From Wikipedia, the free encyclopedia

Molecular scale electronics, also called

single-molecule electronics, is a branch of

nanotechnology that uses single molecules, or nanoscale collections of single molecules, as

electronic components.

Because single molecules constitute the smallest stable structures

imaginable, this miniaturization is the ultimate goal for shrinking

electrical circuits.

The field is often termed simply as "

molecular electronics", but this term is also used to refer to the distantly related field of

conductive polymers and

organic electronics,

which uses the properties of molecules to affect the bulk properties of

a material. A nomenclature distinction has been suggested so that

molecular materials for electronics refers to this latter field of bulk applications, while

molecular scale electronics refers to the nanoscale single-molecule applications treated here.

[1][2]

Fundamental concepts

Conventional

electronics have traditionally been made from bulk materials. Ever

since their invention in 1958, the performance and complexity of

integrated circuits has undergone

exponential growth, a trend named

Moore’s law,

as feature sizes of the embedded components have shrunk accordingly. As

the structures shrink, the sensitivity to deviations increases. In a

few technology generations, when the minimum feature sizes reaches

13 nm, the composition of the devices must be controlled to a precision

of a few atoms

[3]

for the devices to work. With bulk methods growing increasingly

demanding and costly as they near inherent limits, the idea was born

that the components could instead be built up atom by atom in a

chemistry lab (bottom up) versus carving them out of bulk material (

top down).

This is the idea behind molecular electronics, with the ultimate

miniaturization being components contained in single molecules.

In single-molecule electronics, the bulk material is replaced by

single molecules. Instead of forming structures by removing or applying

material after a pattern scaffold, the atoms are put together in a

chemistry lab. In this way, billions of billions of copies are made

simultaneously (typically more than 10

20 molecules are made

at once) while the composition of molecules are controlled down to the

last atom. The molecules used have properties that resemble traditional

electronic components such as a

wire,

transistor or

rectifier.

Single-molecule electronics is an emerging field, and entire

electronic circuits consisting exclusively of molecular sized compounds

are still very far from being realized. However, the unceasing demand

for more computing power, along with the inherent limits of lithographic

methods as of 2016, make the transition seem unavoidable. Currently,

the focus is on discovering molecules with interesting properties and on

finding ways to obtain reliable and reproducible contacts between the

molecular components and the bulk material of the electrodes.

Theoretical basis

Molecular electronics operates in the

quantum realm of distances less than 100 nanometers. The miniaturization down to single molecules brings the scale down to a regime where

quantum mechanics effects are important. In conventional electronic components,

electrons can be filled in or drawn out more or less like a continuous flow of

electric charge.

In contrast, in molecular electronics the transfer of one electron

alters the system significantly. For example, when an electron has been

transferred from a source electrode to a molecule, the molecule gets

charged up, which makes it far harder for the next electron to transfer

(see also

Coulomb blockade).

The significant amount of energy due to charging must be accounted for

when making calculations about the electronic properties of the setup,

and is highly sensitive to distances to conducting surfaces nearby.

The theory of single-molecule devices is especially interesting since

the system under consideration is an open quantum system in

nonequilibrium

(driven by voltage). In the low bias voltage regime, the nonequilibrium

nature of the molecular junction can be ignored, and the

current-voltage traits of the device can be calculated using the

equilibrium electronic structure of the system. However, in stronger

bias regimes a more sophisticated treatment is required, as there is no

longer a

variational principle. In the elastic tunneling case (where the passing electron does not exchange energy with the system), the formalism of

Rolf Landauer

can be used to calculate the transmission through the system as a

function of bias voltage, and hence the current. In inelastic tunneling,

an elegant formalism based on the non-equilibrium

Green's functions of

Leo Kadanoff and

Gordon Baym, and independently by

Leonid Keldysh was advanced by

Ned Wingreen and

Yigal Meir.

This Meir-Wingreen formulation has been used to great success in the

molecular electronics community to examine the more difficult and

interesting cases where the transient electron exchanges energy with the

molecular system (for example through electron-phonon coupling or

electronic excitations).

Further, connecting single molecules reliably to a larger scale

circuit has proven a great challenge, and constitutes a significant

hindrance to commercialization.

Examples

Common

for molecules used in molecular electronics is that the structures

contain many alternating double and single bonds (see also

Conjugated system).

This is done because such patterns delocalize the molecular orbitals,

making it possible for electrons to move freely over the conjugated

area.

Wires

This animation of a rotating carbon nanotube shows its 3D structure.

The sole purpose of

molecular wires

is to electrically connect different parts of a molecular electrical

circuit. As the assembly of these and their connection to a macroscopic

circuit is still not mastered, the focus of research in single-molecule

electronics is primarily on the functionalized molecules: molecular

wires are characterized by containing no

functional groups and are hence composed of plain repetitions of a conjugated building block. Among these are the

carbon nanotubes that are quite large compared to the other suggestions but have shown very promising electrical properties.

The main problem with the molecular wires is to obtain good

electrical contact with the electrodes so that electrons can move freely

in and out of the wire.

Transistors

Single-molecule

transistors

are fundamentally different from the ones known from bulk electronics.

The gate in a conventional (field-effect) transistor determines the

conductance between the source and drain electrode by controlling the

density of charge carriers between them, whereas the gate in a

single-molecule transistor controls the possibility of a single electron

to jump on and off the molecule by modifying the energy of the

molecular orbitals. One of the effects of this difference is that the

single-molecule transistor is almost binary: it is either

on or

off. This opposes its bulk counterparts, which have quadratic responses to gate voltage.

It is the quantization of charge into electrons that is responsible

for the markedly different behavior compared to bulk electronics.

Because of the size of a single molecule, the charging due to a single

electron is significant and provides means to turn a transistor

on or

off (see

Coulomb blockade).

For this to work, the electronic orbitals on the transistor molecule

cannot be too well integrated with the orbitals on the electrodes. If

they are, an electron cannot be said to be located on the molecule or

the electrodes and the molecule will function as a wire.

A popular group of molecules, that can work as the

semiconducting

channel material in a molecular transistor, is the

oligopolyphenylenevinylenes (OPVs) that works by the Coulomb blockade

mechanism when placed between the source and drain electrode in an

appropriate way.

[4] Fullerenes work by the same mechanism and have also been commonly used.

Semiconducting carbon nanotubes have also been demonstrated to work

as channel material but although molecular, these molecules are

sufficiently large to behave almost as bulk

semiconductors.

The size of the molecules, and the low temperature of the

measurements being conducted, makes the quantum mechanical states well

defined. Thus, it is being researched if the quantum mechanical

properties can be used for more advanced purposes than simple

transistors (e.g.

spintronics).

Physicists at the

University of Arizona, in collaboration with chemists from the

University of Madrid, have designed a single-molecule transistor using a ring-shaped molecule similar to

benzene. Physicists at Canada's

National Institute for Nanotechnology

have designed a single-molecule transistor using styrene. Both groups

expect (the designs were experimentally unverified as of June 2005) their respective devices to function at room temperature, and to be controlled by a single electron.

[5]

Rectifiers (diodes)

Hydrogen can be removed from individual

tetraphenylporphyrin (H

2TPP) molecules by applying excess voltage to the tip of a

scanning tunneling microscope (STAM, a); this removal alters the current-voltage (I-V) curves of TPP molecules, measured using the same STM tip, from

diode-like (red curve in b) to

resistor-like (green curve). Image (c) shows a row of TPP, H

2TPP and TPP molecules. While scanning image (d), excess voltage was applied to H

2TPP

at the black dot, which instantly removed hydrogen, as shown in the

bottom part of (d) and in the re-scan image (e). Such manipulations can

be used in single-molecule electronics.

[6]

Molecular

rectifiers

are mimics of their bulk counterparts and have an asymmetric

construction so that the molecule can accept electrons in one end but

not the other. The molecules have an

electron donor (D) in one end and an

electron acceptor (A) in the other. This way, the unstable state D

+ – A

− will be more readily made than D

− – A

+. The result is that an

electric current

can be drawn through the molecule if the electrons are added through

the acceptor end, but less easily if the reverse is attempted.

Methods

One of

the biggest problems with measuring on single molecules is to establish

reproducible electrical contact with only one molecule and doing so

without shortcutting the electrodes. Because the current

photolithographic

technology is unable to produce electrode gaps small enough to contact

both ends of the molecules tested (on the order of nanometers),

alternative strategies are applied.

Molecular gaps

One

way to produce electrodes with a molecular sized gap between them is

break junctions, in which a thin electrode is stretched until it breaks.

Another is

electromigration.

Here a current is led through a thin wire until it melts and the atoms

migrate to produce the gap. Further, the reach of conventional

photolithography can be enhanced by chemically etching or depositing

metal on the electrodes.

Probably the easiest way to conduct measurements on several molecules is to use the tip of a

scanning tunneling microscope (STM) to contact molecules adhered at the other end to a metal substrate.

[7]

Anchoring

A popular way to anchor molecules to the electrodes is to make use of

sulfur's high

chemical affinity to

gold. In these setups, the molecules are

synthesized so that sulfur atoms are placed strategically to function as

crocodile clips

connecting the molecules to the gold electrodes. Though useful, the

anchoring is non-specific and thus anchors the molecules randomly to all

gold surfaces. Further, the

contact resistance

is highly dependent on the precise atomic geometry around the site of

anchoring and thereby inherently compromises the reproducibility of the

connection.

To circumvent the latter issue, experiments has shown that

fullerenes

could be a good candidate for use instead of sulfur because of the

large conjugated π-system that can electrically contact many more atoms

at once than one atom of sulfur.

[8]

Fullerene nanoelectronics

In

polymers,

classical organic molecules are composed of both carbon and hydrogen

(and sometimes additional compounds such as nitrogen, chlorine or

sulphur). They are obtained from petrol and can often be synthesized in

large amounts. Most of these molecules are insulating when their length

exceeds a few nanometers. However, naturally occurring carbon is

conducting, especially graphite recovered from coal or encountered

otherwise. From a theoretical viewpoint,

graphite is a

semi-metal,

a category in between metals and semi-conductors. It has a layered

structure, each sheet being one atom thick. Between each sheet, the

interactions are weak enough to allow an easy manual cleavage.

Tailoring the

graphite

sheet to obtain well defined nanometer-sized objects remains a

challenge. However, by the close of the twentieth century, chemists were

exploring methods to fabricate extremely small graphitic objects that

could be considered single molecules. After studying the interstellar

conditions under which carbon is known to form clusters,

Richard Smalley's

group (Rice University, Texas) set up an experiment in which graphite

was vaporized via laser irradiation. Mass spectrometry revealed that

clusters containing specific

magic numbers of atoms were stable, especially those clusters of 60 atoms.

Harry Kroto,

an English chemist who assisted in the experiment, suggested a possible

geometry for these clusters – atoms covalently bound with the exact

symmetry of a soccer ball. Coined

buckminsterfullerenes, buckyballs, or C

60,

the clusters retained some properties of graphite, such as

conductivity. These objects were rapidly envisioned as possible building

blocks for molecular electronics.

Problems

Artifacts

When

trying to measure electronic traits of molecules, artificial phenomena

can occur that can be hard to distinguish from truly molecular behavior.

[9]

Before they were discovered, these artifacts have mistakenly been

published as being features pertaining to the molecules in question.

Applying a voltage drop on the order of volts across a nanometer

sized junction results in a very strong electrical field. The field can

cause metal atoms to migrate and eventually close the gap by a thin

filament, which can be broken again when carrying a current. The two

levels of conductance imitate molecular switching between a conductive

and an isolating state of a molecule.

Another encountered artifact is when the electrodes undergo chemical

reactions due to the high field strength in the gap. When the

voltage bias is reversed, the reaction will cause

hysteresis in the measurements that can be interpreted as being of molecular origin.

A metallic grain between the electrodes can act as a single electron

transistor by the mechanism described above, thus resembling the traits

of a molecular transistor. This artifact is especially common with

nanogaps produced by the electromigration method.

Commercialization

One

of the biggest hindrances for single-molecule electronics to be

commercially exploited is the lack of methods to connect a molecular

sized circuit to bulk electrodes in a way that gives reproducible

results. At the current state, the difficulty of connecting single

molecules vastly outweighs any possible performance increase that could

be gained from such shrinkage. The difficulties grow worse if the

molecules are to have a certain spatial orientation and/or have multiple

poles to connect.

Also problematic is that some measurements on single molecules are carried out in

cryogenic temperatures (near absolute zero), which is very energy consuming. This is done to reduce

signal noise enough to measure the faint currents of single molecules.

History and recent progress

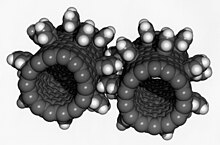

Graphical representation of a

rotaxane, useful as a molecular switch.

In their treatment of so-called

donor-acceptor complexes in the 1940s,

Robert Mulliken and

Albert Szent-Györgyi

advanced the concept of charge transfer in molecules. They subsequently

further refined the study of both charge transfer and energy transfer

in molecules. Likewise, a 1974 paper from

Mark Ratner and Ari Aviram illustrated a theoretical molecular

rectifier.

[10] In 1988, Aviram described in detail a theoretical single-molecule

field-effect transistor. Further concepts were proposed by Forrest Carter of the

Naval Research Laboratory, including single-molecule

logic gates. A wide range of ideas were presented, under his aegis, at a conference entitled

Molecular Electronic Devices in 1988.

[11] These were all theoretical constructs and not concrete devices. The

direct

measurement of the electronic traits of individual molecules awaited

the development of methods for making molecular-scale electrical

contacts. This was no easy task. Thus, the first experiment

directly-measuring the conductance of a single molecule was only

reported in 1995 on a single C

60 molecule by C. Joachim and

J. K. Gimzewsky in their seminal Physical Revie Letter paper and later

in 1997 by Mark Reed and co-workers on a few hundred molecules. Since

then, this branch of the field has advanced rapidly. Likewise, as it has

grown possible to measure such properties directly, the theoretical

predictions of the early workers have been confirmed substantially.

Recent progress in

nanotechnology and nanoscience has facilitated both experimental and theoretical study of molecular electronics. Development of the

scanning tunneling microscope (STM) and later the

atomic force microscope

(AFM) have greatly facilitated manipulating single-molecule

electronics. Also, theoretical advances in molecular electronics have

facilitated further understanding of non-adiabatic charge transfer

events at electrode-electrolyte interfaces.

[12][13]

The concept of molecular electronics was first published in 1974 when

Aviram and Ratner suggested an organic molecule that could work as a

rectifier.

[14]

Having both huge commercial and fundamental interest, much effort was

put into proving its feasibility, and 16 years later in 1990, the first

demonstration of an intrinsic molecular rectifier was realized by

Ashwell and coworkers for a thin film of molecules.

The first measurement of the conductance of a single molecule was

realised in 1994 by C. Joachim and J. K. Gimzewski and published in 1995

(see the corresponding Phys. Rev. Lett. paper). This was the conclusion

of 10 years of research started at IBM TJ Watson, using the scanning

tunnelling microscope tip apex to switch a single molecule as already

explored by A. Aviram, C. Joachim and M. Pomerantz at the end of the

80's (see their seminal Chem. Phys. Lett. paper during this period). The

trick was to use an UHV Scanning Tunneling microscope to allow the tip

apex to gently touch the top of a single

C

60

molecule adsorbed on an Au(110) surface. A resistance of 55 MOhms was

recorded along with a low voltage linear I-V. The contact was certified

by recording the I-z current distance property, which allows measurement

of the deformation of the

C

60

cage under contact. This first experiment was followed by the reported

result using a mechanical break junction method to connect two gold

electrodes to a sulfur-terminated

molecular wire by

Mark Reed and

James Tour in 1997.

[15]

A single-molecule amplifier was implemented by C. Joachim and J.K. Gimzewski in IBM Zurich. This experiment, involving one

C

60

molecule, demonstrated that one such molecule can provide gain in a

circuit via intramolecular quantum interference effects alone.

A collaboration of researchers at

Hewlett-Packard (HP) and

University of California, Los Angeles

(UCLA), led by James Heath, Fraser Stoddart, R. Stanley Williams, and

Philip Kuekes, has developed molecular electronics based on

rotaxanes and

catenanes.

Work is also occurring on the use of single-wall carbon nanotubes as

field-effect transistors. Most of this work is being done by

International Business Machines (

IBM).

Some specific reports of a

field-effect transistor based on molecular

self-assembled monolayers were shown to be fraudulent in 2002 as part of the

Schön scandal.

[16]

Until recently entirely theoretical, the Aviram-Ratner model for a

unimolecular rectifier has been confirmed unambiguously in experiments by a group led by Geoffrey J. Ashwell at

Bangor University, UK.

[17][18][19] Many rectifying molecules have so far been identified, and the number and efficiency of these systems is growing rapidly.

Supramolecular electronics is a new field involving electronics at a

supramolecular level.

An important issue in molecular electronics is the determination of

the resistance of a single molecule (both theoretical and experimental).

For example, Bumm, et al. used STM to analyze a single molecular switch

in a

self-assembled monolayer to determine how conductive such a molecule can be.

[20]

Another problem faced by this field is the difficulty of performing

direct characterization since imaging at the molecular scale is often

difficult in many experimental devices.