recently been called into question.

[151]

Portugal

The

cultivation of hemp in Portuguese lands began around the fourteenth

century onwards, it was raw material for the preparation of rope and

plugs for the Portuguese ships. Colonies for factories for the

production of flax hemp, such as the Royal Flax Hemp Factory in Brazil.

After the Restoration of Independence in 1640, in order to recover

the ailing Portuguese naval fleet, were encouraged its cultivation as

the Royal Decree of D. John IV in 1656. At that time its cultivation was

carried out in Trás-os-Montes, Zone Tower Moncorvo, more precisely in

Vilariça Valley, fertile land for any crop irrigation, and a very large

area, flat and very fertile culture still wide until the last century

grew up tobacco, a plant that needs a large space to expand and grow,

the area lies in the valley of Serra de Bornes.

In 1971, the cultivation of hemp became illegal, and the production

was substantially reduced. Because of EU regulations 1308/70, 619/71 and

1164/89, this law was revoked (for some certified seed varieties).

[152]